Professional Documents

Culture Documents

Engineering Encyclopedia Project Management Managing Materials During Construction

Uploaded by

Mahmoud AlwasifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Encyclopedia Project Management Managing Materials During Construction

Uploaded by

Mahmoud AlwasifCopyright:

Available Formats

Engineering Encyclopedia Project Management

Managing Materials During Construction

• Material normally supplied by contractors (such as consumables and expendables,

hand or power tools, scaffolding, concrete forms, slings, block, tackles, welding

equipment, rods, automotive parts)

• Material which does not conform to the current engineering specifications (such as

asbestos cement pipe and related fittings, over-the-ditch tape wrapping, primer and

asbestos outer wrap, galvanized cable tray)

• Small quantities of pipe

• Prefabricated pipe spools

• Prefabricated structural steel pieces

• Radio and computer components

• Shelf-life material (such as paint, adhesive)

• Spare parts

• Structural plate, structural steel, sheet metal

• Used or damaged valves (For turning in used or damaged valves to Reclamation

for possible use and refurbishing, see GI 365.000)

Procedure to Return Excess Materials

SAMS excess may be returned to SAMS inventory provided the material:

• Is in new or good-as-new condition; and

• Meets the description in the item description data base of the Materials Cataloging

System of an SAMS catalog number; and

• Is expected to have future use as determined by Materials Control Department

(MCD) and remains in new or good-as-new condition until used.

Material is returned to SAMS inventory for full moving average unit price (AUP) credit (without

overhead) to the user. The user receives AUP credit plus overhead if the return is because of

incorrect issue by MSO.

New or good-as-new SAMS material, which has limited use and is deemed salable is returned

with Form A-8764 “New or Good-as-New Material Disposition” for partial credit to the user.

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Project Management

Managing Materials During Construction

SAMS material that is not new or good-as-new is returned to Reclamation with Form A-112

“Reclamation Receipt”; no credit is given to the user.

There are other stipulations which apply in particular situations. The Project Engineer will have to

discuss these with the MSO.

Steps to Avoid Surplus and Excess Materials Generation

The creation of surplus and excess materials are primarily the result of slower than planned

progress during detailed engineering, i.e. late identification of exact quantities and technical

details.

Projects which are fast tracked may also experience materials excesses and surpluses above

normal because of the compressed schedule and the requirement to place purchase orders before

the details of the drawings are ready.

Steps which the Project Engineer may exercise to avoid surplus and excess material include:

• Prepare the design basis and present the Project Proposal thoroughly and

completely

• Address potential problem areas early

• Prepare “neat” takeoffs

• Accurately control the issue of materials to the Contractor

• Store materials at the jobsite so they are in good-as-new condition all the way up

to return after commissioning.

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Project Management

Managing Materials During Construction

WORK AID 1: GUIDELINES IN THE MANAGEMENT OF MATERIAL

ACTIVITIES DURING THE CONSTRUCTION PHASE

The work aid provides guidelines for the development of Material Management activities during

the Construction Phase.

The participant should develop a list of items to ensure that all steps of the materials handling

and logistics processes are considered and in place prior to the start of construction.

The Participant should consider all elements of materials management in preparing the outline for

the Materials Management Plan. On page 2 the elements of materials management are identified.

The Participant should assure that all steps of the procurement process have been considered in

preparing the list of items which must be addressed in order to have a comprehensive Materials

Management Plan for the Construction Phase. The steps are reviewed beginning on page 6.

Saudi Aramco DeskTop Standards 12

Engineering Encyclopedia Project Management

Managing Materials During Construction

GLOSSARY

AUP Average Unit Price

CPM Critical Path Method

DC MATERIALS Direct Charge Materials

IK CONTRACTOR In Kingdom Contractor

MCD Materials Control Department

MSO Material Supply Organization

OOK CONTRACTOR Out of Kingdom Contractor

PO Purchase Order

PR Purchase Requisition

SAMS Saudi Aramco Material System

Saudi Aramco DeskTop Standards 13

You might also like

- Earthship Vol.3 Evolution Beyond EconomicsDocument272 pagesEarthship Vol.3 Evolution Beyond EconomicsSipos Zoltán100% (4)

- Dubai Building Code English 2021Document843 pagesDubai Building Code English 2021Arch Clark Benedict Baguio100% (3)

- Role of Project Management Consultancy IDocument6 pagesRole of Project Management Consultancy ISilva CumbeNo ratings yet

- Construction Quality Plan G16BDocument8 pagesConstruction Quality Plan G16BDavid SeeNo ratings yet

- REDA HAMAD CV - Senior Project EngineerDocument8 pagesREDA HAMAD CV - Senior Project EngineerRida Hamad100% (1)

- Standards of Professional Practice (SPP) On Pre-Design Service SPP Document 201Document189 pagesStandards of Professional Practice (SPP) On Pre-Design Service SPP Document 201MarkMonahanNo ratings yet

- Resume - Fabrication Engineer Heavy Engineering Steel FabricationDocument7 pagesResume - Fabrication Engineer Heavy Engineering Steel Fabricationsivagnanam s67% (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Economic Factors in Materials SelectionDocument19 pagesEconomic Factors in Materials SelectionAnonymous S9qBDVkyNo ratings yet

- PMT 30105Document29 pagesPMT 30105Yousef Adel HassanenNo ratings yet

- Method Statement For Piping Works - B99 Pump StationDocument14 pagesMethod Statement For Piping Works - B99 Pump StationMohamed100% (1)

- How To Estimate The Cost of Mechanical DredgingDocument21 pagesHow To Estimate The Cost of Mechanical DredgingKaren LimNo ratings yet

- Construction ProcedureDocument36 pagesConstruction ProcedureJagdish Busa100% (2)

- Resume - AMIT - PIPING ENGRDocument4 pagesResume - AMIT - PIPING ENGRSanjeev Kumar100% (1)

- Estimate Basis - NNPC Project - 1291 - 26!5!2018Document11 pagesEstimate Basis - NNPC Project - 1291 - 26!5!2018ashwani chandraNo ratings yet

- Jacket Construction of OilDocument5 pagesJacket Construction of OilLousianna MariaNo ratings yet

- Mechanical Integrity Program Development For New Construction - FINALDocument22 pagesMechanical Integrity Program Development For New Construction - FINALMatthew CasertaNo ratings yet

- Praveen Piping Designer ResumeDocument4 pagesPraveen Piping Designer Resumeprvnpg100% (1)

- QAQC Objective & Key Career AchievementsDocument3 pagesQAQC Objective & Key Career Achievementssaffririzal4237100% (2)

- SR. Mechanical EngineerDocument3 pagesSR. Mechanical Engineerulhaq637No ratings yet

- IRM2100 Material SelectionDocument26 pagesIRM2100 Material SelectionThành SơnNo ratings yet

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningFrom EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningNo ratings yet

- TOS PPT Marina BayDocument28 pagesTOS PPT Marina BayDakshata KoliNo ratings yet

- 0 - Chrill Raja Dsilva CVDocument3 pages0 - Chrill Raja Dsilva CVEstefania ChrillNo ratings yet

- 26 Newbuilding Manual Basuki OscarDocument17 pages26 Newbuilding Manual Basuki OscarAnonymous tap9Mv7vdlNo ratings yet

- 2011 Commissioning Best PracticesDocument39 pages2011 Commissioning Best PracticesluisgabrielperezNo ratings yet

- Aqeel CVDocument4 pagesAqeel CVZameel HarisNo ratings yet

- Method Statement For Irrigation 2Document12 pagesMethod Statement For Irrigation 2ashwinNo ratings yet

- Design Criteria and Guidelines For Surface Infrastructure Mechanical and StructuralDocument68 pagesDesign Criteria and Guidelines For Surface Infrastructure Mechanical and Structuraljonodo89No ratings yet

- BCA Coretrade GuidebookDocument52 pagesBCA Coretrade GuidebookpostboxsgNo ratings yet

- Sec03 - Duties and ResponsibilitiesDocument11 pagesSec03 - Duties and ResponsibilitiesYusufNo ratings yet

- Storage of Materials: Engineering Encyclopedia Project Management Managing Materials During ConstructionDocument4 pagesStorage of Materials: Engineering Encyclopedia Project Management Managing Materials During ConstructionMahmoud AlwasifNo ratings yet

- Construction Projec T Administration: Dr. Abubakar SharafatDocument55 pagesConstruction Projec T Administration: Dr. Abubakar Sharafatmalik awansNo ratings yet

- Engineering Encyclopedia: Managing Materials During ConstructionDocument4 pagesEngineering Encyclopedia: Managing Materials During ConstructionMahmoud AlwasifNo ratings yet

- Procurement Responsibility: Consideration in Successful Materials ProcurementDocument3 pagesProcurement Responsibility: Consideration in Successful Materials ProcurementMahmoud Alwasif100% (1)

- Nicmar: National Institute of Construction - . Management and ResearchDocument23 pagesNicmar: National Institute of Construction - . Management and ResearchAmit BhatiaNo ratings yet

- Mohammed Yousuf HussainDocument10 pagesMohammed Yousuf HussainjayshebasNo ratings yet

- Const Project Materials MGTDocument30 pagesConst Project Materials MGTnasru hajiNo ratings yet

- Unit No. 05Document40 pagesUnit No. 05rpkodamNo ratings yet

- TF Tactic Session Infrastructure PlanningDocument49 pagesTF Tactic Session Infrastructure PlanningJoy Boyles AbarquezNo ratings yet

- WMS For Installation of Panel BRD & Capacitor BNKDocument9 pagesWMS For Installation of Panel BRD & Capacitor BNKShahed HussainNo ratings yet

- Ahmed Tawfik CV PIP DDocument5 pagesAhmed Tawfik CV PIP DAhmed TawfikNo ratings yet

- 3rd Batch CMPM ReportersDocument113 pages3rd Batch CMPM Reporterskrizza mae ariasNo ratings yet

- Material Engineer jOB ROLESDocument9 pagesMaterial Engineer jOB ROLESBleep NewsNo ratings yet

- SOW - NEW REAGENT STORAGE WAREHOUSE STRUCTURAL STEEL WORKS - Steel OnlyDocument8 pagesSOW - NEW REAGENT STORAGE WAREHOUSE STRUCTURAL STEEL WORKS - Steel Onlym_muchakaziNo ratings yet

- Materials ManagementDocument10 pagesMaterials ManagementDATTATRAYA GADENo ratings yet

- Adil CV Latest PDFDocument4 pagesAdil CV Latest PDFMuhammad Adil KhanNo ratings yet

- Draft - Static - RYDocument4 pagesDraft - Static - RYGautam VadnereNo ratings yet

- Soil Remediation - Project Execution PlanDocument9 pagesSoil Remediation - Project Execution Plantcc.arshadNo ratings yet

- Biogas TV Aug 3 Burns MacDocument19 pagesBiogas TV Aug 3 Burns MacManikandan SWMSNo ratings yet

- EngineeringDocument11 pagesEngineeringIrfan MahmoodNo ratings yet

- Planning For Building Construction Planning For Building ConstructionDocument13 pagesPlanning For Building Construction Planning For Building ConstructionAbigailNo ratings yet

- Materials Engineer - Jeyaseelan DevavaramDocument9 pagesMaterials Engineer - Jeyaseelan DevavaramJeyaseelan Devavaram100% (1)

- Instructor 693Document13 pagesInstructor 693nodyyyNo ratings yet

- Zia - Rahman - Resume - 3 (Updated)Document8 pagesZia - Rahman - Resume - 3 (Updated)Saud KhanNo ratings yet

- HAC-10143-MS-CIV-002-Method Statement For Mass ConcreteDocument9 pagesHAC-10143-MS-CIV-002-Method Statement For Mass ConcreteHema playsNo ratings yet

- Ce 14 ReviewerDocument3 pagesCe 14 RevieweranikaNo ratings yet

- MS - Excavation & BackfillingDocument30 pagesMS - Excavation & Backfillinglike saddamNo ratings yet

- Unit 2 - Construction Management ContextDocument49 pagesUnit 2 - Construction Management ContextJB RSNJNNo ratings yet

- PR Plan & Hiring PlanDocument6 pagesPR Plan & Hiring PlanRaied AyeshNo ratings yet

- Materials Management-Final - Participant FileDocument42 pagesMaterials Management-Final - Participant FileAhyaanNo ratings yet

- Praveen Piping Field ResumeDocument5 pagesPraveen Piping Field ResumeprvnpgNo ratings yet

- MEGADocument6 pagesMEGAzerroNo ratings yet

- Wa0000.Document4 pagesWa0000.muralidharasethy4No ratings yet

- Wasif CVDocument2 pagesWasif CVTalha BaigNo ratings yet

- Standard Method StatementDocument23 pagesStandard Method StatementNithin MathaiNo ratings yet

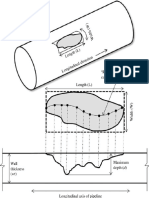

- Dimensions of A Typical Corrosion Defect On PipelineDocument1 pageDimensions of A Typical Corrosion Defect On PipelineMahmoud AlwasifNo ratings yet

- Objectives of A Consulting Services Failure Analysis ReportDocument1 pageObjectives of A Consulting Services Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia: Metallic Communications CableDocument45 pagesEngineering Encyclopedia: Metallic Communications CableMahmoud AlwasifNo ratings yet

- Heat Treatment of Steel: Assessment Performance CriteriaDocument6 pagesHeat Treatment of Steel: Assessment Performance CriteriaMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportDocument1 pageEngineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia: Failure Analysis ReportDocument1 pageEngineering Encyclopedia: Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Basis For The Recommendations in A Consulting Services Failure Analysis ReportDocument1 pageBasis For The Recommendations in A Consulting Services Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Applying The Recommendations of A Failure Analysis Report To Prevent Future FailuresDocument1 pageApplying The Recommendations of A Failure Analysis Report To Prevent Future FailuresMahmoud AlwasifNo ratings yet

- Pages: Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportDocument1 pagePages: Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Procurement Responsibility: Consideration in Successful Materials ProcurementDocument3 pagesProcurement Responsibility: Consideration in Successful Materials ProcurementMahmoud Alwasif100% (1)

- Standard-WPS-AWS-B2-1-1-1-016-94-pdf 8 PDFDocument1 pageStandard-WPS-AWS-B2-1-1-1-016-94-pdf 8 PDFMahmoud AlwasifNo ratings yet

- MT-Procedure 7Document1 pageMT-Procedure 7Mahmoud AlwasifNo ratings yet

- Standard-WPS-AWS-B2-1-1-1-016-94-pdf 16 PDFDocument1 pageStandard-WPS-AWS-B2-1-1-1-016-94-pdf 16 PDFMahmoud AlwasifNo ratings yet

- MT-Procedure 8Document1 pageMT-Procedure 8Mahmoud AlwasifNo ratings yet

- Ackron Product LineDocument14 pagesAckron Product LineSilvester SipayungNo ratings yet

- Batching SlipDocument1 pageBatching SlipanbunilavanNo ratings yet

- Raptor Slim Kenter Shackle R5Document1 pageRaptor Slim Kenter Shackle R5mayankdixit2No ratings yet

- What Is Pre Construction Anti Termite TreatmentDocument4 pagesWhat Is Pre Construction Anti Termite TreatmentvinodNo ratings yet

- Undercarriage Solutions and ComponentsDocument8 pagesUndercarriage Solutions and ComponentsBaggerkingNo ratings yet

- Ngan Yew Teng: Personal InfoDocument1 pageNgan Yew Teng: Personal InfoWesam Salah AlooloNo ratings yet

- Pulidores de Banco Trifasicos Paramount Industria de Motores ElectricosDocument2 pagesPulidores de Banco Trifasicos Paramount Industria de Motores ElectricosLuis Manuel Montoya RiveraNo ratings yet

- SCW OS From Level 1 Up To 5Document254 pagesSCW OS From Level 1 Up To 5Gudeta Jifara100% (3)

- 4.1 Catalogue Hang SangjinDocument77 pages4.1 Catalogue Hang SangjinKiến Huy LưuNo ratings yet

- Seminar 1st SemisterDocument38 pagesSeminar 1st SemisterMohan MylarappaNo ratings yet

- Csi GreenformatDocument67 pagesCsi GreenformatEhab EL-DalyNo ratings yet

- Sarawak Building Works RateDocument55 pagesSarawak Building Works RateChaiYingH100% (1)

- O&M Project JP200991: Equipment Reference To ManualDocument1 pageO&M Project JP200991: Equipment Reference To ManualSUNIL TPNo ratings yet

- Plastic - Pallets and Test SpecificationDocument24 pagesPlastic - Pallets and Test SpecificationKhaledAhmedNo ratings yet

- MTO-Parametric Estimating Guide-2011Document52 pagesMTO-Parametric Estimating Guide-2011Ashton MartynNo ratings yet

- Ashwin Hospital, Katmandu, NEPALDocument9 pagesAshwin Hospital, Katmandu, NEPALHem Agrawal JainNo ratings yet

- JOHN - DEERE - 360plus Rotary Harvesting UnitDocument136 pagesJOHN - DEERE - 360plus Rotary Harvesting UnitАлександр CheryNo ratings yet

- Sharpening and HoningDocument2 pagesSharpening and Honingkostas1977No ratings yet

- RCC - Civil Engineering Objective QuestionsDocument9 pagesRCC - Civil Engineering Objective Questionsutsav_koshtiNo ratings yet

- Keensert GuideDocument2 pagesKeensert GuidePaula Melleby McKeownNo ratings yet

- 20180329081320-Rising High With Dillinger Steel - enDocument6 pages20180329081320-Rising High With Dillinger Steel - enCarsonBakerNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum Vitaeapi-528243784No ratings yet

- Sample CVDocument3 pagesSample CVahamedtouhid899No ratings yet