Professional Documents

Culture Documents

Detalles de Pilotes PDF

Uploaded by

Santiago IbarraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detalles de Pilotes PDF

Uploaded by

Santiago IbarraCopyright:

Available Formats

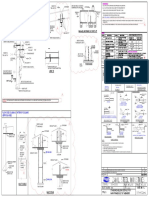

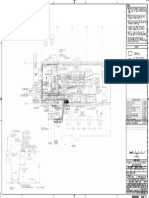

HP PILE

HP PILE

HP PILE FLANGE

FLANGE (TYP.) Y WEB

GENERAL NOTES:

HP PILE 1. PROVIDE MATERIALS AND WORKMANSHIP IN ACCORDANCE WITH THE

PJP CURRENT VERSIONS OF PUBLICATION 408 AND AASHTO/AWS WELDING

HP-PILE FLANGE

(TYP.) CODE D1.5. USE AWS D1.1 FOR WELDING NOT COVERED IN AASHTO/AWS

D1.5. THE NDT REQUIREMENTS IN D1.5 MAY BE WAIVED BY THE

1 …" MAX. STRUCTURE CONTROL ENGINEER.

GRIND END OF PILE ‚"

…" MAX.

PJP 1 FOR FLUSH FIT MIN. 1 2. THIS STANDARD COVERS ONLY "NORMAL DUTY" PILE TIP

(TYP.) SEE ALTERNATE REINFORCEMENT. DESIGNER MAY SPECIFY "HEAVY-DUTY"

DETAIL A. 1 PILE TIP REINFORCEMENT FOR HARD DRIVING CONDITIONS.

THE CONNECTION FOR "HEAVY-DUTY" PILE TIP REINFORCEMENT

TO BE IN ACCORDANCE WITH NOTE 6 ON THIS SHEET.

3. FURNISH AND INSTALL TIP REINFORCEMENT SUPPLIED BY

FU

B

B

TIP BULLETIN 15 APPROVED SUPPLIERS.

REINFORCEMENT

ALTERNATE 4. FURNISH A CERTIFIED STATEMENT THAT THE TIP

FU

REINFORCEMENT STEEL COMPLIES WTIH THE SPECIFICATION

REQUIREMENTS INCLUDING CERTIFIED REPORT SHOWING THE

T

Y DETAIL A CHEMICAL AND PHYSICAL

PHYSICAL PROPERTIES,

PROPERTIES, AND

AND ROLLING

ROLLING DIRECTION

FOR PLATES USED IN THE PREFABRICATED TIPS.

5. DO NOT USE FILLET WELD FOR ATTACHING CAST TIP REINFORCEMENT

ELEVATION VIEW VIEW Y-Y TO HP-PILES.

6. CONNECTION OF TIP REINFORCEMENT TO PILE:

CONN

JOIN HP PILE TO CAST TIPS USING GROOVE WELDS ONLY.

WELD SIZE TO BE THE GREATER OF ‰" OR MINIMUM

GROOVE WELD SIZE RECOMMENDED BY THE TIP MANUFAC-

‚" MIN.

TURER FOR THE PILE/TIP COMBINATION REQUIRED.

(TYP.)

BEVEL OUTSIDE OF EACH FLANGE OF THE HP-PILE FOR

GROOVE WELD, WHERE TIP REINFORCEMENTS ARE NOT

WELD

CAST TIPS PRE-BEVELED OR TO ACHIEVE THE MINIMUM GROOVE

HP- SIZE WELD SIZE.

PILE TYPE A (MIN.) B (MIN.) H (MIN.) T (MIN.)

ATTACH

ATTACH A

A PILE

PILETIP

TIPREINFORCEMENT

REINFORCEMENT ON THE SQUARE

14 X 117 ‰ CUT END OF THE PILE AND HOLD IT IN CLOSE CONTACT

14 X 102 AGAINST THE PILE OR TO ACHIEVE THE MINIMUM

‰

14 X 89 ‰

* 3 ** 1 GROOVE WELD SIZE.

H 14 X 73 ‰ 7. THE WELDS SHOWN ARE SUGGESTED ACCEPTABLE GROOVE WELDS.

