Professional Documents

Culture Documents

M40 With Fly Ash

M40 With Fly Ash

Uploaded by

scribdfree anytimeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M40 With Fly Ash

M40 With Fly Ash

Uploaded by

scribdfree anytimeCopyright:

Available Formats

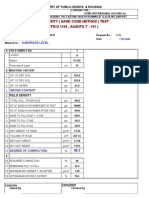

CONCRETE MIX DESIGN

DATE : 12/19/2020

Project :

Location of Project : Mumbai

Grade of Concrete : M 40

Maximum Size of Aggregate : 20 mm

Workability of Concrete Required : 120 +/- 25 mm

Assumed Standard Deviation : 5 Mpa

Degree of Quality Control : Good

Type of Exposure : Mild

Value of 'k' : 1.65

TARGET MEAN STRENGTH N/mm2 : 48.25 Mpa

BASIC DATA

CEMENT

Type of Cement OPC 53 Grade Cement %

Specific Gravity 3.15 83%

FLYASH

Specific Gravity 2.25

Fly ash in Total Cementitious 17%

GGBS

Specific Gravity 2.85

GGBS in Total Cementitious 0%

AGGREGATES

20 MM 10 MM Crushed Sand River Sand

Crushed Rock, Crushed Rock, Crushed Rock,

Type and Source of Aggregates

Turbhe Turbhe Turbhe

Specific Gravity 2.84 2.824 2.81 2.83

Average Specific Gravity 2.825

Water Absorption 1.51% 2.03% 3.50% 3.70%

Aggregates % in Total Agg. 27% 25% 51% 0%

ADMIXTURE

Specific Gravity

Dosage Of Admixture 0.9%

MATERIAL REQUIRED PER m3 OF CONCRETE

Total Cementitious Content 480 Kg

Entraped Air 0%

Cement 400 Kg

Fly Ash 80 Kg

GGBS 0 Kg

Water Cement Ratio 0.32

Free Water 153.6 lits

Total Volume of Aggregates 0.684 Cum

Coarse Aggregates - 20mm 524 Kg

Coarse Aggregates - 10mm 483 Kg

Crushed Sand 980 Kg

River Sand 0 Kg

Admixture 4.32 Kg

Density of Fresh Concrete 2625 Kg/m3

MIX PROPORTION BY WEIGHT:

CEMENT FINE AGGREGATES COARSE AGGREGATES

1 2.04 2.10

FREE (W/C) RATIO 0.32

Note : Mix Design is done by taking aggregates in saturated surface dry condition (SSD).

Note : Correction for water to be done as per moisture content during production.

Note : Do not use it, without doing at least 3 trials with each brand of cement and admixture.

You might also like

- M35 Bhole ConstructionDocument6 pagesM35 Bhole ConstructionBIPL REPORT100% (1)

- Nabll Mix DesignDocument29 pagesNabll Mix DesignPIDCL WITH SUBUDHINo ratings yet

- Field Density (Sand Cone Method) Test (ASTM D 1556, AASHTO T - 191)Document5 pagesField Density (Sand Cone Method) Test (ASTM D 1556, AASHTO T - 191)m8877223No ratings yet

- Department of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurDocument10 pagesDepartment of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurAjayvidyanand SharmaNo ratings yet

- Daily Lesson Plan 11-Amber, Crystal, Emerald, Ruby, SapphireDocument3 pagesDaily Lesson Plan 11-Amber, Crystal, Emerald, Ruby, SapphireLeizel Jane LjNo ratings yet

- Mix Design PQC m40 Opc 53Document7 pagesMix Design PQC m40 Opc 53Dipayan Misra100% (1)

- Maximum Dry Density (Proctor)Document3 pagesMaximum Dry Density (Proctor)ratoooooja24No ratings yet

- Soil GSB WMM by Sand Replacement MethodDocument1 pageSoil GSB WMM by Sand Replacement MethodBrahammanand BairwaNo ratings yet

- Depth of Piles: Dia of Pile 760 Dia of Pile 0.76Document4 pagesDepth of Piles: Dia of Pile 760 Dia of Pile 0.76Khan EngrNo ratings yet

- Soil GSB WMM by Sand Replacement MethodDocument2 pagesSoil GSB WMM by Sand Replacement MethodBrahammanand BairwaNo ratings yet

- Printable CBSE Worksheets For Class 1 To Class 12Document9 pagesPrintable CBSE Worksheets For Class 1 To Class 12Prem SharmaNo ratings yet

