Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 Weld

Uploaded by

Abdul Khaleem KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 Weld

Uploaded by

Abdul Khaleem KhanCopyright:

Available Formats

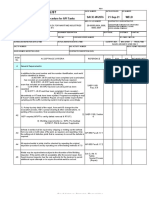

SAUDI ARAMCO ID/Project Inspection Engineering Support Unit Rev. 2014.09.

00 30-Sep-14

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WELD

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

T&I OF CONCRETE RAW WATER TANK # M-15-T-103 6511057288/6511057280 QUMAISH Y.AL-DAGHREER CO

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

N/A N/A N/A N/A

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

N/A N/A N/A N/A

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

- -2022 - -2022 SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL

W

CONTRACTOR INSPECTION LEVEL

H

YES

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Weld Identification Numbering System (As Applicable):

In addition to the spool number and line number identification, each weld shall

be identified as follows:

A) W-01R1. W-01 weld has been completed and examination has

revealed an unacceptable discontinuity that was repaired.

B) W-01R2 - W-01R1 weld repair has been completed and exam has revealed

an unacceptable discontinuity. C) W-01RW - W-

SAEP-1160,

A1 01R2 has been cut out & joint has been rewelded

Para. 6.2

D) W-01T1 - W-01 weld has been

completed. Exam revealed ... E)

W01T2 - An unacceptable weld discontinuity or HT tests have been rejected.

Progressive sampling is reqd & "tracer" welds will be identified. Repairs on

tracer welds require further sampling and the suffix numbering system shall

progress accordingly.

Welds fabricated in the field shall be prefixed with the letter 'F' and welds SAEP-1160,

A2

fabricated in a weld shop with the letter 'S'. Para. 6.2

B General Requirements (Repairs)

Repair welding shall be performed using a properly qualified and approved SAES-W-017,

B1

procedure. AVAILABLE AT SITE FOR INSTRUCTION!!! Para. 17.3

If a weld is still not acceptable after a second repair, then PID has sole authority

SAES-W-017,

B2 for the decision to permit additional repair attempts or to require that the entire

Para. 17.1

weld be cut out.

Repair of fabrication related cracks requires the approval of SA assigned

inspector. Procedure includes inspection, excavation, approved NDT methods SAES-W-017,

B3

to verify removal of defects, and rewelding per WPS. This shall be reviewed and Para. 17.2

approved by the inspector.

Cracks that are related to the base metal or welding consumable shall be

SAES-W-017,

B4 evaluated by CSD before any repair attempts.

Para. 17.2

Crater cracks do not require special repair & shall be ground out.

The repair procedure may utilize a welding procedure previously approved by

SAES-W-017,

B5 CSD in conjunction a separate method statement, or it may be a separate

Para. 17.4

detailed welding procedure.

Repaired welds shall, as a minimum, be inspected using the original testing

SAES-W-017,

B6 method. Additional test methods (NDE, HT, PMI, etc) are also required, if

Para. 17.5

deemed necessary by the authorized SA Inspector.

C Repair of welds and base metal :

Damage or deformation to the base metal or welds, including dimensional

changes, caused by external forces (intentional or accidental) requires special

repair and inspection procedures be submitted to Saudi Aramco Inspection and

if necessary forwarded to CSD for review and approval prior to undertaking the SAES-W-017,

C1

repairs. All external bulging, Para. 17.6

deformation and damages shall be evaluated by a certified API 653

Inspector or Tank Engineer experienced in repair prior to the beginning of

any work.

Saudi Aramco: Company General Use

ER

OR

CO

PLANT NO.

PMCC / MCC NO.

N/A

TRAVEL TIME

SE ONLY

ORK PERMIT REQUIRED?

YES

RE-INSP DATE

Saudi Aramco: Company General Use

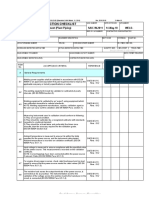

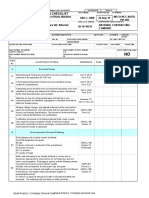

SAUDI ARAMCO ID/Project Inspection Engineering Support Unit Rev. 2014.09.00 30-Sep-14

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WELD

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

T&I OF CONCRETE RAW WATER TANK # M-15-T-103 6511057288/6511057280 QUMAISH Y.AL-DAGHREER CO

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Arc strikes, gouges, and other indications of careless workmanship (such as

SAES-W-017,

C2 surface porosity, uneven weld profiles, and undercut) shall be removed by

Para. 10.6

grinding.

