Professional Documents

Culture Documents

Assessment - 4 - Module of Instruction - Perform Basic Maintenance

Uploaded by

Clarissa BerganteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assessment - 4 - Module of Instruction - Perform Basic Maintenance

Uploaded by

Clarissa BerganteCopyright:

Available Formats

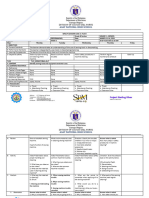

BATAAN PENINSULA STATE UNIVERSITY

COLLEGE OF TECHNOLOGY

City of Balanga 2100 Bataan

PHILIPPINES

Course: BTVTE Date: Dec. 17, 2020

Major: Garments Fashion and Design Section: 3A

Leader’s Name: Eunice B. Detic

Member’s Name: Angelica Dagal

Karen Guzman

Jobelyn Sapnu

Sarah Olaya

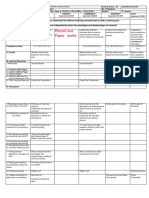

ASSESSMENT # 4

Proposed Module of Instruction

Direction: This assessment is by group. Your group must have the same qualification. Secure a copy

of the competency standard of your group’s qualification. Make an outline of your

proposed module of instruction. Use the table below as your guide.

UNIT TITLE Perform basic maintenance

MODULE TITLE Performing basic maintenance

MODULE DESCRIPTION The learning contents are given for each of

the Learning Outcome. The trainees are

given instruction for their presentation,

like reading of the

information sheets, doing the self checks

and comparing answers to answer key.

They are also provided with the tools in

undergoing their sessions such as the

CBLM, the tools, materials and equipment

based on the training regulations and the

competency-based curriculum.

LEVEL OF QUALIFICATION NC II

NOMINAL DURATIONS 22 Hours

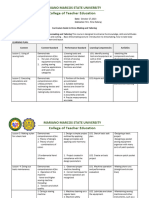

SUMMARY OF LEARNING Upon completion of this module the

trainees/students must be able to :

OUTCOMES 1. Operate machine and assess Its

performance

2. Clean and Lubricate Sewing Machine

ASSESSMENT CRITERIA LO.1 Operate Machine and Assess Its

Performance

1.Lifted the presser foot before starting to

run the

machine.

2Rested both feet on the treadle on ahead

of the

other.

3. The balance wheel and applied

moderate force.

4. Followed the movement of the treadle

and did

not exert too much force on it.

5. Performed four to five rotations

continuously.

6. Stopped the machine from running

without

holding the balance wheel.

Work habits ( 30 % )

1. Correct posture was displayed.

2.Holding of balance wheel was avoided

when the

machine was in motion.

3. Turning back and forth of balance wheel

was

avoided.

4 .Followed the procedure correctly.

L0.2 Clean and Lubricate Sewing Machine

1.Remove the needle if there is any.

2. Unscrew face plate and keep it in the

drawer while cleaning.

3.. Brush dust away and put a little amount

of oil on face plate.

4. Put back the face plate in place.

5. Remove outer bolt, tension dial, and disc

spring of the upper tension.

6. Brush dust and wipe with absorbent

cloth with oil the upper tension.

7. Assemble the upper tension by

following the laid parts in your table.

8. Remove bobbin case.

9. Fasten sides of oscillating hook.

10. Remove dust with lint brush.

11. Put a little amount of machine oil on

moving parts.

12. Return spare parts in place.

13. Remove entangled threads between

head and balance wheel.

14. Brush accumulated dust in the treadle

joints connecting the band wheel.

15. Clean gummy dust on the band wheel.

16. Lubricate all joints and oil slots with

good quality oil.

17. Put a piece of absorbent cloth under the

presser foot for dripping oil.

CONDITION The trainee / student must be provided

with the following:

LO.1 Operate Machine and Assess Its

Performance

Sewing machine

machine needle

thread,

Fabric swatches

pair of scissors

L0.2 Clean and Lubricate Sewing Machine

Quality oil

lint brush

dry paint brush

screw drivers

pen

cotton buds.

