Professional Documents

Culture Documents

Amem201 Lec4 Problems

Amem201 Lec4 Problems

Uploaded by

Fahad XdOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amem201 Lec4 Problems

Amem201 Lec4 Problems

Uploaded by

Fahad XdCopyright:

Available Formats

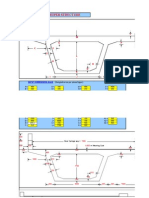

Rolling

A 42 mm thick plate made of low carbon steel is to be reduced to 34 mm in one pass in a rolling

operation. As the thickness is reduced, the plate widens by 4%. The yield strength of the steel plate is

174 MPa and the tensile strength is 290 MPa. The entrance speed of the plate is 15 m/min. The roll

radius is 325 mm and the rotational speed is 49 rev/min. Determine (a) the minimum required

coefficient of friction that would make this rolling operation possible, (b) exit velocity of the plate, and

(c) the roll speed.

42 34

Solution:

2

(a) Maximum draft dmax = µ R

Given that d = to - tf = 42 - 34 = 8.0 mm,

2

µ = 8/325 = 0.0246

0.5

µ = (0.0246) = 0.157

(b) Plate widens by 4%.

towovo = tfwfvf

wf = 1.04 wo

42(w )(15) = 34(1.04w )v

o o f

vf = 42(wo)(15)/ 34(1.04wo) = 630/35.4 = 17.8 m/min

2 2

(c) v = π r N= π(0.325) (49.0) = 16.26 m/min

r

Extrusion

A cylindrical billet that is 100 mm long and 50 mm in diameter is reduced by indirect extrusion

to a 20 mm diameter. The die angle is 90°. The Johnson equation has a = 0.8, b = 1.4, and the

calculated ram pressure is 2578 MPa . Determine (a) extrusion ratio, (b) true strain,

(c) extrusion strain, and (e) ram force.

Solution:

(a) extrusion ratio

2 2 2 2

rx = Ao/Af = Do /Df = (50) /(20) = 6.25

(b) true strain

ε = ln rx = ln 6.25 = 1.833

(c) extrusion strain

εx = a + b ln rx = 0.8 + 1.4(1.833) = 3.366

(d) ram force

2 2 2

Ao = πDo /4 = π(50) /4 = 1963.5 mm

F = 2578(1963.5) = 5,062,000 N

You might also like

- II. Multiple Choice Problem Solving Compilations With SolutionsDocument55 pagesII. Multiple Choice Problem Solving Compilations With SolutionsRamel DionzonNo ratings yet

- Jasper PDFDocument72 pagesJasper PDFLimuel Milo Lebios100% (1)

- Y 240 (3.47) P K Y F PaDocument3 pagesY 240 (3.47) P K Y F PaANER MOHAMED100% (1)

- Design of Shear KeyDocument13 pagesDesign of Shear Keynhulugalla100% (1)

- Worksheet On Metal Forming ProcessesDocument38 pagesWorksheet On Metal Forming Processesberhane100% (1)

- Box Girder ComputationsDocument98 pagesBox Girder ComputationsMark Christopher Del Rosario100% (1)

- Timber Module2Document16 pagesTimber Module2Mac Mac0% (1)

- Steel1 (26pages)Document26 pagesSteel1 (26pages)Kristin Brienne Leander-Renomeron50% (2)

- 2020 Lista de Exercício 01 Bruno Monteiro Costa 569125Document8 pages2020 Lista de Exercício 01 Bruno Monteiro Costa 569125Bruno CostaNo ratings yet

- Pavement Revised DesignDocument17 pagesPavement Revised DesignHendri GoNo ratings yet

- Revised DesignDocument17 pagesRevised DesignHendri Go100% (1)

- Roof Deck Design and Analysis of BeamsDocument5 pagesRoof Deck Design and Analysis of BeamsJt ManaoisNo ratings yet

- Reinforced Concrete With Side PlateDocument1 pageReinforced Concrete With Side PlateHattori HanzoNo ratings yet

- Footing DesignDocument21 pagesFooting Designedsel fagelaNo ratings yet

- Connections 1 - Ch.5 Basic Principles - Exercise Solutions (196-214)Document5 pagesConnections 1 - Ch.5 Basic Principles - Exercise Solutions (196-214)travis8zimmermannNo ratings yet

- Tutorial For Topic 2 - SolutionDocument4 pagesTutorial For Topic 2 - SolutionmarceNo ratings yet

- Tutorial For Topic 2 - SolutionDocument4 pagesTutorial For Topic 2 - Solutionmurwanashyaka augustin100% (1)

- Hoist Design Procedure For EOT CraneDocument14 pagesHoist Design Procedure For EOT CraneKeerthi KumarNo ratings yet

- Lecture Note Pad FootingDocument4 pagesLecture Note Pad FootingNuratiqah SharifahNo ratings yet

