Professional Documents

Culture Documents

Suggestions Status: S. No. Suggestion Given by Status of The Suggestion

Uploaded by

VIBHOR0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

Suggestion Summary

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesSuggestions Status: S. No. Suggestion Given by Status of The Suggestion

Uploaded by

VIBHORCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

Supersonic Turners Pvt. Ltd.

Suggestions Status

Status Date: 1st Oct 02

S. no. Suggestion Given By Status of the

suggestion

1 Channel use on machine for stopping without radius pc to go a head Yogendra Implemented

2 Yogendra Implemented

3 Yogendra Implemented

Using of face black pieces for setting bore machine and setting scrap of bore Pankaj , Babloo Implemented

4

machine to set trepanning machines

Providing of separate tool kit for every machine to reduce setting time loss due to Babloo Implemented

5

tool search

Fixing of wooden blocks in open space between machine and floor to avoid fallen Lal Chand Ji Implemented

6 pieces going under the machine and also to reduce stray piece mix up cases with

OK material

Use perforated sheet with holes bigger enough to allow the chips to fall through Babloo Implemented

7 at Inner track machine, for better house keeping and eliminating segregation of with

chips from Jalis before putting it in the hopper for auto inspection modification

8 Put handles on swarf containers for ease in handling and swarf disposal Mohan Lal Implemented

Use similar kind of back supports on both trepanning machines, so as to avoid Bhandari Implemented

9

down time of one machine when the other is in break down Pathak

10 Modification in chip breaker design of bore peeling machine Yogendra Implemented

11 Put a table in front of bore hopper for less fatigue to operator Yogendra Implemented

12 Installation of plate in bore machine hopper to avoid pieces stucking in hopper Yogendra Implemented

Assign responsibility of up keep of cutting oils, Mobil oil, rust top oils etc to Satyanarayan implementation

13

reduce wastage

Assign responsibility of daily checking of water and oil in DG set to reduce down Satyanarayan implementation

14 time due to delay in DG operation because of oil / diesel unavailability in case of

power failure

Clearance of setting boxes on shift wise basis to fix accountability shift wise for Satyanarayan Implemented

15

setting pieces reduction

Install dials at insert regrinding machine to monitor grinding depth of insert so Babloo Implemented

16

that higher no of tool regrinds can be achieved

Procure a welding set in STPL to reduce down time due to getting small repairs Babloo Implemented

17

done from out side

Start vendor visits to reduce quality problems on line Mohan Lal Implemented

18

Jangid

Keep Hard material in grinding separate to avoid down time due to tool breakage’s Shankar Lal Implemented

19

due to hard material

20 Display setting parameters on all machines to reduce variation in process Mayank Implemented

21 Display instruction at compressor area for operation to avoid mishandling Mayank Implementation

22 Display instruction at DG area for operation to avoid mishandling Satyanarayan Implementation

Run auto insp. in night shift to increase material flow and give quality feed back in Bhandari Implemented

23

night shift

Install dial on tool post to reduce setting variations and setting scrap Lal Chand Pending

24

implementation

Use inserts after coating to get extra tool life Lal Chand Pending

25

Implementation

25

2

You might also like

- Apqp PDFDocument2 pagesApqp PDFChandru JattiNo ratings yet

- Apqp PDFDocument2 pagesApqp PDFChandru JattiNo ratings yet

- SOP Tadano Crane 25TDocument32 pagesSOP Tadano Crane 25Tmahindra hardinataNo ratings yet

- 2014.05.08 GNJBQ Agitator ManualDocument31 pages2014.05.08 GNJBQ Agitator ManualHamed Gerami100% (1)

- Class 5 Imo 4 Years Sample PaperDocument9 pagesClass 5 Imo 4 Years Sample Paperkalyan555No ratings yet

- APQP-PPAP - Workbook ExampleDocument37 pagesAPQP-PPAP - Workbook ExampleVIBHOR50% (2)

- 1 Brother Machine Check Points For Long Shut Down-3Document17 pages1 Brother Machine Check Points For Long Shut Down-3jaganksNo ratings yet

- Worksheet Grinding DJF3012Document8 pagesWorksheet Grinding DJF3012suhaizyra0% (1)

