Professional Documents

Culture Documents

Saudi Arabian Oil Company: 18.0 Packing and Preparation For Shipment

Uploaded by

Parthiban ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Arabian Oil Company: 18.0 Packing and Preparation For Shipment

Uploaded by

Parthiban RCopyright:

Available Formats

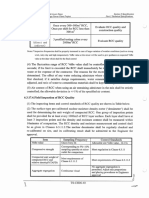

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

AAB SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

material is below the strength of that material at room temperature, the hydrostatic

WAB

test pressure shall be multiplied by a factor obtained by dividing the allowable

working stress for the material at room temperature by that at operating temperature.

ENGG CERT

CIB

The stress values used shall conform to those given in ASME B31.3 for piping or in

the Code for tanks. The pressure thus obtained shall then be the minimum pressure

NSA

at which the hydrostatic test shall be performed. Actual hydrostatic test pressures

shall be shown on the data sheet.

All pressure tests shall be in accordance with the requirements of the Code. In the

event a discrepancy exists between the Code test pressure and the test pressure in

this Practice, the higher pressure shall govern.

DESCRIPTION

Tests shall be maintained for a sufficient period of time (not less than 1 hour) to

ISSUED FOR CONSTRUCTION

permit complete examination of parts under pressure. The hydrostatic test shall be

considered satisfactory when no leak or drop in pressure is observed.

As the system is assembled, tank, piping, and all associated components shall be

surface-cleaned, internally inspected, and/or flushed.

All foreign material shall be removed from the pipe before connecting to the

equipment. The manufacturer’s specific pipe cleaning procedures and acceptance

19000-9284

JO/EWO

CER 11-

criteria shall be followed, unless otherwise specified on the data sheet.

07/16/19

When specified on the data sheet, a factory and site performance test shall be

DATE

performed to verify compliance with the stated or guaranteed performance.

NO.

REV

00

Continuity tests shall be performed on all electrical circuits before final inspection.

DISCIPLINE

ENGINEER

NSA All operational alarms and safety devices shall be functionally tested by simulating

07/16/19

04/14/13

DATE: the condition(s) required for actuation.

PROJECT

ENGINEER

HMA The Purchaser shall specify additional testing requirements on the data sheets.

04/14/13

07/16/19

DATE:

CERTIFIED 18.0 PACKING AND PREPARATION FOR SHIPMENT

CIB

04/14/13

07/16/19

DATE: Packing and shipping preparation shall be as per Saudi Aramco standards & Packing

CONSTRUCTION

AGENCY specification specified in the Material requisition.

WAB

DATE:

07/16/19

Spare parts and parts shipped loose shall be tagged with the Vendor’s part numbers or

OPERATIONS item numbers and the equipment tag numbers for easy identification.

ABB

07/16/19 All openings shall be protected/sealed with gaskets and carbon steel blinds.

DATE:

CONTROL NUMBER

VERIFICATION

All connections not to be connected to COMPANY’S piping shall be supplied with

EDSD

gaskets, bolts and blinds.

DATE:

BY:

All interconnections to COMPANY’S equipment/piping shall be clearly designated and

REVISIONCERTIFICATION

labeled accordingly.

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

00 A

11-19000-9284-001

Vendor shall include with the shipment of items a signed release for shipment form. It is

(DCC) NO. _____________________

the Vendor responsibility to obtain the signature from the COMPANY authorized

TECHNICAL SPECIFICATIONS FOR CORROSION INHIBITOR INJECTION DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

SKID TIE-IN HRML-824 WS WELL TO HRML PWI DOC

434 TE- 126923 28

GOSP A OF 00

HARMALIYAH SAUDI ARABIA JO / EWO:

11-19000-9284 31

EDSD/2616-0399.doc

You might also like

- Code Case 2742 - Sec XDocument2 pagesCode Case 2742 - Sec XlincinkrishnanNo ratings yet

- Load Testing of Motors: Common Methods, Procedures: Test Can Verify Nameplate RatingDocument3 pagesLoad Testing of Motors: Common Methods, Procedures: Test Can Verify Nameplate RatingAli JafferyNo ratings yet

- App 1 PDFDocument2 pagesApp 1 PDFSantos RandazzoNo ratings yet

- Section 3 Performance RequirementsDocument1 pageSection 3 Performance RequirementsAbit BronjaNo ratings yet