THE

THE CONTRACTOR MAY USE ANY PREQUALIFIED GROOVE WELDS

12 X 84 ‰ APPROVED BY THE ENGINEER.

HP PILE (ABOVE) 12 X 74 ‰

2•

* ** ƒ 8. T

THE DEPARTMENT MAY REJECT AN APPROVED PILE TIP TYPE,

12 X 63 ‰ IF FOUND UNSUITABLE FOR A JOB SITE BASED UPON DRIVING

12 X 53 ‰ RECORDS.

A

10 X 57 ‰ * 2„ ** •

PLAN

= REFER TO NOTES 6 AND 7, THIS SHT.

TYPICAL HP-PILE TIP * = FLANGE THICKNESS + ‚" MIN. + FIT-UP TOLERANCE …" MAX.

** = WEB THICKNESS + 2 x ‚" MIN. + 2 x FIT-UP TOLERANCE …" MAX.

HP-PILE TIP REINFORCEMENT DETAILS

1•" x 1•" ANGLE

(FOR 45° BEVELS ONLY)

PJP

Š" MIN.

PJP

Š" MIN.

SCARFING END OF PILE

(H OR PIPE PILE)

SEE ALTERNATE

DETAIL B

SEE ALTERNATE 60°+

-

DETAIL B

ƒ" LP MIN.

SEE ALTERNATE

Š" MIN.

PJP

COMMONWEALTH OF PENNSYLVANIA

DETAIL B DEPARTMENT OF TRANSPORTATION

BUREAU OF PROJECT DELIVERY

1

CLOSED END PILE OPEN END PILES

1

STANDARD

ALTERNATE

STEEL PILE TIP REINFORCEMENTS

DETAIL B

& SPLICES

PIPE PILE TIP REINFORCEMENT

RECOMMENDED NOV. 26, 2013 RECOMMENDED NOV. 26, 2013 SHEET 1 OF 3

CHIEF BRIDGE ENGINEER ACTING DIR, BUR. OF PROJECT DELIVERY

BC-757M

SEE NOTE B

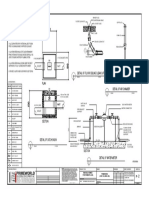

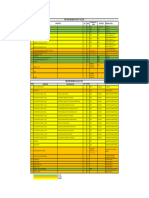

GENERAL NOTES:

(TYP.)

Š"

1. METHOD 1 SHOWS GROOVE WELDED FLANGE AND WEB SPLICES.

HP PILE 2. METHOD 2 SHOWS SPLICE DETAILS USING SPLICER.

FLANGE "MB"

3. BARS "MA" AND "MB" TO BE IN ACCORDANCE WITH AWS CODE FOR

A (TYP.) WEB

WELD BACKING. RECOMMENDED MINIMUM SIZE IS 1‚" x ‰".

UP

C

L WEB

WEB "MA" PROVIDE ADDITIONAL WELD AS

* ƒ" PER SPLICER MANUFACTURER

45°

L

FIELD WELDING NOTES:

"MA"

C C

2"

MIN.

1. SUBMIT A WELD PROCEDURE SPECIFICATION TO THE ENGINEER

‚ "

…"

A **

2

FOR APPROVAL BEFORE WELDING IS PERFORMED.

/

L

B-U4a OR BACK-UP PLATE

B B

B-U2a (AS REQUIRED) 2. USE THE MANUAL SHIELDED METAL ARC PROCESS WITH

PROPERLY DRIED ELECTRODES CONFORMING TO AWS

CLASSIFICATION E-7016, E-7018 OR E-7028.

SEE NOTE B

3. DRY THE ELECTRODES FOR AT LEAST TWO HOURS AT A

DRY THE

TEMPERATURE BETWEEN 450° AND 500°F PRIOR TO USE.

REDRY ELECTRODES IF NOT USED WITHIN FOUR HOURS.

SPLICER

PLAN SECTION A-A (TYP.) Removed original Method 1 Detail, renamed DO NOT REDRY ELECTRODES MORE THAN ONE TIME.

DO NOT USE ELECTRODES WHICH HAVE DRIED OUT AND

Š"

original Method 2 Detail to Method 1, CRACKED, OR THOSE WHICH HAVE BEEN WET. STORE

ALL LOW HYDROGEN ELECTRODES IN SUITABLE OVENS HELD

METHOD 1 METHOD 2 relocated original Method 3 Detail from sht.3 AT A TEMPERATURE OF AT LEAST 250°F.

