Professional Documents

Culture Documents

Connections 1 - Ch.5 Basic Principles - Exercise Solutions (196-214)

Uploaded by

travis8zimmermannCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Connections 1 - Ch.5 Basic Principles - Exercise Solutions (196-214)

Uploaded by

travis8zimmermannCopyright:

Available Formats

Connections I - Chapter 5: Basic Principles - Homework Exercise Solutions

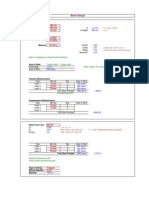

Part II: Standard Connections, Chapter 5 - Basic principles, Shear - Exercise 1 - Ref. P.196

Calculate the reaction at the supports using:

1. Direct equation for Rf = 0.5UDL (The method presented on slide 195)

2. Beam Load Tables

W310x79 beam (NOTE I HAVE CHANGED THE SECTION SIZE FROM SLIDE 196)

ASTM A572 Gr. 50

10 m span

Uniform load

Solution:

Really what we are asking here is to calculate the factored beam end reaction to satisfy the beam's

laterally supported factored bending capacity under a uniform load (0.5UDL).

1. From Beam Selection Table, slide 193 (P. 5-96 of CISC HSC, 10th ed.), for W310x79:

Mr = 397 kN-m

Rf = 0.5UDL = 4Mr/L = (4)(397 kN-m)/10m = 158.8 = 159 kN

2. From the Beam Load Table, slide 194 (P. 5-130 of CISC HSC, 10th ed.), for W310x79, span = 10 m:

Total Uniformly Distributed Factored Load (UDL) = 318 kN

Therefore, 0.5UDL = 318/2 = 159 kN

Part II: Standard Connections, Chapter 5 - Basic principles, Reduced section - Exercise 2 - Ref. P.205

Calculate the factored capacity of the coped beam section (top flange coped).

W360x33 beam

ASTM A572 Gr. 50

Cope dimensions: 125 mm long x 50 mm deep

End connection is 10 mm thick end plate welded to end of beam

Supporting beam web thickness is 8 mm

Solution:

From Section 6 of CISC HSC for W360x33: d = 349 mm, b = 127 mm, t = 8.5 mm, w = 5.8 mm

5.8 A1 = b x h1 = (127)(8.5) = 1080 mm2

A2 A2 = w x h2 = (5.8)(290.5) = 1685 mm2

d1 = 8.5/2 = 4.25 mm

145.3

d2 = 299 - 145.3 = 153.7 mm

349 - 50 = 299

Yt

290.5

yCG = (A1d1 + A2d2)/(A1 + A2)

= [(1080)(4.25) + (1685)(153.7)]/(1080+1685)

y2

ENA

x x = 95.33 mm

d2

y1

ycg

Yb

Ix1 = b(h1)3/12 = (127)(8.5)3/12 =6499 mm4

d1

8.5

Ix2 = w(h2)3/12 = (5.8)(290.5)3/12 = 11.85x106 mm4

A1 127 y1 = ycg - d1 = 95.33 - 4.25 = 91.08 mm

y2 = d2 - ycg = 153.7 - 95.33 = 58.37 mm

Ixx = Ix1 + Ix2 + A1y12 + A2y22 = 6499 + 11.85x106 + (1080)(91.08)2 + (1685)(58.37)2 = 26.56 x 106 mm4

Yb = ycg = 95.33 mm

Yt = D - ycg = 299 - 95.33 = 203.7 mm

Sn = Ixx/(max. of Yb or Yt) = (26.56x106)/203.7 = 130.4 x 103 mm3

e = 139

125

50

Centerline of

supporting

member

W360x33

Mf

Vrc

Criticial section in bending

e = 8/2 + 10 + 125 = 139 mm

From Table 3-22, P. 3-40 of CISC HSC, 10th ed. (slide 133), for ASTM A572, Gr. 50: Fy = 345 MPa