- Gas Pressure RegulatorDocument5 pagesGas Pressure RegulatormusaveerNo ratings yet

- UG-99 Standard Hydrostatic Test: ASME BPVC - VIII.1-2019 UG-99Document3 pagesUG-99 Standard Hydrostatic Test: ASME BPVC - VIII.1-2019 UG-99sergiotero100% (1)

- Equation of State Influences On Compressor Performance 1713501505Document10 pagesEquation of State Influences On Compressor Performance 1713501505thakuryaNo ratings yet

- Al-Muslin, H. Develop Acceptance Criteria of Pressure Test of Buried Pipeline Using Uncertainity Analysis. 2011Document8 pagesAl-Muslin, H. Develop Acceptance Criteria of Pressure Test of Buried Pipeline Using Uncertainity Analysis. 2011IvanRodriguezNo ratings yet

- Condition Monitoring and Diagnostic Aspects of Gas Turbine PDFDocument10 pagesCondition Monitoring and Diagnostic Aspects of Gas Turbine PDFchdiNo ratings yet

- Aashto T209-12Document15 pagesAashto T209-12Emran BanatNo ratings yet

- Etso-C71 Cs-Etso 0Document6 pagesEtso-C71 Cs-Etso 0Egis ShegaNo ratings yet

- Badotherm BaseCal Web-Based Performance ToolDocument6 pagesBadotherm BaseCal Web-Based Performance ToolRizky MuhammadNo ratings yet

- Astm d3236 1988 PDFDocument10 pagesAstm d3236 1988 PDFHsaam HsaamNo ratings yet

- Apparent Viscosity of Hot Melt Adhesives and Coating MaterialsDocument8 pagesApparent Viscosity of Hot Melt Adhesives and Coating MaterialsAshref HasanNo ratings yet

- Stationary Sprinkler: Irrigation SystemDocument21 pagesStationary Sprinkler: Irrigation Systempolanski12345No ratings yet

- Functional Safety Oriented Compressor Surge ModellingDocument4 pagesFunctional Safety Oriented Compressor Surge ModellingemaengNo ratings yet

- ASME B31.3 Golden WeldDocument1 pageASME B31.3 Golden WeldmohamedNo ratings yet

- SD PDFDocument7 pagesSD PDFTech To BarNo ratings yet

- Pressure Testing Piping Systems: The Test RequirementDocument3 pagesPressure Testing Piping Systems: The Test RequirementnainaNo ratings yet

- SPE6760 - Determining Stressintubing Usingtriaxial EvaluationDocument8 pagesSPE6760 - Determining Stressintubing Usingtriaxial EvaluationYoucef Benferdi100% (1)

- Sizing Steam TrapsDocument4 pagesSizing Steam Trapsjesus_manrique2753No ratings yet

- PDF Del Nuevo Publicado en 1983 PDFDocument12 pagesPDF Del Nuevo Publicado en 1983 PDFpepeNo ratings yet

- Saudi Arabian Oil Company: 14.0 Coating/PaintingDocument1 pageSaudi Arabian Oil Company: 14.0 Coating/PaintingParthiban RNo ratings yet

- Aama 501-1-05Document7 pagesAama 501-1-05ELENA NAVAS100% (1)

- 1562WKS 17 Energy Safety COP For Harmonic LevelsDocument16 pages1562WKS 17 Energy Safety COP For Harmonic LevelsgastonmdqNo ratings yet

- Piping For Process Plants Part 6 PDFDocument7 pagesPiping For Process Plants Part 6 PDFSandra MArrugoNo ratings yet

- Water Resistance Testing of Windows and DoorsDocument78 pagesWater Resistance Testing of Windows and Doorsanwarali1975No ratings yet

- Purcell 1949Document10 pagesPurcell 1949pavka789No ratings yet

- Astm D4402Document4 pagesAstm D4402jegancivilNo ratings yet

- Ais 037Document53 pagesAis 037sharad.neoNo ratings yet

- Theoretical Maximum Specific Gravity and Density of Hot Mix Asphalt (HMA)Document3 pagesTheoretical Maximum Specific Gravity and Density of Hot Mix Asphalt (HMA)Budhi KurniawanNo ratings yet