- Vidyalangar Sample TestDocument4 pagesVidyalangar Sample Testpaptc642002No ratings yet

- Box Girder Super Structure1Document87 pagesBox Girder Super Structure1hemantkle2u75% (4)

- Lec6 TorsionDocument26 pagesLec6 TorsionJordan DavidsonNo ratings yet

- SolutionDocument3 pagesSolutionMohammed Alryani100% (1)

- Design Test 1 - (With Memo)Document5 pagesDesign Test 1 - (With Memo)Tukisho MacheteNo ratings yet

- Pinned Base Plate (Rs Shear Key)Document7 pagesPinned Base Plate (Rs Shear Key)winlugue3059100% (2)

- Column To Beam Connection Check (EP-01)Document3 pagesColumn To Beam Connection Check (EP-01)Md. Mahmudle HassanNo ratings yet

- Unit 3 32,33,34,35Document3 pagesUnit 3 32,33,34,35Deepanshu VermaNo ratings yet

- BeamDocument18 pagesBeamAfia S Hameed100% (1)

- N0174147G Manufacturing ProcessesDocument10 pagesN0174147G Manufacturing Processesphillip chirongweNo ratings yet

- Beam-Column Hunch-End Plate Moment Conn PDFDocument11 pagesBeam-Column Hunch-End Plate Moment Conn PDFnagiA ahmedNo ratings yet

- Gia Cong CokhiDocument55 pagesGia Cong CokhitranngNo ratings yet

- RollingDocument4 pagesRollingمؤيد الحطابNo ratings yet

- Control of Cracking by Distribution of Reinforcement (CL 10.6.4-ACI 318-05)Document4 pagesControl of Cracking by Distribution of Reinforcement (CL 10.6.4-ACI 318-05)vijaystructuralNo ratings yet

- Powerscrew SampleDocument3 pagesPowerscrew Sampleemilianojr gameNo ratings yet

- Steps in Designing A Rectangular BeamDocument8 pagesSteps in Designing A Rectangular BeamIvan GonzalesNo ratings yet

- TCC11 Element Design - Xls of Slab and BeamDocument12 pagesTCC11 Element Design - Xls of Slab and BeamAmadu Farrow100% (1)

- HMWK 3 Problem SolutionsDocument6 pagesHMWK 3 Problem SolutionsMD Al-AminNo ratings yet

- Homework Solution p3Document10 pagesHomework Solution p3Petro ManNo ratings yet

- Conrod Design Numerical 2023 ModifiedDocument2 pagesConrod Design Numerical 2023 ModifiedSanjay PatelNo ratings yet

- Vtu e Notes Mpiii 14Document8 pagesVtu e Notes Mpiii 14Qalu vibesNo ratings yet

- SCBDocument14 pagesSCBselvaganeshNo ratings yet

- RCC11 Element DesignDocument6 pagesRCC11 Element DesignAli IssamNo ratings yet

- Solution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minDocument11 pagesSolution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minwoihoNo ratings yet

- Determine The Bearing Plate DimensionsDocument9 pagesDetermine The Bearing Plate DimensionsNiranjan ShresthaNo ratings yet

- Base PlateDocument7 pagesBase Plateabdul karee100% (6)

- MATH Timber Design and Construction MethDocument6 pagesMATH Timber Design and Construction MethHades HadesNo ratings yet

- TCC11 Element DesignDocument8 pagesTCC11 Element DesignMelinda GordonNo ratings yet

- Ce234 Technical Study On CFRP - Simbajon - RetchieDocument15 pagesCe234 Technical Study On CFRP - Simbajon - RetchieRitch SimbajonNo ratings yet

- Staircase Design FinalDocument18 pagesStaircase Design FinalSiddiqui RanaNo ratings yet

- Assignment 10solutionDocument3 pagesAssignment 10solutionxopoc27809No ratings yet

- 3rd Plate SampleDocument39 pages3rd Plate SampleJhunel Ivan Goyena100% (1)

- Rectangular Beam ExampleDocument18 pagesRectangular Beam ExampleNur Syaf FiqahNo ratings yet

- Continuation of Machne DesignDocument38 pagesContinuation of Machne DesignHalley Mayer TorresNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- O level Physics Questions And Answer Practice Papers 3From EverandO level Physics Questions And Answer Practice Papers 3Rating: 3 out of 5 stars3/5 (1)

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- 9400 Icaa1Document4 pages9400 Icaa1Fahad XdNo ratings yet

- Example - Surgical Plan Rev01Document5 pagesExample - Surgical Plan Rev01Fahad XdNo ratings yet

- Project Management: Defining and Managing The ProjectDocument20 pagesProject Management: Defining and Managing The ProjectFahad XdNo ratings yet

- Protecting Induction Motor From Phase & Temperature: Hardware SpecificationsDocument2 pagesProtecting Induction Motor From Phase & Temperature: Hardware SpecificationsFahad XdNo ratings yet