Mr = φFySn = 0.9(345 N/mm2)(130.4 x 103 mm3)/106 = 40.49 kN-m

Mf = (Vrc)(e) = Vrc (0.139 m)

Mf = Mr

Vrc (0.139 m) = 40.49 kN-m

Vrc = (40.49 kN-m)/(0.139 m) = 291 kN Governs capacity of coped section

Calculate Shear Capacity of Coped Section (just out of curiosity)

Fs = 0.66Fy = (0.66)(345) = 227.7 MPa

Anw = D x w = (299)(5.8) = 1734 mm2

Vrn = φAnwFS = 0.9(1734 mm2)(227.7 MPa)/1000 = 355 kN

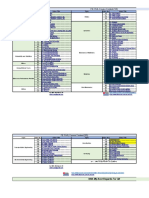

Part II: Standard Connections, Chapter 5 - Basic principles, Reduced section - Exercise 3 - Ref. P.208

Calculate the factored capacity of the coped beam section (both flanges coped).

W360x33 beam

ASTM A572 Gr. 50

Cope dimensions (top and bottom flanges): 125 mm long x 50 mm deep

End connection is 10 mm thick end plate welded to end of beam

Supporting beam web thickness is 8 mm

Solution:

From Section 6 of CISC HSC for W360x33: d = 349 mm, b = 127 mm, t = 8.5 mm, w = 5.8 mm

hO = 349 - 2(50) = 249 mm

Sn = w(hO)2/6 = (5.8)(249)2/6 = 59.93x103 mm3

From Table 3-22, P. 3-40 of CISC HSC, 10th ed. (slide 133), for ASTM A572, Gr. 50: Fy = 345 MPa

Mr = φFySn = 0.9(345 MPa)(59.93x103 mm3)/106 = 18.61 kN-m

e = 8/2 + 10 + 125 = 139 mm

Mf = (Vrc)(e) = Vrc (0.139 m)

Mf = Mr

Vrc (0.139 m) = 18.61 kN-m

Vrc = (18.61 kN-m)/(0.139 m) = 134 kN Governs capacity of coped section

Calculate Shear Capacity of Coped Section (just out of curiosity)

Fs = 0.66Fy = (0.66)(345) = 227.7 MPa

Anw = D x w = (249)(5.8) = 1444 mm2

Vrn = φAnwFS = 0.9(1444 mm2)(227.7 MPa)/1000 = 296 kN

Part II: Standard Connections, Chapter 5 - Basic principles, Reduced section - Exercise 4 - Ref. P.213

Determine the thickness required for the web reinforcing doubler plate for the double coped beam.

W360x33 beam

Vf - Vrc = 98 kN

Plate material: CSA G40.21 300W

Cope dimensions (top and bottom flanges): 125 mm long x 50 mm deep

Assume the web doubler plate extends to within 10 mm of the top and bottom of the coped section.

Solution:

Vp = Vf - Vrc = 98 kN

dp = 349 - 2(50+10) = 229 mm

Sn = tp(dp)2/6 = tp(229)2/6 = 8740tp mm3

From Table 3-22, P. 3-40 of CISC HSC, 10th ed. (slide 133), for CSA G40.21 300W: Fy = 300 MPa

Mr = φFySn = 0.9(300 MPa)(8740tp mm3)/106 = 2.360tp kN-m

e = 8/2 + 10 + 125 = 139 mm

Mf = (Vp)(e) = (98 kN)(0.139 m) = 13.62 kN-m

Mf = Mr

13.62 kN-m = 2.360tp kN-m

tp = 13.62/2.360 = 5.77 mm Likely choose PL1/4" (6.35 mm) or PL3/8"(9.53 mm)

Note:

Since this exercise is based on the beam from Exercise 3 with Fy = 345 MPa and the reinforcing web doubler plate

Fy = 300 MPa the doubler plate will reach its yield point prior to the coped beam section reaching it's yield point

(assuming approx. equal height). In this case the analysis may be a little unconservative since we would be pushing

the doubler plate into the plastic deformation range before the coped beam section reaches it's yield point and

stability could be a concern.

