Professional Documents

Culture Documents

Concrete Construction Article PDF - Selecting A Mix To Meet Strength Specifications PDF

Uploaded by

srikantheraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Construction Article PDF - Selecting A Mix To Meet Strength Specifications PDF

Uploaded by

srikantheraCopyright:

Available Formats

Selecting a mix to meet

strength specifications

By Bruce A. Suprenant

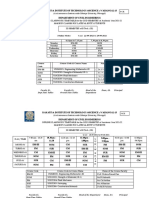

TABLE 1. MODIFICATION FACTOR FOR STANDARD

P

roject specifications require the DEVIATION WHEN LESS THAN 30 TESTS ARE AVAILABLE

28-day concrete compressive

strength to be 3500 psi with a

margin of safety set by the American NUMBER OF TESTS MODIFICATION FACTOR FOR STANDARD DEVIATION

Concrete Institute’s (ACI) “Building 15 1.16

Code Requirements for Reinforced 20 1.08

Concrete.” Do you need a new mix 25 1.03

design? Generally not, but make sure 30 or more 1.00

the mix design selected meets ACI cri-

teria for strength requirements. Interpolate for intermediate numbers of tests.

ACI 318 STRENGTH REQUIREMENTS

The average strength of the mix

design must always exceed the speci- TABLE 2. REQUIRED AVERAGE COMPRESSIVE

fied value of the 28-day compressive

strength, f c. ACI 318 indicates the

STRENGTH WHEN DATA ARE NOT AVAILABLE

amount by which the average TO ESTABLISH A STANDARD DEVIATION

strength of a concrete mix, f cr, should

exceed f c. The amount of excess SPECIFIED COMPRESSIVE REQUIRED AVERAGE

strength depends on the expected STRENGTH, f c, PSI COMPRESSIVE STRENGTH, f cr, PSI

variability of test results as expressed Less than 3000 psi f c 1000

by a standard deviation, s, for a par- 3000 to 5000 f c 1200

ticular concrete mix. ACI criteria are Over 5000 f c 1400

based on probabilistic concepts and

are intended to ensure that adequate records for which the standard devia- facility does not have test records meet-

strength will be developed in the tion is calculated: ing the above requirements, but does

structure. • (a) Shall represent materials, have a record based on 15 to 29 consec-

Required average strength. ACI quality control procedures, and con- utive tests, a standard deviation shall

requires the average compressive ditions similar to those expected, and be established as the product of the cal-

strength, f cr, used as the basis for changes in materials and proportions culated standard deviation and the

selection of concrete proportions, to within test records shall not have modification factor shown in Table 1.

be the larger of one of the following: been more restricted than those for To be acceptable, test records shall meet

(1) f cr f c 1.34s the proposed work. requirements A and B and represent

(2) f cr f c 2.33s 500 • (b) Shall represent concrete pro- only a single record of consecutive tests

Equation 1 provides a probability of duced to meet a specified strength or that span a period of not less than 45

1 in 100 that averages of three consec- strengths within 1000 psi of that spec- calendar days.

utive strength tests will be below the ified for proposed work. When there are less than 15 tests,

specified strength, f c. Equation 2 also • (c) Shall consist of at least 30 con- use Table 2 to determine the required

provides the same 1 in 100 probability secutive tests or two groups of con- average strength f cr.

that an individual test is more than secutive tests totaling at least 30 tests.

500 psi below the specified strength A strength test shall be the average of EXAMPLE CALCULATIONS

f c. the strengths of two cylinders made The specifications require f c to be

Standard deviation. The standard from the same sample of concrete and 3000 psi in accordance with ACI 318.

deviation for each mix must be deter- tested at 28 days or at test age desig- The concrete production facility has

mined from strength tests. ACI pro- nated for determination of f c. test records on a mix that provides an

vides the following criteria on test • (d) Where a concrete production average strength of 3700 psi with a

standard deviation of 500 psi. Will STRENGTH INCREASE OR DECREASE

this mix meet the ACI criteria? DURING CONSTRUCTION

Use equations 1 and 2 to calculate As more data becomes available

the required average strength. during construction, ACI allows f cr

(1) f cr 3000 1.34(500) 3670 psi to change as the quality contro l

(2) f cr 3000 2.33(500) 500 3665 improves. Typically, quality control

psi improves after the kinks are ironed

The largest value, 3670 psi, is less out during job start-up. This allows

than the average mix strength of 3700 the concrete supplier to save money

psi. Therefore, the selected mix would by reducing cement content to

satisfy ACI criteria for an f c of 3000 achieve a lower strength. However,

psi. there may be a minimum cement

content level that can’t be reduced

PRECAUTIONS because of special exposure condi-

When choosing a mix and evaluat- tions.