CONTENTS LO1. Operate machine and assess Its

performance

1.1 Proper handling of machine is observed

and identified

1.2 Common machine troubles

LO2. Clean and Lubricate Sewing Machine

2.1 Regular and safety procedures in

machine cleaning are observed and

followed.

2.2 Regular maintenance schedules

are observed and recorded

TRAINING METHODOLOGY LO1. Operate machine and assess Its

performance

Lecture/ discussion

Demonstration

Self-paced instruction

LO2. Clean and Lubricate Sewing Machine

Lecture/ discussion

Demonstration

Self-paced instruction

ASSESSMENT METHOD LO1. Operate machine and assess Its

performance

Written Test

Practical Demonstration w/ Oral

Questioning

Interview

Portfolio

LO2. Clean and Lubricate Sewing Machine

Written Test

Practical Demonstration w/ Oral

Questioning

Interview

Portfolio

You might also like

- Invisible CitiesDocument14 pagesInvisible Citiesvelveteeny0% (1)

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDocument30 pagesThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanNo ratings yet

- Beauty Care NC IIIDocument72 pagesBeauty Care NC IIIMairem Barruga0% (1)

- Diesel Power Plant Operation and Maintenance NC IIIDocument81 pagesDiesel Power Plant Operation and Maintenance NC IIIAljon BalanagNo ratings yet

- Bar & Beverage Mngt.Document46 pagesBar & Beverage Mngt.Darlene Mae Humbe100% (1)

- Words of Radiance: Book Two of The Stormlight Archive - Brandon SandersonDocument6 pagesWords of Radiance: Book Two of The Stormlight Archive - Brandon Sandersonxyrytepa0% (3)

- Technological Institute of The Philippines Aurora Boulevard, Cubao, Quezon CityDocument7 pagesTechnological Institute of The Philippines Aurora Boulevard, Cubao, Quezon CityRyan David MacayanNo ratings yet

- Healthy Apps Us New VarDocument9 pagesHealthy Apps Us New VarJESUS DELGADONo ratings yet

- CBC Automotive Servicing NC I January 2019Document88 pagesCBC Automotive Servicing NC I January 2019Mark Marasigan100% (3)

- Unit 1 Module 3 Rep in PlantsDocument26 pagesUnit 1 Module 3 Rep in Plantstamesh jodhanNo ratings yet

- SWBL DocumentsDocument38 pagesSWBL DocumentsJeffrey Ryan Alonsagay83% (6)

- Record and Paper WorksDocument3 pagesRecord and Paper WorksJay Ann Diaz GicaNo ratings yet

- Module 4 - Dressmaking 8 RevisedDocument4 pagesModule 4 - Dressmaking 8 RevisedJuan Vicente100% (1)

- 4 Common Read InterpretDocument57 pages4 Common Read InterpretFrancis Junifer Maniego100% (1)

- Cbc-Driving NC IiDocument7 pagesCbc-Driving NC IiAndrea PabalinasNo ratings yet

- IA-Info SheetDocument50 pagesIA-Info SheetJean ChristianNo ratings yet

- Automotive Mechanical Assembly NC IIDocument92 pagesAutomotive Mechanical Assembly NC IISkill-Power Institute, Inc Cabanatuan CityNo ratings yet

- CBLM PackageDocument32 pagesCBLM PackageRalph Castillo100% (5)

- Quality Control of Rigid Pavements 1Document58 pagesQuality Control of Rigid Pavements 1pranjpatil100% (1)

- CBC-Driving NC IIDocument68 pagesCBC-Driving NC IISSVTC LRCNo ratings yet

- Consumer Electronics Servicing NC IIIDocument85 pagesConsumer Electronics Servicing NC IIIAleli Joy Profugo DalisayNo ratings yet

- FG AMHQ0301 Sewing Machine Operator 25-01-2018Document263 pagesFG AMHQ0301 Sewing Machine Operator 25-01-2018Vachan Abhilekh ThakurNo ratings yet

- CBC AutomotiveservicingnciiDocument128 pagesCBC AutomotiveservicingnciiAlvic RamirezNo ratings yet

- Driving NC IIDocument68 pagesDriving NC IIRhendel Sanchez0% (1)

