Professional Documents

Culture Documents

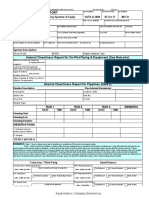

VSM For Job No J1947 A1 Time Log Sheet

Uploaded by

gowtham_venkat_4Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VSM For Job No J1947 A1 Time Log Sheet

Uploaded by

gowtham_venkat_4Copyright:

Available Formats

VSM for Job no J1947 A1

Time Log Sheet

Date Time

Sl. No of Manpower Change Over

Activity No of Lift Rework Time Inspection Time Remarks

No. used Time

Start End Start End Total (in mins)

RAW MATERIAL INSPECTION AND

1

CLEARANCE

2 CUTTING PLAN CLEARANCE

SHROUD BODY PLATE & FACE

3

PLATE RAW MATERIAL CUTTING

4 SHROUD BODY PLATE PRESSING

5 QC INSPECTION & CLEARANCE

SHROUD BODY PLATES EXTRA

6 LENGTH (BEND SIDE) MARKING &

CUTTING

SHROUD BODY PLATES EDGE

7

PREPARTION

8 SHROUD BODY PLATES FITUP

9 QC INSPECTION & CLEARANCE

10 SHROUD BODY PLATES WELDING

TEMPLATE CHECKING BY

11

PRODUCTION

100% MT INSPECTION ON WELD

12

JOINTS

13 QC INSPECTION & CLEARANCE

SHROUD FACE PLATE EDGE

14

PREPARATION

SHROUD FACE PLATE WITH BODY

15

PLATE FITMENT

SHROUD FACE PLATE WITH BODY

16

PLATE WELDING

100% MT INSPECTION ON WELD

17

JOINTS

SHROUD BODY PLATE MARKING

18 FOR SEMIC CIRCULAR &

TRAPEZOIDAL ENDS

19 QC INSPECTION & CLEARANCE

SHROUD BODY PLATE CUTTING

20 FOR SEMIC CIRCULAR &

TRAPEZOIDAL ENDS

QC FINAL INSPECTION &

21

CLEARANCE

22 POST WELD HEAT TREATMENT

100% MT ON WELD JOINTS &

23

HARDNESS CHECKING

24 QC INSPECTION & CLEARANCE

25 SHROUD SENT FOR MACHING

26 SHROUD MACHING MARKING

27 QC INSPECTION & CLEARANCE

28 SHROUD MACHINING

INTERNAL QC INSPECTION

29

CLEARANCE

CUSTOMER QC INSPECTION

30

CLEARANCE

BLASTING & QC INSPECTION

31

CLERANCE

APPLICATION OF RUST

32

PREVENTIVE OIL

33 QC INSPECTION FINAL CLEARANCE

Value Stream Mapping Page of Acoustics India Private Limited

VSM for Job no J1947 A2

Time Log Sheet

Date Time

Sl. No of Manpower Change Over

Activity No of Lift Rework Time Inspection Time Remarks

No. used Time

Start End Start End Total (in mins)