- Cement Concrtet Mix Design of M-20 Grade For RCC WorkDocument7 pagesCement Concrtet Mix Design of M-20 Grade For RCC WorkSandip Roy100% (1)

- V (2H 0.86+A) L: Fecha: Labor Altura (HP.) Ancho (Ap) Largo (LP.) Cubicacion Espesor: (PLG)Document5 pagesV (2H 0.86+A) L: Fecha: Labor Altura (HP.) Ancho (Ap) Largo (LP.) Cubicacion Espesor: (PLG)Walter Aviles HuamanNo ratings yet

- Rock Support Example 2Document6 pagesRock Support Example 2Imran SaikatNo ratings yet

- Model I.R. - GSB+WBM GR - II+CC - 20.01.2014Document38 pagesModel I.R. - GSB+WBM GR - II+CC - 20.01.2014yedlasNo ratings yet

- Mix Design CalculationDocument8 pagesMix Design CalculationEr Digvijay SinghNo ratings yet

- All in AggregateDocument12 pagesAll in AggregateGaurav SharmaNo ratings yet

- DBM Job MixDocument3 pagesDBM Job MixSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Under Ground Metal Mining Assignment: Topic:-Support System Submitted ToDocument55 pagesUnder Ground Metal Mining Assignment: Topic:-Support System Submitted ToANSHUL YADAVNo ratings yet

- Sand Replacement TestDocument8 pagesSand Replacement Testkrishna buildconNo ratings yet

- Test Report Volume - 2 PDFDocument495 pagesTest Report Volume - 2 PDFakilan100% (1)

- 100% Fly Ash in ConcreteDocument19 pages100% Fly Ash in ConcreteVinay BabuNo ratings yet

- Moisture Correction..02Document2 pagesMoisture Correction..02Er Dnyaneshwar PatilNo ratings yet

- Observation Sheet For Bitumen Extraction Test: Name of Division Name of Sub DivisionDocument2 pagesObservation Sheet For Bitumen Extraction Test: Name of Division Name of Sub DivisionramNo ratings yet

- D 6032 - 96 - Determining Rock Quality Designation (RQD) of Rock CoreDocument4 pagesD 6032 - 96 - Determining Rock Quality Designation (RQD) of Rock Corezuheib63No ratings yet

- CBR Test 10 NewDocument42 pagesCBR Test 10 NewNurhalizah PutriNo ratings yet

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 pagesM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeNo ratings yet

- Diameter in MM.: Grain Size AnalysisDocument13 pagesDiameter in MM.: Grain Size AnalysisImran KhanNo ratings yet

- Mechanical Ventilation For Individual Pen Calf Barn CalculatorDocument3 pagesMechanical Ventilation For Individual Pen Calf Barn CalculatorChristopher LloydNo ratings yet

- Strength Prediction Model For ConcreteDocument6 pagesStrength Prediction Model For ConcreteIDESNo ratings yet

- Maiti Fly Ash ConcreteDocument19 pagesMaiti Fly Ash ConcreteBilal Ahmed BarbhuiyaNo ratings yet

- Fly Ash in Concrete Production, Properties and Uses - R C Joshi, R P Lohita - Google BooksDocument1 pageFly Ash in Concrete Production, Properties and Uses - R C Joshi, R P Lohita - Google BooksJiabin LiNo ratings yet

- Concrete Compressive StrengthDocument4 pagesConcrete Compressive StrengthFranklyn P. Genove100% (1)

- 04 Atkinson Eq Square Law Friction&Shock LossDocument31 pages04 Atkinson Eq Square Law Friction&Shock LossNandika Reza FaisalNo ratings yet

- Compressive Strength Test WorksheetDocument3 pagesCompressive Strength Test WorksheetLloyd R. Ponce100% (1)

- Steel Rolling Margin Register Final26 12 14Document12 pagesSteel Rolling Margin Register Final26 12 14Om Krish RamNo ratings yet

- Paver Block DesignDocument1 pagePaver Block DesignSonti KumarNo ratings yet

- Test Report On Extraction of Bitumen From Bituminous Paving Mixture and Mechanical Size AnalysisDocument12 pagesTest Report On Extraction of Bitumen From Bituminous Paving Mixture and Mechanical Size AnalysisLakmal JayashanthaNo ratings yet

- Bituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Document4 pagesBituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Mozibur RahmanNo ratings yet

