Professional Documents

Culture Documents

Buckling Check: Material Data

Uploaded by

ding liuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buckling Check: Material Data

Uploaded by

ding liuCopyright:

Available Formats

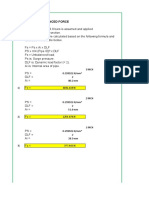

Buckling Check

( in accordance with ABS Rules, Steel Vessels, 1997, 5/2A.5.2.2, 5/2AB)

Project

Member ID Bottom grd Calculated b PS

Load Case Max combined loads Date 12/12/2020

INPUT DATA

Material Data

E 2.07E+05 N/mm2 Elastic modulus

u 0.3 Poisson's ratio

Pr 0.6 Proportional linear elastic limit of structure, 0.6 for steel

Plate/Panel Data

fy 235 N/mm2 Yeild strength of plate

Sm 1 Strength reduction factor, see notes*

tn 16 mm Plate thickness

sL 915 mm Longitudinal spacing

sT 2500 mm Transverse spacing

C1 1.1 See notes*

C2 1.2 See notes*

b 3000 mm Width between longitudinal bulkheads, parallel to sL

l 15000 mm Length between transverse bulkheads, parallel to sT

Scantling of Longitudinals

fy 355 N/mm2 Yeild strength of longitudinals

Sm 0.908 Strength reduction factor, see notes*

Type A A (angle), FB(flat bar) or T (Tee bar)

hw 75 mm Web height of longitudinals

tw 6 mm Web thickness of longitudinals

bf 50 mm Flange width of longitudinals

tf 6 mm Flange thickness of longitudinals

b1 0 mm Smaller outstanding dim. of flange w.r.t. centerline of web

be 500 mm Effective breadth as specified in Figure 5/2A.4.4b, line b

12 middle

Scantling of Transverses

Type A A (angle), FB(flat bar) or T (Tee bar)

hwg 650 mm Web height of transverses

twg 10 mm Web thickness of transverses

bfg 200 mm Flange width of transverses

tfg 10 mm Flange thickness of transverses

Loading Data

fL 10 N/mm2 Calculated total compressive stress in long. direction for the plate

fT 73 N/mm2 Calculated total compressive stress in transverse/vertical direction

fLT 58 N/mm2 Calculated total shear stress

pn 0 N/mm2 Lateral pressure

If Girder Buckling is to be checked, input additional data as follows

Girder Plate Data

fy 235 N/mm2 Yeild strength of girders

Sm 1 Strength reduction factor, see notes*

tn 10 mm Web plate thickness of the girder

s 650 mm Longitudinal spacing of girder plate, =web height if no add. stiffeners applied

l 3000 mm Transverse spacing of girder plate, =dist. btw long. bhd unless tripping bkt applied

C1 1 See notes*

C2 1.1 See notes*

Girder Loading Data

fLg (fT) 73 N/mm2 Calculated compressive stress along length of the girder

fb 0 N/mm2 Calculated ideal bending stress of girder

fLTg 0 N/mm2 Calculated total shear stress of girder

Ideal bending L Long plate (L) or Wide plate (W), see notes

OUTPUT DATA

Plate buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fT/RtfcT)^2+(fLT/fcLT)^2<=1

fcL fcT fcLT Unity Check 0.91

182 88 124 Results Ok

Ultimate Strength Check

Critical stress for ultimate buckling (lbf/in2)

fuL fuT fuLT

195 95 127

Unity Check Criteria

U.C. 1 0.21 ((fL/fuL)^2+(fLT/fuLT)^2) / Sm

U.C. 2 0.81 ((fT/RtfuT)^2+(fLT/fuLT)^2) / Sm

U.C. 3 0.79 ((fL/fuL)^2+(fT/RtfuT)^2-h(fL/fuL)(fT/RtfuT)+(fLT/fuLT)^2) / Sm

Results Ok

Panel buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2)

Criteria (fL/fcL)^2+(fT/fcT)^2<=Sm

fcL fcT Unity Check 0.10

229 233 Results Ok

Stiffener buckling check

Buckling State Limit:

n 3 Number of half waves which yields a smallest fET

fET 245 lbf/in2 Eular stress for tortional/flexural buckling

Critical buckling stress (lbf/in2)

axial comp torsional/flexural Criteria fL/(fc*Ae/A)+mfb/fy<=Sm

fca fct Unity Check 0.21

52 231 Results Ok

Girder buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fb/fcb)^2+(fLT/fcLT)^2<=Sm

fcLg fcb fLTg Unity Check 0.21

160 224 118 Results Ok

Notes:

1. Sm Strength reduction factor

ordinary strength steel

Grade H32 Grade H36 Grade H40

1 0.95 0.908 0.875

2. Values of C1 and C2

plate panels between angles or tee stiffeners plate panels between flat bars or bulb plates

C1 1.1 1

C2 1.3 within the double bottom or double side 1.2 within the double bottom or double side

1.2 elsewhere 1.1 elsewhere

3. Ideal bending patten

a). Long plate b). Wide plate

-fb fb

l>=s fb l>s

fb l

s l

s

-fb -fb

-fb

fb

Calculated Data

panel data

section properties of longitudinals (excluding associated plating)

Eccentricity mm Inertia momen mm4

exLo 10.000 IxL ###

eyLo 53.700 IyL ###

section properties of longitudinals w/ effective breadth be

Eccentricity eyLe = 11.917 mm4

Section modu Sme = 44947.791 mm3

section properties of stiffeners w/ associated plating bw

Longitudinals Transverses

Effective plat mm 915.00 2500.00

Eccentricity mm 2.56 70.36

Net sectional mm2 750.00 8500.00

Inertia moment mm4 95830.77 ### (alone about neutral axis of combined cross section)

Intertia momen mm4 ### ###

calculated data of plate buckling check

buckling state limit

fyL 235 N/mm2 Yield stress for uniaxail comprssion

fyT 235 N/mm2 Yield stress for uniaxail comprssion

fyLT 136 N/mm2 Yield stress for edge shear

KL 4.4

KT 1.5430275

KLT 6.4634064

q 0.5 Lateral load parameter

Rt 1 Reduction factor acconting for lateral load effects

fEL 251.45 N/mm2 Eular stress in longitudinal direction

fET 88.18 N/mm2 Eular stress in transverse direction

fELT 369.37 N/mm2 Eular shear stress

Effective Width

b 1.93

h 0.54

C 0.83

bwL 760.39 mm Effective width of associated plate for longitudinals

bwT 1005.56 mm Effective width of associated plate for transverses

calculated data of panel buckling check

tL 16.819672 mm Net equivalent thickness of plating and stiffener in long. direaction

tT 19.4 mm Net equivalent thickness of plating and stiffener in transverse direaction

DL 604234123

DT 1.383E+11

FL 19.449077

FT 0.0514163

h 0.0716636

kL 4

kT 378.41256

fEL 2381.8942 N/mm2 Eular stress in longitudinal direction

fET 7814.5471 N/mm2 Eular stress in transverse direction

calculated data of stiffener buckling check

Axial compression

As 750 mm2 Net sectional area of longitudinal, excluding assicocated plate

A 15390 mm2 Total net sectional area

Ae 15390.00 mm2 Effective net sectional area

r 12.57 mm2 Radius of gyration

m 1.2405504 Amplification factor

M 0 N-mm Max. bending moment induced by lateral pressure

fb 0 N/mm2 Local bending stress

fE 52 N/mm2 Eular stress

Torsional/flexural buckling

u 1 Unsymmetry factor

mt 0

a 2.732

Co 308879

Iyf 175000 mm4

Io 2764785 mm4 Polar moment of inertia

G 4.46E+08 Warping constant

K 9000.00 St. Venant trosion constant for longitudinals(only) cross section

fcL 231 N/mm2 Critical buck. stress for associated plate corresponding to n-half waves

calculated data of girder buckling check

fyLg 235 N/mm2 Yield stress for uniaxail comprssion

fyb 235 N/mm2 Yield stress for uniaxail comprssion

fyLTg 136 N/mm2 Yield stress for edge shear

KLg 4

Kb 24

KLTg 5.5277778

fELg 176.95 N/mm2 Eular stress in longitudinal direction of girder plate

fEb 1061.67 N/mm2 Eular stress in transverse direction of girder plate

fELTg 244.53 N/mm2 Eular shear stress of girder plate

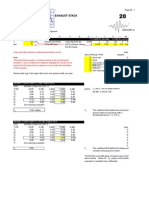

Buckling Check

( in accordance with ABS Rules, Steel Vessels, 1997, 5/2A.5.2.2, 5/2AB)

