Professional Documents

Culture Documents

Summary of API Inspection Frequencies 1581169054

Uploaded by

Tuğrulhan ÖzdemirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Summary of API Inspection Frequencies 1581169054

Uploaded by

Tuğrulhan ÖzdemirCopyright:

Available Formats

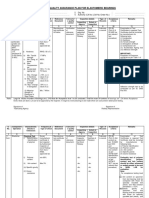

Pressure Vessels (API 510) Piping (API 570)

Visual Thickness

Continuous service Non-continuous service Circuit description

External measurement

a) Flammable services that can autorefrigerate

(e.g., LPG)

Visual External Lower of 5 yrs or the required internal/ on- Class 1 primary process piping b) Pressurized services that can rapidly 5 5

vaporize

Inspection stream inspection The same as for vessels in

c) H2S >3%wt in gaseous stream

(done with the - or - continuous service d) Anhydrous hydrogen chloride

vessel in service) A RBI assessment may allow interval >5 yrs e) Hydrofluoric acid (HF)

f) Piping over or adjacent to water / public

Class 1 secondary SBP (≤NPS 2) throughways 5 5

g) Flammable services operating above auto-

ignition temperature

If RL ≥ 4 yrs => lower of ½ RL or 10 yrs

Class 2 primary process piping a) On-site hydrocarbons that will slowly 5 10

If RL < 4 yrs => full RL up to 2 yrs

Internal/On- vaporize during release

- or - Based on the number of b) hydrogen, fuel gas, and natural gas

stream

A RBI assessment may allow interval >½ RL years of actual service Class 2 secondary SBP (≤NPS 2) c) on-site strong acids and caustics optional optional

Inspection

or 10 yrs, but if RBI interval > 10 yrs, RBI

assessment interval not to exceed 10 yrs Class 3 primary process piping 10 10

Services that are flammable but do not

significantly vaporize when they leak and are

not located in high-activity areas

The RBI assessment shall be updated after each inspection as per API 580, Section 14. Class 3 secondary SBP (≤NPS 2) optional optional

Pressure vessel RBI records should be in accordance with API 580, Section 16.

Services that are essentially nonflammable and

Class 4 process piping optional optional

nontoxic

Tanks (API 653) Components of a piping system that normally

have no significant flow. Some examples

include blanked branches, lines with normally

First Inspection Interval Following Inspection Intervals when When

closed block valves, lines with one end blanked,

corrosion corrosion

pressurized dummy support legs, stagnant

Class 2, 3 SBP Deadlegs has been has been

Routine Visual control valve bypass piping, spare pump piping,

Monthly (do not have to be done by an Inspector) experienced or experienced or

Inspection level bridles, relief valve inlet and outlet

is anticipated is anticipated

header piping, pump trim bypass lines, high-

point vents, sample points, drains, bleeders,

Full External and instrument connections.

Inspection (visual- Locations where chemicals or process additives

Lower of RCA/4N ( ¼ corrosion life) of the shell or 5 yrs are introduced into a process stream. E.g.,

only done with the

tank in service) corrosion inhibitors, neutralizers, process

antifoulants, desalter demulsifiers, oxygen

scavengers, caustic, and water washes.

Injection Points Injection points do not include locations where by class 3

Straight 5 yrs if the corrosion rate is Lower of RCA/2N ( ½ corrosion life ) of the shell two process streams join (mix points). E.g.,

Shell UT Inspection

not known or 15 yrs chlorinating agents in reformers, water

injection in overhead systems, polysulfide

Full Internal 10 yrs Period as long as minimum bottom thickness is injection in catalytic cracking wet gas, antifoam

Inspection - or - not reached (6.4.2.2) injections, inhibitors, and neutralizers.

(mainly about a longer RBI-derived period up to - or - 12 in. (305 mm) below to 6 in. (150 mm) above

inspecting the tank 20 yrs (30 yrs with Release a RBI-derived period up to 20 yrs Soil-to-air interface the soil surface. Pipe running parallel with the by class –

bottom) Prevention Barrier) (30 yrs with Release Prevention Barrier) soil surface that contacts the soil is included.

A RBI assessment may be used to increase or decrease the inspection limits described in Table.

The results of the RBI assessment can be used to establish appropriate frequency for internal, external and in- When RBI assessment is used to increase inspection interval limits, RBI assessments shall be conducted at intervals not

service inspections. The RBI assessment shall be reviewed and approved at intervals not to exceed 10 years or to exceed the respective limits. The RBI assessment shall be updated after each piping inspection.

more often if warranted by process, equipment, or consequence changes. Piping RBI records should be in accordance with API 580.