NOTE B: EXTEND BAR "MB" A MINIMUM OF 2" BEYOND THE FLANGE

to this sht. and renamed it to Method 2 4. DO NOT WELD WHEN SURFACES ARE WET OR EXPOSED TO

DO

RAIN, SNOW, WIND OR WHEN WELDERS ARE EXPOSED TO

EDGE TO ALLOW FOR WELD INITIATION AND TERMINATION. INCLEMENT CONDITIONS THAT WILL HAMPER GOOD

REMOVE PORTION OF BAR "MB" BEYOND THE EDGE OF FLANGE WORKMANSHIP.

AND GRIND FLUSH AFTER FINAL WELDING IS COMPLETE.

5. REMOVE ANY MOISTURE FROM FOG, DEW ETC. PRESENT

RE

BEFORE WELDING.

HP PILE

WEB SEE NOTE A (TYP.) 6. PROVIDE

PRO WIND BREAKS TO PROTECT WORKING AREAS FROM

COPE WEB 1" "MA" DIRECT WIND.

LEGEND RADIUS (TYP.)

"MB" 7. DO NOT WELD WHEN THE AMBIENT TEMPERATURE IS BELOW 0°F.

* - B-U4a (TYP.) OR B-U2a AT SPLICER, 45°

"MA" C

L SPLICE

B-U4a/B-U4b OR B-U2a/B-U2 BEYOND SPLICER (TYP.)

8. PREHEAT METAL TO AT LEAST 70°F IN AN AREA AT

LEAST 3" AWAY FROM THE WELD IN ALL DIRECTIONS AND

** - THE SINGLE BEVEL GROOVE WELDS B-U4a

45° MAINTAIN AT THIS MINIMUM TEMPERATURE DURING WELDING.

AND B-U4b ARE LIMITED TO THE HORIZONTAL

MIN.

WELDING POSITION ONLY PER THE AWS CODE.

‚ "

9. PROVIDE BACKING PLATES AND WELD TABS FOR FLANGE WELDS

MIN.

‚ "

C

L SPLICE OF THE SAME MATERIAL AS THE PILE TO BE SPLICED.

MAY LEAVE BACKING PLATES IN PLACE.

"MB" ** COPE WEB 1"

ONLY AWS CERTIFIED WELDERS ALLOWED TO PERFORM THE WELDING.

(TYP.) 10.

(TYP.)

RADIUS BOTH ENDS.

FLANGE FLANGE 11. FOR SCARFING DETAILS, SEE SHEET 1.

„"

HP PILE

„" MAX. (TYP.) FLANGE MAX. SPLICE NOTES:

BACK GOUGING

BACK-UP „" 1. DO NOT ALLOW PILE SPLICING ON ANY PORTION

IS MANDATORY

PLATE OF PILE THAT IS TO REMAIN EXPOSED ABOVE

FOR THIS JOINT.

FINISHED GROUND LINE IN COMPLETED STRUCTURE.

45° SECTION C-C

45° SECTION B-B

2. PROVIDE SPLICED SLEEVE MATERIAL SAME AS

(B-U4a FLANGE WELD SHOWN) (B-U2a ALTERNATE FLANGE WELD SHOWN) PILE MATERIAL.

0" TO „" 3. USE EITHER THE "SPLICER SLEEVE" OR "ALL

‚"

WEB COPE AND BACK-UP WELDED ALTERNATES.

PLATE DETAIL 4. LET WELDS COOL TO AIR TEMPERATURE BEFORE

DRIVING PILES.

NOTE A: END OF WELD TO BE GROUND SMOOTH AND FLUSH WITH WEB COPE. 5. SPLICE MUST DEVELOP THE YIELD STRENGTH

OF THE PILE IN BEARING AND BENDING.

6. REFER TO SEC. 1005.2(c) OF PUB. 408 FOR

SPLICE LOCATION REQUIREMENTS.

** ** WEDGE

B-U4a OR B-U4b 7. GRIND WELD SMOOTH WITH EDGE OF FLANGE IF

PLATE

(RECOMMENDED) PILE IS UNSUPPORTED IN WELD AREA SUCH AS:

IN AIR, WATER OR SOFT MUD (INCLUDING SCOUR

BACK GOUGING ZONES OR OTHER VOID AREAS).

IS MANDATORY

WEDGE

FOR THIS JOINT. PLATE

D D

D P

’" CLAMP L

BACK-UP

FLANGE FLANGE

PLATE

CLAMP

PLATE

(TYP.)