Project

Member ID Fwd bhd below drillfloor, mid Calculated b PS

Load Case Max combined loads Date 12/12/2020

INPUT DATA

Material Data

E 2.07E+05 N/mm2 Elastic modulus

u 0.3 Poisson's ratio

Pr 0.6 Proportional linear elastic limit of structure, 0.6 for steel

Plate/Panel Data

fy 355 N/mm2 Yeild strength of plate

Sm 0.908 Strength reduction factor, see notes*

tn 14 mm Plate thickness

sL 738 mm Longitudinal spacing

sT 2000 mm Transverse spacing

C1 1.1 See notes*

C2 1.2 See notes*

b 1475 mm Width between longitudinal bulkheads, parallel to sL

l 7500 mm Length between transverse bulkheads, parallel to sT

Scantling of Longitudinals

fy 355 N/mm2 Yeild strength of longitudinals

Sm 0.908 Strength reduction factor, see notes*

Type A A (angle), FB(flat bar) or T (Tee bar)

hw 140 mm Web height of longitudinals

tw 8 mm Web thickness of longitudinals

bf 19 mm Flange width of longitudinals

tf 8 mm Flange thickness of longitudinals

b1 0 mm Smaller outstanding dim. of flange w.r.t. centerline of web

be 0 mm Effective breadth as specified in Figure 5/2A.4.4b, line b

12 middle

Scantling of Transverses

Type A A (angle), FB(flat bar) or T (Tee bar)

hwg 650 mm Web height of transverses

twg 10 mm Web thickness of transverses

bfg 200 mm Flange width of transverses

tfg 10 mm Flange thickness of transverses

Loading Data

fL 6.6 N/mm2 Calculated total compressive stress in long. direction for the plate

fT 61.9 N/mm2 Calculated total compressive stress in transverse/vertical direction

fLT 42.1 N/mm2 Calculated total shear stress

pn 0 N/mm2 Lateral pressure

If Girder Buckling is to be checked, input additional data as follows

Girder Plate Data

fy 235 N/mm2 Yeild strength of girders

Sm 1 Strength reduction factor, see notes*

tn 10 mm Web plate thickness of the girder

s 650 mm Longitudinal spacing of girder plate, =web height if no add. stiffeners applied

l 1475 mm Transverse spacing of girder plate, =dist. btw long. bhd unless tripping bkt applied

C1 1 See notes*

C2 1.1 See notes*

Girder Loading Data

fLg (fT) 61.9 N/mm2 Calculated compressive stress along length of the girder

fb 0 N/mm2 Calculated ideal bending stress of girder

fLTg 0 N/mm2 Calculated total shear stress of girder

Ideal bending L Long plate (L) or Wide plate (W), see notes

OUTPUT DATA

Plate buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fT/RtfcT)^2+(fLT/fcLT)^2<=1

fcL fcT fcLT Unity Check 0.41

253 104 182 Results Ok

Ultimate Strength Check

Critical stress for ultimate buckling (lbf/in2)

fuL fuT fuLT

273 132 188

Unity Check Criteria

U.C. 1 0.06 ((fL/fuL)^2+(fLT/fuLT)^2) / Sm

U.C. 2 0.30 ((fT/RtfuT)^2+(fLT/fuLT)^2) / Sm

U.C. 3 0.29 ((fL/fuL)^2+(fT/RtfuT)^2-h(fL/fuL)(fT/RtfuT)+(fLT/fuLT)^2) / Sm

Results Ok

Panel buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2)

Criteria (fL/fcL)^2+(fT/fcT)^2<=Sm

fcL fcT Unity Check 0.03

354 354 Results Ok

Stiffener buckling check

Buckling State Limit:

n 3 Number of half waves which yields a smallest fET

fET 292 lbf/in2 Eular stress for tortional/flexural buckling

Critical buckling stress (lbf/in2)

axial comp torsional/flexural Criteria fL/(fc*Ae/A)+mfb/fy<=Sm

fca fct Unity Check 0.03

282 251 Results Ok

Girder buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fb/fcb)^2+(fLT/fcLT)^2<=Sm

fcLg fcb fLTg Unity Check 0.15

160 224 119 Results Ok

Notes:

1. Sm Strength reduction factor

ordinary strength steel

Grade H32 Grade H36 Grade H40

1 0.95 0.908 0.875

2. Values of C1 and C2

plate panels between angles or tee stiffeners plate panels between flat bars or bulb plates

C1 1.1 1

C2 1.3 within the double bottom or double side 1.2 within the double bottom or double side

1.2 elsewhere 1.1 elsewhere

3. Ideal bending patten

a). Long plate b). Wide plate

-fb fb

l>=s fb l>s

fb l

s l

s

-fb -fb

-fb

fb

Calculated Data

panel data

section properties of longitudinals (excluding associated plating)

Eccentricity mm Inertia momen mm4

exLo 1.135 IxL ###

eyLo 78.843 IyL 6211.925

section properties of longitudinals w/ effective breadth be

Eccentricity eyLe = 78.843 mm4

Section modu Sme = 40639.882 mm3

section properties of stiffeners w/ associated plating bw

Longitudinals Transverses

Effective plat mm 738.00 2000.00

Eccentricity mm 8.59 93.49

Net sectional mm2 1272.00 8500.00

Inertia moment mm4 ### ### (alone about neutral axis of combined cross section)

Intertia momen mm4 ### ###

calculated data of plate buckling check

buckling state limit

fyL 355 N/mm2 Yield stress for uniaxail comprssion

fyT 355 N/mm2 Yield stress for uniaxail comprssion

fyLT 205 N/mm2 Yield stress for edge shear

KL 4.4

KT 1.5490342

KLT 6.4731084

q 0.5 Lateral load parameter

Rt 1 Reduction factor acconting for lateral load effects

fEL 295.94 N/mm2 Eular stress in longitudinal direction

fET 104.19 N/mm2 Eular stress in transverse direction

fELT 435.37 N/mm2 Eular shear stress

Effective Width

b 2.18

h 0.41

C 0.77

bwL 567.07 mm Effective width of associated plate for longitudinals

bwT 744.40 mm Effective width of associated plate for transverses

calculated data of panel buckling check

tL 15.723577 mm Net equivalent thickness of plating and stiffener in long. direaction

tT 18.25 mm Net equivalent thickness of plating and stiffener in transverse direaction

DL 2.91E+09

DT 1.639E+11

FL 13.930725

FT 0.0717838

h 0.1171039

kL 4

kT 194.30446

fEL 25179.654 N/mm2 Eular stress in longitudinal direction

fET 40758.908 N/mm2 Eular stress in transverse direction

calculated data of stiffener buckling check

Axial compression

As 1272 mm2 Net sectional area of longitudinal, excluding assicocated plate

A 11604 mm2 Total net sectional area

Ae 11604.00 mm2 Effective net sectional area

r 28.52 mm2 Radius of gyration

m 1.0161569 Amplification factor

M 0 N-mm Max. bending moment induced by lateral pressure

fb 0 N/mm2 Local bending stress

fE 415 N/mm2 Eular stress

Torsional/flexural buckling

u 1 Unsymmetry factor

mt 1

a 2.710

Co 256553

Iyf 16651.409 mm4

Io 10400486 mm4 Polar moment of inertia

G 3.77E+08 Warping constant

K 27136.00 St. Venant trosion constant for longitudinals(only) cross section

fcL 272 N/mm2 Critical buck. stress for associated plate corresponding to n-half waves

calculated data of girder buckling check

fyLg 235 N/mm2 Yield stress for uniaxail comprssion

fyb 235 N/mm2 Yield stress for uniaxail comprssion

fyLTg 136 N/mm2 Yield stress for edge shear

KLg 4

Kb 24

KLTg 6.1167883

fELg 176.95 N/mm2 Eular stress in longitudinal direction of girder plate

fEb 1061.67 N/mm2 Eular stress in transverse direction of girder plate

fELTg 270.59 N/mm2 Eular shear stress of girder plate

Buckling Check

( in accordance with ABS Rules, Steel Vessels, 1997, 5/2A.5.2.2, 5/2AB)

Project

Member ID Fwd bhd below drillfloor, mid Calculated b PS

Load Case Max combined loads Date 12/12/2020

INPUT DATA

Material Data

E 2.07E+05 N/mm2 Elastic modulus

u 0.3 Poisson's ratio

Pr 0.6 Proportional linear elastic limit of structure, 0.6 for steel

Plate/Panel Data

fy 355 N/mm2 Yeild strength of plate

Sm 0.908 Strength reduction factor, see notes*

tn 15 mm Plate thickness

sL 1000 mm Longitudinal spacing

sT 1500 mm Transverse spacing

C1 1.1 See notes*

C2 1.2 See notes*

b 1000 mm Width between longitudinal bulkheads, parallel to sL

l 1500 mm Length between transverse bulkheads, parallel to sT

Scantling of Longitudinals

fy 355 N/mm2 Yeild strength of longitudinals

Sm 0.908 Strength reduction factor, see notes*

Type A A (angle), FB(flat bar) or T (Tee bar)

hw 140 mm Web height of longitudinals

tw 8 mm Web thickness of longitudinals

bf 19 mm Flange width of longitudinals

tf 8 mm Flange thickness of longitudinals

b1 0 mm Smaller outstanding dim. of flange w.r.t. centerline of web

be 0 mm Effective breadth as specified in Figure 5/2A.4.4b, line b

12 middle

Scantling of Transverses

Type A A (angle), FB(flat bar) or T (Tee bar)

hwg 650 mm Web height of transverses

twg 10 mm Web thickness of transverses

bfg 200 mm Flange width of transverses

tfg 10 mm Flange thickness of transverses

Loading Data

fL 108.6 N/mm2 Calculated total compressive stress in long. direction for the plate

fT 2.6 N/mm2 Calculated total compressive stress in transverse/vertical direction

fLT 8.6 N/mm2 Calculated total shear stress

pn 0 N/mm2 Lateral pressure

If Girder Buckling is to be checked, input additional data as follows

Girder Plate Data

fy 355 N/mm2 Yeild strength of girders

Sm 0.908 Strength reduction factor, see notes*

tn 16 mm Web plate thickness of the girder

s 750 mm Longitudinal spacing of girder plate, =web height if no add. stiffeners applied

l 750 mm Transverse spacing of girder plate, =dist. btw long. bhd unless tripping bkt applied