- Abdominal Exam Guide: Palpation, Inspection & Surface MarkingsDocument4 pagesAbdominal Exam Guide: Palpation, Inspection & Surface MarkingsPhysician AssociateNo ratings yet

- Design and Fabrication of Low-Cost Groundnut Sheller MachineDocument31 pagesDesign and Fabrication of Low-Cost Groundnut Sheller MachineSaurabh Vaidya100% (1)

- RP Alignment Rev0 26.03.2007Document40 pagesRP Alignment Rev0 26.03.2007Dhanish KumarNo ratings yet

- Class-5 IMODocument2 pagesClass-5 IMOanushagurralaNo ratings yet

- 08.DM Pillar FCDocument67 pages08.DM Pillar FCashutoshpal21No ratings yet

- Street lighting cable installation methodDocument12 pagesStreet lighting cable installation methodAzree Mohd Noor100% (9)

- Cot 1 Detailed Lesson Plan in Science 10Document3 pagesCot 1 Detailed Lesson Plan in Science 10Arlen FuentebellaNo ratings yet

- Side Sealing Machine Operation GuideDocument30 pagesSide Sealing Machine Operation GuideRocio GimenezNo ratings yet

- Introduction to Grinding Process Optimization Using Taguchi MethodsDocument27 pagesIntroduction to Grinding Process Optimization Using Taguchi Methodsranarani2013100% (1)

- Use of Remote Sensing to Estimate Paddy Area and Production: A HandbookFrom EverandUse of Remote Sensing to Estimate Paddy Area and Production: A HandbookNo ratings yet

- KF2.5-200 - With-M-C - GB - 03-15 KRACHT Bomba PDFDocument8 pagesKF2.5-200 - With-M-C - GB - 03-15 KRACHT Bomba PDFJairo Andrés FA100% (1)

- Nutrition and Diet Therapy 12Th Edition Roth Solutions Manual Full Chapter PDFDocument30 pagesNutrition and Diet Therapy 12Th Edition Roth Solutions Manual Full Chapter PDFgretchenmilesdxeh3100% (8)

- Aditya Industries company profileDocument26 pagesAditya Industries company profileTushar KhorateNo ratings yet

- Supplier Technical Audit Report Example GMRDocument8 pagesSupplier Technical Audit Report Example GMRMohammad Faraz AkhterNo ratings yet

- Sewn Product Machinery & Equipments - IIDocument30 pagesSewn Product Machinery & Equipments - IIVachan Abhilekh ThakurNo ratings yet

- 20-03-19 Far - West Blood Bank, Dhangadi Nepal, QA Daily Report No 125.Document7 pages20-03-19 Far - West Blood Bank, Dhangadi Nepal, QA Daily Report No 125.roan sthaNo ratings yet

- Screens Reference ListDocument3 pagesScreens Reference Listanamika.advaitNo ratings yet

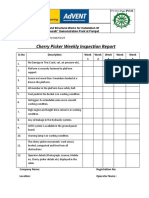

- Cherry Picker Weekly Inspection Report: SR - No Description Week 1 Week 2 Week 3 Week 4 Week 5Document2 pagesCherry Picker Weekly Inspection Report: SR - No Description Week 1 Week 2 Week 3 Week 4 Week 5Dth InfraNo ratings yet

- Toyota Motor Manufacturing: Addressing the Seat ProblemDocument9 pagesToyota Motor Manufacturing: Addressing the Seat ProblemPrash SNo ratings yet

- Auto Blast Machine Work LoadDocument1 pageAuto Blast Machine Work Loadloveselvan43No ratings yet

- Assessment of The Overall Equipment Effectiveness in A Sack Manufacturing Company in Kano, NigeriaDocument4 pagesAssessment of The Overall Equipment Effectiveness in A Sack Manufacturing Company in Kano, NigeriaRaji Bello UmarNo ratings yet

- Enhancement of Arecanut Dehusking MachineDocument6 pagesEnhancement of Arecanut Dehusking MachineSannidhi V. ShettyNo ratings yet

- Final ReportDocument74 pagesFinal Reportapi-3703129100% (5)

- Water Dispenser Manual Nov 2021Document10 pagesWater Dispenser Manual Nov 2021ErGaurav KumarNo ratings yet