- Mina SantanderDocument12 pagesMina SantanderJefferson JesusNo ratings yet

- KCC PQC Mix BlendingDocument2 pagesKCC PQC Mix BlendingQuality JamNo ratings yet

- RA Brick WorkDocument2 pagesRA Brick WorksatpuraNo ratings yet

- Concrete Requisition: Sign of P&M Sign of QC Sign of Project Manager Sign of Site Incharge Incharge EngineerDocument11 pagesConcrete Requisition: Sign of P&M Sign of QC Sign of Project Manager Sign of Site Incharge Incharge EngineerGino BrownNo ratings yet

- Compressive Strength of AAC BlockDocument11 pagesCompressive Strength of AAC BlockImran KhanNo ratings yet

- 169 1 Fine Aggregate SandDocument1 page169 1 Fine Aggregate SanddhwaniNo ratings yet

- Sieve Analysis For Fine Aggregate - Kico ProjectDocument1 pageSieve Analysis For Fine Aggregate - Kico ProjectMitendra ChauhanNo ratings yet

- M45Document6 pagesM45Prakash HitechNo ratings yet

- Sub-Regional Transport Enhancement Project: Modified Proctor Compaction TestDocument15 pagesSub-Regional Transport Enhancement Project: Modified Proctor Compaction Testsakar shresthaNo ratings yet

- Dense Graded Bituminous Macadam v-30 & 40Document28 pagesDense Graded Bituminous Macadam v-30 & 40a k pantNo ratings yet

- Bitumen (Ext)Document1 pageBitumen (Ext)venkateswara rao PothinaNo ratings yet

- Individual Sieve Analysisi of 10Mm, 6Mm, & Fine Aggregate (Crushed Sand) For Avarage % of PassingDocument3 pagesIndividual Sieve Analysisi of 10Mm, 6Mm, & Fine Aggregate (Crushed Sand) For Avarage % of PassingAshok amlapureNo ratings yet

- Pour Card: Correction For Moisture Content For DLCDocument1 pagePour Card: Correction For Moisture Content For DLCQuality JamNo ratings yet

- Mix DesignDocument1 pageMix Designfaizankhan23No ratings yet

- Bitumen Lab Test ChargesDocument7 pagesBitumen Lab Test ChargesRenga PandiNo ratings yet

- Analysis of DCPT ResultDocument2 pagesAnalysis of DCPT ResultHendro WidagdoNo ratings yet

- Test Report Field Density Test Sand Replacement Method: Project NameDocument25 pagesTest Report Field Density Test Sand Replacement Method: Project NameKreesthu ReddyNo ratings yet

- National Highways Authority of India: Bitumen Extraction TestDocument2 pagesNational Highways Authority of India: Bitumen Extraction Testmanish upadhyayNo ratings yet

- DP1-2-1 Vedlegg Til State of The Art BoreteknikkDocument308 pagesDP1-2-1 Vedlegg Til State of The Art BoreteknikkpellazgusNo ratings yet

- Combine Flakiness & Elongation TestDocument1 pageCombine Flakiness & Elongation TestFariha AzadNo ratings yet

- Seal CoatDocument30 pagesSeal CoatMujahid choudharyNo ratings yet

- Filter Media 15.1.2015Document17 pagesFilter Media 15.1.2015Prashant SinghNo ratings yet

- IELTS Listening Test Beginner-Elementary-Pre-Intermediate Listening - 0Document4 pagesIELTS Listening Test Beginner-Elementary-Pre-Intermediate Listening - 0Ahmed FouadNo ratings yet

- M30 With Fly AshDocument1 pageM30 With Fly AshRishabhNo ratings yet

- Beam Design With Deflection CheckDocument2 pagesBeam Design With Deflection Checkscribdfree anytimeNo ratings yet

- Deed of AgreementDocument2 pagesDeed of Agreementscribdfree anytimeNo ratings yet

- M 40Document4 pagesM 40scribdfree anytimeNo ratings yet

- Column PDFDocument206 pagesColumn PDFscribdfree anytimeNo ratings yet

- Brief PDFDocument647 pagesBrief PDFscribdfree anytimeNo ratings yet

- I. Stipulations For Proportioning of M35 Grade Concrete: Table 5-IS456Document5 pagesI. Stipulations For Proportioning of M35 Grade Concrete: Table 5-IS456scribdfree anytimeNo ratings yet

- Company Name: Job InformationDocument3 pagesCompany Name: Job Informationscribdfree anytimeNo ratings yet

- Fractional Calculus PDFDocument7 pagesFractional Calculus PDFShorouk Al- IssaNo ratings yet

- 2023-Physics-Informed Radial Basis Network (PIRBN) A LocalDocument41 pages2023-Physics-Informed Radial Basis Network (PIRBN) A LocalmaycvcNo ratings yet

- Free Space Optics: The Speed of Fiber The Flexibility of WirelessDocument8 pagesFree Space Optics: The Speed of Fiber The Flexibility of WirelessSaad AhsanNo ratings yet

- 50+ Contoh Soal Latihan UN Dan UNBK Bahasa iNGGRIS SMK Paket ADocument12 pages50+ Contoh Soal Latihan UN Dan UNBK Bahasa iNGGRIS SMK Paket AMadrasah Aliyah Al-Mursalin100% (1)

- Ebook Ebook PDF Physical Geography 11th Edition PDFDocument41 pagesEbook Ebook PDF Physical Geography 11th Edition PDFderek.lewis562100% (37)

- SC1932 PDFDocument4 pagesSC1932 PDFA MahmoodNo ratings yet

- Discipline and Ideas in The Applied Social SciencesDocument15 pagesDiscipline and Ideas in The Applied Social SciencesCin DyNo ratings yet

- Escaniels ResumeDocument1 pageEscaniels ResumeMarlon C. ManaloNo ratings yet

- C-R Molinié, Semiostylistique - L'effet de L'art.Document2 pagesC-R Molinié, Semiostylistique - L'effet de L'art.Helen Perdicoyianni-PaleologouNo ratings yet

- Physics 4TH Quarter Mid ExamDocument4 pagesPhysics 4TH Quarter Mid ExamAbebe BayeNo ratings yet

- Module 5Document9 pagesModule 5Kentjohn QuiraoNo ratings yet

- Life 2E Elementary Unit 1 WB - 0 PDFDocument8 pagesLife 2E Elementary Unit 1 WB - 0 PDFJonh Henry ArdilaNo ratings yet

- SK NYU Terminal Blocks EDocument240 pagesSK NYU Terminal Blocks EAnonymous hxQ7PNOQNo ratings yet

- Multiple Intelligences SurveyDocument2 pagesMultiple Intelligences SurveyGodwynne ArabellaNo ratings yet

- Data Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeDocument10 pagesData Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeRisa RidmaNo ratings yet

- Nfc-Iet Multan: Tomb of Shah Rukn-E-Alam Multan, PakistanDocument27 pagesNfc-Iet Multan: Tomb of Shah Rukn-E-Alam Multan, PakistanSADIA SAMINo ratings yet

- Sample Class Program Sy 2024-2025Document7 pagesSample Class Program Sy 2024-2025Jordan Cerezo MonasterialNo ratings yet

- University of Galway v13Document113 pagesUniversity of Galway v13IsaCoboNo ratings yet

- BUTLER, J. Bodies and Power, Revisited PDFDocument7 pagesBUTLER, J. Bodies and Power, Revisited PDFAluanaGuiNo ratings yet

- Mechanisms For Improving Mass Transfer in Food With UltrasoundDocument7 pagesMechanisms For Improving Mass Transfer in Food With UltrasoundalexNo ratings yet

- Hope ScaleDocument1 pageHope Scalemade_of_stormNo ratings yet

- Pharmacognosy - Herbal Drug Technology (PDFDrive)Document38 pagesPharmacognosy - Herbal Drug Technology (PDFDrive)fdfsd fdgdfNo ratings yet

- XII 301-1-2 1 MS UnsignedDocument23 pagesXII 301-1-2 1 MS Unsignedchootuc435No ratings yet

- ASCII Table: Christian James O. Pacilan BS Indtech 1MTDocument3 pagesASCII Table: Christian James O. Pacilan BS Indtech 1MTChristian James PACILANNo ratings yet

- Clinical Skills Coordinator Job DescriptionDocument6 pagesClinical Skills Coordinator Job DescriptionYee Han KwongNo ratings yet

- 5 Detector FumDocument2 pages5 Detector FumAnonymous YWmB9HDgNo ratings yet

- Assessment Form 2.2 NovDocument2 pagesAssessment Form 2.2 NovElla TrayaNo ratings yet

- Tarea 2Document4 pagesTarea 2Enmanuel AlmonteNo ratings yet