C1 1 See notes*

C2 1.1 See notes*

Girder Loading Data

fLg (fT) 97.8 N/mm2 Calculated compressive stress along length of the girder

fb 120 N/mm2 Calculated ideal bending stress of girder

fLTg 105.3 N/mm2 Calculated total shear stress of girder

Ideal bending L Long plate (L) or Wide plate (W), see notes

OUTPUT DATA

Plate buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fT/RtfcT)^2+(fLT/fcLT)^2<=1

fcL fcT fcLT Unity Check 0.35

185 105 174 Results Ok

Ultimate Strength Check

Critical stress for ultimate buckling (lbf/in2)

fuL fuT fuLT

231 169 187

Unity Check Criteria

U.C. 1 0.25 ((fL/fuL)^2+(fLT/fuLT)^2) / Sm

U.C. 2 0.00 ((fT/RtfuT)^2+(fLT/fuLT)^2) / Sm

U.C. 3 0.24 ((fL/fuL)^2+(fT/RtfuT)^2-h(fL/fuL)(fT/RtfuT)+(fLT/fuLT)^2) / Sm

Results Ok

Panel buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2)

Criteria (fL/fcL)^2+(fT/fcT)^2<=Sm

fcL fcT Unity Check 0.10

354 355 Results Ok

Stiffener buckling check

Buckling State Limit:

n 3 Number of half waves which yields a smallest fET

fET 339 lbf/in2 Eular stress for tortional/flexural buckling

Critical buckling stress (lbf/in2)

axial comp torsional/flexural Criteria fL/(fc*Ae/A)+mfb/fy<=Sm

fca fct Unity Check 0.45

299 266 Results Ok

Girder buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fb/fcb)^2+(fLT/fcLT)^2<=Sm

fcLg fcb fLTg Unity Check 0.61

266 342 192 Results Ok

Notes:

1. Sm Strength reduction factor

ordinary strength steel

Grade H32 Grade H36 Grade H40

1 0.95 0.908 0.875

2. Values of C1 and C2

plate panels between angles or tee stiffeners plate panels between flat bars or bulb plates

C1 1.1 1

C2 1.3 within the double bottom or double side 1.2 within the double bottom or double side

1.2 elsewhere 1.1 elsewhere

3. Ideal bending patten

a). Long plate b). Wide plate

-fb fb

l>=s fb l>s

fb l

s l

s

-fb -fb

-fb

fb

Calculated Data

panel data

section properties of longitudinals (excluding associated plating)

Eccentricity mm Inertia momen mm4

exLo 1.135 IxL ###

eyLo 78.843 IyL 6211.925

section properties of longitudinals w/ effective breadth be

Eccentricity eyLe = 78.843 mm4

Section modu Sme = 40639.882 mm3

section properties of stiffeners w/ associated plating bw

Longitudinals Transverses

Effective plat mm 1000.00 1500.00

Eccentricity mm 6.13 110.08

Net sectional mm2 1272.00 8500.00

Inertia moment mm4 ### ### (alone about neutral axis of combined cross section)

Intertia momen mm4 ### ###

calculated data of plate buckling check

buckling state limit

fyL 355 N/mm2 Yield stress for uniaxail comprssion

fyT 355 N/mm2 Yield stress for uniaxail comprssion

fyLT 205 N/mm2 Yield stress for edge shear

KL 4.4

KT 2.5037037

KLT 7.8295556

q 0.5 Lateral load parameter

Rt 1 Reduction factor acconting for lateral load effects

fEL 185.03 N/mm2 Eular stress in longitudinal direction

fET 105.29 N/mm2 Eular stress in transverse direction

fELT 329.25 N/mm2 Eular shear stress

Effective Width

b 2.76

h 0.12

C 0.65

bwL 650.98 mm Effective width of associated plate for longitudinals

bwT 712.40 mm Effective width of associated plate for transverses

calculated data of panel buckling check

tL 16.272 mm Net equivalent thickness of plating and stiffener in long. direaction

tT 20.666667 mm Net equivalent thickness of plating and stiffener in transverse direaction

DL 2.203E+09

DT 2.1E+11

FL 4.6868116

FT 0.2133647

h 0.1069687

kL 4

kT 22.225665

fEL 52133.887 N/mm2 Eular stress in longitudinal direction

fET 101368.46 N/mm2 Eular stress in transverse direction

calculated data of stiffener buckling check

Axial compression

As 1272 mm2 Net sectional area of longitudinal, excluding assicocated plate

A 16272 mm2 Total net sectional area

Ae 16272.00 mm2 Effective net sectional area

r 24.40 mm2 Radius of gyration

m 1.2517728 Amplification factor

M 0 N-mm Max. bending moment induced by lateral pressure

fb 0 N/mm2 Local bending stress

fE 540 N/mm2 Eular stress

Torsional/flexural buckling

u 1 Unsymmetry factor

mt 1

a 1.500

Co 232875

Iyf 16651.409 mm4

Io 10400486 mm4 Polar moment of inertia

G 3.77E+08 Warping constant

K 27136.00 St. Venant trosion constant for longitudinals(only) cross section

fcL 263 N/mm2 Critical buck. stress for associated plate corresponding to n-half waves

calculated data of girder buckling check

fyLg 355 N/mm2 Yield stress for uniaxail comprssion

fyb 355 N/mm2 Yield stress for uniaxail comprssion

fyLTg 205 N/mm2 Yield stress for edge shear

KLg 4

Kb 24

KLTg 9.34

fELg 340.24 N/mm2 Eular stress in longitudinal direction of girder plate

fEb 2041.44 N/mm2 Eular stress in transverse direction of girder plate

fELTg 794.46 N/mm2 Eular shear stress of girder plate

Buckling Check

( in accordance with ABS Rules, Steel Vessels, 1997, 5/2A.5.2.2, 5/2AB)

Project

Member ID Fwd bhd below drillfloor, mid Calculated b PS

Load Case Max combined loads Date 12/12/2020

INPUT DATA

Material Data

E 2.07E+05 N/mm2 Elastic modulus

u 0.3 Poisson's ratio

Pr 0.6 Proportional linear elastic limit of structure, 0.6 for steel

Plate/Panel Data

fy 355 N/mm2 Yeild strength of plate

Sm 0.908 Strength reduction factor, see notes*

tn 16 mm Plate thickness

sL 500 mm Longitudinal spacing

sT 1500 mm Transverse spacing

C1 1.1 See notes*

C2 1.2 See notes*

b 500 mm Width between longitudinal bulkheads, parallel to sL

l 1500 mm Length between transverse bulkheads, parallel to sT

Scantling of Longitudinals

fy 355 N/mm2 Yeild strength of longitudinals

Sm 0.908 Strength reduction factor, see notes*

Type A A (angle), FB(flat bar) or T (Tee bar)

hw 140 mm Web height of longitudinals

tw 8 mm Web thickness of longitudinals

bf 19 mm Flange width of longitudinals

tf 8 mm Flange thickness of longitudinals

b1 0 mm Smaller outstanding dim. of flange w.r.t. centerline of web

be 0 mm Effective breadth as specified in Figure 5/2A.4.4b, line b

12 middle

Scantling of Transverses

Type A A (angle), FB(flat bar) or T (Tee bar)

hwg 650 mm Web height of transverses

twg 10 mm Web thickness of transverses

bfg 200 mm Flange width of transverses

tfg 10 mm Flange thickness of transverses

Loading Data

fL 58.6 N/mm2 Calculated total compressive stress in long. direction for the plate

fT 95.9 N/mm2 Calculated total compressive stress in transverse/vertical direction

fLT 72.7 N/mm2 Calculated total shear stress

pn 0 N/mm2 Lateral pressure

If Girder Buckling is to be checked, input additional data as follows

Girder Plate Data

fy 355 N/mm2 Yeild strength of girders

Sm 0.908 Strength reduction factor, see notes*

tn 16 mm Web plate thickness of the girder

s 750 mm Longitudinal spacing of girder plate, =web height if no add. stiffeners applied

l 750 mm Transverse spacing of girder plate, =dist. btw long. bhd unless tripping bkt applied