‚" 0" TO „"

45° 60°

„"

D D COMMONWEALTH OF PENNSYLVANIA

D

DEPARTMENT OF TRANSPORTATION

BUREAU OF PROJECT DELIVERY

STANDARD

B-U2a OR B-U2 PLAN - HP PILE WITH CLAMPS SECTION D-D

(RECOMMENDED) SHOWN USING CLAMPS TO HOLD STEEL PILE TIP REINFORCEMENTS

PILE DURING WELDING

JOINT DETAILS POSITIONING DETAILS & SPLICES

WEB COPE NOT SHOWN, SEE SECTION B-B AND

C-C FOR DETAILS. THE CONTRACTOR MAY ELECT

TO USE THE BACK GOUGED JOINT DETAILS B-U4b RECOMMENDED NOV. 26, 2013 RECOMMENDED NOV. 26, 2013

SHEET 2 OF 3

OR B-U2 IN LIEU OF DETAILS B-U4a OR B-U2a.

HP-PILE SPLICE DETAILS

CHIEF BRIDGE ENGINEER ACTING DIR, BUR. OF PROJECT DELIVERY

BC-757M

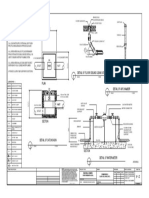

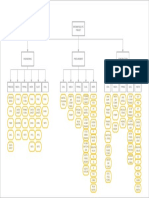

SPLICE NOTES:

1. DO NOT ALLOW PILE SPLICING ON ANY PORTION

M

OF PILE THAT IS TO REMAIN EXPOSED ABOVE

2" MIN. FINISHED GROUND LINE IN COMPLETED STRUCTURE.

NOTE: MACHINE

PIPE (TYP.)

BACKING BACKING RING TO BE FLAT

PILE BACKING 2. PROVIDE SPLICED SLEEVE MATERIAL SAME AS

RING, SEE CUT FROM SAME PILE

RING PILE MATERIAL.

DETAIL C SIZE AS IS BEING

SPLICED. CUT AND BEND

F 3. USE EITHER THE "SPLICER SLEEVE" OR "ALL

TO FIT INSIDE DIAMETER WELDED ALTERNATES.

OF PILE.

4. LET WELDS COOL TO AIR TEMPERATURE BEFORE

BACK-UP DRIVING PILES.

WALL PLATE

5. SPLICE MUST DEVELOP THE YIELD STRENGTH

SEE NOTE C THICKNESS

OF THE PILE IN BEARING AND BENDING.

PIPE

BACKING 6. REFER TO SEC. 1005.2(b) OF PUB. 408 FOR

PILE

F RING SPLICE LOCATION REQUIREMENTS.

WALL

THICKNESS PLAN

(PIPE PILE NOT SHOWN FOR CLARITY)

ELEVATION - SPLICE SECTION F-F DETAIL C

USING ALL WELDED ALTERNATE

NOTE C: IF PIPE WALL THICKNESS EXCEEDS ‚", USE WELD

DETAIL B-U2a OR B-U4a SHOWN ON SHEET 2 OF 3.

PIPE PILE

AFTER SEATING PILE, WELD WITH CONTINUOUS

‚" MIN. FILLET WELD, TOP AND BOTTOM.

**

SPLICER SPLICER

SLEEVE SLEEVE

ƒ "

PILE SHELL

•"

6"

‡"

2… "

MIN.

…"

6"

‰" MAX.

‚" ROOT OPENING

‚"

MIN. WALL

THICKNESS

SEE DETAIL D ‚"

PIPE PILE

CUT THIS END OF SHELL TO A

NOTE:

CONFIGURATION SUCH THAT THE FILLET

INCREASE WELD SIZE

WELD ALONG THE CUT EDGE TO HAVE A

G BASED ON ROOT OPENING.

TOTAL LENGTH NOT LESS THAN 6 TIMES

THE DIAMETER OF THE SHELL.

ELEVATION - SPLICE SECTION G-G DETAIL D FLUTED TUBE

ALL DIMENSIONS ARE MINIMUM

(USING SPLICER SLEEVE)

SPLICE DETAIL

**

WELD SIZE DEPENDS

ON PIPE WALL

THICKNESS.