- A Case Study On Motorcycle Driven Ploughing MachineDocument20 pagesA Case Study On Motorcycle Driven Ploughing Machinemani manisNo ratings yet

- Inventory ManagementDocument20 pagesInventory ManagementYogita WaghNo ratings yet

- A Case Study On Motorcycle Driven Ploughing MachineDocument20 pagesA Case Study On Motorcycle Driven Ploughing MachineAsikinNo ratings yet

- Microsoft Word - Control Philosophy For Reclaimer PDFDocument7 pagesMicrosoft Word - Control Philosophy For Reclaimer PDFVijayakumar SamyNo ratings yet

- 11/5/2012 Anju RanaDocument20 pages11/5/2012 Anju Ranan2oh1No ratings yet

- Modification of Gravity Conveyor Roll Design With Motor Driver On Wobbling MachineDocument1 pageModification of Gravity Conveyor Roll Design With Motor Driver On Wobbling MachineDwi DhanNo ratings yet

- FigureDocument35 pagesFigureLokesh GurjarNo ratings yet

- Sona GroupDocument56 pagesSona GroupbrindatammaNo ratings yet

- LDMS Smed SbubDocument16 pagesLDMS Smed SbubsmitaNo ratings yet

- Design and Fabrication of Groundnut ShellerDocument7 pagesDesign and Fabrication of Groundnut ShellerIJRASETPublications100% (1)

- 2023 ERCS Finding List A2-5Document4 pages2023 ERCS Finding List A2-5Khine ZinNo ratings yet

- Toyota Motor Manufacturing, U.S.A., Inc.: Lean SystemsDocument18 pagesToyota Motor Manufacturing, U.S.A., Inc.: Lean SystemsmuralimadhavaregurigupthaNo ratings yet

- Journalnx DesignDocument2 pagesJournalnx DesignJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Bull Machines Private Limited ProfileDocument44 pagesBull Machines Private Limited Profilemanojkumar024No ratings yet

- Analisa Perawatan Mesin Ripple Mill Menggunakan Metode Pert Di PT Ujong NeubokDocument7 pagesAnalisa Perawatan Mesin Ripple Mill Menggunakan Metode Pert Di PT Ujong NeubokShuar diynNo ratings yet

- BALL BEARING MANUFACTURING PROJECTDocument53 pagesBALL BEARING MANUFACTURING PROJECTSagar HaraneshaNo ratings yet

- Measure Surface Texture and Lead Angle of ShaftsDocument7 pagesMeasure Surface Texture and Lead Angle of Shaftsshivam daveNo ratings yet

- Training Report of SwarajDocument39 pagesTraining Report of SwarajMohit BishnoiNo ratings yet

- Maintenance and Training of Machinery EquipmentDocument6 pagesMaintenance and Training of Machinery Equipmentryan fernandezNo ratings yet

- Design of an Earth AugerDocument22 pagesDesign of an Earth AugerJOSUVA BRIGHT YNo ratings yet

- Willpower Engineers - Profile PresentationDocument18 pagesWillpower Engineers - Profile PresentationpmlmkpNo ratings yet

- A Review On Design and Fabrication of GR PDFDocument4 pagesA Review On Design and Fabrication of GR PDFFiraol GudisaNo ratings yet

- Dv03pub40 ScriptDocument22 pagesDv03pub40 ScriptjeremyNo ratings yet

- Bajrangi Project ReportDocument46 pagesBajrangi Project ReportAmodTKvideosNo ratings yet

- XS122PD MANUAL DE OPERAÇÃO - EnglishDocument44 pagesXS122PD MANUAL DE OPERAÇÃO - EnglishAntonio MedeirosNo ratings yet

- Process Optimization for Flange Yoke ManufacturingDocument57 pagesProcess Optimization for Flange Yoke ManufacturingNitin100% (1)

- Journalnx DesignDocument3 pagesJournalnx DesignJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Production Planning and ControlDocument22 pagesProduction Planning and ControlAbhishek Saini0% (1)

- JR Tools Industrial Training PresentationDocument22 pagesJR Tools Industrial Training PresentationShrikaNt kambleNo ratings yet