ing test records, carefully select a mix When concrete strength is low, ACI

similar to that for the proposed work. requires an increase in the average

Consider changes in type and brand strength. This frequently is accom-

of cement, admixtures, aggregate plished by adding portland cement;

source, mix proportions, batching, however, it also may be accom-

mixing, delivery, or testing to signifi- plished by changes in mix propor-

cantly alter the mix so that test tions, reductions in or better control

records from the new mix can’t be of slump, reduction in delivery time,

combined with the previous test closer control of air content, or an

records. In general changes in materi- improvement in the quality of test-

als and procedures have a larger effect ing.

on the average strength level than on

the standard deviation.

PUBLICATION #J940611

Copyright © 1994, The Aberdeen Group

All rights reserved

You might also like

- Limit On Strength of Normal Weight Concrete: S. K. Ghosh, PH.DDocument6 pagesLimit On Strength of Normal Weight Concrete: S. K. Ghosh, PH.DAnasA.QatananiNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- High-Strength Concrete in U.S. Codes and Standards S.K. GhoshDocument16 pagesHigh-Strength Concrete in U.S. Codes and Standards S.K. GhoshGuilhermeFregoneziNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Evaluating Low Concrete Strength Test Results: Colorado Procedure 65-16Document6 pagesEvaluating Low Concrete Strength Test Results: Colorado Procedure 65-16Saad SANo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP 35 - Testing Compressive Strength of ConcreteAshutosh NautiyalNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP 35 - Testing Compressive Strength of ConcreteAshutosh NautiyalNo ratings yet

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- Testing Compressive Strength of Concrete PDFDocument2 pagesTesting Compressive Strength of Concrete PDFaaNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Breaks Evaluation CIP09pDocument2 pagesBreaks Evaluation CIP09pgemotorresNo ratings yet

- Factors in The Proportioning of Quality Concrete Mixtures: Workability StrengthDocument54 pagesFactors in The Proportioning of Quality Concrete Mixtures: Workability Strengthzzz_monsterNo ratings yet

- Flexural Strength of ConcreteDocument3 pagesFlexural Strength of ConcretevikasNo ratings yet

- Concrete Durability Requirement in QCS 2014Document1 pageConcrete Durability Requirement in QCS 2014Zohaib Sattar NagraNo ratings yet

- Concrete Strength Acceptance: by Bruce A. SuprenantDocument3 pagesConcrete Strength Acceptance: by Bruce A. SuprenantBruce SuprenantNo ratings yet

- CIP35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerNo ratings yet

- Testing The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixDocument2 pagesTesting The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixPritha DasNo ratings yet

- PCI Nov01 Limit On StrengthDocument6 pagesPCI Nov01 Limit On StrengthMark Gerald Prades RegalaNo ratings yet

- Learning Material RCDDocument18 pagesLearning Material RCDChristian John BiolNo ratings yet

- What Is Meant by Charactyeristic Strength of ConcreteDocument4 pagesWhat Is Meant by Charactyeristic Strength of ConcretemmabeeNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument7 pagesCIP 35 - Testing Compressive Strength of ConcretesudhakarmnNo ratings yet

- Concrete Strength AcceptanceDocument1 pageConcrete Strength AcceptanceRaghavan ARNo ratings yet

- Compressive Strength of Cores and Specification Compliance: ReferencesDocument3 pagesCompressive Strength of Cores and Specification Compliance: Referencesabegaa aberaNo ratings yet

- Acceptance Criteria For Durability TestDocument6 pagesAcceptance Criteria For Durability TestcesaraleNo ratings yet

- 09pr PDFDocument2 pages09pr PDFSamalla PrashanthNo ratings yet

- Testing The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixDocument4 pagesTesting The Compressive Strength of Concrete - What, Why, & How - Nevada Ready Mixdhan singhNo ratings yet