PIPE PILE SPLICE DETAILS

COMMONWEALTH OF PENNSYLVANIA

DEPARTMENT OF TRANSPORTATION

BUREAU OF PROJECT DELIVERY

STANDARD

STEEL PILE TIP REINFORCEMENTS

& SPLICES

RECOMMENDED NOV. 26, 2013 RECOMMENDED NOV. 26, 2013

SHEET 3 OF 3

CHIEF BRIDGE ENGINEER ACTING DIR, BUR. OF PROJECT DELIVERY

BC-757M

You might also like

- Saudi Arabian Oil Company: DA-728550 005 P 0A3 K11 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-728550 005 P 0A3 K11 RestrictedWaqarNo ratings yet

- PR-402 2021-578Document1 pagePR-402 2021-578Krishna SankarNo ratings yet

- Sys-002-A-Welding Map-02Document1 pageSys-002-A-Welding Map-02Ahmed OokaNo ratings yet

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocument1 pageDetail of Floor/ Ceiling Clean Out: Plumbing NotesRODEAN HOPE LACSINo ratings yet

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocument1 pageDetail of Floor/ Ceiling Clean Out: Plumbing NotesHana YeppeodaNo ratings yet

- CM0202, Compressor DWG-2Document2 pagesCM0202, Compressor DWG-2ansariiqbal9570No ratings yet

- Saudi Arabian Oil Company: DA-728390 005 P 0A3 K10 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-728390 005 P 0A3 K10 RestrictedWaqarNo ratings yet

- Diagrama Sugerido de Instalación Bomba Horizontal PDFDocument1 pageDiagrama Sugerido de Instalación Bomba Horizontal PDFIvan D. CasallasNo ratings yet

- Schedule of Loads and Computation: Pb1 (Lighting & Power Panel) Schedule of Loads and Computation: Pb2 (Acu Panel)Document1 pageSchedule of Loads and Computation: Pb1 (Lighting & Power Panel) Schedule of Loads and Computation: Pb2 (Acu Panel)alezandro del rossiNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- FPR Ceiling UpdatedDocument2 pagesFPR Ceiling Updatedankit yadavNo ratings yet

- ,5 (-J - $438 DBGFC 631-44AJ: I Customer Part No., Y51 q955Document2 pages,5 (-J - $438 DBGFC 631-44AJ: I Customer Part No., Y51 q955dieselmotorsbogotasasNo ratings yet

- 1516 e (Sheet 3 of 3) 15 Mva 66 - 11.550 KV Aet - 1374Document1 page1516 e (Sheet 3 of 3) 15 Mva 66 - 11.550 KV Aet - 1374shravan Kumar SinghNo ratings yet

- Ynjdc Dsco DD DWG PJW Gen Mec Acv 00501Document1 pageYnjdc Dsco DD DWG PJW Gen Mec Acv 00501Sk NgNo ratings yet

- Different Brand of Different Brand Of: DiversityDocument40 pagesDifferent Brand of Different Brand Of: DiversityGas, Oil & Mining Contractor MagazineNo ratings yet

- Electrical Layout - L2Document1 pageElectrical Layout - L2sushant moreyNo ratings yet

- 02.1 Inventario Equipos 1500 PW-160 - XLSXDocument17 pages02.1 Inventario Equipos 1500 PW-160 - XLSXROBERSON ROMERÒNo ratings yet

- Construction Notes: ElevationDocument1 pageConstruction Notes: ElevationJohn PaderangaNo ratings yet

- Saudi Arabian Oil Company: DA-728849 005 P 0A3 K13 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-728849 005 P 0A3 K13 RestrictedWaqarNo ratings yet

- HES Bid Set Fire Protection DrawingsDocument5 pagesHES Bid Set Fire Protection DrawingsMansoor Abdul KhaderNo ratings yet

- Eil Job No.: A545: OwnerDocument35 pagesEil Job No.: A545: OwnerSandip SurNo ratings yet

- B A C E D F H G I K J L L M: Line Identification Fire and Safety Process PipelinesDocument3 pagesB A C E D F H G I K J L L M: Line Identification Fire and Safety Process PipelinesJoséMiguelSánchezGNo ratings yet

- Spec 04 Gas TurbinesDocument12 pagesSpec 04 Gas TurbinesJovana Vuksanovic100% (1)

- 3285 MsdsDocument1 page3285 MsdsArnaldo J Brito ÑNo ratings yet

- Wa0000.Document4 pagesWa0000.سلطان السواعيرNo ratings yet

- Stratovent-Tb Hood-Front View 08-22-13Document1 pageStratovent-Tb Hood-Front View 08-22-13apara_jitNo ratings yet