- Competency - Based Learning Materials: Secto R: Qualification: Unit of CompetencyDocument66 pagesCompetency - Based Learning Materials: Secto R: Qualification: Unit of CompetencyFredy Datahan PaviaNo ratings yet

- Module 3 SuperviseDocument44 pagesModule 3 SuperviseDnca AlaanNo ratings yet

- CBC - Automotive Servicing NC I - OLDDocument93 pagesCBC - Automotive Servicing NC I - OLDWingwing Padilla Abrasado Villarmino0% (1)

- Zomato Restaurant Clustering & Sentiment Analysis - Ipynb - ColaboratoryDocument27 pagesZomato Restaurant Clustering & Sentiment Analysis - Ipynb - Colaboratorybilal nagoriNo ratings yet

- Standards Procedure For Sewing Machine OperationsDocument3 pagesStandards Procedure For Sewing Machine OperationsReg OligarioNo ratings yet

- Sla At&tDocument2 pagesSla At&tCésar Lainez Lozada TorattoNo ratings yet

- OCP Java SE 7 Programmer II Certification Guide: Prepare for the 1ZO-804 examFrom EverandOCP Java SE 7 Programmer II Certification Guide: Prepare for the 1ZO-804 examNo ratings yet

- CBC - Automotive Servicing NC I - January 2019Document90 pagesCBC - Automotive Servicing NC I - January 2019florence baliwang83% (6)

- Discuss Briefly The Provisions of RA 1425Document2 pagesDiscuss Briefly The Provisions of RA 1425Clarissa Bergante100% (1)

- Final Module Grade 8 T L e DressmakingDocument50 pagesFinal Module Grade 8 T L e DressmakingZahara SantiNo ratings yet

- Q3 TLE07 W6 Mar21 NEMIDocument6 pagesQ3 TLE07 W6 Mar21 NEMIGinalynRapirapHuitNo ratings yet

- CBC - Automotive Servicing NCLL (Migrated)Document14 pagesCBC - Automotive Servicing NCLL (Migrated)Wingwing Padilla Abrasado Villarmino100% (2)

- Launder Linen and Guests' Clothes: D1.HHK - CL3.05 Trainee ManualDocument78 pagesLaunder Linen and Guests' Clothes: D1.HHK - CL3.05 Trainee ManualJohn brylle LlemitNo ratings yet

- Cleaning Procedures in Hardware ComponentsDocument24 pagesCleaning Procedures in Hardware ComponentsClang ClangNo ratings yet

- Perform Basic MaintenanceDocument60 pagesPerform Basic MaintenanceJexylon TenederoNo ratings yet

- DRIVING NC II Course StructureDocument2 pagesDRIVING NC II Course StructurePierre PakilitNo ratings yet

- CBC - Automotive Body Painting NC IIDocument121 pagesCBC - Automotive Body Painting NC IIJagie PantaleonNo ratings yet

- CBC Auto NC 1 2020Document133 pagesCBC Auto NC 1 2020Ait Biñan100% (1)

- Curriculum Guide JADEIBUSDocument3 pagesCurriculum Guide JADEIBUSjadetacata001No ratings yet

- DLL March 20-24Document15 pagesDLL March 20-24Jan Bryan EslavaNo ratings yet

- CBC-Tailoring NC IIDocument66 pagesCBC-Tailoring NC IICharmaine Mae RetizaNo ratings yet

- Maintain and Operate An Industrial Laundry: D1.HHK - CL3.04 Assessor ManualDocument52 pagesMaintain and Operate An Industrial Laundry: D1.HHK - CL3.04 Assessor ManualJohn brylle LlemitNo ratings yet

- 2CBC AutoDocument143 pages2CBC AutoMark MarasiganNo ratings yet

- G7 LEAP - Week 5 SMAWDocument3 pagesG7 LEAP - Week 5 SMAWSHERELYN RODRIGUEZNo ratings yet

- Week 1 G7 Module TailoringDocument9 pagesWeek 1 G7 Module TailoringRency LandichoNo ratings yet

- Facilitate Learning SessionDocument31 pagesFacilitate Learning SessionRaymund MontoyaNo ratings yet