RAW MATERIAL INSPECTION AND

1

CLEARANCE

2 CUTTING PLAN CLEARANCE

SHROUD BODY PLATE & FACE

3

PLATE RAW MATERIAL CUTTING

4 SHROUD BODY PLATE PRESSING

5 QC INSPECTION & CLEARANCE

SHROUD BODY PLATES EXTRA

6 LENGTH (BEND SIDE) MARKING &

CUTTING

SHROUD BODY PLATES EDGE

7

PREPARTION

8 SHROUD BODY PLATES FITUP

9 QC INSPECTION & CLEARANCE

10 SHROUD BODY PLATES WELDING

TEMPLATE CHECKING BY

11

PRODUCTION

100% MT INSPECTION ON WELD

12

JOINTS

13 QC INSPECTION & CLEARANCE

SHROUD FACE PLATE EDGE

14

PREPARATION

SHROUD FACE PLATE WITH BODY

15

PLATE FITMENT

SHROUD FACE PLATE WITH BODY

16

PLATE WELDING

100% MT INSPECTION ON WELD

17

JOINTS

SHROUD BODY PLATE MARKING

18 FOR SEMIC CIRCULAR &

TRAPEZOIDAL ENDS

19 QC INSPECTION & CLEARANCE

SHROUD BODY PLATE CUTTING

20 FOR SEMIC CIRCULAR &

TRAPEZOIDAL ENDS

QC FINAL INSPECTION &

21

CLEARANCE

22 POST WELD HEAT TREATMENT

100% MT ON WELD JOINTS &

23

HARDNESS CHECKING

24 QC INSPECTION & CLEARANCE

25 SHROUD SENT FOR MACHING

26 SHROUD MACHING MARKING

27 QC INSPECTION & CLEARANCE

28 SHROUD MACHINING

INTERNAL QC INSPECTION

29

CLEARANCE

CUSTOMER QC INSPECTION

30

CLEARANCE

BLASTING & QC INSPECTION

31

CLERANCE

APPLICATION OF RUST

32

PREVENTIVE OIL

33 QC INSPECTION FINAL CLEARANCE

Value Stream Mapping Page of Acoustics India Private Limited

VSM for Job no J1947 A3

Time Log Sheet

Date Time

Sl. No of Manpower Change Over

Activity No of Lift Rework Time Inspection Time Remarks

No. used Time

Start End Start End Total (in mins)

RAW MATERIAL INSPECTION AND

1

CLEARANCE

2 CUTTING PLAN CLEARANCE

SHROUD BODY PLATE & FACE

3

PLATE RAW MATERIAL CUTTING

4 SHROUD BODY PLATE PRESSING

5 QC INSPECTION & CLEARANCE

SHROUD BODY PLATES EXTRA

6 LENGTH (BEND SIDE) MARKING &

CUTTING

SHROUD BODY PLATES EDGE

7

PREPARTION

8 SHROUD BODY PLATES FITUP

9 QC INSPECTION & CLEARANCE

10 SHROUD BODY PLATES WELDING

TEMPLATE CHECKING BY

11

PRODUCTION

100% MT INSPECTION ON WELD

12

JOINTS

13 QC INSPECTION & CLEARANCE

SHROUD FACE PLATE EDGE

14

PREPARATION

SHROUD FACE PLATE WITH BODY

15

PLATE FITMENT

SHROUD FACE PLATE WITH BODY

16

PLATE WELDING

100% MT INSPECTION ON WELD

17

JOINTS

SHROUD BODY PLATE MARKING

18 FOR SEMIC CIRCULAR &

TRAPEZOIDAL ENDS

19 QC INSPECTION & CLEARANCE

SHROUD BODY PLATE CUTTING

20 FOR SEMIC CIRCULAR &

TRAPEZOIDAL ENDS

QC FINAL INSPECTION &

21

CLEARANCE

22 POST WELD HEAT TREATMENT

100% MT ON WELD JOINTS &

23

HARDNESS CHECKING

24 QC INSPECTION & CLEARANCE

25 SHROUD SENT FOR MACHING

26 SHROUD MACHING MARKING

27 QC INSPECTION & CLEARANCE

28 SHROUD MACHINING

INTERNAL QC INSPECTION

29

CLEARANCE

CUSTOMER QC INSPECTION

30

CLEARANCE

BLASTING & QC INSPECTION

31

CLERANCE

APPLICATION OF RUST

32

PREVENTIVE OIL

33 QC INSPECTION FINAL CLEARANCE

Value Stream Mapping Page of Acoustics India Private Limited

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- News letter Compressor 2Document1 pageNews letter Compressor 2Hanan Darmala HananNo ratings yet

- Side FacingDocument1 pageSide FacingChiller PartyNo ratings yet

- Lembar 1Document1 pageLembar 1saepudin 40No ratings yet

- Air Compressor Monthly Inspection ReportDocument1 pageAir Compressor Monthly Inspection ReportVigneshwaraNo ratings yet