- eveηr 300~500m3Document1 pageeveηr 300~500m3dana setiawanNo ratings yet

- Nissens AC System Diagnostics Poster 98x68+-+Operating+Pressures+R134A+-+ENGDocument1 pageNissens AC System Diagnostics Poster 98x68+-+Operating+Pressures+R134A+-+ENGВладислав Якубов0% (1)

- 8.3.2 General Test ConditionsDocument1 page8.3.2 General Test Conditionsevonik123456No ratings yet

- C 260 - 00 Qzi2mc1sruqDocument5 pagesC 260 - 00 Qzi2mc1sruqTemur LomidzeNo ratings yet

- 06hsfuse PDFDocument126 pages06hsfuse PDFvoNo ratings yet

- A High-Speed Earthing Switch in Gas-InsulatedDocument6 pagesA High-Speed Earthing Switch in Gas-InsulatedFranco MolinaNo ratings yet

- Pipeline and Hazardous Materials Safety Admin., DOT 178.337-3Document4 pagesPipeline and Hazardous Materials Safety Admin., DOT 178.337-3AssemNo ratings yet

- Project Data MiningDocument4 pagesProject Data MiningMuhammad SalmanNo ratings yet

- Apparent Viscosity of Asphalt Emulsion Residues and Non-Newtonian Bitumens by Vacuum Capillary ViscometerDocument7 pagesApparent Viscosity of Asphalt Emulsion Residues and Non-Newtonian Bitumens by Vacuum Capillary ViscometerJuan Carlos MejiaNo ratings yet

- Obtaining Hydrostatic Design Basis For Thermoplastic Pipe Materials or Pressure Design Basis For Thermoplastic Pipe ProductsDocument16 pagesObtaining Hydrostatic Design Basis For Thermoplastic Pipe Materials or Pressure Design Basis For Thermoplastic Pipe ProductsDuy NguyenNo ratings yet

- Optical Measurement of The Valve Temperature - A Precise Measuring Method - Porsche Engineering Magazine 01-2015Document3 pagesOptical Measurement of The Valve Temperature - A Precise Measuring Method - Porsche Engineering Magazine 01-2015emperor_vamsiNo ratings yet

- Leak Testing USP40 Chap 1207.2Document16 pagesLeak Testing USP40 Chap 1207.2Ha0% (1)

- What Is The Function of Turbine DroopDocument48 pagesWhat Is The Function of Turbine Droopanon_246649396100% (1)

- B.R. Pedersen, Baker Hughes INTEQ, J. Zajaczkowski, Statoil: Service DescriptionDocument3 pagesB.R. Pedersen, Baker Hughes INTEQ, J. Zajaczkowski, Statoil: Service Descriptionme firmansyahNo ratings yet

- Astm D877-87Document4 pagesAstm D877-87Pancho Flores100% (1)

- 35-sdms-01 Rev.01Document14 pages35-sdms-01 Rev.01Mohammad FathiNo ratings yet

- TheFuelRateIndicator Bosch66Document22 pagesTheFuelRateIndicator Bosch66ennioNo ratings yet

- ASTM D 2171 - 01 (Standard Test Method For Viscosity of Asphalts by Vacuum Capillary Viscometer)Document8 pagesASTM D 2171 - 01 (Standard Test Method For Viscosity of Asphalts by Vacuum Capillary Viscometer)Sudip MukhopadhyayNo ratings yet

- Ta2 6015 WSN00129Document10 pagesTa2 6015 WSN00129mourtalla.rabeNo ratings yet

- Testing Application Standard TAS 201-94Document6 pagesTesting Application Standard TAS 201-94Shawn DeolNo ratings yet

- At2 de 336DLDocument7 pagesAt2 de 336DLAngelo Reyes G.No ratings yet

- Iecvsjec LDocument3 pagesIecvsjec LBosko BajalicaNo ratings yet

- Nitriding DatasheetDocument4 pagesNitriding DatasheetamitNo ratings yet

- CFR 2011 Title49 Vol3 Sec192 513Document1 pageCFR 2011 Title49 Vol3 Sec192 513AssemNo ratings yet

- ARP5996A-Evaluation of Coking Propensity of Aviation Lubricants Using The Hot Liquid Process Simulator (HLPS) Single Phase Flow TechniqueDocument17 pagesARP5996A-Evaluation of Coking Propensity of Aviation Lubricants Using The Hot Liquid Process Simulator (HLPS) Single Phase Flow TechniqueJicheng PiaoNo ratings yet