Temporary welded attachments or temporary tack welds shall be removed by a

method that will not cause tearing or bending of the base metal. The method

used shall not reduce the thickness of the base metal below the minimum

specified thickness. (Technique) 1. Tank

construction aids (temporary attachments) holding shell courses together

shall not be removed by hammer. 2. Rather,

SAES-W-017,

C3 grinding of temporary welds shall be sufficient to decrease weld size so

Para. 10.7

that attachments can be tapped off and removed by hammer, not beaten.

One hand taps with the hammer and one hand holds the attachment from

fall. 3. Complete repairs by removing all weld

protrusions flush to sound metal & MT.

EVIDENCE OF HAMMER MARKS ARE UNACCEPTABLE TO

SA.

If the component thickness exceeds 20 mm, or the SMYS > 290 MPa, MT or PT

of areas are performed where temporary welds have been removed, or weld SAES-W-017,

C4

repairs to ground areas of the base material have been made, or arc strikes Para. 10.9

after repair by grinding.

If any grinding reduces the base metal thickness < the design minimum, the

ground area shall be rewelded and ground flush with the original base metal SAES-W-017,

C5

surface or the component shall be replaced. Rewelding shall be done only with Para. 10.8

the prior approval SA/PID.

D Welder & Welding Operator Qualification:

All welders shall be qualified in accordance with ASME SEC IX and SAEP-321, SAES-W-017,

D1

SAEP-323, and SAEP-324, as applicable, for all welding, including repair welds. Para. 8.1

All properly certified Contractor welders shall be registered by PID and issued a SAES-W-017,

D3

valid JCC prior to the start of the work. Para. 8.1

Remarks

REFERENCE DOCUMENTS:

1. SAEP-1160, Tracking and Reporting of Welding, NDT and Pressure Testing for Capital Projects, (10 July 2011)

2. SAES-W-017, Welding Requirements for API Tanks, (13 December 2011)

3. SAEP-324, Certification Review and Registration of Project Welders and Brazers, (27 September 2009)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

khaleem khan

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

ER

OR

GHREER CO

RE-INSP DATE

Work Verified

Work Verified

Work Verified

ES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Weld Repair Procedure ReviewDocument9 pagesSaudi Aramco Weld Repair Procedure ReviewIrshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Inspect Weld OverlaysDocument3 pagesInspect Weld OverlaysRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Basheer VadakkethilNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- SAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresDocument4 pagesSAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- Sac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API TanksDocument14 pagesSac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API Tankshusnain aliNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- SAIC-W-2086 In-Process Welding Inspection PDFDocument5 pagesSAIC-W-2086 In-Process Welding Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldDocument23 pagesSaudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- SAIC-W-2005 Rev 8Document5 pagesSAIC-W-2005 Rev 8saravananmenmathiNo ratings yet

- Saic W 2005Document1 pageSaic W 2005Abdelaziz MohamedNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 Weldm4metzNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saudi Aramco refractory installation checklistDocument3 pagesSaudi Aramco refractory installation checklistAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco welding inspection checklistDocument3 pagesSaudi Aramco welding inspection checklistManoj KumarNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldpravinNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- SAIC-W-2007 Rev 8Document6 pagesSAIC-W-2007 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Reinstatement Procedure ChecklistDocument5 pagesSaudi Aramco Reinstatement Procedure ChecklistpravinNo ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- SAIC-W-2082 Validation of Welding Equipment (EE)Document4 pagesSAIC-W-2082 Validation of Welding Equipment (EE)karioke mohaNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Jul-18 WeldjahaanNo ratings yet

- Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldRijwan MohammadNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- SAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld InspectionDocument5 pagesSAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld Inspectionاحمد حسنNo ratings yet

- Saudi Aramco welding checklistDocument13 pagesSaudi Aramco welding checklistAnonymous S9qBDVky100% (1)

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechjunaidNo ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldjeswinNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Saic L 2008Document4 pagesSaic L 2008babjihanumanthuNo ratings yet

- SAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevDocument3 pagesSAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevAnonymous S9qBDVkyNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Manual FK2500 Cooling UnitDocument27 pagesManual FK2500 Cooling UnitGogzNo ratings yet