- What To Do When Cylinder Breaks Are LowDocument3 pagesWhat To Do When Cylinder Breaks Are LowRommel Villaroman EstevesNo ratings yet

- Concrete Mix DesignDocument49 pagesConcrete Mix Designankit100% (4)

- Concrete Mix Design - (Part 1 & Part 2) PPT7Document39 pagesConcrete Mix Design - (Part 1 & Part 2) PPT7JuliaNo ratings yet

- Defense - Data CollectionDocument3 pagesDefense - Data CollectionJohn Khim Ivan GalangNo ratings yet

- 72.core Cut Reference SP-24Document1 page72.core Cut Reference SP-24DMJ NagpurNo ratings yet

- Testing of Material-Lab-Report-7Document6 pagesTesting of Material-Lab-Report-7Mariefel Therese AlsaNo ratings yet

- Ch05 Design Code and Commentary Approved Version Revised 13-01-18Document17 pagesCh05 Design Code and Commentary Approved Version Revised 13-01-18owaisNo ratings yet

- Item 900 - Reinforced Concrete 900.1 DescriptionDocument9 pagesItem 900 - Reinforced Concrete 900.1 DescriptionEster MarianNo ratings yet

- Compressive Strength Recommendations For Protecting Concrete From Multiple Freezing-and-Thawing CyclesDocument5 pagesCompressive Strength Recommendations For Protecting Concrete From Multiple Freezing-and-Thawing CyclesBruce SuprenantNo ratings yet

- Lab ReportDocument44 pagesLab ReportNepali Kanchoo100% (1)

- 2-Prof. Zahid Ahmad Siddiqi Lec-2-Introduction PDFDocument34 pages2-Prof. Zahid Ahmad Siddiqi Lec-2-Introduction PDFHAFIZ ARSALAN ALINo ratings yet

- Pullout Strength of Hardened Concrete - C900 - 15Document10 pagesPullout Strength of Hardened Concrete - C900 - 15Ahmad ThaherNo ratings yet

- Proper Procedures For Evaluating Low Strengths: CEMEX USA - Technical Bulletin 1.0Document3 pagesProper Procedures For Evaluating Low Strengths: CEMEX USA - Technical Bulletin 1.0abebechNo ratings yet

- General NotesDocument3 pagesGeneral NotesALI RAZANo ratings yet

- Airport Paving QualityDocument8 pagesAirport Paving QualityDjokovic AlarconNo ratings yet

- Mix DesignDocument25 pagesMix Designmahmud.shakkwarNo ratings yet

- Tieu Chuan EN 206-1 Cua Chau AuDocument9 pagesTieu Chuan EN 206-1 Cua Chau AuPhạm Thanh BìnhNo ratings yet

- CH 3-2-Portland Cement Concrete MixDocument81 pagesCH 3-2-Portland Cement Concrete MixHind AwadNo ratings yet

- Punching Shear Resistance of SlabDocument8 pagesPunching Shear Resistance of SlablinkgreencoldNo ratings yet

- Chapter 2Document17 pagesChapter 2htetwyan54No ratings yet

- Proper Use of The Rebound Hammer Updated To Reflect The Changes To ASTM C805Document6 pagesProper Use of The Rebound Hammer Updated To Reflect The Changes To ASTM C805Niroshan PereraNo ratings yet

- Astm C 900-15Document10 pagesAstm C 900-15HAMZA RASHEEDNo ratings yet

- l05 092Document7 pagesl05 092rammirisNo ratings yet

- CIP16 - Flexural Strength of ConcreteDocument2 pagesCIP16 - Flexural Strength of ConcretePECMURUGANNo ratings yet

- Understanding Minimum Specified Compressive StrengthDocument2 pagesUnderstanding Minimum Specified Compressive StrengthsasikumareNo ratings yet

- Reinforced Concrete Design On ACI - Part 1 PDFDocument45 pagesReinforced Concrete Design On ACI - Part 1 PDFshahrol905No ratings yet

- Cylinder Strength Versus Cube StrengthDocument26 pagesCylinder Strength Versus Cube Strengthfsirfan100% (2)

- Statistical Analysis ConcreteDocument12 pagesStatistical Analysis Concreterowaters100% (2)