- A Report On In-Plant Training: Vighnahar Tyre Industries, Pvt. Ltd. Sangamner MIDC, AhmednagarDocument7 pagesA Report On In-Plant Training: Vighnahar Tyre Industries, Pvt. Ltd. Sangamner MIDC, AhmednagarNighute SureshNo ratings yet

- Fettling The Most Ignored Operation in Foundries: Prashant MestryDocument10 pagesFettling The Most Ignored Operation in Foundries: Prashant MestrySonthi BhaskarNo ratings yet

- Biomass Briquette MachineDocument4 pagesBiomass Briquette Machineramanathan72-1No ratings yet

- No - 9 WK 14 Jit - KanbanDocument23 pagesNo - 9 WK 14 Jit - KanbanMahadi SidikNo ratings yet

- IRIS NV Elevator Maintenance Manual SectionsDocument12 pagesIRIS NV Elevator Maintenance Manual SectionsAndiosoNo ratings yet

- Manual SSM3001 5001Document136 pagesManual SSM3001 5001Niranjan PuduruNo ratings yet

- Standard Operating Procedure: Multi Angle SawDocument10 pagesStandard Operating Procedure: Multi Angle SawBhaskarNo ratings yet

- Perancangan Mesin Pengurai Sabut Kelapa PDFDocument7 pagesPerancangan Mesin Pengurai Sabut Kelapa PDFRoni100% (1)

- List of Trainers: S.No. Name SubjectDocument1 pageList of Trainers: S.No. Name SubjectVIBHORNo ratings yet

- SKF Supplier Quality Manual, Edition 5.0 PDFDocument16 pagesSKF Supplier Quality Manual, Edition 5.0 PDFVIBHORNo ratings yet

- PP Stock Verification SheetDocument1 pagePP Stock Verification SheetVIBHORNo ratings yet

- Engineering Change Notice for Supersonic TurnersDocument1 pageEngineering Change Notice for Supersonic TurnersVIBHORNo ratings yet

- Process Capability Analysis for Lathe MachineDocument19 pagesProcess Capability Analysis for Lathe MachineVIBHORNo ratings yet

- S 296001-1 A3 APQP Status Report enDocument2 pagesS 296001-1 A3 APQP Status Report enParthi NatarajNo ratings yet

- Manufacturning Fecablity ReviewDocument2 pagesManufacturning Fecablity ReviewVIBHORNo ratings yet

- STPL II Significant Characteristics ListDocument3 pagesSTPL II Significant Characteristics ListVIBHORNo ratings yet

- Operator Skill Matrix: Supersonic TurnerDocument2 pagesOperator Skill Matrix: Supersonic TurnerVIBHORNo ratings yet

- 17 Total BD: MMM Total Break DownDocument2 pages17 Total BD: MMM Total Break DownVIBHORNo ratings yet

- S CustomerDocument1 pageS CustomerParthi NatarajNo ratings yet

- X Bar Chart: Machine NameDocument2 pagesX Bar Chart: Machine NameVIBHORNo ratings yet

- Drawing File CoverDocument2 pagesDrawing File CoverVIBHORNo ratings yet

- TS16949 Presentation - Nov 12Document20 pagesTS16949 Presentation - Nov 12isash123No ratings yet

- Amendment ISO TS - Rules 4th EditionDocument53 pagesAmendment ISO TS - Rules 4th EditionVIBHORNo ratings yet

- Attendance 1 Nov 11 25 AmDocument1 pageAttendance 1 Nov 11 25 AmVIBHORNo ratings yet

- Normal Body Temperature Ranges & Fever Thresholds ExplainedDocument1 pageNormal Body Temperature Ranges & Fever Thresholds ExplainedVIBHORNo ratings yet

- Bureau Veritas Certification: Application Form FOR Iso/Ts 16949 CertificationDocument15 pagesBureau Veritas Certification: Application Form FOR Iso/Ts 16949 CertificationVIBHORNo ratings yet

- Imo Exam SyllabusDocument1 pageImo Exam SyllabusSubhas ChakrabartiNo ratings yet

- Invoice: Mehr Appliances and Services LLPDocument1 pageInvoice: Mehr Appliances and Services LLPVIBHORNo ratings yet