C1 1 See notes*

C2 1.1 See notes*

Girder Loading Data

fLg (fT) 97.8 N/mm2 Calculated compressive stress along length of the girder

fb 120 N/mm2 Calculated ideal bending stress of girder

fLTg 105.3 N/mm2 Calculated total shear stress of girder

Ideal bending L Long plate (L) or Wide plate (W), see notes

OUTPUT DATA

Plate buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fT/RtfcT)^2+(fLT/fcLT)^2<=1

fcL fcT fcLT Unity Check 0.30

319 262 197 Results Ok

Ultimate Strength Check

Critical stress for ultimate buckling (lbf/in2)

fuL fuT fuLT

352 262 199

Unity Check Criteria

U.C. 1 0.18 ((fL/fuL)^2+(fLT/fuLT)^2) / Sm

U.C. 2 0.30 ((fT/RtfuT)^2+(fLT/fuLT)^2) / Sm

U.C. 3 0.27 ((fL/fuL)^2+(fT/RtfuT)^2-h(fL/fuL)(fT/RtfuT)+(fLT/fuLT)^2) / Sm

Results Ok

Panel buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2)

Criteria (fL/fcL)^2+(fT/fcT)^2<=Sm

fcL fcT Unity Check 0.11

355 355 Results Ok

Stiffener buckling check

Buckling State Limit:

n 3 Number of half waves which yields a smallest fET

fET 672 lbf/in2 Eular stress for tortional/flexural buckling

Critical buckling stress (lbf/in2)

axial comp torsional/flexural Criteria fL/(fc*Ae/A)+mfb/fy<=Sm

fca fct Unity Check 0.21

321 310 Results Ok

Girder buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fb/fcb)^2+(fLT/fcLT)^2<=Sm

fcLg fcb fLTg Unity Check 0.61

266 342 192 Results Ok

Notes:

1. Sm Strength reduction factor

ordinary strength steel

Grade H32 Grade H36 Grade H40

1 0.95 0.908 0.875

2. Values of C1 and C2

plate panels between angles or tee stiffeners plate panels between flat bars or bulb plates

C1 1.1 1

C2 1.3 within the double bottom or double side 1.2 within the double bottom or double side

1.2 elsewhere 1.1 elsewhere

3. Ideal bending patten

a). Long plate b). Wide plate

-fb fb

l>=s fb l>s

fb l

s l

s

-fb -fb

-fb

fb

Calculated Data

panel data

section properties of longitudinals (excluding associated plating)

Eccentricity mm Inertia momen mm4

exLo 1.135 IxL ###

eyLo 78.843 IyL 6211.925

section properties of longitudinals w/ effective breadth be

Eccentricity eyLe = 78.843 mm4

Section modu Sme = 40639.882 mm3

section properties of stiffeners w/ associated plating bw

Longitudinals Transverses

Effective plat mm 500.00 1500.00

Eccentricity mm 10.75 105.00

Net sectional mm2 1272.00 8500.00

Inertia moment mm4 ### ### (alone about neutral axis of combined cross section)

Intertia momen mm4 ### ###

calculated data of plate buckling check

buckling state limit

fyL 355 N/mm2 Yield stress for uniaxail comprssion

fyT 355 N/mm2 Yield stress for uniaxail comprssion

fyLT 205 N/mm2 Yield stress for edge shear

KL 4.4

KT 1.4814815

KLT 6.3628889

q 0.5 Lateral load parameter

Rt 1 Reduction factor acconting for lateral load effects

fEL 842.09 N/mm2 Eular stress in longitudinal direction

fET 283.53 N/mm2 Eular stress in transverse direction

fELT 1217.76 N/mm2 Eular shear stress

Effective Width

b 1.29

h 0.85

C 0.99

bwL 496.12 mm Effective width of associated plate for longitudinals

bwT 740.99 mm Effective width of associated plate for transverses

calculated data of panel buckling check

tL 18.544 mm Net equivalent thickness of plating and stiffener in long. direaction

tT 21.666667 mm Net equivalent thickness of plating and stiffener in transverse direaction

DL 4.197E+09

DT 2.126E+11

FL 8.0037864

FT 0.1249409

h 0.1375319

kL 4

kT 64.351271

fEL 254123.81 N/mm2 Eular stress in longitudinal direction

fET 388786.62 N/mm2 Eular stress in transverse direction

calculated data of stiffener buckling check

Axial compression

As 1272 mm2 Net sectional area of longitudinal, excluding assicocated plate

A 9272 mm2 Total net sectional area

Ae 9272.00 mm2 Effective net sectional area

r 31.54 mm2 Radius of gyration

m 1.0694415 Amplification factor

M 0 N-mm Max. bending moment induced by lateral pressure

fb 0 N/mm2 Local bending stress

fE 902 N/mm2 Eular stress

Torsional/flexural buckling

u 1 Unsymmetry factor

mt 1

a 3.000

Co 565248

Iyf 16651.409 mm4

Io 10400486 mm4 Polar moment of inertia

G 3.77E+08 Warping constant

K 27136.00 St. Venant trosion constant for longitudinals(only) cross section

fcL 766 N/mm2 Critical buck. stress for associated plate corresponding to n-half waves

calculated data of girder buckling check

fyLg 355 N/mm2 Yield stress for uniaxail comprssion

fyb 355 N/mm2 Yield stress for uniaxail comprssion

fyLTg 205 N/mm2 Yield stress for edge shear

KLg 4

Kb 24

KLTg 9.34

fELg 340.24 N/mm2 Eular stress in longitudinal direction of girder plate

fEb 2041.44 N/mm2 Eular stress in transverse direction of girder plate

fELTg 794.46 N/mm2 Eular shear stress of girder plate

Buckling Check

( in accordance with ABS Rules, Steel Vessels, 1997, 5/2A.5.2.2, 5/2AB)

Project

Member ID Fwd bhd below drillfloor, mid Calculated b PS

Load Case Max combined loads Date 12/12/2020

INPUT DATA

Material Data

E 2.07E+05 N/mm2 Elastic modulus

u 0.3 Poisson's ratio

Pr 0.6 Proportional linear elastic limit of structure, 0.6 for steel

Plate/Panel Data

fy 355 N/mm2 Yeild strength of plate

Sm 0.908 Strength reduction factor, see notes*

tn 20 mm Plate thickness

sL 800 mm Longitudinal spacing

sT 2500 mm Transverse spacing

C1 1.1 See notes*

C2 1.2 See notes*

b 800 mm Width between longitudinal bulkheads, parallel to sL

l 2500 mm Length between transverse bulkheads, parallel to sT

Scantling of Longitudinals

fy 355 N/mm2 Yeild strength of longitudinals

Sm 0.908 Strength reduction factor, see notes*

Type A A (angle), FB(flat bar) or T (Tee bar)

hw 140 mm Web height of longitudinals

tw 8 mm Web thickness of longitudinals

bf 19 mm Flange width of longitudinals

tf 8 mm Flange thickness of longitudinals

b1 0 mm Smaller outstanding dim. of flange w.r.t. centerline of web

be 0 mm Effective breadth as specified in Figure 5/2A.4.4b, line b

12 middle

Scantling of Transverses

Type A A (angle), FB(flat bar) or T (Tee bar)

hwg 650 mm Web height of transverses

twg 10 mm Web thickness of transverses

bfg 200 mm Flange width of transverses

tfg 10 mm Flange thickness of transverses

Loading Data

fL 14.7 N/mm2 Calculated total compressive stress in long. direction for the plate

fT 76.3 N/mm2 Calculated total compressive stress in transverse/vertical direction

fLT 26.1 N/mm2 Calculated total shear stress

pn 0 N/mm2 Lateral pressure

If Girder Buckling is to be checked, input additional data as follows

Girder Plate Data

fy 235 N/mm2 Yeild strength of girders

Sm 1 Strength reduction factor, see notes*

tn 10 mm Web plate thickness of the girder

s 650 mm Longitudinal spacing of girder plate, =web height if no add. stiffeners applied

l 800 mm Transverse spacing of girder plate, =dist. btw long. bhd unless tripping bkt applied

C1 1 See notes*

C2 1.1 See notes*

Girder Loading Data

fLg (fT) 76.3 N/mm2 Calculated compressive stress along length of the girder

fb 0 N/mm2 Calculated ideal bending stress of girder

fLTg 0 N/mm2 Calculated total shear stress of girder

Ideal bending L Long plate (L) or Wide plate (W), see notes

OUTPUT DATA

Plate buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fT/RtfcT)^2+(fLT/fcLT)^2<=1

fcL fcT fcLT Unity Check 0.22

296 170 191 Results Ok

Ultimate Strength Check

Critical stress for ultimate buckling (lbf/in2)

fuL fuT fuLT

320 170 194

Unity Check Criteria

U.C. 1 0.02 ((fL/fuL)^2+(fLT/fuLT)^2) / Sm

U.C. 2 0.24 ((fT/RtfuT)^2+(fLT/fuLT)^2) / Sm

U.C. 3 0.23 ((fL/fuL)^2+(fT/RtfuT)^2-h(fL/fuL)(fT/RtfuT)+(fLT/fuLT)^2) / Sm

Results Ok

Panel buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2)