- Technological Institute of The Philippines Aurora Boulevard, Cubao, Quezon CityDocument6 pagesTechnological Institute of The Philippines Aurora Boulevard, Cubao, Quezon CityRyan David MacayanNo ratings yet

- Basic CompetenccDocument36 pagesBasic CompetenccFreddbel CubillasNo ratings yet

- Clean Public Areas, Facilities and Equipment: D1.HHK - CL3.02 Trainee ManualDocument108 pagesClean Public Areas, Facilities and Equipment: D1.HHK - CL3.02 Trainee ManualAmy Amper Pelenio-LofrancoNo ratings yet

- CBC-Tailoring NC IIDocument66 pagesCBC-Tailoring NC IICharmaine Mae RetizaNo ratings yet

- Competency-Based Curriculum: Dumingag Technological Training SchoolDocument72 pagesCompetency-Based Curriculum: Dumingag Technological Training Schoolverneiza balbastroNo ratings yet

- How To Clean and Oil The Sewing MachineDocument2 pagesHow To Clean and Oil The Sewing MachineROJANE F. BERNAS, PhD.No ratings yet

- RSL StewardingDocument8 pagesRSL StewardingZila Saidin0% (1)

- Natural Gas Vehicle PT-P1 - A1Document4 pagesNatural Gas Vehicle PT-P1 - A1Faris DanialNo ratings yet

- CBC - M.ses NC IiDocument58 pagesCBC - M.ses NC IiAllan Q VenusNo ratings yet

- Jobsheet 1 Winding-Operation-1Document8 pagesJobsheet 1 Winding-Operation-1alifsafiyNo ratings yet

- 6) Perform Underchassis Preventive MaintenanceDocument52 pages6) Perform Underchassis Preventive MaintenanceROSAN YUMANGNo ratings yet

- Perform Basic MaintenanceDocument34 pagesPerform Basic MaintenanceTangonan Darrel100% (2)

- Barbering NC 2Document97 pagesBarbering NC 2Mithz SuNe YahNo ratings yet

- Standards-Based Lesson Plan: Lesson Title and Duration Learner Outcomes / Objectives StandardsDocument3 pagesStandards-Based Lesson Plan: Lesson Title and Duration Learner Outcomes / Objectives StandardsJocelyn TeriteNo ratings yet

- Gear Report Troubleshoot123Document6 pagesGear Report Troubleshoot1231171 KumaresanNo ratings yet

- Tle 8 Week 6Document7 pagesTle 8 Week 6Jhon Jomarie Adlawon RobasNo ratings yet

- Experiment No. 3 Wet Preparation of Disturbed Soil Samples 1. Objective (S) : 2. Intended Learning Outcomes (Ilos)Document6 pagesExperiment No. 3 Wet Preparation of Disturbed Soil Samples 1. Objective (S) : 2. Intended Learning Outcomes (Ilos)MewnEProwtNo ratings yet

- Weekly Home Learning Plan Grade 9 Automotive: Quarter 1, Week 3-4, (March 8, 2021)Document4 pagesWeekly Home Learning Plan Grade 9 Automotive: Quarter 1, Week 3-4, (March 8, 2021)sandoy melzNo ratings yet

- CBC Machining NC IDocument79 pagesCBC Machining NC IKaren Mae Altarejos AlocNo ratings yet

- 5 Classroom Management Tips For Technology IntegrationDocument2 pages5 Classroom Management Tips For Technology IntegrationClarissa BerganteNo ratings yet

- Savory Party BreadDocument3 pagesSavory Party BreadClarissa BerganteNo ratings yet

- Assessment - 4 - Module of InstructionDocument1 pageAssessment - 4 - Module of InstructionClarissa BerganteNo ratings yet

- Maam AndreaDocument4 pagesMaam AndreaClarissa BerganteNo ratings yet

- The Concept of The Smartphone in Mobile LearningDocument4 pagesThe Concept of The Smartphone in Mobile LearningClarissa BerganteNo ratings yet

- Savory Party Bread: Ham N' Cheese Biscuit StacksDocument3 pagesSavory Party Bread: Ham N' Cheese Biscuit StacksClarissa BerganteNo ratings yet

- College OF Echnology: Assignment No. 3Document1 pageCollege OF Echnology: Assignment No. 3Clarissa BerganteNo ratings yet

- Wellness and Mental Health in 2020 Online LearningDocument4 pagesWellness and Mental Health in 2020 Online LearningClarissa BerganteNo ratings yet

- College OF Echnology: Activity Sheet No. 3Document4 pagesCollege OF Echnology: Activity Sheet No. 3Clarissa BerganteNo ratings yet

- Clarissa Bergante1Preassessment Chapter 3Document4 pagesClarissa Bergante1Preassessment Chapter 3Clarissa BerganteNo ratings yet

- 8 A - 1615864446 - 1605148379 - 1579835163 - Topic - 8.A.EffectiveSchoolsDocument9 pages8 A - 1615864446 - 1605148379 - 1579835163 - Topic - 8.A.EffectiveSchoolsYasodhara ArawwawelaNo ratings yet

- IM1 Calculus 2 Revised 2024 PUPSMBDocument14 pagesIM1 Calculus 2 Revised 2024 PUPSMBEunice AlonzoNo ratings yet

- ICMApprovedCentres - Ghana PDFDocument8 pagesICMApprovedCentres - Ghana PDFPrince Kelly100% (2)

- 4.2.4.5 Packet Tracer - Connecting A Wired and Wireless LAN InstructionsDocument5 pages4.2.4.5 Packet Tracer - Connecting A Wired and Wireless LAN InstructionsAhmadHijaziNo ratings yet

- W.C. Hicks Appliances: Client Name SKU Item Name Delivery Price Total DueDocument2 pagesW.C. Hicks Appliances: Client Name SKU Item Name Delivery Price Total DueParth PatelNo ratings yet

- Subject OrientationDocument15 pagesSubject OrientationPearl OgayonNo ratings yet

- Carnegie Mellon Thesis RepositoryDocument4 pagesCarnegie Mellon Thesis Repositoryalisonreedphoenix100% (2)

- 2201 IntGCSE (9-1) Subject Grade Boundaries V1Document4 pages2201 IntGCSE (9-1) Subject Grade Boundaries V1Fariha RahmanNo ratings yet

- China Training WCDMA 06-06Document128 pagesChina Training WCDMA 06-06ryanz2009No ratings yet

- OT Initial Assessment (OTIA) 2022-11-15Document2 pagesOT Initial Assessment (OTIA) 2022-11-15funtikarNo ratings yet

- Design of Reinforced Cement Concrete ElementsDocument14 pagesDesign of Reinforced Cement Concrete ElementsSudeesh M SNo ratings yet

- LP32HS User Manual v1Document52 pagesLP32HS User Manual v1tonizx7rrNo ratings yet

- MFE Module 1 .Document15 pagesMFE Module 1 .Adarsh KNo ratings yet

- Jacob Stewart ResumeDocument2 pagesJacob Stewart Resumeapi-250063152No ratings yet

- CFD Turbina Michell BankiDocument11 pagesCFD Turbina Michell BankiOscar Choque JaqquehuaNo ratings yet

- Genuine Fakes: How Phony Things Teach Us About Real StuffDocument2 pagesGenuine Fakes: How Phony Things Teach Us About Real StuffGail LeondarWrightNo ratings yet

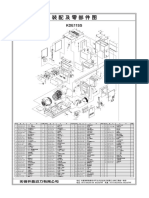

- KDE11SSDocument2 pagesKDE11SSluisgomezpasion1No ratings yet

- Lightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationDocument2 pagesLightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationAnas BasarahNo ratings yet

- The Linguistic Colonialism of EnglishDocument4 pagesThe Linguistic Colonialism of EnglishAdriana MirandaNo ratings yet

- 2nd Term Project 4º Eso Beauty Canons 2015-16 DefinitivoDocument2 pages2nd Term Project 4º Eso Beauty Canons 2015-16 DefinitivopasferacosNo ratings yet

- Culture 2007 2013 Projects Overview 2018-03-18Document133 pagesCulture 2007 2013 Projects Overview 2018-03-18PontesDeboraNo ratings yet

- (Sat) - 072023Document7 pages(Sat) - 072023DhananjayPatelNo ratings yet