- Pre-Commissioning Pipeline Pressure TestDocument19 pagesPre-Commissioning Pipeline Pressure TestTrustEmma100% (3)

- Utility ChecklistDocument30 pagesUtility ChecklistSomnath SinghNo ratings yet

- Cleanong Water TankDocument10 pagesCleanong Water Tankudan syambasulNo ratings yet

- CONVEYORDocument1 pageCONVEYORfaiqnashrullahNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- Contoh Painting ReportDocument1 pageContoh Painting ReportYudha Andrie Sasi ZenNo ratings yet

- Form Motor Solo Run Interlock FuncDocument1 pageForm Motor Solo Run Interlock FuncImam HanafiNo ratings yet

- Gas Compressor Unit (7 Compressor) ON-Z-1301 A/B/C/D/E/F/GDocument28 pagesGas Compressor Unit (7 Compressor) ON-Z-1301 A/B/C/D/E/F/GSoumitra GuptaNo ratings yet

- Checklist Concrete WorksDocument2 pagesChecklist Concrete WorksVenkataramanaiah Puli88% (33)

- LNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneDocument1 pageLNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneRajuNo ratings yet

- PPM Checklist - Air Circuit Breaker (Acb)Document1 pagePPM Checklist - Air Circuit Breaker (Acb)Mohamed Firdaus Bin ZakariaNo ratings yet

- Rotor Liquid Penetrant RecordsDocument21 pagesRotor Liquid Penetrant RecordsHimanyu RafiqNo ratings yet

- Satr A 2008Document2 pagesSatr A 2008Shahzad HussainNo ratings yet

- Daily Inspection Report: Client. Project. DRG - Title. Project No. Identity of InspectionDocument6 pagesDaily Inspection Report: Client. Project. DRG - Title. Project No. Identity of InspectionEngr Saeed AnwarNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechSajid ShaikhNo ratings yet

- Trav 53108MH92 Shank - OrigDocument1 pageTrav 53108MH92 Shank - OrigTimur SonkayaNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Remove & Install Turbocharge: Skill Certification MaterialDocument1 pageRemove & Install Turbocharge: Skill Certification MaterialnurhadiNo ratings yet

- Meenakshi Polymers 4M Change InspectionDocument4 pagesMeenakshi Polymers 4M Change InspectionKaran Malhi100% (1)

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Horas MaquinaDocument7 pagesHoras MaquinaDAVIDLUNA8No ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- Master List of Checklist New With All LOGOsDocument22 pagesMaster List of Checklist New With All LOGOsRahul Jaiswal100% (1)

- Acid TankDocument10 pagesAcid Tankudan syambasulNo ratings yet

- CGK065-Pressure Test ReportDocument4 pagesCGK065-Pressure Test ReportTWI CertificationNo ratings yet

- Sharma2018 Article ProcessCapabilityImprovementThDocument14 pagesSharma2018 Article ProcessCapabilityImprovementThharieduidNo ratings yet

- SAIC E 2010 in Situ Test OfAirCoolersDocument1 pageSAIC E 2010 in Situ Test OfAirCoolersAnonymous S9qBDVkyNo ratings yet

- Plumbing Works ChecklistDocument4 pagesPlumbing Works ChecklistAarnav SinghNo ratings yet

- Effectiveness MonitoringDocument4 pagesEffectiveness MonitoringVenkatesh KumarNo ratings yet

- Piston Manufacturing Record BookDocument3 pagesPiston Manufacturing Record BookcharlesbenwariNo ratings yet

- Frm-plt-015 Periodical Service GraderDocument3 pagesFrm-plt-015 Periodical Service GraderAbi Yusuf CahyadiNo ratings yet

- APQP Timeline PlanDocument1 pageAPQP Timeline PlanPradeep Kumar KelembathNo ratings yet