Criteria (fL/fcL)^2+(fT/fcT)^2<=Sm

fcL fcT Unity Check 0.05

354 355 Results Ok

Stiffener buckling check

Buckling State Limit:

n 3 Number of half waves which yields a smallest fET

fET 454 lbf/in2 Eular stress for tortional/flexural buckling

Critical buckling stress (lbf/in2)

axial comp torsional/flexural Criteria fL/(fc*Ae/A)+mfb/fy<=Sm

fca fct Unity Check 0.09

184 288 Results Ok

Girder buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fb/fcb)^2+(fLT/fcLT)^2<=Sm

fcLg fcb fLTg Unity Check 0.23

160 224 123 Results Ok

Notes:

1. Sm Strength reduction factor

ordinary strength steel

Grade H32 Grade H36 Grade H40

1 0.95 0.908 0.875

2. Values of C1 and C2

plate panels between angles or tee stiffeners plate panels between flat bars or bulb plates

C1 1.1 1

C2 1.3 within the double bottom or double side 1.2 within the double bottom or double side

1.2 elsewhere 1.1 elsewhere

3. Ideal bending patten

a). Long plate b). Wide plate

-fb fb

l>=s fb l>s

fb l

s l

s

-fb -fb

-fb

fb

Calculated Data

panel data

section properties of longitudinals (excluding associated plating)

Eccentricity mm Inertia momen mm4

exLo 1.135 IxL ###

eyLo 78.843 IyL 6211.925

section properties of longitudinals w/ effective breadth be

Eccentricity eyLe = 78.843 mm4

Section modu Sme = 40639.882 mm3

section properties of stiffeners w/ associated plating bw

Longitudinals Transverses

Effective plat mm 800.00 2500.00

Eccentricity mm 5.77 58.33

Net sectional mm2 1272.00 8500.00

Inertia moment mm4 ### ### (alone about neutral axis of combined cross section)

Intertia momen mm4 ### ###

calculated data of plate buckling check

buckling state limit

fyL 355 N/mm2 Yield stress for uniaxail comprssion

fyT 355 N/mm2 Yield stress for uniaxail comprssion

fyLT 205 N/mm2 Yield stress for edge shear

KL 4.4

KT 1.4583429

KLT 6.32456

q 0.5 Lateral load parameter

Rt 1 Reduction factor acconting for lateral load effects

fEL 513.97 N/mm2 Eular stress in longitudinal direction

fET 170.35 N/mm2 Eular stress in transverse direction

fELT 738.78 N/mm2 Eular shear stress

Effective Width

b 1.66

h 0.67

C 0.90

bwL 722.20 mm Effective width of associated plate for longitudinals

bwT 1026.03 mm Effective width of associated plate for transverses

calculated data of panel buckling check

tL 21.59 mm Net equivalent thickness of plating and stiffener in long. direaction

tT 23.4 mm Net equivalent thickness of plating and stiffener in transverse direaction

DL 2.764E+09

DT 1.421E+11

FL 8.3672399

FT 0.1195137

h 0.0772886

kL 4

kT 70.179564

fEL 56560.422 N/mm2 Eular stress in longitudinal direction

fET 93756.214 N/mm2 Eular stress in transverse direction

calculated data of stiffener buckling check

Axial compression

As 1272 mm2 Net sectional area of longitudinal, excluding assicocated plate

A 17272 mm2 Total net sectional area

Ae 17272.00 mm2 Effective net sectional area

r 23.72 mm2 Radius of gyration

m 1.0869343 Amplification factor

M 0 N-mm Max. bending moment induced by lateral pressure

fb 0 N/mm2 Local bending stress

fE 184 N/mm2 Eular stress

Torsional/flexural buckling

u 1 Unsymmetry factor

mt 1

a 3.125

Co 690000

Iyf 16651.409 mm4

Io 10400486 mm4 Polar moment of inertia

G 3.77E+08 Warping constant

K 27136.00 St. Venant trosion constant for longitudinals(only) cross section

fcL 468 N/mm2 Critical buck. stress for associated plate corresponding to n-half waves

calculated data of girder buckling check

fyLg 235 N/mm2 Yield stress for uniaxail comprssion

fyb 235 N/mm2 Yield stress for uniaxail comprssion

fyLTg 136 N/mm2 Yield stress for edge shear

KLg 4

Kb 24

KLTg 7.980625

fELg 176.95 N/mm2 Eular stress in longitudinal direction of girder plate

fEb 1061.67 N/mm2 Eular stress in transverse direction of girder plate

fELTg 353.03 N/mm2 Eular shear stress of girder plate

Buckling Check

( in accordance with ABS Rules, Steel Vessels, 1997, 5/2A.5.2.2, 5/2AB)

Project

Member ID Fwd bhd below drillfloor, mid Calculated b PS

Load Case Max combined loads Date 12/12/2020

INPUT DATA

Material Data

E 2.07E+05 N/mm2 Elastic modulus

u 0.3 Poisson's ratio

Pr 0.6 Proportional linear elastic limit of structure, 0.6 for steel

Plate/Panel Data

fy 355 N/mm2 Yeild strength of plate

Sm 0.908 Strength reduction factor, see notes*

tn 14 mm Plate thickness

sL 738 mm Longitudinal spacing

sT 2000 mm Transverse spacing

C1 1.1 See notes*

C2 1.2 See notes*

b 1475 mm Width between longitudinal bulkheads, parallel to sL

l 7500 mm Length between transverse bulkheads, parallel to sT

Scantling of Longitudinals

fy 355 N/mm2 Yeild strength of longitudinals

Sm 0.908 Strength reduction factor, see notes*

Type A A (angle), FB(flat bar) or T (Tee bar)

hw 140 mm Web height of longitudinals

tw 8 mm Web thickness of longitudinals

bf 19 mm Flange width of longitudinals

tf 8 mm Flange thickness of longitudinals

b1 0 mm Smaller outstanding dim. of flange w.r.t. centerline of web

be 0 mm Effective breadth as specified in Figure 5/2A.4.4b, line b

12 middle

Scantling of Transverses

Type A A (angle), FB(flat bar) or T (Tee bar)

hwg 650 mm Web height of transverses

twg 10 mm Web thickness of transverses

bfg 200 mm Flange width of transverses

tfg 10 mm Flange thickness of transverses

Loading Data

fL 4.6 N/mm2 Calculated total compressive stress in long. direction for the plate

fT 0.6 N/mm2 Calculated total compressive stress in transverse/vertical direction

fLT 72.2 N/mm2 Calculated total shear stress

pn 0 N/mm2 Lateral pressure

If Girder Buckling is to be checked, input additional data as follows

Girder Plate Data

fy 235 N/mm2 Yeild strength of girders

Sm 1 Strength reduction factor, see notes*

tn 10 mm Web plate thickness of the girder

s 650 mm Longitudinal spacing of girder plate, =web height if no add. stiffeners applied

l 1475 mm Transverse spacing of girder plate, =dist. btw long. bhd unless tripping bkt applied

C1 1 See notes*

C2 1.1 See notes*

Girder Loading Data

fLg (fT) 0.6 N/mm2 Calculated compressive stress along length of the girder

fb 0 N/mm2 Calculated ideal bending stress of girder

fLTg 0 N/mm2 Calculated total shear stress of girder

Ideal bending L Long plate (L) or Wide plate (W), see notes

OUTPUT DATA

Plate buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fT/RtfcT)^2+(fLT/fcLT)^2<=1

fcL fcT fcLT Unity Check 0.16

253 104 182 Results Ok

Ultimate Strength Check

Critical stress for ultimate buckling (lbf/in2)

fuL fuT fuLT

273 132 188

Unity Check Criteria

U.C. 1 0.16 ((fL/fuL)^2+(fLT/fuLT)^2) / Sm

U.C. 2 0.16 ((fT/RtfuT)^2+(fLT/fuLT)^2) / Sm

U.C. 3 0.16 ((fL/fuL)^2+(fT/RtfuT)^2-h(fL/fuL)(fT/RtfuT)+(fLT/fuLT)^2) / Sm

Results Ok

Panel buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2)

Criteria (fL/fcL)^2+(fT/fcT)^2<=Sm

fcL fcT Unity Check 0.00

354 354 Results Ok

Stiffener buckling check

Buckling State Limit:

n 3 Number of half waves which yields a smallest fET

fET 292 lbf/in2 Eular stress for tortional/flexural buckling

Critical buckling stress (lbf/in2)

axial comp torsional/flexural Criteria fL/(fc*Ae/A)+mfb/fy<=Sm

fca fct Unity Check 0.02

282 251 Results Ok

Girder buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fb/fcb)^2+(fLT/fcLT)^2<=Sm

fcLg fcb fLTg Unity Check 0.00

160 224 119 Results Ok

Notes:

1. Sm Strength reduction factor

ordinary strength steel

Grade H32 Grade H36 Grade H40

1 0.95 0.908 0.875

2. Values of C1 and C2

plate panels between angles or tee stiffeners plate panels between flat bars or bulb plates

C1 1.1 1

C2 1.3 within the double bottom or double side 1.2 within the double bottom or double side

1.2 elsewhere 1.1 elsewhere

3. Ideal bending patten

a). Long plate b). Wide plate

-fb fb

l>=s fb l>s

fb l

s l

s

-fb -fb

-fb

fb

Calculated Data

panel data

section properties of longitudinals (excluding associated plating)

Eccentricity mm Inertia momen mm4

exLo 1.135 IxL ###

eyLo 78.843 IyL 6211.925

section properties of longitudinals w/ effective breadth be

Eccentricity eyLe = 78.843 mm4

Section modu Sme = 40639.882 mm3

section properties of stiffeners w/ associated plating bw

Longitudinals Transverses

Effective plat mm 738.00 2000.00

Eccentricity mm 8.59 93.49

Net sectional mm2 1272.00 8500.00

Inertia moment mm4 ### ### (alone about neutral axis of combined cross section)

Intertia momen mm4 ### ###

calculated data of plate buckling check

buckling state limit

fyL 355 N/mm2 Yield stress for uniaxail comprssion

fyT 355 N/mm2 Yield stress for uniaxail comprssion

fyLT 205 N/mm2 Yield stress for edge shear

KL 4.4

KT 1.5490342

KLT 6.4731084

q 0.5 Lateral load parameter

Rt 1 Reduction factor acconting for lateral load effects

fEL 295.94 N/mm2 Eular stress in longitudinal direction

fET 104.19 N/mm2 Eular stress in transverse direction

fELT 435.37 N/mm2 Eular shear stress

Effective Width

b 2.18

h 0.41

C 0.77

bwL 567.07 mm Effective width of associated plate for longitudinals

bwT 744.40 mm Effective width of associated plate for transverses

calculated data of panel buckling check

tL 15.723577 mm Net equivalent thickness of plating and stiffener in long. direaction

tT 18.25 mm Net equivalent thickness of plating and stiffener in transverse direaction

DL 2.91E+09

DT 1.639E+11

FL 13.930725

FT 0.0717838

h 0.1171039

kL 4

kT 194.30446

fEL 25179.654 N/mm2 Eular stress in longitudinal direction

fET 40758.908 N/mm2 Eular stress in transverse direction

calculated data of stiffener buckling check

Axial compression

As 1272 mm2 Net sectional area of longitudinal, excluding assicocated plate

A 11604 mm2 Total net sectional area

Ae 11604.00 mm2 Effective net sectional area

r 28.52 mm2 Radius of gyration

m 1.011206 Amplification factor

M 0 N-mm Max. bending moment induced by lateral pressure

fb 0 N/mm2 Local bending stress

fE 415 N/mm2 Eular stress

Torsional/flexural buckling

u 1 Unsymmetry factor

mt 1

a 2.710

Co 256553

Iyf 16651.409 mm4

Io 10400486 mm4 Polar moment of inertia

G 3.77E+08 Warping constant

K 27136.00 St. Venant trosion constant for longitudinals(only) cross section

fcL 272 N/mm2 Critical buck. stress for associated plate corresponding to n-half waves

calculated data of girder buckling check

fyLg 235 N/mm2 Yield stress for uniaxail comprssion

fyb 235 N/mm2 Yield stress for uniaxail comprssion

fyLTg 136 N/mm2 Yield stress for edge shear

KLg 4

Kb 24

KLTg 6.1167883

fELg 176.95 N/mm2 Eular stress in longitudinal direction of girder plate

fEb 1061.67 N/mm2 Eular stress in transverse direction of girder plate

fELTg 270.59 N/mm2 Eular shear stress of girder plate

Buckling Check

( in accordance with ABS Rules, Steel Vessels, 1997, 5/2A.5.2.2, 5/2AB)

Project

Member ID Fwd bhd below drillfloor, mid Calculated b PS

Load Case Max combined loads Date 12/12/2020

INPUT DATA

Material Data

E 2.07E+05 N/mm2 Elastic modulus

u 0.3 Poisson's ratio

Pr 0.6 Proportional linear elastic limit of structure, 0.6 for steel

Plate/Panel Data

fy 355 N/mm2 Yeild strength of plate

Sm 0.908 Strength reduction factor, see notes*

tn 14 mm Plate thickness

sL 738 mm Longitudinal spacing

sT 2000 mm Transverse spacing

C1 1.1 See notes*

C2 1.2 See notes*

b 1475 mm Width between longitudinal bulkheads, parallel to sL

l 7500 mm Length between transverse bulkheads, parallel to sT

Scantling of Longitudinals

fy 355 N/mm2 Yeild strength of longitudinals

Sm 0.908 Strength reduction factor, see notes*

Type A A (angle), FB(flat bar) or T (Tee bar)

hw 140 mm Web height of longitudinals

tw 8 mm Web thickness of longitudinals

bf 19 mm Flange width of longitudinals

tf 8 mm Flange thickness of longitudinals

b1 0 mm Smaller outstanding dim. of flange w.r.t. centerline of web

be 0 mm Effective breadth as specified in Figure 5/2A.4.4b, line b

12 middle

Scantling of Transverses

Type A A (angle), FB(flat bar) or T (Tee bar)

hwg 650 mm Web height of transverses

twg 10 mm Web thickness of transverses

bfg 200 mm Flange width of transverses

tfg 10 mm Flange thickness of transverses

Loading Data

fL 49.5 N/mm2 Calculated total compressive stress in long. direction for the plate

fT 32.7 N/mm2 Calculated total compressive stress in transverse/vertical direction

fLT 32.2 N/mm2 Calculated total shear stress

pn 0 N/mm2 Lateral pressure

If Girder Buckling is to be checked, input additional data as follows

Girder Plate Data

fy 235 N/mm2 Yeild strength of girders

Sm 1 Strength reduction factor, see notes*

tn 10 mm Web plate thickness of the girder

s 650 mm Longitudinal spacing of girder plate, =web height if no add. stiffeners applied

l 1475 mm Transverse spacing of girder plate, =dist. btw long. bhd unless tripping bkt applied

C1 1 See notes*

C2 1.1 See notes*

Girder Loading Data

fLg (fT) 32.7 N/mm2 Calculated compressive stress along length of the girder

fb 0 N/mm2 Calculated ideal bending stress of girder

fLTg 0 N/mm2 Calculated total shear stress of girder

Ideal bending L Long plate (L) or Wide plate (W), see notes

OUTPUT DATA

Plate buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fT/RtfcT)^2+(fLT/fcLT)^2<=1

fcL fcT fcLT Unity Check 0.17

253 104 182 Results Ok

Ultimate Strength Check

Critical stress for ultimate buckling (lbf/in2)

fuL fuT fuLT

273 132 188

Unity Check Criteria

U.C. 1 0.07 ((fL/fuL)^2+(fLT/fuLT)^2) / Sm

U.C. 2 0.10 ((fT/RtfuT)^2+(fLT/fuLT)^2) / Sm

U.C. 3 0.12 ((fL/fuL)^2+(fT/RtfuT)^2-h(fL/fuL)(fT/RtfuT)+(fLT/fuLT)^2) / Sm

Results Ok

Panel buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2)

Criteria (fL/fcL)^2+(fT/fcT)^2<=Sm

fcL fcT Unity Check 0.03

354 354 Results Ok

Stiffener buckling check

Buckling State Limit:

n 3 Number of half waves which yields a smallest fET

fET 292 lbf/in2 Eular stress for tortional/flexural buckling

Critical buckling stress (lbf/in2)

axial comp torsional/flexural Criteria fL/(fc*Ae/A)+mfb/fy<=Sm

fca fct Unity Check 0.22

282 251 Results Ok

Girder buckling check

Buckling State Limit:

Critical buckling stress (lbf/in2) Criteria (fL/fcL)^2+(fb/fcb)^2+(fLT/fcLT)^2<=Sm

fcLg fcb fLTg Unity Check 0.04

160 224 119 Results Ok

Notes:

1. Sm Strength reduction factor

ordinary strength steel

Grade H32 Grade H36 Grade H40

1 0.95 0.908 0.875

2. Values of C1 and C2

plate panels between angles or tee stiffeners plate panels between flat bars or bulb plates

C1 1.1 1

C2 1.3 within the double bottom or double side 1.2 within the double bottom or double side

1.2 elsewhere 1.1 elsewhere

3. Ideal bending patten

a). Long plate b). Wide plate

-fb fb

l>=s fb l>s

fb l

s l

s

-fb -fb

-fb

fb

Calculated Data

panel data

section properties of longitudinals (excluding associated plating)