- Attendance 1 Nov 11 25 AmDocument1 pageAttendance 1 Nov 11 25 AmVIBHORNo ratings yet

- Supplier Feasibility Format New 2020Document24 pagesSupplier Feasibility Format New 2020VIBHORNo ratings yet

- Attendance 11-01-2020 11-32Document10 pagesAttendance 11-01-2020 11-32VIBHORNo ratings yet

- Grinding Tools InstructionsDocument1 pageGrinding Tools InstructionsVIBHORNo ratings yet

- The Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiDocument192 pagesThe Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiShenandoa LeãoNo ratings yet

- The Effect of Online Game Addiction To TheDocument5 pagesThe Effect of Online Game Addiction To TheRafuell Amper CablasNo ratings yet

- Glover U Business Plan 2022 DigitalDocument25 pagesGlover U Business Plan 2022 DigitalJustin CarruthNo ratings yet

- 0000 0000 0335Document40 pages0000 0000 0335Hari SetiawanNo ratings yet

- Deviz 12 KW Cu Invertor de 15 KWDocument2 pagesDeviz 12 KW Cu Invertor de 15 KWcontscribdNo ratings yet

- Soal Bing XiDocument9 pagesSoal Bing XiRhya GomangNo ratings yet

- Landmark Church School WBSDocument4 pagesLandmark Church School WBSbayoNo ratings yet

- 3D Solar System With Opengl and C#Document4 pages3D Solar System With Opengl and C#Shylaja GNo ratings yet

- FNCP Family Nursing Care Plan 1 Poor Environmental Sanitation Health ThreatDocument2 pagesFNCP Family Nursing Care Plan 1 Poor Environmental Sanitation Health Threatbraceceeem03No ratings yet

- Tpe Reflection AssignmentDocument5 pagesTpe Reflection Assignmentapi-351869082No ratings yet

- Class Record (Science 9) S.Y. 2020-2021Document8 pagesClass Record (Science 9) S.Y. 2020-2021Wilmar EspinosaNo ratings yet

- Cambodia's Rich Literary HeritageDocument5 pagesCambodia's Rich Literary HeritageChelle LancetaNo ratings yet

- 5 Set Model Question Mathematics (116) MGMT XI UGHSSDocument13 pages5 Set Model Question Mathematics (116) MGMT XI UGHSSSachin ChakradharNo ratings yet

- Sri Bhavishya Educational AcademyDocument4 pagesSri Bhavishya Educational AcademyAnonymous A6Jnef04No ratings yet

- Channel Emotions into FlowDocument2 pagesChannel Emotions into Flowmaxalves77No ratings yet

- CHE135 - Ch1 Intro To Hazard - MII - L1.1Document26 pagesCHE135 - Ch1 Intro To Hazard - MII - L1.1SyafiyatulMunawarahNo ratings yet

- PDF 20220814 211454 0000Document6 pagesPDF 20220814 211454 0000Madhav MehtaNo ratings yet

- Module 26Document27 pagesModule 26Ven Zyndryx De JoyaNo ratings yet

- Office AutomationDocument12 pagesOffice AutomationMad GirlNo ratings yet

- Appendix A. Second QuantizationDocument24 pagesAppendix A. Second QuantizationAgtc TandayNo ratings yet

- Macroeconomics: University of Economics Ho Chi Minh CityDocument193 pagesMacroeconomics: University of Economics Ho Chi Minh CityNguyễn Văn GiápNo ratings yet

- Thesis FormatDocument10 pagesThesis FormatMin Costillas ZamoraNo ratings yet

- China VS1-24 Series Indoor High Voltage Vacuum Circuit Breaker Factory and Manufacturers - GhoritDocument6 pagesChina VS1-24 Series Indoor High Voltage Vacuum Circuit Breaker Factory and Manufacturers - GhoritKalidass BackNo ratings yet

- Units 3 - 4 Workshop A2Document3 pagesUnits 3 - 4 Workshop A2S4N7Y PRONo ratings yet

- 302340KWDocument22 pages302340KWValarmathiNo ratings yet

- Programme EnergyDocument9 pagesProgramme EnergyAbdulazizNo ratings yet