- Atmospherc Pressure Vs AltitudeDocument1 pageAtmospherc Pressure Vs Altitudezoran cukovicNo ratings yet

- WIKA - BAN - GB - 10-02Document1 pageWIKA - BAN - GB - 10-02Mohamed MusaNo ratings yet

- Web SlingsDocument25 pagesWeb SlingsParthiban RNo ratings yet

- Direct Charge Purchase Requisition ERDD Maintenance DivisionDocument1 pageDirect Charge Purchase Requisition ERDD Maintenance DivisionParthiban RNo ratings yet

- Saudi Aramco: Company General UseDocument1 pageSaudi Aramco: Company General UseParthiban RNo ratings yet

- Notes: Total Amount (USD) 15% VAT (USD) Net Total Amount (USD)Document1 pageNotes: Total Amount (USD) 15% VAT (USD) Net Total Amount (USD)Parthiban RNo ratings yet

- Saudi Aramco: Company General UseDocument1 pageSaudi Aramco: Company General UseParthiban RNo ratings yet

- Saudi Aramco: Company General UseDocument1 pageSaudi Aramco: Company General UseParthiban RNo ratings yet

- Loadout Analysis TRNC02955-10001 1Document1 pageLoadout Analysis TRNC02955-10001 1Parthiban RNo ratings yet

- Saudi Arabian Oil Company: 17.2 TestingDocument1 pageSaudi Arabian Oil Company: 17.2 TestingParthiban RNo ratings yet

- Saudi Arabian Oil Company: 2.1 Project DocumentsDocument1 pageSaudi Arabian Oil Company: 2.1 Project DocumentsParthiban RNo ratings yet

- Saudi Arabian Oil Company: End of SpecificationDocument1 pageSaudi Arabian Oil Company: End of SpecificationParthiban RNo ratings yet

- Saudi Arabian Oil Company: 19.0 LubricationDocument1 pageSaudi Arabian Oil Company: 19.0 LubricationParthiban RNo ratings yet

- Saudi Arabian Oil Company: 14.0 Coating/PaintingDocument1 pageSaudi Arabian Oil Company: 14.0 Coating/PaintingParthiban RNo ratings yet

- Saudi Arabian Oil Company: 21.0 Pre-Commissioning and CommissioningDocument1 pageSaudi Arabian Oil Company: 21.0 Pre-Commissioning and CommissioningParthiban RNo ratings yet

- Saudi Arabian Oil CompanyDocument1 pageSaudi Arabian Oil CompanyParthiban RNo ratings yet

- Saudi Arabian Oil Company: 13.0 Instrumentation and ControlDocument1 pageSaudi Arabian Oil Company: 13.0 Instrumentation and ControlParthiban RNo ratings yet

- Schedule of BenefitsDocument1 pageSchedule of BenefitsParthiban RNo ratings yet

- How Much Value PDFDocument1 pageHow Much Value PDFParthiban RNo ratings yet

- What Is Fiscal MeteringDocument1 pageWhat Is Fiscal MeteringParthiban RNo ratings yet

- Saudi Arabian Oil Company: 12.0 ElectricalDocument1 pageSaudi Arabian Oil Company: 12.0 ElectricalParthiban RNo ratings yet

- How Much ValueDocument1 pageHow Much ValueParthiban RNo ratings yet

- How Much Value PDFDocument1 pageHow Much Value PDFParthiban RNo ratings yet

- Chapter 1Document1 pageChapter 1Parthiban RNo ratings yet

- CVDocument1 pageCVVinodrajNo ratings yet

- Provide and Ensure Space For Float RemovalDocument1 pageProvide and Ensure Space For Float RemovalParthiban RNo ratings yet

- Resolution PDFDocument2 pagesResolution PDFParthiban RNo ratings yet

- SecxDocument1 pageSecxSham GaerlanNo ratings yet

- Agenda PDFDocument1 pageAgenda PDFParthiban RNo ratings yet

- 526Document13 pages526jeas grejoy andrewsNo ratings yet

- Higgins - A 9 PDFDocument1 pageHiggins - A 9 PDFParthiban RNo ratings yet

- JWT Magazine December 2023Document130 pagesJWT Magazine December 2023Arbab AlamNo ratings yet