Eccentricity mm Inertia momen mm4

exLo 1.135 IxL ###

eyLo 78.843 IyL 6211.925

section properties of longitudinals w/ effective breadth be

Eccentricity eyLe = 78.843 mm4

Section modu Sme = 40639.882 mm3

section properties of stiffeners w/ associated plating bw

Longitudinals Transverses

Effective plat mm 738.00 2000.00

Eccentricity mm 8.59 93.49

Net sectional mm2 1272.00 8500.00

Inertia moment mm4 ### ### (alone about neutral axis of combined cross section)

Intertia momen mm4 ### ###

calculated data of plate buckling check

buckling state limit

fyL 355 N/mm2 Yield stress for uniaxail comprssion

fyT 355 N/mm2 Yield stress for uniaxail comprssion

fyLT 205 N/mm2 Yield stress for edge shear

KL 4.4

KT 1.5490342

KLT 6.4731084

q 0.5 Lateral load parameter

Rt 1 Reduction factor acconting for lateral load effects

fEL 295.94 N/mm2 Eular stress in longitudinal direction

fET 104.19 N/mm2 Eular stress in transverse direction

fELT 435.37 N/mm2 Eular shear stress

Effective Width

b 2.18

h 0.41

C 0.77

bwL 567.07 mm Effective width of associated plate for longitudinals

bwT 744.40 mm Effective width of associated plate for transverses

calculated data of panel buckling check

tL 15.723577 mm Net equivalent thickness of plating and stiffener in long. direaction

tT 18.25 mm Net equivalent thickness of plating and stiffener in transverse direaction

DL 2.91E+09

DT 1.639E+11

FL 13.930725

FT 0.0717838

h 0.1171039

kL 4

kT 194.30446

fEL 25179.654 N/mm2 Eular stress in longitudinal direction

fET 40758.908 N/mm2 Eular stress in transverse direction

calculated data of stiffener buckling check

Axial compression

As 1272 mm2 Net sectional area of longitudinal, excluding assicocated plate

A 11604 mm2 Total net sectional area

Ae 11604.00 mm2 Effective net sectional area

r 28.52 mm2 Radius of gyration

m 1.1353962 Amplification factor

M 0 N-mm Max. bending moment induced by lateral pressure

fb 0 N/mm2 Local bending stress

fE 415 N/mm2 Eular stress

Torsional/flexural buckling

u 1 Unsymmetry factor

mt 1

a 2.710

Co 256553

Iyf 16651.409 mm4

Io 10400486 mm4 Polar moment of inertia

G 3.77E+08 Warping constant

K 27136.00 St. Venant trosion constant for longitudinals(only) cross section

fcL 272 N/mm2 Critical buck. stress for associated plate corresponding to n-half waves

calculated data of girder buckling check

fyLg 235 N/mm2 Yield stress for uniaxail comprssion

fyb 235 N/mm2 Yield stress for uniaxail comprssion

fyLTg 136 N/mm2 Yield stress for edge shear

KLg 4

Kb 24

KLTg 6.1167883

fELg 176.95 N/mm2 Eular stress in longitudinal direction of girder plate

fEb 1061.67 N/mm2 Eular stress in transverse direction of girder plate

fELTg 270.59 N/mm2 Eular shear stress of girder plate

You might also like

- 4 - PFC To Hanging Plate ConnDocument13 pages4 - PFC To Hanging Plate Connabdul khaderNo ratings yet

- RSW - Buoys InstallationDocument9 pagesRSW - Buoys Installationothman salahNo ratings yet

- Crimp PLTDocument5 pagesCrimp PLTSai SushankNo ratings yet

- Moment Baseplate Design Rev. 0Document3 pagesMoment Baseplate Design Rev. 0Bok MortegaNo ratings yet

- Beams On Elastic FoundationsDocument3 pagesBeams On Elastic FoundationsIgnatius SamrajNo ratings yet

- HiPAP Family Brochure v3 LowresDocument13 pagesHiPAP Family Brochure v3 LowresLi Ann ChungNo ratings yet

- Stability CritariaDocument9 pagesStability CritariaAbu Bakar Siddke RumiNo ratings yet

- Wind Speed Calculation As Per SP-1275Document7 pagesWind Speed Calculation As Per SP-1275Siva baalanNo ratings yet

- Surge ForceDocument2 pagesSurge ForceJ A S JASNo ratings yet

- Symbol: Principal ParticularsDocument9 pagesSymbol: Principal ParticularsNiloy SahaNo ratings yet

- Pt. Tripatra Engineering: Calculation SheetDocument6 pagesPt. Tripatra Engineering: Calculation SheetriandiNo ratings yet

- Platform Calculation (Jan 22-2012)Document28 pagesPlatform Calculation (Jan 22-2012)SAMER OSMANNo ratings yet

- Holevolume CalcDocument59 pagesHolevolume Calcalsahel2004666No ratings yet

- 194 2427 194 T Tot H H : Input OutputDocument19 pages194 2427 194 T Tot H H : Input Outputxuankhoi doanvanNo ratings yet

- Fentek Marine Systems: Project TitleDocument6 pagesFentek Marine Systems: Project TitleTeo Keng ChauNo ratings yet

- Aashhto LRFD 2007 - Concrete Deck Design: HC 17,5 CM OKDocument7 pagesAashhto LRFD 2007 - Concrete Deck Design: HC 17,5 CM OKprasadnn2001No ratings yet

- Shell BC-10 - FPSO Hogging and Sagging Enforced Displacements On Topsides Roel SoelemanDocument6 pagesShell BC-10 - FPSO Hogging and Sagging Enforced Displacements On Topsides Roel SoelemanRoel SoelemanNo ratings yet

- Offcom Completa - v.01Document7 pagesOffcom Completa - v.01Argonauta_navegadorNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque CalculatorsopapilasNo ratings yet

- Torispherical Cone With KnuckleDocument2 pagesTorispherical Cone With KnuckleSajal KulshresthaNo ratings yet

- Rapp Buckling Strength of Stiffened Flat Plates SH92 3014: Input: Principal DataDocument36 pagesRapp Buckling Strength of Stiffened Flat Plates SH92 3014: Input: Principal Datading liuNo ratings yet

- Himesh PanchalDocument12 pagesHimesh PanchalHimesh PanchalNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- Spreaer Beam&Lifting Line Beam p3Document2 pagesSpreaer Beam&Lifting Line Beam p3Sabrang LorNo ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- Loadline Calculations - Finding Various Drafts From Loadline Certificate ParticlarsDocument1 pageLoadline Calculations - Finding Various Drafts From Loadline Certificate ParticlarsPrinceNo ratings yet

- Front End Engineering Design (Feed) For Gas Lift Compression ProjectDocument14 pagesFront End Engineering Design (Feed) For Gas Lift Compression Projectsutomo rochmandaNo ratings yet

- Lifting LugDocument17 pagesLifting LugbkprodhNo ratings yet

- Wind and Wave LoadsDocument10 pagesWind and Wave LoadsMuhammad ArqamNo ratings yet

- Weld Neck Flange DesignDocument2 pagesWeld Neck Flange DesignKashif KaziNo ratings yet

- Calculation 2019 - Tugboat CW Kort NozzleDocument2 pagesCalculation 2019 - Tugboat CW Kort NozzleAchmad RadjakibulNo ratings yet

- Calculations For Rectangular Storage TankDocument44 pagesCalculations For Rectangular Storage TankSiva ShankarNo ratings yet

- Lashing FormulaDocument1 pageLashing FormulaMuhammad FitrahNo ratings yet

- DESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomDocument11 pagesDESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomAsaru DeenNo ratings yet

- Technical Evaluation HAM BAKERDocument1 pageTechnical Evaluation HAM BAKEReko123No ratings yet

- MagnorDocument2 pagesMagnorAntónio NôroNo ratings yet

- Pedestal Crane AnalisistDocument40 pagesPedestal Crane AnalisistMuhsiin AliiNo ratings yet

- Design Base Plate For I Beam - Bottom BracketDocument1 pageDesign Base Plate For I Beam - Bottom BracketCon CanNo ratings yet

- Exhaust Stack: Engineering With The SpreadsheetDocument16 pagesExhaust Stack: Engineering With The SpreadsheetMakanjuola Ronald OlaitanNo ratings yet

- Towing Design Rev2Document19 pagesTowing Design Rev2Ludovic LandemaineNo ratings yet

- SWIODocument1 pageSWIOpreeti kumariNo ratings yet

- Seismic Load Calculation of The Tank As Per IS 1893Document1 pageSeismic Load Calculation of The Tank As Per IS 1893ParthibanNo ratings yet

- Conexion 1Document262 pagesConexion 1luisfdogaviriaNo ratings yet

- Circular Plate Stress CheckDocument2 pagesCircular Plate Stress CheckNaresh KumarNo ratings yet

- Lifting Davit Spreadsheet Structure (Robin)Document2 pagesLifting Davit Spreadsheet Structure (Robin)TsukomaruNo ratings yet