- 02 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of DoubtDocument3 pages02 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of DoubtRVNLPKG6B VBL-GTLMNo ratings yet

- Chapter 3b-Concrete Mix DesignDocument16 pagesChapter 3b-Concrete Mix DesignPaul SsewankamboNo ratings yet

- CIP 16 - Flexural Strength of ConcreteDocument2 pagesCIP 16 - Flexural Strength of ConcreteEkinawa AwanikeNo ratings yet

- A-1 Marks ReportDocument2 pagesA-1 Marks ReportsrikantheraNo ratings yet

- 3ce R Som 18303 1Document3 pages3ce R Som 18303 1srikantheraNo ratings yet

- SFD and BMDDocument83 pagesSFD and BMDKaisar HassanNo ratings yet

- Office of The Dean, Research and DevelopmentDocument1 pageOffice of The Dean, Research and DevelopmentsrikantheraNo ratings yet

- Updated - MAKEUP CLASSES FOR LATERAL ENTRY STUDENTS - 1Document2 pagesUpdated - MAKEUP CLASSES FOR LATERAL ENTRY STUDENTS - 1srikantheraNo ratings yet

- Table of Specifications (Tos) : Kakatiya Institute of Technology and Science: Warangal-15Document6 pagesTable of Specifications (Tos) : Kakatiya Institute of Technology and Science: Warangal-15srikantheraNo ratings yet

- DAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 03.08.19Document4 pagesDAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 03.08.19srikantheraNo ratings yet

- DAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 05.08.19Document5 pagesDAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 05.08.19srikantheraNo ratings yet

- DAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 10.08.19Document4 pagesDAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 10.08.19srikantheraNo ratings yet

- DAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 08.08.19Document5 pagesDAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 08.08.19srikantheraNo ratings yet

- DAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 07.08.19Document5 pagesDAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 07.08.19srikantheraNo ratings yet

- Mom - E&v-U18ce604 - 6ce - 2020-21Document1 pageMom - E&v-U18ce604 - 6ce - 2020-21srikantheraNo ratings yet

- DAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 09.08.19Document5 pagesDAILY REPORT On ACTIVITIES - INDUCTION PROGRAMME - CED - 09.08.19srikantheraNo ratings yet

- Daily Report On Activities - Induction Programme - Ced - 06.08.19Document5 pagesDaily Report On Activities - Induction Programme - Ced - 06.08.19srikantheraNo ratings yet

- Course Project CircularDocument1 pageCourse Project CircularsrikantheraNo ratings yet

- Course Project CircularDocument1 pageCourse Project CircularsrikantheraNo ratings yet

- U18CE606Document2 pagesU18CE606srikantheraNo ratings yet

- U18CE606Document2 pagesU18CE606srikantheraNo ratings yet

- IV & VI Sem Course Coordinators 2020-21Document2 pagesIV & VI Sem Course Coordinators 2020-21srikantheraNo ratings yet

- Course Project CircularDocument1 pageCourse Project CircularsrikantheraNo ratings yet

- IV & VI Sem Course Coordinators 2020-21Document2 pagesIV & VI Sem Course Coordinators 2020-21srikantheraNo ratings yet

- Mom - E&v-U18ce604 - 6ce - 2020-21Document1 pageMom - E&v-U18ce604 - 6ce - 2020-21srikantheraNo ratings yet

- Mom CmeDocument2 pagesMom CmesrikantheraNo ratings yet

- IV & VI Sem Course Coordinators 2020-21Document2 pagesIV & VI Sem Course Coordinators 2020-21srikantheraNo ratings yet

- U18CE606Document2 pagesU18CE606srikantheraNo ratings yet

- Mom - Aas. 2020-21Document1 pageMom - Aas. 2020-21srikantheraNo ratings yet

- Mom - Aee - 6C A.Y. 2020-21Document1 pageMom - Aee - 6C A.Y. 2020-21srikantheraNo ratings yet

- Mom - Aas. 2020-21Document1 pageMom - Aas. 2020-21srikantheraNo ratings yet

- Mom - E&v-U18ce604 - 6ce - 2020-21Document1 pageMom - E&v-U18ce604 - 6ce - 2020-21srikantheraNo ratings yet

- Mom - E&v-U18ce604 - 6ce - 2020-21Document1 pageMom - E&v-U18ce604 - 6ce - 2020-21srikantheraNo ratings yet