- Stratovent-Tb Hood-Front View PDFDocument1 pageStratovent-Tb Hood-Front View PDFapara_jitNo ratings yet

- 15 - 1B Ah-5vomDocument1 page15 - 1B Ah-5vomMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- GA - HVD StationDocument1 pageGA - HVD StationNawfel ArafathNo ratings yet

- Erection Scope Details of CFA and IMT - SOT-09122072Document1 pageErection Scope Details of CFA and IMT - SOT-09122072sunilkrishnamurthy1No ratings yet

- Pengenalan PLTU Teluk Sirih PDFDocument19 pagesPengenalan PLTU Teluk Sirih PDFDinata Putra100% (1)

- WPG 151AH31: 14 MM 14 MMDocument24 pagesWPG 151AH31: 14 MM 14 MMMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- WWP541 5 CCRBDocument10 pagesWWP541 5 CCRBchrisNo ratings yet

- ELECTRICAL MODEL SONCIO For A3 - E2-ModelDocument1 pageELECTRICAL MODEL SONCIO For A3 - E2-ModelChris ChanNo ratings yet

- Side View Front View Back View: B U S B A RDocument1 pageSide View Front View Back View: B U S B A RHytech Pvt. Ltd.No ratings yet

- Saudi Arabian Oil Company: DA-727580 005 P 0A3 K05 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-727580 005 P 0A3 K05 RestrictedWaqarNo ratings yet

- WPG 100PH30: For Contact Details - Visit WWW - Warman.co - Za For Contact Details - Visit WWW - Warman.co - ZaDocument4 pagesWPG 100PH30: For Contact Details - Visit WWW - Warman.co - Za For Contact Details - Visit WWW - Warman.co - ZaMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Small Revision-4Document4 pagesSmall Revision-4Noman KhalidNo ratings yet

- PT Note 1Document1 pagePT Note 1mosharNo ratings yet

- Lightolier Lytetroff Recessed Fluorescent Brochure 1988Document8 pagesLightolier Lytetroff Recessed Fluorescent Brochure 1988Alan MastersNo ratings yet

- Me1 MotoDocument1 pageMe1 MotoarchtgozarNo ratings yet

- 11 5000 Shaffer Bolted Annular Bop Spec SheetDocument1 page11 5000 Shaffer Bolted Annular Bop Spec SheetJoel SNo ratings yet

- Service Installation Pole Mount (Shown) : Notes: Grounding SystemDocument1 pageService Installation Pole Mount (Shown) : Notes: Grounding SystemEnrique Hdez. E.No ratings yet

- UNITED A319 - A320 Cockpit Panel Guides and System DiagramsDocument18 pagesUNITED A319 - A320 Cockpit Panel Guides and System DiagramsBELISARIO100% (1)

- Dim 4aef12 750gpm Vs 185 Psi 150 HP Rotacion IzquierdaDocument1 pageDim 4aef12 750gpm Vs 185 Psi 150 HP Rotacion IzquierdaJAFETT ESCOBAL HUAMANNo ratings yet

- Short Guide 1/3: Manages Black and WhiteDocument3 pagesShort Guide 1/3: Manages Black and WhiteaNo ratings yet

- NF-S-150-100-FD140HT, 142HP-EGT-586-Layout1Document1 pageNF-S-150-100-FD140HT, 142HP-EGT-586-Layout1khalid mohamedNo ratings yet

- General Notes:: Fillet Weld TableDocument1 pageGeneral Notes:: Fillet Weld Tablefrancis sebastian lagamayoNo ratings yet

- Kitchen Ansul System With Mechanical Gas Valve Wiring BUCKEYE BFR 10Document4 pagesKitchen Ansul System With Mechanical Gas Valve Wiring BUCKEYE BFR 10JhoNo ratings yet

- Brownfield Epc ProjectDocument1 pageBrownfield Epc ProjectDio AkhbarNo ratings yet

- Eastern Railway (Railline) : BurdwanDocument1 pageEastern Railway (Railline) : BurdwanKoushick RoyNo ratings yet

- 70ft Mast Rig Up LayoutDocument1 page70ft Mast Rig Up LayoutrishitharanNo ratings yet

- "Important Warning": Aux. El. Ref. ElDocument2 pages"Important Warning": Aux. El. Ref. ElKenzoNo ratings yet