- Youngs Modulus b3 2010Document2 pagesYoungs Modulus b3 2010bakellyNo ratings yet

- Buoy Calculation Depth 14M Calculation Navigation Buoy DataDocument34 pagesBuoy Calculation Depth 14M Calculation Navigation Buoy DataDIANTORONo ratings yet

- Heat ExchangersDocument30 pagesHeat ExchangersvpjagannaathNo ratings yet

- Load CasesDocument8 pagesLoad Casestebodin_319100% (1)

- Structural Design Support VesselDocument95 pagesStructural Design Support VesselMarco CordonNo ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- Flange Design Mmcobc 3.1 2010Document6 pagesFlange Design Mmcobc 3.1 2010bakellyNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Abs Bukl+sfDocument269 pagesAbs Bukl+sfding liuNo ratings yet

- Project Proposed 2 Cell Box Culvert Title Design of 2 Cell Box CulvertDocument31 pagesProject Proposed 2 Cell Box Culvert Title Design of 2 Cell Box CulvertSudip ShresthaNo ratings yet

- LRFD Live Load Distribution Factors: TxdotDocument27 pagesLRFD Live Load Distribution Factors: TxdotJozeef AlKhoureNo ratings yet

- Design Calculation For Splice & Bottom Plate of Vertical Column MembersDocument4 pagesDesign Calculation For Splice & Bottom Plate of Vertical Column Membersinnovativekarthi100% (1)

- Timber DesignDocument144 pagesTimber DesignChristopher ArceNo ratings yet

- Total Strength Assessment: Buckling and Ultimate StrengthDocument30 pagesTotal Strength Assessment: Buckling and Ultimate Strengthding liuNo ratings yet

- Hull Basic Training Course: Outfitting (Rudder, Hatch Cover)Document26 pagesHull Basic Training Course: Outfitting (Rudder, Hatch Cover)ding liuNo ratings yet

- Hull Basic Training Course: Basic Theory of Structural DesignDocument39 pagesHull Basic Training Course: Basic Theory of Structural Designding liuNo ratings yet

- 辽宁维航基业科技有限公司 Vh-Marinetech Co.,LtdDocument21 pages辽宁维航基业科技有限公司 Vh-Marinetech Co.,Ltdding liuNo ratings yet

- 17.1 - Drillship Class and Stat - FLNG DifferencesDocument38 pages17.1 - Drillship Class and Stat - FLNG Differencesding liuNo ratings yet

- Hull Basic Training Course: Fundamentals of Steel MaterialDocument34 pagesHull Basic Training Course: Fundamentals of Steel Materialding liuNo ratings yet

- 16 - Drillship Class and Stat - FPSODocument92 pages16 - Drillship Class and Stat - FPSOding liuNo ratings yet

- 17.2 - Drillship Class and Stat - Floating Offshore Liquefied Gas TerminalDocument32 pages17.2 - Drillship Class and Stat - Floating Offshore Liquefied Gas Terminalding liuNo ratings yet

- Bulkling Check (P1420)Document3 pagesBulkling Check (P1420)ding liuNo ratings yet

- Sheet1: Rapp Buckling Strength of Stiffened Flat Plates SH92 3014Document8 pagesSheet1: Rapp Buckling Strength of Stiffened Flat Plates SH92 3014ding liuNo ratings yet

- Foldable Bike and Pmds On Public TransportDocument5 pagesFoldable Bike and Pmds On Public Transportding liuNo ratings yet

- CarDocument19 pagesCarding liuNo ratings yet

- Total Strength Assessment: Buckling and Ultimate StrengthDocument30 pagesTotal Strength Assessment: Buckling and Ultimate Strengthding liuNo ratings yet

- Ajeas Joint FlexibilityDocument7 pagesAjeas Joint Flexibilityding liuNo ratings yet

- 4.2 Load Combinations For DMG Analysis: Calculation SheetDocument2 pages4.2 Load Combinations For DMG Analysis: Calculation Sheetding liuNo ratings yet

- Rapp Buckling Strength of Stiffened Flat Plates SH92 3014: Input: Principal DataDocument36 pagesRapp Buckling Strength of Stiffened Flat Plates SH92 3014: Input: Principal Datading liuNo ratings yet

- Abs Bukl+sfDocument269 pagesAbs Bukl+sfding liuNo ratings yet

- Ocean Wave Model Output Parameters: Jean-Raymond Bidlot Ecmwf Jean - Bidlot@ecmwf - Int February 27, 2020Document27 pagesOcean Wave Model Output Parameters: Jean-Raymond Bidlot Ecmwf Jean - Bidlot@ecmwf - Int February 27, 2020ding liuNo ratings yet

- 清洗机样本册2020 04 03+HIGH+PRESSURE+WASHER+E-CATALOGUEDocument25 pages清洗机样本册2020 04 03+HIGH+PRESSURE+WASHER+E-CATALOGUEding liuNo ratings yet

- The Limitations On The Use of The IMO CSS Code in Project Cargo-Case Study: Grillage Design For The Sea Transport of Gas Slug CatchersDocument19 pagesThe Limitations On The Use of The IMO CSS Code in Project Cargo-Case Study: Grillage Design For The Sea Transport of Gas Slug Catchersding liuNo ratings yet

- SEU Dynamic Analysis GN E-Feb17 PDFDocument40 pagesSEU Dynamic Analysis GN E-Feb17 PDFding liuNo ratings yet

- Load Sharing Strategies in Multiple Compressor Refrigeration SystemsDocument8 pagesLoad Sharing Strategies in Multiple Compressor Refrigeration SystemsLiu YangtzeNo ratings yet

- GATE General Aptitude GA Syllabus Common To AllDocument2 pagesGATE General Aptitude GA Syllabus Common To AllAbiramiAbiNo ratings yet

- Modulation and Frequency Synthesis X Digital Wireless RadioDocument233 pagesModulation and Frequency Synthesis X Digital Wireless Radiolcnblzr3877No ratings yet

- Dr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Document2 pagesDr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Najeebuddin AhmedNo ratings yet

- SettingsDocument3 pagesSettingsrusil.vershNo ratings yet

- Exoskeleton ArmDocument5 pagesExoskeleton Armc214ocNo ratings yet

- Chapter 1: Investment Landscape: Financial GoalsDocument8 pagesChapter 1: Investment Landscape: Financial GoalsshubhamNo ratings yet

- TP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Document12 pagesTP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Felix ChewNo ratings yet

- Drill String DesignDocument118 pagesDrill String DesignMohamed Ahmed AlyNo ratings yet

- Managerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Document40 pagesManagerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Uzma Khan100% (1)

- B.ST Case Study Class 12Document214 pagesB.ST Case Study Class 12Anishka Rathor100% (1)

- IOSA Information BrochureDocument14 pagesIOSA Information BrochureHavva SahınNo ratings yet

- Bismillah SpeechDocument2 pagesBismillah SpeechanggiNo ratings yet

- Conflict WaiverDocument2 pagesConflict WaiverjlurosNo ratings yet

- Simavi - Project Officer PROPOPIDocument4 pagesSimavi - Project Officer PROPOPIAgus NugrahaNo ratings yet

- RetrieveDocument8 pagesRetrieveSahian Montserrat Angeles HortaNo ratings yet

- 7Document101 pages7Navindra JaggernauthNo ratings yet

- ATLAS HONDA Internship ReportDocument83 pagesATLAS HONDA Internship ReportAhmed Aitsam93% (14)

- Brochure 2017Document44 pagesBrochure 2017bibiana8593No ratings yet

- 9.admin Rosal Vs ComelecDocument4 pages9.admin Rosal Vs Comelecmichelle zatarainNo ratings yet

- Unit 13 - Business Hotels and Sales ConferencesDocument24 pagesUnit 13 - Business Hotels and Sales ConferencesMiguel Angel Escoto CanoNo ratings yet

- White Button Mushroom Cultivation ManualDocument8 pagesWhite Button Mushroom Cultivation ManualKhurram Ismail100% (4)

- Electrical Estimate Template PDFDocument1 pageElectrical Estimate Template PDFMEGAWATT CONTRACTING AND ELECTRICITY COMPANYNo ratings yet

- Sales Manager Latin AmericaDocument3 pagesSales Manager Latin Americaapi-76934736No ratings yet

- Customer Satisfaction-ICICI Bank-Priyanka DhamijaDocument85 pagesCustomer Satisfaction-ICICI Bank-Priyanka DhamijaVarun GuptaNo ratings yet

- Lemon AidDocument17 pagesLemon AidJade Anne Mercado BalmesNo ratings yet

- Hardware Architecture For Nanorobot Application in Cancer TherapyDocument7 pagesHardware Architecture For Nanorobot Application in Cancer TherapyCynthia CarolineNo ratings yet

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualDocument12 pagesIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- Preventive Maintenance - HematologyDocument5 pagesPreventive Maintenance - HematologyBem GarciaNo ratings yet

- BACE Marketing Presentation FINALDocument14 pagesBACE Marketing Presentation FINALcarlosfelix810% (1)