- Mobile: Project Manager: Mobile: Project Manager: MobileDocument1 pageMobile: Project Manager: Mobile: Project Manager: MobileBleep NewsNo ratings yet

- DSQR - RaltechDocument10 pagesDSQR - RaltechHimanshu MishraNo ratings yet

- Doc2020060514191604-Exp 05-2020 PPT Anexo VDocument11 pagesDoc2020060514191604-Exp 05-2020 PPT Anexo VMarcos CedeñoNo ratings yet

- Bulldozer MonthlyDocument1 pageBulldozer MonthlyFlorfloresta Alfa OneNo ratings yet

- Ttracc. - 913 T 1Document4 pagesTtracc. - 913 T 1Paolo AmaniNo ratings yet

- Quality Control: Concrete Pour RecordDocument1 pageQuality Control: Concrete Pour RecordBrookeNo ratings yet

- Sr. No. Description of Work. CharacteristicDocument3 pagesSr. No. Description of Work. Characteristicrgrao85No ratings yet

- Checklist False CeilingDocument1 pageChecklist False CeilingVenkataramanaiah PuliNo ratings yet

- CDPL-EEL-SNM-PUMP-QY-0002 - Pump Inspection and Test Procedure 4TP-47938 - R0Document23 pagesCDPL-EEL-SNM-PUMP-QY-0002 - Pump Inspection and Test Procedure 4TP-47938 - R0Amit KumarNo ratings yet

- Nom de Technicien Signature Durée D'intervention: Ordinary Maintenance 100 H For Forklift Fantuzzi (FDC250)Document8 pagesNom de Technicien Signature Durée D'intervention: Ordinary Maintenance 100 H For Forklift Fantuzzi (FDC250)Peix HichamNo ratings yet

- Concrete Works ChecklistDocument1 pageConcrete Works Checklistmallikarjuna ketheNo ratings yet

- Construction Instrument Tubing Pressure & Leak Test ProcedureDocument9 pagesConstruction Instrument Tubing Pressure & Leak Test Procedurezack zeeartNo ratings yet

- ERBIL COMBINED CYCLE POWER PROJECT TEST PACK CHECKLISTDocument38 pagesERBIL COMBINED CYCLE POWER PROJECT TEST PACK CHECKLISTAbdülHak ÖZkara100% (1)

- Satr A 2010Document2 pagesSatr A 2010nadeem shaikhNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test Reportnadeem shaikhNo ratings yet

- Cooling Tower Maintenance RecordDocument2 pagesCooling Tower Maintenance Recordtuan syarifNo ratings yet

- Line Balance 059Document39 pagesLine Balance 059smitaNo ratings yet

- SITE/10/20 Checklist for Screeding ProjectDocument5 pagesSITE/10/20 Checklist for Screeding ProjectAlphaNo ratings yet

- OBSC Production ReportDocument5 pagesOBSC Production ReportOBSC PerfectionNo ratings yet

- Caltech - Coatem NF6Document1 pageCaltech - Coatem NF6gowtham_venkat_4No ratings yet

- FDA 21 CFR Part 11 Compliance DocumentDocument15 pagesFDA 21 CFR Part 11 Compliance DocumentRamón CéspedNo ratings yet

- Staff Details - SANKARANDocument1 pageStaff Details - SANKARANgowtham_venkat_4No ratings yet

- PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation EditionDocument3 pagesPDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Editiongowtham_venkat_4No ratings yet

- QA & QC Shift Details - February 2021Document2 pagesQA & QC Shift Details - February 2021gowtham_venkat_4No ratings yet

- Thermaline 4700: Selection & Specification DataDocument4 pagesThermaline 4700: Selection & Specification Datagowtham_venkat_4No ratings yet

- Properties of Common AbrasivesDocument1 pageProperties of Common Abrasivesgowtham_venkat_4No ratings yet