- Saif Powertec Limited Project "Standard Operating Process" As-Is DocumentDocument6 pagesSaif Powertec Limited Project "Standard Operating Process" As-Is DocumentAbhishekChowdhuryNo ratings yet

- Gen Ed 3 and 4Document96 pagesGen Ed 3 and 4Sabalza, Ruffelyn AnnNo ratings yet

- Presentación de Stefanini PDFDocument24 pagesPresentación de Stefanini PDFramontxu06No ratings yet

- Ranthambore Tiger Reserve (Current) UMDocument8 pagesRanthambore Tiger Reserve (Current) UMSmriti SrivastavaNo ratings yet

- Prisma-Daps Brochure EN PDFDocument8 pagesPrisma-Daps Brochure EN PDFHasan GhanoumNo ratings yet

- 812 Series: Delay On Make TimerDocument49 pages812 Series: Delay On Make TimerJuan Pablo Merck SifontesNo ratings yet

- THS A10 2Document1 pageTHS A10 2JACKY PGNo ratings yet

- Sigint Operations NsaDocument162 pagesSigint Operations NsadenitobastianNo ratings yet

- C 15 Mini ProjectDocument12 pagesC 15 Mini ProjectMr.single KANYANo ratings yet

- A StarDocument8 pagesA StarAlineNo ratings yet

- A Very Important Thread Thread by Nishant Bliss Mar 16, 22 From RattibhaDocument5 pagesA Very Important Thread Thread by Nishant Bliss Mar 16, 22 From RattibhaSyedmahmoodNo ratings yet

- ASSIGNMENT 1 - Firing If Howitzer Gun - HaleemaMalik MS19Document7 pagesASSIGNMENT 1 - Firing If Howitzer Gun - HaleemaMalik MS19Haleema MalikNo ratings yet

- Department of Electrical Engineering Analogue and Digital CommunicationDocument11 pagesDepartment of Electrical Engineering Analogue and Digital CommunicationZubair KhalidNo ratings yet

- Subject Outline: 41889 Application Development in The iOS EnvironmentDocument10 pagesSubject Outline: 41889 Application Development in The iOS EnvironmentmjNo ratings yet

- Bootstrap FrameworkDocument3 pagesBootstrap FrameworkkashyapNo ratings yet

- Business Analytics: Certificate Program inDocument20 pagesBusiness Analytics: Certificate Program inSANTHAN KUMARNo ratings yet

- Learning Element 3Document17 pagesLearning Element 3niel lunaNo ratings yet

- Scada Study MaterialDocument9 pagesScada Study MaterialSaravanakumar KNo ratings yet

- 5ebe4bdc69b31 - 1589529561 - Shantanu Kawale - ResumeDocument2 pages5ebe4bdc69b31 - 1589529561 - Shantanu Kawale - ResumeKunal NagNo ratings yet

- Populasi Dan Sampel Skala PengukuranDocument25 pagesPopulasi Dan Sampel Skala PengukuranJuan KarnadiNo ratings yet

- Thesis JournalDocument7 pagesThesis JournalVincent SpadeNo ratings yet

- Consolidate Data From Multiple Worksheets Into A Summary Worksheet in ExcelDocument10 pagesConsolidate Data From Multiple Worksheets Into A Summary Worksheet in ExcelThomas WongNo ratings yet

- E207 - Communication Systems: Worksheet For Lesson 07: Standing WavesDocument8 pagesE207 - Communication Systems: Worksheet For Lesson 07: Standing Waves张瑜征No ratings yet

- DHT22 DatasheetDocument2 pagesDHT22 DatasheetMarco TorresNo ratings yet

- Lexium Mdrive: LMD - P57 Pulse / Direction InputDocument5 pagesLexium Mdrive: LMD - P57 Pulse / Direction InputTăng TrườngNo ratings yet

- DOL StartersDocument2 pagesDOL StartersAbhi TiwariNo ratings yet

- Pipe and Tube Sizes PDFDocument32 pagesPipe and Tube Sizes PDFAlvaro Gonza HuallaNo ratings yet

- Elevator Traffic AnalysisDocument52 pagesElevator Traffic Analysisstanjack99No ratings yet

- Cloud Computing Program BrochureDocument19 pagesCloud Computing Program BrochurePriyanka KNo ratings yet

- 11english TestDocument2 pages11english TestSampiNo ratings yet