- Manual Nov 2019Document152 pagesManual Nov 2019Cristhiano Barbosa100% (2)

- Learn To Weld - Beginning MIG Welding and Metal Fabrication Basics (PDFDrive)Document362 pagesLearn To Weld - Beginning MIG Welding and Metal Fabrication Basics (PDFDrive)Jeļena KrētaineNo ratings yet

- OKICAT11 04bDocument26 pagesOKICAT11 04bMohan SelvakumarNo ratings yet

- 2008 Morikawa TEC IFA ACES21 Advanced Urea Production Technology - 2Document15 pages2008 Morikawa TEC IFA ACES21 Advanced Urea Production Technology - 2MubasharNo ratings yet

- 95 Scs 4 Sr. No.5Document3 pages95 Scs 4 Sr. No.5Bhupender RamchandaniNo ratings yet

- Euronorme SuduraDocument1 pageEuronorme SuduragulieionutNo ratings yet

- Push-In Fittings and Connectors QS, Quick StarDocument93 pagesPush-In Fittings and Connectors QS, Quick StarNikolat84No ratings yet

- Bluescope Sheet Coil Product Guide Nov 20101Document54 pagesBluescope Sheet Coil Product Guide Nov 20101vijay_paliwal9903No ratings yet

- Komatsu Motor Grader Gd655 3c Shop ManualDocument20 pagesKomatsu Motor Grader Gd655 3c Shop Manualwalter100% (19)

- Dissimilar Metal Welding CrackingDocument10 pagesDissimilar Metal Welding CrackingMohd SyafiqNo ratings yet

- 4100 1998 - A1 2012Document30 pages4100 1998 - A1 2012Farid TataNo ratings yet

- Company Profile 2012Document50 pagesCompany Profile 2012Nhà Thép Trí ViệtNo ratings yet

- Electrode IDentificationDocument3 pagesElectrode IDentificationAmit AgarwalNo ratings yet

- 2 LG Manual Engl PDFDocument100 pages2 LG Manual Engl PDFwayne1925No ratings yet

- SY Echanic Auto Ele Elecn 08 06-14 PDFDocument28 pagesSY Echanic Auto Ele Elecn 08 06-14 PDFSasidharanNo ratings yet

- Metal Bellows Engineering Applications White PaperDocument14 pagesMetal Bellows Engineering Applications White PaperKhalidPeerNo ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- GB 50128-2005-EnDocument52 pagesGB 50128-2005-En柳德米拉100% (2)

- Alloy IndexDocument105 pagesAlloy IndexPeñaloz GustavoNo ratings yet

- Snap-On ALUMINUM WELDING Mhg5a Owners ManualDocument20 pagesSnap-On ALUMINUM WELDING Mhg5a Owners ManualSeathStevenson100% (1)

- DLT 5019-94 Specification For Manufacture-Erection and Formal Acceptance of Gate Hoist in Hydraulic and Hydroelectric ProjectsDocument50 pagesDLT 5019-94 Specification For Manufacture-Erection and Formal Acceptance of Gate Hoist in Hydraulic and Hydroelectric ProjectsAlexander GotteNo ratings yet

- Series 6: Valves & Wellhead Equipment: Standard Edition SectionDocument21 pagesSeries 6: Valves & Wellhead Equipment: Standard Edition SectionSarathiraja SekarNo ratings yet

- Miller Mark - Viii2Document44 pagesMiller Mark - Viii2gerardo ozNo ratings yet

- Hot Work ProgramDocument14 pagesHot Work ProgramImtiyaz AkhtarNo ratings yet

- Post Weld Toe Treatments Improve Fatigue Life FEA StudyDocument89 pagesPost Weld Toe Treatments Improve Fatigue Life FEA Studyvikrant GarudNo ratings yet

- BK291 PDFDocument104 pagesBK291 PDFAqua SamaNo ratings yet

- CE Marking GuideDocument74 pagesCE Marking Guiderrkishore0No ratings yet

- ASTM's Steel Standards GuideDocument63 pagesASTM's Steel Standards GuideNagarjun ReddyNo ratings yet

- Tank Erection Method Statement For Mot Oil Storage TanksDocument13 pagesTank Erection Method Statement For Mot Oil Storage TanksErmal RulaNo ratings yet