Professional Documents

Culture Documents

Charts and Tables PDF

Charts and Tables PDF

Uploaded by

Abdo0 ratings0% found this document useful (0 votes)

19 views2 pagesOriginal Title

Charts and Tables.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views2 pagesCharts and Tables PDF

Charts and Tables PDF

Uploaded by

AbdoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Table 1 Standard Values of Center Distance

Ser. Center Distance a [mm]

1 63 100 160 250 315

2 50 63 63 80 100 125 160 200 250 315

3 50 63 63 71 80 90 100 112 125 140 160 180 200 224 250 280 315

1 400 630 1000 1600

2 400 500 630 800 1000 1250 1600 2000

3 355 400 450 500 560 630 710 800 900 1000 1120 1250 1400 1600 1800 2000

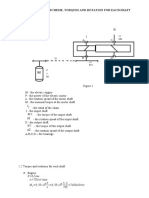

Fig. 3 Distribution of correction factors for reduction gear drive

Table 2 Dimensions for Standard Gearing

Description Pinion Gear

Number of teeth z1 z2

Pitch circle diameter do1 =z1 m do2 = z2 m

Tip circle diameter da1=do1+2m da2 = do2+ 2 m

Root circle diameter df1=do1-2.5m df2=do2-2.5m

Base circle diameter db1=do1 cos db2= do2 cos

Tooth thickness on pitch circle s = e = p / 2 = m / 2

Total Tooth Height, h h = 2.25m

Gear Width, b b = 0.5 do1

Center distance d + d2 z + z2

ao = 1 =m 1

2 2

ra2 2 - rb2 2 ra1 2 - rb1 2 - a sin

Contact Ratio,

m * cos

Mechanical and Industrial Engineering Department

Machine Dynamics, ME 243

Table 3 Dimensions of Gears in a So-Gearing

Description Pinion Gear

Number of teeth z1 z2

Pitch circle diameter do1 = z1 m do2 =z2 m

Base Circle Diameter, db1, db2 db1=do1 cos w db2=do2 cos w

Tip circle diameter da1= do1 + 2m + 2 x1 m da2 =do2 + 2 m - 2 x1 m

Root circle diameter df1 = do1 - 2(1.25 - x1) m df2=do2 - 2(1.25 + x1) m

Modification Pitch circle diameter dw1=do1 cos / cos w dw2=do2 cos / cos w

Center Distance ao = m (z1+ z2) / 2

Center distance after modification aw=a= ao cos / cos w

Tooth thickness on pitch circle s1 = m/2 + 2 x1 m tan s2=m/2 - 2.x1 m tan

Involute pressure angle inv α = tanα – (α.π/180)

Involute Function inv αw = tanαw – (αw.π/180)

Total Tooth Height, h h ≈ 2.25m

Gear Width, b b = 0.5 do1

Working Pressure Angle z 1 z 2 inv w inv

x1 x 2

2 tan

ra2 - rb 2 - a w sin w

2 2 2 2

ra1 - rb1

Contact Ratio,

m * cos w

Table 4 Dimensions of Gears in an S-Gearing

Description Pinion Gear

Number of teeth z1 z2

Pitch circle diameter do1 = z1 m do2 =z2 m

Standard Center Distance ao = m (z1+ z2) / 2

Center distance after modification aw= a = ao cos / cos w

Involute pressure angle inv α = tanα – (α.π/180)

Involute Function inv αw = tanαw – (αw.π/180)

Sum of profile correction z 1 z 2 inv w inv

x1 x 2

2 tan

Base Circle Diameter, db1, db2 db1=do1 cos w db2=do2 cos w

Tip circle diameter da1= 2(a + m – x2 m)- do2 da2 =2(a + m - x1 m)- do1

Root circle diameter df1 = do1 - 2(1.25 - x1) m df2=do2 - 2(1.25 - x2) m

Modification Pitch circle diameter dw1=do1 cos / cos w dw2=do2 cos / cos w

Tooth thickness on pitch circle s1 = m/2 + 2 x1 m tan s2=m/2 + 2 x2 m tan

Topping y.m =ao+(x1+x2)m-a

Total Tooth Height, h h ≈ 2.25m

Gear Width, b b = 0.5 do1

ra2 - rb 2 - a w sin w

2 2 2 2

ra1 - rb1

Contact Ratio,

m * cos w

Power = Mt * [Watt]

Mt = Ft * d/2 [N.m] for standard Gears

Mt = Ft * dw /2 [N.m] for corrected Gears

tan α = Fr /Ft for standard Gears

tan αw = Fr /Ft for corrected Gears

FN = [(Fr)2 + (Ft)2]1/2 [N]

Mechanical and Industrial Engineering Department

Machine Dynamics, ME 243

You might also like

- Kinds of GearsDocument51 pagesKinds of GearsIrfanNo ratings yet

- Calculation of Gear Dimensions - KHK Gears PDFDocument25 pagesCalculation of Gear Dimensions - KHK Gears PDFlawlawNo ratings yet

- UR M56 (Rev.2 Oct 2013) CLNDocument22 pagesUR M56 (Rev.2 Oct 2013) CLNKarthikeyan NatarajanNo ratings yet

- M56 Marine Gears - Load Capacity of Involute Parallel Axis Spur and Helical Gears M56Document25 pagesM56 Marine Gears - Load Capacity of Involute Parallel Axis Spur and Helical Gears M56Harshith PurushothamNo ratings yet

- Calculation of Gear Dimensions - KHKDocument23 pagesCalculation of Gear Dimensions - KHKvinan44482No ratings yet

- Calculation of Gear DimensionsDocument22 pagesCalculation of Gear DimensionsdressfeetNo ratings yet

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- a R i z m mn b α β fo c x Ψ Ψm ΨyDocument6 pagesa R i z m mn b α β fo c x Ψ Ψm ΨykuttuasrNo ratings yet

- 2507 Physics Paper With Solution EveningDocument8 pages2507 Physics Paper With Solution EveningPiya BasuNo ratings yet

- One Side Beam-Beam ConnectionDocument1 pageOne Side Beam-Beam Connectionsamon.itc2019No ratings yet

- Spur Gear: Speed Input Speed Output R R R R R VDocument12 pagesSpur Gear: Speed Input Speed Output R R R R R Vprakash tyagiNo ratings yet

- Calculation For Standard Straight Bevel GearDocument1 pageCalculation For Standard Straight Bevel GearDhanesh KumarNo ratings yet

- Фланцевые соединения dast v4.3 - EDocument3 pagesФланцевые соединения dast v4.3 - EZdrobau VitalieNo ratings yet

- Designing "Slab Type" Raft / Footing For Bending Moment and One-Way ShearDocument8 pagesDesigning "Slab Type" Raft / Footing For Bending Moment and One-Way ShearMuhammad HasanNo ratings yet

- Structural ConnectionsDocument26 pagesStructural ConnectionsAlemtsehay ShiferawNo ratings yet

- Chapter 2 Gear Drive-3Document41 pagesChapter 2 Gear Drive-3Abaziz Mousa OutlawZzNo ratings yet

- Equilibrio Lastre FessurateDocument8 pagesEquilibrio Lastre FessurateEric GugginoNo ratings yet

- Theory of Gears r3Document53 pagesTheory of Gears r3gamini ranaweeraNo ratings yet

- CH3 Worm Gear Design-1Document38 pagesCH3 Worm Gear Design-1Abaziz Mousa OutlawZzNo ratings yet

- Gear Mathematics For Bevel & Hypoid GearsDocument7 pagesGear Mathematics For Bevel & Hypoid GearsDiego CarrascoNo ratings yet

- Earth Work in Civil Engineering Projects: Cut Corrected CutDocument12 pagesEarth Work in Civil Engineering Projects: Cut Corrected Cutaloki987No ratings yet

- Cone Development: SR Description 1 Cone Top Dia - D1 (MM) 2 Cone Bottom Dia - D2 (MM) 3 Cone Height - H (MM)Document7 pagesCone Development: SR Description 1 Cone Top Dia - D1 (MM) 2 Cone Bottom Dia - D2 (MM) 3 Cone Height - H (MM)neelNo ratings yet

- Spur GearsDocument7 pagesSpur GearsAkshay JadhavNo ratings yet

- 0.1 Eingangskennwerte: 0.1.1 AllgemeinesDocument7 pages0.1 Eingangskennwerte: 0.1.1 AllgemeineslöliNo ratings yet

- Kunci Jawaban UCP-1 Gasal 2021-22Document2 pagesKunci Jawaban UCP-1 Gasal 2021-22Ali Impron IINo ratings yet

- Gear Dimensions Are Determined in Accordance With Their SpecificationsDocument60 pagesGear Dimensions Are Determined in Accordance With Their SpecificationsChetan PrajapatiNo ratings yet

- Thick-Walled Cylinder and Compound Cylinder Theory October 2, 2008Document5 pagesThick-Walled Cylinder and Compound Cylinder Theory October 2, 2008Nyasha ChipokaNo ratings yet

- Spur GearsDocument6 pagesSpur GearsKedar GorwadkarNo ratings yet

- The Electrical Engineering HandbookDocument8 pagesThe Electrical Engineering HandbookSandal JepitNo ratings yet

- Design of Raft ThicknessDocument4 pagesDesign of Raft Thicknessvel suriyaNo ratings yet

- Paper-1: Hints & SolutionsDocument12 pagesPaper-1: Hints & SolutionsPrashantNo ratings yet

- Materi Roda Gigi PayungDocument11 pagesMateri Roda Gigi PayungSteven WijayNo ratings yet

- 9.8 Calculation For Gleason System Spiral Bevel Gear: Z Z M B M - 'H M - HDocument2 pages9.8 Calculation For Gleason System Spiral Bevel Gear: Z Z M B M - 'H M - HRZW R100% (2)

- Sukanta Mandal Pcme602Document11 pagesSukanta Mandal Pcme602Sukanta MandalNo ratings yet

- Perancangan BautDocument10 pagesPerancangan BautBayu WibisonoNo ratings yet

- Gear 2Document4 pagesGear 2Omar KeshkNo ratings yet

- End Plate - Bolted ConnectionDocument3 pagesEnd Plate - Bolted ConnectionASKOKONo ratings yet

- Problem Solutions For Chapter 12Document10 pagesProblem Solutions For Chapter 12api-19870706No ratings yet

- SolutiojDocument7 pagesSolutiojDevil HamNo ratings yet

- Physics Paper 2 SL MarkschemeDocument11 pagesPhysics Paper 2 SL MarkschemeAbdul RaqeebNo ratings yet

- Oo1. Structural Scheme, Torques and Rotation For Each Shaft: N 705rot /min M P NDocument23 pagesOo1. Structural Scheme, Torques and Rotation For Each Shaft: N 705rot /min M P NCsabesz BenczoNo ratings yet

- Design of Column-Beam Bolted ConnectionsDocument5 pagesDesign of Column-Beam Bolted ConnectionsSamwel KuriaNo ratings yet

- Gate Solved Paper - MeDocument38 pagesGate Solved Paper - MeHarish Jahan MohanNo ratings yet

- Meshing Spur GearsDocument25 pagesMeshing Spur GearsCherrydhelNo ratings yet

- WE-5-2 Fin Plate ConnectionDocument10 pagesWE-5-2 Fin Plate ConnectionPedro AlmeidaNo ratings yet

- Spiral Bevel Gear Arcoid System ZFTKK 250-1Document4 pagesSpiral Bevel Gear Arcoid System ZFTKK 250-1er_winwibowo100% (2)

- Details of GearsDocument88 pagesDetails of Gearsramchandra rao deshpandeNo ratings yet

- Techsec 4Document5 pagesTechsec 4Azrul Azis JwNo ratings yet

- Bracing ConnectionsDocument3 pagesBracing ConnectionspradeeshNo ratings yet

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Footings Design - Isolated PadDocument12 pagesFootings Design - Isolated Padmaruthiinfra structuresNo ratings yet

- Bar Bending Schedule (Part 1,2)Document33 pagesBar Bending Schedule (Part 1,2)Engr Zin Myo MinNo ratings yet

- GearDocument14 pagesGearAnimesh ManiNo ratings yet

- BEAM SampleDocument70 pagesBEAM SampleAira Joyce Salazar100% (1)

- Answers to Selected Problems in Multivariable Calculus with Linear Algebra and SeriesFrom EverandAnswers to Selected Problems in Multivariable Calculus with Linear Algebra and SeriesRating: 1.5 out of 5 stars1.5/5 (2)

- Analytic Geometry: Graphic Solutions Using Matlab LanguageFrom EverandAnalytic Geometry: Graphic Solutions Using Matlab LanguageNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Tables of the Function w (z)- e-z2 ? ex2 dx: Mathematical Tables Series, Vol. 27From EverandTables of the Function w (z)- e-z2 ? ex2 dx: Mathematical Tables Series, Vol. 27No ratings yet

- CH 09Document99 pagesCH 09AbdoNo ratings yet

- Exam Gear DesignDocument11 pagesExam Gear DesignAbdoNo ratings yet

- Chapter 1 PDFDocument43 pagesChapter 1 PDFAbdoNo ratings yet

- Stress Intensity Factor Determination OF Radially Cracked Circular Rings Subjected To Tension Using Photoelastic TechniqueDocument6 pagesStress Intensity Factor Determination OF Radially Cracked Circular Rings Subjected To Tension Using Photoelastic TechniqueAbdoNo ratings yet

- Shell Flowmeter Eng1neer1ng Handbook: EditionDocument3 pagesShell Flowmeter Eng1neer1ng Handbook: EditionDineshNo ratings yet

- InspireDesigner Installation Guide V8.1.0.1Document36 pagesInspireDesigner Installation Guide V8.1.0.1AOMNo ratings yet

- Mill) Dan Ekstrak Daun Terhadap Penurunan Kadar Gula Darah Pada TDocument10 pagesMill) Dan Ekstrak Daun Terhadap Penurunan Kadar Gula Darah Pada TJonathan RyanNo ratings yet

- Remed SurveyDocument4 pagesRemed Surveysamantha sarahNo ratings yet

- SR Secondary Maths Text BookDocument578 pagesSR Secondary Maths Text BookVamsidhar ReddyNo ratings yet

- 2 Block SystemDocument25 pages2 Block SystemSovia DumiyantiNo ratings yet

- Resident Physics Lectures: Attenuation MathDocument25 pagesResident Physics Lectures: Attenuation MathSebastian GutierrezNo ratings yet

- Muthoot Institute of Technology and Science Exam Cell S2 Time Table - Internal Exam 2: July 2020 TIME: 9.30 AM TO 11.30 AMDocument1 pageMuthoot Institute of Technology and Science Exam Cell S2 Time Table - Internal Exam 2: July 2020 TIME: 9.30 AM TO 11.30 AMrichard miniNo ratings yet

- Service Manual: TFT LCD Monitor Model: L500BDocument37 pagesService Manual: TFT LCD Monitor Model: L500BVlade NaumovskiNo ratings yet

- How To Make Gold Methods For Transmutation of Silver To GoldDocument19 pagesHow To Make Gold Methods For Transmutation of Silver To Goldaaaa100% (5)

- 1060 M Hydraulic Operated Concrete Block Making MachineDocument6 pages1060 M Hydraulic Operated Concrete Block Making MachineTejas T S TejasNo ratings yet

- Life Process Nutrition Question 1Document3 pagesLife Process Nutrition Question 1Nakshatra PaliwalNo ratings yet

- Planetary Fact Sheet - Metric - NASADocument2 pagesPlanetary Fact Sheet - Metric - NASAapi-3704956No ratings yet

- Delta Log Interpretation 79Document44 pagesDelta Log Interpretation 79ragil saputroNo ratings yet

- Secury Module XPSAC5121Document4 pagesSecury Module XPSAC5121juan ochoaNo ratings yet

- Stability Testing of Tansformer REF Protection SchemeDocument1 pageStability Testing of Tansformer REF Protection SchemeBala M100% (13)

- Supermax SeriesDocument4 pagesSupermax Seriesyury1102No ratings yet

- Manual EngDocument103 pagesManual EngGoran KlemčićNo ratings yet

- Ash Ring Formation in KilnDocument4 pagesAsh Ring Formation in KilnSiddharth SinghNo ratings yet

- Lift Every Voice and Sing - MelodyDocument5 pagesLift Every Voice and Sing - Melodygstith9597No ratings yet

- 643 Data Analysis PlanDocument8 pages643 Data Analysis Planapi-329054769No ratings yet

- Department of Education: Performance Task in Mathematics 9Document2 pagesDepartment of Education: Performance Task in Mathematics 9Rochelle AlmodalNo ratings yet

- Az-500 Set-1Document103 pagesAz-500 Set-1Digambar S TatkareNo ratings yet

- SAP CC Solution Brief - TelcoDocument4 pagesSAP CC Solution Brief - Telco1knw0nNo ratings yet

- Celdas BongshinDocument42 pagesCeldas Bongshinalgama-2009No ratings yet

- Mathematics Grade 10Document11 pagesMathematics Grade 10Yoga PratamaNo ratings yet

- 03 Handout 1Document7 pages03 Handout 1Adrasteia ZachryNo ratings yet

- Công Ty Cổ Phần Obdvietnam TỔNG ĐÀI HỖ TRỢ: 02871.088.881Document2 pagesCông Ty Cổ Phần Obdvietnam TỔNG ĐÀI HỖ TRỢ: 02871.088.881ANH LÊNo ratings yet

- Mono Point Bendix - Renault 19Document98 pagesMono Point Bendix - Renault 19Ivan Alilovic100% (1)

- Physical Geography MCQDocument8 pagesPhysical Geography MCQMRINMOY SAHANo ratings yet