You might also like

- JetProp DLX STC ST00541SE Maintenance Manual 560.1001Document4 pagesJetProp DLX STC ST00541SE Maintenance Manual 560.1001Edwin Forgiel17% (6)

- Tank 7 Repair Procedure Rev1Document6 pagesTank 7 Repair Procedure Rev1Mohd Shafuaaz Kassim33% (3)

- API 570 PresentationDocument36 pagesAPI 570 PresentationMohamed El Sayad100% (1)

- API 570 Open BookDocument9 pagesAPI 570 Open BookMusa ÇelikNo ratings yet

- API 510 Study PlanDocument7 pagesAPI 510 Study Plankoib789100% (2)

- Standard QA Plan (Elastomeric Bearings)Document8 pagesStandard QA Plan (Elastomeric Bearings)ghaghra bridgeNo ratings yet

- Fired Heaters Operation Troubleshooting 1589699753 PDFDocument80 pagesFired Heaters Operation Troubleshooting 1589699753 PDFAliNo ratings yet

- Asnt NDT Level 3: How and Why Become CertifiedDocument16 pagesAsnt NDT Level 3: How and Why Become CertifiedAli100% (4)

- Intuitive Control Algorithm Development of 4WIS/4WID Using A SpaceMouseDocument46 pagesIntuitive Control Algorithm Development of 4WIS/4WID Using A SpaceMouseTyler KimNo ratings yet

- A Project Report On SonalikaDocument76 pagesA Project Report On SonalikaRohan Jain0% (2)

- API 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsDocument6 pagesAPI 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsIbtehaj ManiNo ratings yet

- API RP 572 QuizDocument17 pagesAPI RP 572 Quizamalhaj2013No ratings yet

- Daily Exam 7 (Closed) : Professional Training and ConsultationDocument5 pagesDaily Exam 7 (Closed) : Professional Training and ConsultationCss SfaxienNo ratings yet

- API 510 PC 20 31 Aug05 Mid Session ClosedDocument13 pagesAPI 510 PC 20 31 Aug05 Mid Session ClosedCss SfaxienNo ratings yet

- N2 - Rev ADocument13 pagesN2 - Rev AChirag ShahNo ratings yet

- API 570 Day 5 Book (1 To 130)Document137 pagesAPI 570 Day 5 Book (1 To 130)melvinNo ratings yet

- API 510-Kuwait PetroleumDocument392 pagesAPI 510-Kuwait PetroleumVijay Kumar100% (1)

- Chapter3API653 Tank InspectionDocument106 pagesChapter3API653 Tank InspectioniraprobotNo ratings yet

- Allowed To Use The ASME Codes and The API Books On The First Portion of The Test Only. No ReferenceDocument209 pagesAllowed To Use The ASME Codes and The API Books On The First Portion of The Test Only. No Referencejay2kay5793No ratings yet

- MSTS Mark's API 510 STUDY GUIDE.Document30 pagesMSTS Mark's API 510 STUDY GUIDE.Hares SlalNo ratings yet

- API Training ClassDocument57 pagesAPI Training ClassSakthi Pk100% (3)

- API Icp 510 Exam Pack (Dec2013)Document3 pagesAPI Icp 510 Exam Pack (Dec2013)freemechguy0% (1)

- Api 653 Preparatory Course: Exam 4 - Closed BookDocument4 pagesApi 653 Preparatory Course: Exam 4 - Closed BookNuwan Ranaweera100% (1)

- 11.API 574 Practive QnsDocument6 pages11.API 574 Practive QnsvamsikrishnaNo ratings yet

- API Standard 653 - Tank Inspection, Repair, Alteration, and ReconstructionDocument28 pagesAPI Standard 653 - Tank Inspection, Repair, Alteration, and ReconstructionChozha RajanNo ratings yet

- API 570 Day 4 BookDocument80 pagesAPI 570 Day 4 BookZaidi AftabNo ratings yet

- Sis Book1Document99 pagesSis Book1Hamza AlamNo ratings yet

- API 510 QUIZ No.4Document5 pagesAPI 510 QUIZ No.4Hatem RagabNo ratings yet

- API 570 DEC 2009 ClosedDocument17 pagesAPI 570 DEC 2009 ClosedMohammedBujairNo ratings yet

- Question 36 Begins The Closed Book Portion of This ExamDocument25 pagesQuestion 36 Begins The Closed Book Portion of This ExamBeantickNo ratings yet

- API 570 DemoDocument6 pagesAPI 570 Demojaire esparzaNo ratings yet

- API 570 - Mockup CB - Paper 2Document16 pagesAPI 570 - Mockup CB - Paper 2Shanawas Abdul Razak100% (1)

- Daily Points To Recall (Day 1) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (Day 1) : Professional Training and ConsultationshakeelahmadjsrNo ratings yet

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDocument8 pagesAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinNo ratings yet

- 1.API 570 & Asme DefinitionsDocument59 pages1.API 570 & Asme DefinitionsAMAL VISHNUNo ratings yet

- API 510 - Book 6Document119 pagesAPI 510 - Book 6nathaniel ekaikoNo ratings yet

- Heat Exchanger InspectionDocument15 pagesHeat Exchanger InspectionroyNo ratings yet

- Prep Material QB-576Document5 pagesPrep Material QB-576Raheem Khan100% (1)

- API 570 Daily ExamDocument3 pagesAPI 570 Daily Examalouis100% (1)

- API 570, Piping Inspection Code (June 2006) .: (DAY 2 - Sections 1 To 6)Document5 pagesAPI 570, Piping Inspection Code (June 2006) .: (DAY 2 - Sections 1 To 6)vishal bailur100% (1)

- API 510 Examination Sample ItemsDocument3 pagesAPI 510 Examination Sample ItemsMagira PasaribuNo ratings yet

- API 510 Preparatory TrainingDocument362 pagesAPI 510 Preparatory TrainingAnonymous ACFRCjZNo ratings yet

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDocument8 pagesAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinNo ratings yet

- Daily Points To Recall (Day 4) : Page 1 of 2Document2 pagesDaily Points To Recall (Day 4) : Page 1 of 2HemaNo ratings yet

- Api RP 581 Risk Based Inspection Methodology: Webcorr Corrosion Consulting Services PresentsDocument2 pagesApi RP 581 Risk Based Inspection Methodology: Webcorr Corrosion Consulting Services PresentsfaisalNo ratings yet

- ch4 - API 574 PDFDocument6 pagesch4 - API 574 PDFRAMADOSSNo ratings yet

- API571 - NEW APP - Effective 2011 - CompletedDocument12 pagesAPI571 - NEW APP - Effective 2011 - Completedtong2jeNo ratings yet

- API 570 Course Model Test 9Document5 pagesAPI 570 Course Model Test 9Ismail Jamaluddin100% (1)

- TDI33 Tank Inspection Suitaility For Service API 653 Sec 4Document29 pagesTDI33 Tank Inspection Suitaility For Service API 653 Sec 4Faizal SattuNo ratings yet

- API 510 Data Sheets - QuizletDocument1 pageAPI 510 Data Sheets - Quizletads_1203No ratings yet

- Final Exam (Closed Book) : Answer SheetDocument13 pagesFinal Exam (Closed Book) : Answer SheetDAMIAN ALEJANDRO100% (1)

- API 510 Data Sheet - AnswersDocument6 pagesAPI 510 Data Sheet - Answersjithinjose86No ratings yet

- Intervalos InspDocument4 pagesIntervalos InspMarlon QuinteroNo ratings yet

- DS 1 CatDocument38 pagesDS 1 CatMuhammad Bilal Khattak100% (1)

- Test Report 2Document14 pagesTest Report 2Rogelio PabuayaNo ratings yet

- Standard Cigre Gas Sf6Document1 pageStandard Cigre Gas Sf6fajar9nugraha-2No ratings yet

- BSIBV-ITP-09-1 For Liquid Epoxy Coating On Fittings Rev. 0Document5 pagesBSIBV-ITP-09-1 For Liquid Epoxy Coating On Fittings Rev. 0AMALENDU PAULNo ratings yet

- Gu01 2009 Standard ReferenceDocument7 pagesGu01 2009 Standard ReferenceFrancis BoeyNo ratings yet

- DS1 Standards DP BHADocument3 pagesDS1 Standards DP BHAGeotag100% (1)

- CFR 2011 Title49 Vol3 Sec192 627Document1 pageCFR 2011 Title49 Vol3 Sec192 627AssemNo ratings yet

- IMG - 0195 PSME Code 2008 184Document1 pageIMG - 0195 PSME Code 2008 184rii amosNo ratings yet

- API 570 Final OpenDocument13 pagesAPI 570 Final OpenGreg Agullana Cañares Jr.100% (3)

- Training Fresh EntrantsDocument121 pagesTraining Fresh EntrantsPriyank SutariyaNo ratings yet

- Piping NotesDocument17 pagesPiping Notesravindra_jivaniNo ratings yet

- Asme Iso Ibr 1697868370Document65 pagesAsme Iso Ibr 1697868370AliNo ratings yet

- Understanding Microbiologically Influenced Corrosion MIC 1697549073Document7 pagesUnderstanding Microbiologically Influenced Corrosion MIC 1697549073Ali0% (1)

- Flow Accelerated Corrosion (FAC) of Deaerator TankDocument1 pageFlow Accelerated Corrosion (FAC) of Deaerator TankAliNo ratings yet

- Interesting Article From USA Is There A UK Safety Alert 1611502714Document2 pagesInteresting Article From USA Is There A UK Safety Alert 1611502714AliNo ratings yet

- Quick Reference Guide: Section VIII, Division I - 2017 EditionDocument1 pageQuick Reference Guide: Section VIII, Division I - 2017 EditionVenicio AchermanNo ratings yet

- Lecture1: Principles of CorrosionDocument70 pagesLecture1: Principles of CorrosionAliNo ratings yet

- Engineering Fundamentals For Piping Pipelines ASME B31 1577476940Document1 pageEngineering Fundamentals For Piping Pipelines ASME B31 1577476940AliNo ratings yet

- A Course On Piing Systems Vibration Solution - 1557224499Document1 pageA Course On Piing Systems Vibration Solution - 1557224499AliNo ratings yet

- Advanced NDT Techniques Presentation 1572625262Document12 pagesAdvanced NDT Techniques Presentation 1572625262Ali100% (1)

- Pms Color ChartDocument20 pagesPms Color ChartAnaidNo ratings yet

- ImplementationsDocument14 pagesImplementationsanuNo ratings yet

- CRM100 - Precision Navigation and Pointing GyroscopeDocument34 pagesCRM100 - Precision Navigation and Pointing GyroscopeStanley Ochieng' OumaNo ratings yet

- Ibm Thinkpad r30Document36 pagesIbm Thinkpad r30dwayne_hibbertNo ratings yet

- Wire Mooring Ropes - Inspection ManualDocument26 pagesWire Mooring Ropes - Inspection ManualaditiyaNo ratings yet

- V Convocation Gold Medals ListDocument10 pagesV Convocation Gold Medals ListDaniel KinneyNo ratings yet

- Us 20221109Document22 pagesUs 20221109javier roviraNo ratings yet

- Front Hub & Spindle PartsDocument14 pagesFront Hub & Spindle PartsAmit Chopra Amit100% (1)

- JW Pump Curve - F3514g-F3524g-F3524gsiDocument1 pageJW Pump Curve - F3514g-F3524g-F3524gsikman548No ratings yet

- Ck1401 - Dual Stepper Motor Controller: Circuit DescriptionDocument6 pagesCk1401 - Dual Stepper Motor Controller: Circuit DescriptionYasir KhanNo ratings yet

- Procedure Tejas 2GB 512MB Disk Software Upgradation in MADMDocument8 pagesProcedure Tejas 2GB 512MB Disk Software Upgradation in MADMBSNL DGPNo ratings yet

- Ee04 801 - Jun11Document1 pageEe04 801 - Jun11Angamuthu AnanthNo ratings yet

- K4D261638FDocument18 pagesK4D261638F9183290782No ratings yet

- 2007 Ford Freestar Repair ManualDocument320 pages2007 Ford Freestar Repair Manuale_wastedNo ratings yet

- AS - NZS 4200.2-1994 Installation RequirementsDocument11 pagesAS - NZS 4200.2-1994 Installation RequirementsMorten PedersenNo ratings yet

- Bubble Map 2021-06-09Document1 pageBubble Map 2021-06-09Tserendolgor Enkh-AmgalanNo ratings yet

- Plate Load TestDocument3 pagesPlate Load TestniteshNo ratings yet

- Spare of Eot Crane Bar-Mill Angul1Document10 pagesSpare of Eot Crane Bar-Mill Angul1Rakesh Karan SinghNo ratings yet

- Aerodynamic Analysis of Rear Wings and Rear SpoilerDocument9 pagesAerodynamic Analysis of Rear Wings and Rear SpoilerBảo Toàn LêNo ratings yet

- Quick Charge Device ListDocument11 pagesQuick Charge Device ListdrabssbNo ratings yet

- Building The Kra Canal andDocument9 pagesBuilding The Kra Canal andPete Maverick MitchellNo ratings yet

- Avancar Trias XLDocument1 pageAvancar Trias XLRaghvendra ManiNo ratings yet

- 4339 Woodbury InformationMap Victoria PointDocument1 page4339 Woodbury InformationMap Victoria PointCheryl GoodenoughNo ratings yet

- Fd60hz Secador Atlas Copco - ManualDocument8 pagesFd60hz Secador Atlas Copco - ManualEdvaldo França100% (1)

- Paper 3C1 Examples Sheet 8: Control Systems: David Corrigan 2011Document3 pagesPaper 3C1 Examples Sheet 8: Control Systems: David Corrigan 2011Armando MaloneNo ratings yet

- Tsunami Disaster Mitigation System in JapanDocument20 pagesTsunami Disaster Mitigation System in JapanRounak PramanikNo ratings yet

- Measurement Values: Absolute Color Scales (Available When Display Type Is Absolute)Document26 pagesMeasurement Values: Absolute Color Scales (Available When Display Type Is Absolute)rafael_dvgNo ratings yet