- Official Websites: How To Determine Applicable Product Safety Standards: 5 MethodsDocument9 pagesOfficial Websites: How To Determine Applicable Product Safety Standards: 5 MethodsChandru HanchinalNo ratings yet

- PLC S7 1200 Cpu1214cDocument8 pagesPLC S7 1200 Cpu1214cbsb1912No ratings yet

- Caja de Super 10Document178 pagesCaja de Super 10AnGel Amaya100% (1)

- 8 5 3 NotesDocument3 pages8 5 3 Notesejr3ganNo ratings yet

- Spread Spectrum Techniques FHSSDocument27 pagesSpread Spectrum Techniques FHSSvarun m s s sNo ratings yet

- ErC-DU Planning Manual 10aug2009Document45 pagesErC-DU Planning Manual 10aug2009berto_diego100% (14)

- DHI-NVR2116-4KS2 Datasheet 20171212 PDFDocument3 pagesDHI-NVR2116-4KS2 Datasheet 20171212 PDFRen RenNo ratings yet

- Webdispatcher TimeoutsDocument9 pagesWebdispatcher Timeoutsowl meadowNo ratings yet

- Introduction To Namespaces: Figure ADocument6 pagesIntroduction To Namespaces: Figure ASangeetha BajanthriNo ratings yet

- program Name: Departmental StoreDocument6 pagesprogram Name: Departmental StoreAkshara ReddyNo ratings yet

- How To Configure Site-To-Site IKEv2 IPSec VPN Using Pre-Shared Key AuthenticationDocument14 pagesHow To Configure Site-To-Site IKEv2 IPSec VPN Using Pre-Shared Key AuthenticationCoolzero CoolzeroNo ratings yet

- 21-01-01 Ericsson v. Samsung EDTX Amended ComplaintDocument62 pages21-01-01 Ericsson v. Samsung EDTX Amended ComplaintFlorian MuellerNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- PCB Design RuleDocument43 pagesPCB Design RuletrinhdieuhvktqsNo ratings yet

- Free 3 of 9Document1 pageFree 3 of 9yspn2006No ratings yet

- Safety Observer DefinitionsDocument6 pagesSafety Observer DefinitionsWarwick AudetNo ratings yet

- D6377-20 Presión de VaporDocument8 pagesD6377-20 Presión de VaporAngel MurilloNo ratings yet

- Arduino and Visual Basic Part 2 - Receiving Data From The Arduino - Martyn CurreyDocument26 pagesArduino and Visual Basic Part 2 - Receiving Data From The Arduino - Martyn CurreysabteleNo ratings yet

- Trezorerie Municipiul SF - GheorDocument1 pageTrezorerie Municipiul SF - GheorDeny DenisaNo ratings yet

- SD 9100G PDFDocument65 pagesSD 9100G PDFkirilla2006No ratings yet

- CCNA Exploration 2: Chapter 2 Toets Antwoorden / CCNA Routing Protocols and Concepts Exam 2 AnswersDocument6 pagesCCNA Exploration 2: Chapter 2 Toets Antwoorden / CCNA Routing Protocols and Concepts Exam 2 AnswersHei NekenNo ratings yet

- Durco IOM Big MX Butterfly Valve V-380-E PDFDocument28 pagesDurco IOM Big MX Butterfly Valve V-380-E PDFUtku Kepcen100% (1)

- MobileComm Corporate ProfileDocument28 pagesMobileComm Corporate ProfileArshadullah KhanNo ratings yet

- DesktopDocument24 pagesDesktopSubramanyam IbsNo ratings yet

- Senr6564 10 01 AllDocument208 pagesSenr6564 10 01 AllGianna Frola100% (1)

- Surface Safety Valve PsDocument2 pagesSurface Safety Valve PsmirzasdNo ratings yet

- 7900 RangeDocument16 pages7900 RangePhilippine Bus Enthusiasts SocietyNo ratings yet

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To Informationarindam_chowdhu1926No ratings yet

- Kokan Mercantile Co-Operative Bank LTD.: Grievance Redressal PolicyDocument3 pagesKokan Mercantile Co-Operative Bank LTD.: Grievance Redressal Policy077 - Ubaid dhansayNo ratings yet