- ISA - The Total Solution For A HIPPS RequirementsDocument17 pagesISA - The Total Solution For A HIPPS RequirementsRatnin PanityingNo ratings yet

- M800 M80 E80 PLC Development ManualDocument736 pagesM800 M80 E80 PLC Development ManualTensaigaNo ratings yet

- Course Objective - Rhce On Rhel5: Redhat Certified EngineerDocument4 pagesCourse Objective - Rhce On Rhel5: Redhat Certified Engineerarsalanhanif80No ratings yet

- 4 Questions Pseries AIX System SupportDocument21 pages4 Questions Pseries AIX System SupportR D SandeepNo ratings yet

- Project Proposal For Excise & Taxation Department, KPKDocument13 pagesProject Proposal For Excise & Taxation Department, KPKbestthaneverNo ratings yet

- VoIP 20100826Document566 pagesVoIP 20100826nitin10685No ratings yet

- Catalogo Kaeser PDFDocument7 pagesCatalogo Kaeser PDForlando_ubaldoNo ratings yet

- Layer 2 VPN ArchitecturesDocument948 pagesLayer 2 VPN Architecturesakshaymit0No ratings yet

- What Is IPDocument70 pagesWhat Is IPElaine Tan-DiazNo ratings yet

- VersaMed Ivent201 Service Manual 0 PDFDocument173 pagesVersaMed Ivent201 Service Manual 0 PDFJessica Albarran DominguezNo ratings yet

- Iso 898-1Document11 pagesIso 898-1bloggerparthi88% (8)

- SetaPDF Signer API Manual 1.5.1Document87 pagesSetaPDF Signer API Manual 1.5.1Ernesto GarciaNo ratings yet

- Panasonic Sip IvrDocument2 pagesPanasonic Sip IvrbudituxNo ratings yet

- Toyota Multiplex ResistanceDocument21 pagesToyota Multiplex ResistanceYdelkadiasmela Dominguezmorel100% (4)

- AS350 - Full Capacity - Spec - Rev2.2Document5 pagesAS350 - Full Capacity - Spec - Rev2.2Fin HasNo ratings yet

- VFD Wiring Best Practices - AP040076EN PDFDocument5 pagesVFD Wiring Best Practices - AP040076EN PDFIsmael Ochoa JimenezNo ratings yet

- Service Manual Skoda-Octavia-3 PDFDocument136 pagesService Manual Skoda-Octavia-3 PDFPetruta50% (2)

- Ip Voice Recorder: Technical ManualDocument25 pagesIp Voice Recorder: Technical ManualkamalNo ratings yet

- Akshaya Patra (Final Report)Document31 pagesAkshaya Patra (Final Report)sneharaj86100% (2)

- DEBEG 442X Installation ManualDocument55 pagesDEBEG 442X Installation Manualchristos1157100% (4)

- Exam 2Document5 pagesExam 2Syed Ali HassanNo ratings yet

- Guidance Brochure BRCGS Transition ENG A4 Final 1Document8 pagesGuidance Brochure BRCGS Transition ENG A4 Final 1jai soniNo ratings yet

- Golden Ratio Phase 2Document14 pagesGolden Ratio Phase 2Carrie MeseroleNo ratings yet

- Max-3 Ehf CatalogDocument2 pagesMax-3 Ehf Catalogಶ್ರೀಕಾಂತ್ ತಿಪ್ಪೇರುದ್ರಪ್ಪNo ratings yet

- What Is QualityDocument7 pagesWhat Is QualityRoubina NuckcheddyNo ratings yet

- Onkyo-Tx SR309Document56 pagesOnkyo-Tx SR309malickjsNo ratings yet

- 77 Guidelines of CBSEDocument8 pages77 Guidelines of CBSEashishkkrNo ratings yet

- ASTM - F1335-2004 - Norma Resistencia TuberíasDocument11 pagesASTM - F1335-2004 - Norma Resistencia TuberíasToni VidalNo ratings yet

- Nullifire BrochureDocument4 pagesNullifire BrochureScott O'ReillyNo ratings yet

- Upto 145kV 40ka 3150A Operating ManualDocument12 pagesUpto 145kV 40ka 3150A Operating ManualNiloy DebroyNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet