Professional Documents

Culture Documents

Saudi Arabian Oil Company

Uploaded by

Parthiban ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Arabian Oil Company

Uploaded by

Parthiban RCopyright:

Available Formats

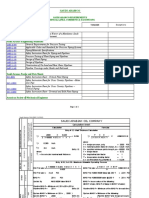

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

AAB SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

xii. Operation & Maintenance Manuals

WAB

xiii. Alarm List

ENGG CERT

CIB

xiv. Calibration sheet

NSA

xv. All required certificate

All Vendor developed documents and drawings shall comply with the requirements

of SAES-J-003.

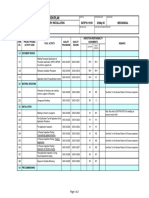

Vendor shall be responsible for producing final shop drawings for the Corrosion

Inhibitor Injection Skid that provide complete Vendor and installation details

DESCRIPTION

associated with all instrumentation and control components that form part of the

ISSUED FOR CONSTRUCTION

Corrosion Inhibitor Injection Skid. These shall be submitted to Client for review and

approval.

Vendor shall develop inspection and test procedures associated with all

instrumentation and control components that form part of the Corrosion Inhibitor

Injection Skid, which shall be submitted to Client for review and approval. These

shall be comprised of but not limited to:

19000-9284

JO/EWO

CER 11-

i. Inspection and test procedures for instrument mounting and hook ups.

ii. Inspection and test procedures for instrument tube leak / pressure testing.

07/16/19

DATE

iii. Inspection and test procedures for instrument cable, conduit and tray

installations.

NO.

REV

00

DISCIPLINE

ENGINEER Vendor shall be responsible for developing and maintaining complete QA/QC

NSA

07/16/19

04/14/13

records associated with the design, procurement installation and testing of all

DATE:

PROJECT

instrumentation including cables and hook up materials.

ENGINEER

HMA

04/14/13

Vendor has to specify and supply all instrumentation required as per P&ID to

07/16/19

DATE: ensure safe and reliable operation of the Chemical Injection Skid. Instrumentation

CERTIFIED

CIB shall be in accordance with Saudi Aramco standards and this specification.

04/14/13

07/16/19

DATE:

CONSTRUCTION

For the Corrosion Inhibitor skid Vendor shall supply and install all instrumentation.

AGENCY

WAB

Following are the instrumentation requirements for the Corrosion Inhibitor injection

07/16/19

skid.

DATE:

OPERATIONS

• One Low Low Level switch on Corrosion Inhibitor Tank.

ABB

• One Pressure Transmitter at common discharge of CI pumps

07/16/19

DATE:

• One Level transmitter to measure the CIS tank level

CONTROL NUMBER

VERIFICATION

• Reflex type Level Gauge on Corrosion Inhibitor Tank

EDSD

• One Flow transmitter at the common discharge of each Corrosion Inhibitor

DATE:

Pump

BY:

•

REVISIONCERTIFICATION

One Pressure Gauge at the discharge of each Corrosion Inhibitor Pump.

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

00 A

11-19000-9284-001

• One Pressure switch and Pressure gauge for Diaphragm detection of each

(DCC) NO. _____________________

pump.

TECHNICAL SPECIFICATIONS FOR CORROSION INHIBITOR INJECTION DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

SKID TIE-IN HRML-824 WS WELL TO HRML PWI DOC

434 TE- 126923 24

GOSP A OF 00

HARMALIYAH SAUDI ARABIA JO / EWO:

11-19000-9284 31

EDSD/2616-0399.doc

You might also like

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Ieee 603-1998Document39 pagesIeee 603-1998Arogya Raju Pudhota100% (1)

- KKS ConceptDocument6 pagesKKS ConceptAmit Nigam100% (2)

- PSA Chapter 07Document95 pagesPSA Chapter 07anggit100% (1)

- Saudi Arabian Oil Company: 13.0 Instrumentation and ControlDocument1 pageSaudi Arabian Oil Company: 13.0 Instrumentation and ControlParthiban RNo ratings yet

- Saudi Arabian Oil Company: 21.0 Pre-Commissioning and CommissioningDocument1 pageSaudi Arabian Oil Company: 21.0 Pre-Commissioning and CommissioningParthiban RNo ratings yet

- Saudi Arabian Oil Company: 17.2 TestingDocument1 pageSaudi Arabian Oil Company: 17.2 TestingParthiban RNo ratings yet

- 000-A-JD-801400-231 - Rev B SOW - Part-5 PDFDocument6 pages000-A-JD-801400-231 - Rev B SOW - Part-5 PDFSenthil KumarNo ratings yet

- Saudi Arabian Oil Company: 19.0 LubricationDocument1 pageSaudi Arabian Oil Company: 19.0 LubricationParthiban RNo ratings yet

- 000-A-JD-801400-231 - Rev B SOW - Part-4Document8 pages000-A-JD-801400-231 - Rev B SOW - Part-4Senthil KumarNo ratings yet

- Saudi Arabian Oil Company: 2.1 Project DocumentsDocument1 pageSaudi Arabian Oil Company: 2.1 Project DocumentsParthiban RNo ratings yet

- Saudi Arabian Oil Company: 5.5 TANK H45-D-8B Fire Detection & Foam Skid H45-U-0104 ActivationDocument2 pagesSaudi Arabian Oil Company: 5.5 TANK H45-D-8B Fire Detection & Foam Skid H45-U-0104 Activationsalman1111aNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- SAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Document3 pagesSAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Anonymous S9qBDVkyNo ratings yet

- SAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresDocument4 pagesSAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- Helipad Lighting SystemDocument11 pagesHelipad Lighting SystemEhsan ShaukatNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldDocument13 pagesSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- SAIC N 2019 ReviewVerifyApplicatorPre QualRecord EL RevDocument2 pagesSAIC N 2019 ReviewVerifyApplicatorPre QualRecord EL RevAnonymous S9qBDVkyNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- SACIC-CV-0001 Rev.04 Survey and CoordinatesDocument3 pagesSACIC-CV-0001 Rev.04 Survey and CoordinatesEr Nizamuddin AliNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet

- Communication Scope of Work BI-10-01483-0002Document18 pagesCommunication Scope of Work BI-10-01483-0002Afareen KhanNo ratings yet

- SAIC-W-2007 Rev 8Document6 pagesSAIC-W-2007 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- Saudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldAbdul Khaleem KhanNo ratings yet

- RE-286330 - MS Installation & Commissioning Rev ADocument12 pagesRE-286330 - MS Installation & Commissioning Rev AJohn Philip Buntales100% (1)

- Instrument Air - Gate Valve Data SheetDocument2 pagesInstrument Air - Gate Valve Data SheetHabib ur rahmanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldDocument6 pagesSaudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Aramco Scaffolding Safety-1Document17 pagesAramco Scaffolding Safety-1ATUL CHAUGULENo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- 59-Qa60-R-201 - 0 - Equipment Numbering SystemDocument59 pages59-Qa60-R-201 - 0 - Equipment Numbering SystemNad EemNo ratings yet

- 1 SATIP-N-110-01 Castable Refractory InstallationDocument2 pages1 SATIP-N-110-01 Castable Refractory Installationsonalisabir100% (1)

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- SAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld InspectionDocument5 pagesSAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld Inspectionاحمد حسنNo ratings yet

- SAIC-W-2005 Rev 8Document5 pagesSAIC-W-2005 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19Document3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19harisNo ratings yet

- SATIP Q 006 02 (Recovered)Document10 pagesSATIP Q 006 02 (Recovered)Abdul HannanNo ratings yet

- Instrument and Telecom Cable List: Saudi Arabian Oil CompanyDocument9 pagesInstrument and Telecom Cable List: Saudi Arabian Oil CompanyKarim Abd El HamidNo ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- SAIC-W-2086 In-Process Welding Inspection PDFDocument5 pagesSAIC-W-2086 In-Process Welding Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- SAIC-Q-1043 Asphalt Core Density Testing InspectionDocument3 pagesSAIC-Q-1043 Asphalt Core Density Testing InspectionAbdul HannanNo ratings yet

- Nitrogrn - Gate Valve Data SheetDocument2 pagesNitrogrn - Gate Valve Data SheetHabib ur rahmanNo ratings yet

- GEMSS-E-15 Rev 02current TransformersDocument12 pagesGEMSS-E-15 Rev 02current Transformersmohammad kassarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saic M 1067Document2 pagesSaic M 1067mathew.genesis.inspNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Basheer VadakkethilNo ratings yet

- Safety Requirements For ScaffoldsDocument17 pagesSafety Requirements For ScaffoldsRackie Enriquez83% (6)

- Web SlingsDocument25 pagesWeb SlingsParthiban RNo ratings yet

- Direct Charge Purchase Requisition ERDD Maintenance DivisionDocument1 pageDirect Charge Purchase Requisition ERDD Maintenance DivisionParthiban RNo ratings yet

- Saudi Aramco: Company General UseDocument1 pageSaudi Aramco: Company General UseParthiban RNo ratings yet

- Notes: Total Amount (USD) 15% VAT (USD) Net Total Amount (USD)Document1 pageNotes: Total Amount (USD) 15% VAT (USD) Net Total Amount (USD)Parthiban RNo ratings yet

- Saudi Aramco: Company General UseDocument1 pageSaudi Aramco: Company General UseParthiban RNo ratings yet

- Saudi Aramco: Company General UseDocument1 pageSaudi Aramco: Company General UseParthiban RNo ratings yet

- Loadout Analysis TRNC02955-10001 1Document1 pageLoadout Analysis TRNC02955-10001 1Parthiban RNo ratings yet

- Saudi Arabian Oil Company: 18.0 Packing and Preparation For ShipmentDocument1 pageSaudi Arabian Oil Company: 18.0 Packing and Preparation For ShipmentParthiban RNo ratings yet

- Saudi Arabian Oil Company: 2.1 Project DocumentsDocument1 pageSaudi Arabian Oil Company: 2.1 Project DocumentsParthiban RNo ratings yet

- Saudi Arabian Oil Company: End of SpecificationDocument1 pageSaudi Arabian Oil Company: End of SpecificationParthiban RNo ratings yet

- Saudi Arabian Oil Company: 14.0 Coating/PaintingDocument1 pageSaudi Arabian Oil Company: 14.0 Coating/PaintingParthiban RNo ratings yet

- Schedule of BenefitsDocument1 pageSchedule of BenefitsParthiban RNo ratings yet

- How Much Value PDFDocument1 pageHow Much Value PDFParthiban RNo ratings yet

- What Is Fiscal MeteringDocument1 pageWhat Is Fiscal MeteringParthiban RNo ratings yet

- Saudi Arabian Oil Company: 12.0 ElectricalDocument1 pageSaudi Arabian Oil Company: 12.0 ElectricalParthiban RNo ratings yet

- How Much ValueDocument1 pageHow Much ValueParthiban RNo ratings yet

- How Much Value PDFDocument1 pageHow Much Value PDFParthiban RNo ratings yet

- Chapter 1Document1 pageChapter 1Parthiban RNo ratings yet

- CVDocument1 pageCVVinodrajNo ratings yet

- Provide and Ensure Space For Float RemovalDocument1 pageProvide and Ensure Space For Float RemovalParthiban RNo ratings yet

- Resolution PDFDocument2 pagesResolution PDFParthiban RNo ratings yet

- SecxDocument1 pageSecxSham GaerlanNo ratings yet

- Agenda PDFDocument1 pageAgenda PDFParthiban RNo ratings yet

- 526Document13 pages526jeas grejoy andrewsNo ratings yet

- Higgins - A 9 PDFDocument1 pageHiggins - A 9 PDFParthiban RNo ratings yet

- Basic DesignDocument18 pagesBasic DesignM AhmadNo ratings yet

- Measurements and InstrumentationsDocument2 pagesMeasurements and InstrumentationsmaheshboobalanNo ratings yet

- Exxon ResumeDocument3 pagesExxon Resumeapi-273808824No ratings yet

- A081 ILFM AD 0049 RevDocument65 pagesA081 ILFM AD 0049 RevMarcus BarberNo ratings yet

- Branch CodeDocument3 pagesBranch CodeAhir MukherjeeNo ratings yet

- Senior Electrical Instrumentation Designer in Houston TX Resume Thanh NguyenDocument2 pagesSenior Electrical Instrumentation Designer in Houston TX Resume Thanh NguyenThanhNguyenNo ratings yet

- Piping & Instrumentation Diagram P&Id: Dr. - Ing. Naveed RamzanDocument41 pagesPiping & Instrumentation Diagram P&Id: Dr. - Ing. Naveed RamzanMahmoud Abdelghafar ElhussienyNo ratings yet

- Installation Guidelines: Steam Conditioning ValvesDocument67 pagesInstallation Guidelines: Steam Conditioning ValvesSunil KNo ratings yet

- Instrumentation Design Engineering Oil Gas BrochureDocument8 pagesInstrumentation Design Engineering Oil Gas Brochuresakthivel palaniNo ratings yet

- Job Posting 10015704 - Instrumentation Technician: Start Date CompanyDocument2 pagesJob Posting 10015704 - Instrumentation Technician: Start Date CompanyZulkernain Omer TariqNo ratings yet

- Title Install or Replace, Test, and Commission Industrial Instrumentation Level 4 Credits 10Document5 pagesTitle Install or Replace, Test, and Commission Industrial Instrumentation Level 4 Credits 10renjithv_4No ratings yet

- Jawaharlal Nehru Technological University HyderabadDocument5 pagesJawaharlal Nehru Technological University HyderabadMukesh BishtNo ratings yet

- Amie AppliDocument9 pagesAmie Applimarisamy_lntNo ratings yet

- MindMap The 9 Key Elements Video 05 PRE-COMMISSIONINGDocument1 pageMindMap The 9 Key Elements Video 05 PRE-COMMISSIONINGpadmanabha007No ratings yet

- D 0000 Is Ett 00002 - 0Document16 pagesD 0000 Is Ett 00002 - 0Arnold Vasquez SalirrosasNo ratings yet

- FF TransmitterDocument4 pagesFF TransmitterTochukwu OnuohaNo ratings yet

- C12 In-Place InclinometerDocument4 pagesC12 In-Place InclinometerJulio AlcantaraNo ratings yet

- B Tech EIEDocument139 pagesB Tech EIEgaddam sarathNo ratings yet

- AamcatDocument13 pagesAamcatshwetha AlsNo ratings yet

- ISA 75.19 - 1995 - Hydro Static Testing of Control ValvesDocument34 pagesISA 75.19 - 1995 - Hydro Static Testing of Control Valvesachari_swapnil100% (1)

- Chart Recorder - Rototherm - Clearscan - ManualDocument26 pagesChart Recorder - Rototherm - Clearscan - Manualshahulkms100% (1)

- Valve MaintenanceDocument20 pagesValve MaintenanceSaka MpfmNo ratings yet

- Sonatrach Mark - VI Maintenance VOL - I PDFDocument1,016 pagesSonatrach Mark - VI Maintenance VOL - I PDFمحمد أبو لؤي100% (4)

- BME 3101 - Assignment of Chapter - 1 - Question AnswerDocument24 pagesBME 3101 - Assignment of Chapter - 1 - Question AnswerMEHEDI HASANNo ratings yet

- Seminarprojects ComDocument3 pagesSeminarprojects ComyespapaNo ratings yet

- Modern Automated Control Systems in The Oil and Gas Industry Example On Installation of Preliminary Gas Preparation KumliDocument5 pagesModern Automated Control Systems in The Oil and Gas Industry Example On Installation of Preliminary Gas Preparation KumliFernandoNo ratings yet