When this situation occurs the coped beam section should be analyzed as though it has a yield strength equal to

the doubler plate yield strength (choose the minimum Fy of the two). This approach would be on the conservative

side, but still reasonable.

You might also like

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Steel Beam DesignDocument26 pagesSteel Beam DesignWazini D. Izani100% (1)

- Unit 3 32,33,34,35Document3 pagesUnit 3 32,33,34,35Deepanshu VermaNo ratings yet

- Rectangular Beam ExampleDocument18 pagesRectangular Beam ExampleNur Syaf FiqahNo ratings yet

- Design of Principal Rafter BeamDocument2 pagesDesign of Principal Rafter BeamSameer MaqboolNo ratings yet

- Design SectionDocument19 pagesDesign SectionKrishna KumarNo ratings yet

- Task 2.2Document15 pagesTask 2.2Mordecai de ValoisNo ratings yet

- Plate Girder DesignDocument8 pagesPlate Girder Designkalpanaadhi100% (1)

- Steel Design To Eurocode 3 - University of Sheffield Structural Engineering MastersDocument13 pagesSteel Design To Eurocode 3 - University of Sheffield Structural Engineering Mastersfatabass100% (13)

- Example 2 Simply Supported Beam - Flanged Section PDFDocument7 pagesExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (1)

- 500cubic Metre Concrete Tank DesignDocument18 pages500cubic Metre Concrete Tank DesignWjz WjzNo ratings yet

- Design of Intermediate Flanged Beam for Classroom HallDocument7 pagesDesign of Intermediate Flanged Beam for Classroom HallWilson PatyalNo ratings yet

- Pengiraan TiangDocument7 pagesPengiraan TiangfyqaeNo ratings yet

- Moment Resistance Calculation of a Class 4 W150x22 BeamDocument1 pageMoment Resistance Calculation of a Class 4 W150x22 BeamstructuresNo ratings yet

- Structural Designsteel BeamDocument7 pagesStructural Designsteel BeamAtienza Design StudioNo ratings yet

- Design of FootingDocument67 pagesDesign of FootingHarlene Marie M. Ilagan100% (1)

- Unit 3 Limit State of ServiceabilityDocument55 pagesUnit 3 Limit State of ServiceabilityManoj SharmaNo ratings yet

- Member resistance under combined bi-axial bending and axial compressionDocument12 pagesMember resistance under combined bi-axial bending and axial compressionrd radenNo ratings yet

- 4.5 - Design of DRS - Simply SupportedDocument18 pages4.5 - Design of DRS - Simply Supportedron thombareNo ratings yet

- CSE 362 Design of Steel Structures Section Properties and CapacitiesDocument19 pagesCSE 362 Design of Steel Structures Section Properties and CapacitiesRufus ChengNo ratings yet

- Beam-Column Hunch-End Plate Moment Conn PDFDocument11 pagesBeam-Column Hunch-End Plate Moment Conn PDFnagiA ahmedNo ratings yet

- Section 12Document7 pagesSection 12Mubeen AkhtarNo ratings yet

- DesignDocument34 pagesDesignAbhay SuwalNo ratings yet

- Beam Tutorial 1 Worked SolutionDocument8 pagesBeam Tutorial 1 Worked SolutionMeyer EdouardNo ratings yet

- BoltDocument23 pagesBoltMohamad Syahmi0% (1)

- 6beam DesignDocument41 pages6beam DesignMohd Nurkhalis WainiNo ratings yet

- 10 - Structural Design of HCU - Example 2Document11 pages10 - Structural Design of HCU - Example 2Philip Lionel PeterNo ratings yet

- RCC DESIGN CASE STUDYDocument25 pagesRCC DESIGN CASE STUDYWHATS APP STATUSNo ratings yet

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443No ratings yet

- 6.0 Reka Bentuk Rasuk Disokong MudahDocument22 pages6.0 Reka Bentuk Rasuk Disokong MudahPuteri Buntat Cendawan BiruNo ratings yet

- Design of Two-Way Slab and BeamsDocument36 pagesDesign of Two-Way Slab and Beamsveenabalu20No ratings yet

- BeamDocument18 pagesBeamAfia S Hameed100% (1)

- Design of Steel Structure (Chapter 2) by DR R BaskarDocument57 pagesDesign of Steel Structure (Chapter 2) by DR R Baskarelect aksNo ratings yet

- Flexural Member DesignDocument21 pagesFlexural Member Designbaraka100% (1)

- Example Flange Beam PDFDocument17 pagesExample Flange Beam PDFFarhana HussinNo ratings yet

- Design of Two Way SlabDocument64 pagesDesign of Two Way SlabVINOTHINI100% (1)

- Door OpeningDocument8 pagesDoor OpeningMd MohsinNo ratings yet

- Plate GirderDocument11 pagesPlate GirderAfia S HameedNo ratings yet

- Manyam Dr.s HouseDocument33 pagesManyam Dr.s HouseDurga Rama Swamy KalvakolanuNo ratings yet

- Manyam Dr.s House 2.5Document33 pagesManyam Dr.s House 2.5Durga Rama Swamy KalvakolanuNo ratings yet

- Example 1: Simply Supported Rectangular Beam: Referent Calculation ResultDocument5 pagesExample 1: Simply Supported Rectangular Beam: Referent Calculation ResultMohd NazwalNo ratings yet

- 3 10problemsDocument1 page3 10problemsBoopathi YoganathanNo ratings yet

- Design of Isolated Square (Axially Loaded) Pad FootingDocument7 pagesDesign of Isolated Square (Axially Loaded) Pad FootingNikhil100% (1)

- Bab V Balok Induk: Gambar 5.1 Profil Baja WFDocument15 pagesBab V Balok Induk: Gambar 5.1 Profil Baja WFBintang Laksamana E.PNo ratings yet

- RCD7 2Document23 pagesRCD7 2Nelle SarmientoNo ratings yet

- UC section runway beam design calculationsDocument2 pagesUC section runway beam design calculationsParthiban ArivazhaganNo ratings yet

- Strap FootingDocument6 pagesStrap Footingrukesh104No ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsIbrahim El SharNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- Design of Stair CaseDocument65 pagesDesign of Stair CaseNikhil100% (1)

- Calculation On Sizing of SlabDocument20 pagesCalculation On Sizing of SlabazhimsyammelNo ratings yet

- Design of Composite ColumnDocument7 pagesDesign of Composite Columnorode franklynNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Connections 1 - Ch.4 Tension Members Notes (154-187)Document12 pagesConnections 1 - Ch.4 Tension Members Notes (154-187)travis8zimmermannNo ratings yet

- A Yield Line Component Method For Bolted Flange Connections-1Document24 pagesA Yield Line Component Method For Bolted Flange Connections-1sebastian9033100% (2)

- Connections 1 - Ch.2 Bolts Notes (48-93)Document18 pagesConnections 1 - Ch.2 Bolts Notes (48-93)travis8zimmermannNo ratings yet

- Connections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (2 of 2) (233-248)Document14 pagesConnections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (2 of 2) (233-248)travis8zimmermannNo ratings yet

- Connections 1 - Ch.2 Bolts Notes (48-93)Document18 pagesConnections 1 - Ch.2 Bolts Notes (48-93)travis8zimmermannNo ratings yet

- Connections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (2 of 2) (233-248)Document14 pagesConnections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (2 of 2) (233-248)travis8zimmermannNo ratings yet

- Connections 1 - Ch.6 Bolted Shear Connections Exercises (222-248)Document3 pagesConnections 1 - Ch.6 Bolted Shear Connections Exercises (222-248)travis8zimmermannNo ratings yet

- Connections 1 - Ch.6 Bolted Shear Connections Notes (215-248)Document4 pagesConnections 1 - Ch.6 Bolted Shear Connections Notes (215-248)travis8zimmermannNo ratings yet