- WHO 2019 Ncov IPC - Masks 2020.4 Eng PDFDocument16 pagesWHO 2019 Ncov IPC - Masks 2020.4 Eng PDFSyed DanishNo ratings yet

- Staff Details - GOWTHAMDocument1 pageStaff Details - GOWTHAMgowtham_venkat_4No ratings yet

- Avesta Welding ManualDocument300 pagesAvesta Welding Manual66apenlullenNo ratings yet

- Untitled DiagramDocument1 pageUntitled Diagramgowtham_venkat_4No ratings yet

- FlowcharTDocument1 pageFlowcharTgowtham_venkat_4No ratings yet

- Surface Preparation Standards OverviewDocument38 pagesSurface Preparation Standards OverviewEric So100% (1)

- Respirator Vs Surgical Mask Flyer - Final PDFDocument2 pagesRespirator Vs Surgical Mask Flyer - Final PDFshanu khanNo ratings yet

- Indian Standard: Code of Practice FOR Design and Construction of Shallow Foundations On RocksDocument15 pagesIndian Standard: Code of Practice FOR Design and Construction of Shallow Foundations On RocksjndlsmtNo ratings yet

- Is 2830 1992Document9 pagesIs 2830 1992Sunny SaparNo ratings yet

- Indian Standard875Document10 pagesIndian Standard875Mohammad Tawfiq WaraNo ratings yet

- 1 .ASM HandbookDocument3 pages1 .ASM Handbookgowtham_venkat_40% (2)

- Supply and Fabrication Steel Structures SpecificationDocument18 pagesSupply and Fabrication Steel Structures Specificationgowtham_venkat_4No ratings yet

- Pregatirea Suprafetelor Pentru VopsireDocument4 pagesPregatirea Suprafetelor Pentru VopsireValentin GalbenNo ratings yet

- Gas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task AnalysisDocument6 pagesGas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task Analysisgowtham_venkat_4No ratings yet

- VSM 1Document1 pageVSM 1gowtham_venkat_4No ratings yet

- Weldability of High Performance SteelsDocument16 pagesWeldability of High Performance Steelsgowtham_venkat_4No ratings yet

- EN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 OnwardsDocument1 pageEN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 Onwardsgowtham_venkat_4No ratings yet

- Nitric Acid Manufacturing ProcessDocument7 pagesNitric Acid Manufacturing ProcessLenin PrabhuNo ratings yet

- Flow Side Asy LHDocument1 pageFlow Side Asy LHgowtham_venkat_4No ratings yet

- 21055-Acoustics India - 15nosDocument27 pages21055-Acoustics India - 15nosgowtham_venkat_4No ratings yet

- Cosmos Products: Technical Service Data SheetDocument1 pageCosmos Products: Technical Service Data Sheetgowtham_venkat_4No ratings yet

- Threads Standard Reference Guide Rev4 PDFDocument21 pagesThreads Standard Reference Guide Rev4 PDFPham CongNo ratings yet

- Surrealismo TriplevDocument13 pagesSurrealismo TriplevVictor LunaNo ratings yet

- Afro Asian LiteratureDocument62 pagesAfro Asian LiteratureNicsyumulNo ratings yet

- Kim Hoff PAR 117 JDF 1115 Separation AgreementDocument9 pagesKim Hoff PAR 117 JDF 1115 Separation AgreementlegalparaeagleNo ratings yet

- Motor-Catalog English 2013 PDFDocument80 pagesMotor-Catalog English 2013 PDFILham Dwi PutraNo ratings yet

- Evosys Fixed Scope Offering For Oracle Fusion Procurement Cloud ServiceDocument12 pagesEvosys Fixed Scope Offering For Oracle Fusion Procurement Cloud ServiceMunir AhmedNo ratings yet

- Tsu m7 Practice Problems Integral CalculusDocument1 pageTsu m7 Practice Problems Integral CalculusJAMNo ratings yet

- Sadie's Drawing Materials: Buy Your Supplies atDocument5 pagesSadie's Drawing Materials: Buy Your Supplies atAlison De Sando ManzoniNo ratings yet

- Midterm Exam Report Python code Fibonacci sequenceDocument2 pagesMidterm Exam Report Python code Fibonacci sequenceDim DimasNo ratings yet

- Diseñadores Del Siglo XX - Las Figuras Clave Del Diseño y - Dormer, Peter - 1993 - Barcelona - Ceac - 9780747202684 - Anna's ArchiveDocument264 pagesDiseñadores Del Siglo XX - Las Figuras Clave Del Diseño y - Dormer, Peter - 1993 - Barcelona - Ceac - 9780747202684 - Anna's ArchiveSilvina RodríguezNo ratings yet

- MgstreamDocument2 pagesMgstreamSaiful ManalaoNo ratings yet

- Window On The Wetlands BrochureDocument2 pagesWindow On The Wetlands BrochureliquidityNo ratings yet

- Sustainable Farming FPO Promotes Natural AgricultureDocument4 pagesSustainable Farming FPO Promotes Natural AgricultureSHEKHAR SUMITNo ratings yet

- Sesame Seed: T. Y. Tunde-Akintunde, M. O. Oke and B. O. AkintundeDocument20 pagesSesame Seed: T. Y. Tunde-Akintunde, M. O. Oke and B. O. Akintundemarvellous ogbonnaNo ratings yet

- Moldavian DressDocument16 pagesMoldavian DressAnastasia GavrilitaNo ratings yet

- Deconstuctionist CriticismDocument3 pagesDeconstuctionist CriticismStephanie PVNo ratings yet

- SMEspdfDocument13 pagesSMEspdflilpumpdidnothingwrong dNo ratings yet

- Bread and Pastry Production NC II 1st Edition 2016Document454 pagesBread and Pastry Production NC II 1st Edition 2016Brian Jade CadizNo ratings yet

- 10th IIT Foundation PDFDocument170 pages10th IIT Foundation PDFbondala pavan100% (1)

- Development Plan-Part IV, 2022-2023Document3 pagesDevelopment Plan-Part IV, 2022-2023Divina bentayao100% (5)

- 3.part I-Foundations of Ed (III)Document25 pages3.part I-Foundations of Ed (III)Perry Arcilla SerapioNo ratings yet

- ENGLISH 7 FIRST QUARTER EXAMDocument2 pagesENGLISH 7 FIRST QUARTER EXAMAlleli Faith Leyritana100% (1)

- Form of SpesDocument2 pagesForm of SpesMark Dave SambranoNo ratings yet

- What Is The Time Value of MoneyDocument6 pagesWhat Is The Time Value of MoneySadia JuiNo ratings yet

- Phaser 6510WC6515 Brochure EnglishDocument4 pagesPhaser 6510WC6515 Brochure EnglishToma ObretenovNo ratings yet

- A Text-Book of Colloquial Japanese, Based On The Lehrbuch Der Japanischen Umgangssprache by Dr. Rudolf Lange (1907)Document634 pagesA Text-Book of Colloquial Japanese, Based On The Lehrbuch Der Japanischen Umgangssprache by Dr. Rudolf Lange (1907)asdf123123100% (1)

- Credit As A Means of Investment in Medieval Islamic TradDocument6 pagesCredit As A Means of Investment in Medieval Islamic TradIfanaNo ratings yet

- New Monasticism: An Interspiritual Manifesto For Contemplative Life in The 21st CenturyDocument32 pagesNew Monasticism: An Interspiritual Manifesto For Contemplative Life in The 21st CenturyWorking With Oneness100% (8)

- PRAGMATISMDocument22 pagesPRAGMATISMChristian Jay A MoralesNo ratings yet

- The Merchant of Venice QuestionsDocument9 pagesThe Merchant of Venice QuestionsHaranath Babu50% (4)

- Return Snowball Device SafelyDocument1 pageReturn Snowball Device SafelyNoneNo ratings yet