- Connections 1 - Ch.3 Welds Notes (94-153)Document15 pagesConnections 1 - Ch.3 Welds Notes (94-153)travis8zimmermannNo ratings yet

- Connections 1 - Ch.7 Welded Shear Connections - Exercise Solutions (2 of 2) (265-268)Document4 pagesConnections 1 - Ch.7 Welded Shear Connections - Exercise Solutions (2 of 2) (265-268)travis8zimmermannNo ratings yet

- Connections 1 - Ch.2,3 Summarized Exercises (150-153)Document1 pageConnections 1 - Ch.2,3 Summarized Exercises (150-153)travis8zimmermannNo ratings yet

- Connections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (1 of 2) (222-229) Rev1Document9 pagesConnections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (1 of 2) (222-229) Rev1travis8zimmermannNo ratings yet

- Vehicular Load Chart For Bar GratingDocument2 pagesVehicular Load Chart For Bar Gratingtravis8zimmermannNo ratings yet

- Connections 1 - Ch.5 Basic Principles - Exercises (196-214)Document2 pagesConnections 1 - Ch.5 Basic Principles - Exercises (196-214)travis8zimmermannNo ratings yet

- Plate Stress/ Load - Based On Simple Boundary On 4 SidesDocument15 pagesPlate Stress/ Load - Based On Simple Boundary On 4 Sidestravis8zimmermannNo ratings yet

- Ducati Hypermotard 1100 1100s 2008-2009 (English) PDFDocument741 pagesDucati Hypermotard 1100 1100s 2008-2009 (English) PDFtravis8zimmermann75% (8)

- 6061 T6 MaterialDocument2 pages6061 T6 Materialtravis8zimmermannNo ratings yet

- Monorail DesignDocument12 pagesMonorail Designtravis8zimmermannNo ratings yet

- Vanguard Steel Product ManualDocument158 pagesVanguard Steel Product Manualtravis8zimmermannNo ratings yet

- Machining AllowanceDocument1 pageMachining Allowancetravis8zimmermannNo ratings yet

- FL Catalogue PDFDocument64 pagesFL Catalogue PDFGustavo1722No ratings yet

- Sec 11 ChainDocument26 pagesSec 11 Chaintravis8zimmermannNo ratings yet

- Steel Product Sheets 4340Document3 pagesSteel Product Sheets 4340travis8zimmermannNo ratings yet

- Sec 12 Barsx Safety and Fiberglass GratingDocument51 pagesSec 12 Barsx Safety and Fiberglass Gratingtravis8zimmermannNo ratings yet

- Sec 06 Tube and PipeDocument60 pagesSec 06 Tube and Pipetravis8zimmermannNo ratings yet

- Aluminum 6061 T6Document1 pageAluminum 6061 T6travis8zimmermannNo ratings yet

- Steel Product Sheets 4140Document3 pagesSteel Product Sheets 4140travis8zimmermannNo ratings yet

- Sec 13 Expanded MeshDocument15 pagesSec 13 Expanded Meshtravis8zimmermannNo ratings yet

- Sec 15 Processing ServicesDocument11 pagesSec 15 Processing Servicestravis8zimmermannNo ratings yet

- Sec 14 Weights and Useful DataDocument24 pagesSec 14 Weights and Useful Datatravis8zimmermannNo ratings yet

- Chapter 4Document9 pagesChapter 4dearsaswatNo ratings yet

- A Study On The Economic Benefit of UsingDocument7 pagesA Study On The Economic Benefit of UsingSherwin ConcepcionNo ratings yet

- ENG 2020-1168-01 Calcs - Seren ParkDocument27 pagesENG 2020-1168-01 Calcs - Seren ParkMona GamalNo ratings yet

- Mechanics of SolidsDocument23 pagesMechanics of Solidsarun777999No ratings yet

- Coastal Construction Manual Equations SpreadsheetDocument25 pagesCoastal Construction Manual Equations SpreadsheetguhanbadboyNo ratings yet

- BS en 13230-6-2020 - (2023-05-31 - 08-25-53 PM)Document64 pagesBS en 13230-6-2020 - (2023-05-31 - 08-25-53 PM)Alireza MashhadizadehNo ratings yet

- Damage Assessment and Repair TechniquesDocument10 pagesDamage Assessment and Repair TechniquesSatya kaliprasad vangaraNo ratings yet

- Solving a Propped Beam Problem with Increasing Load Using Different MethodsDocument5 pagesSolving a Propped Beam Problem with Increasing Load Using Different Methodsindrajit sodhaNo ratings yet

- InTech-Mechanical Properties of Mems MaterialsDocument12 pagesInTech-Mechanical Properties of Mems MaterialsNico Ortega MirandaNo ratings yet

- Diploma SyllabusDocument324 pagesDiploma SyllabusCindy JonesNo ratings yet

- Example of Engineering ReportDocument48 pagesExample of Engineering ReportJayvee ArimbuyutanNo ratings yet

- 2009 F.zilm PDFDocument237 pages2009 F.zilm PDFArthur RebouçasNo ratings yet

- AECOsim Building Designer Structural Framing Metric TRN019800 1 0001 - Mott MacDonald - 31 Oct 2013Document30 pagesAECOsim Building Designer Structural Framing Metric TRN019800 1 0001 - Mott MacDonald - 31 Oct 2013Keerthi KrishnanNo ratings yet

- 2022 - Flexible Riser Tensile Armour Stress Assessment in The Bend Stiffener RegionDocument16 pages2022 - Flexible Riser Tensile Armour Stress Assessment in The Bend Stiffener RegionMarcelo CaireNo ratings yet

- Lifting PointDocument2 pagesLifting PointDipak BorsaikiaNo ratings yet

- EC2 Ch03aDocument15 pagesEC2 Ch03asunilarunaNo ratings yet

- Pile Design From Australian Guidebook For Structural EngineersDocument1 pagePile Design From Australian Guidebook For Structural EngineersAinie ButtNo ratings yet

- Aae009 - Fem - Question BankDocument16 pagesAae009 - Fem - Question BankChekka SudheerNo ratings yet

- EngiLab Beam.2D ML TutorialDocument47 pagesEngiLab Beam.2D ML TutorialCarlos LazoNo ratings yet

- ASTM C1609 - Flexural Performance of FRC (Using Beam With Third-Point Loading) PDFDocument9 pagesASTM C1609 - Flexural Performance of FRC (Using Beam With Third-Point Loading) PDFAndresEduardoRenjifoRestrepoNo ratings yet

- FE CIVIL COURSE OVERVIEWDocument4 pagesFE CIVIL COURSE OVERVIEWAmr HamedNo ratings yet

- Din 1045-1 Manual PDFDocument0 pagesDin 1045-1 Manual PDFkedagaalNo ratings yet

- Design of Steel Footbridges 2005Document36 pagesDesign of Steel Footbridges 2005Richard FangNo ratings yet

- AISC 1963 v02Document20 pagesAISC 1963 v02Ignacio Hiram M Roque100% (1)

- DESIGN OF INTZE WATER TANKDocument21 pagesDESIGN OF INTZE WATER TANKAbhijeet GuptaNo ratings yet

- BNBC 2020 StructureDocument1,455 pagesBNBC 2020 StructureMd. Mominul IslamNo ratings yet

- UB SectionsDocument355 pagesUB Sectionsandyhr0% (1)

- 12 - Floor VibrationDocument3 pages12 - Floor VibrationDarren ThoonNo ratings yet

- APEGBC Eng Syllabus MechanicalDocument22 pagesAPEGBC Eng Syllabus MechanicalbaljinderNo ratings yet

- Slab Culvert Design With Example (Upto Moment Calculation)Document14 pagesSlab Culvert Design With Example (Upto Moment Calculation)VYSYAKH AJITHNo ratings yet