Professional Documents

Culture Documents

Facts at Your Fingertips-201103-Infrared Temperature Measurement

Uploaded by

onizuka-t2263Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Facts at Your Fingertips-201103-Infrared Temperature Measurement

Uploaded by

onizuka-t2263Copyright:

Available Formats

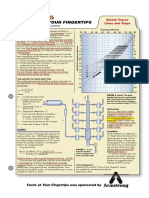

Infrared

Temperature

Department Editor: Scott Jenkins Measurement

ontact-based temperature sensors, such as Operation

C thermocouples and resistance temperature

detectors (RTDs), have demonstrated ac-

curate and cost-effective operation throughout

Most IR thermometers operate

according to the same basic

operating principles (Figure 1).

EMISSIVITY VALUES OF COMMON MATERIALS*

Material

Silver (polished)

Emissivity

0.01

the chemical process industries (CPI). However, A bandwidth ilter and optical Aluminum (unoxidized) 0.02

there are many applications and settings lens are used to focus the IR Gold (polished) 0.02

where they are simply not practical. In those energy emitted by an object Aluminum (heavily oxidized) 0.20

cases, engineers can turn to a host of non- onto a detector, which converts Zinc (bright galvanized) 0.23

contact temperature measurement devices, the IR radiation into an electri- Steel (316 polished) 0.28

many of which are based on measuring cal signal. After compensating

Soil (plowed field) 0.38

infrared (IR) radiation. IR thermometers can for emissivity (see below) and

routinely perform measurements in situations ambient temperature, an analog Iron (liquid) 0.43

where readings with contact thermometers output is generated to provide Iron (rusted) 0.65

would be virtually impossible. Situations where temperature measurement. The Water 0.67

IR-based temperature measurement should be analog signal can be converted Sand 0.76

considered include the following: to digital when fast acquisition Steel (cold rolled) 0.80

• Rapid and frequent temperature readings rates are required. Wood (oak planed) 0.91

are required

Brick (red, rough) 0.93

• Objects are moving Emissivity

• Objects are within strong electromagnetic The emission of thermal radia- Carbon (Lampblack) 0.95

fields, such as in processes involving induc- tion is a surface phenomenon Ice 0.98

tion or microwave heating for most materials. The term *Provided for illustrative purposes only.

• Rapid thermal changes are the norm emissivity refers to an object’s

• Objects needing measurement are located ability to emit thermal radiation.

Emissivity is defined as the ratio between the (distance-to-spot ratio). Higher ratios mean

in process chambers or behind windows

energy emitted by an object at a given tem- better resolution.

• The surface temperature of an object or

Ideally, the target being measured should fill

equipment requires measurement perature and a perfect radiator, or blackbody,

the instrument’s FOV. For the best perfor-

• Locations are inaccessible to contact at the same temperature. Emissivity values

lie between zero and one. IR thermometers mance, the target object area should exceed

thermometers

the FOV by a factor of about 1.5 (Figure 2).

• Areas to be measured would be damaged generally have the ability to compensate for

or contaminated by contact measurement the different emissivity values of materials.

Materials with the highest emissivity values Calibration

• Varying surface-temperature distributions are

are the easiest to measure accurately with IR IR thermometers can be calibrated by aiming

present

at blackbody radiators that are designed

• Objects are made from materials with low thermometers, while those with low emissivities

are more difficult. For example, some polished, specifically for calibration and testing. By vary-

heat capacity and low thermal conductivity

ing the source temperature of the blackbody,

• Materials to be measured are gaseous, such shiny metallic surfaces, such as aluminum, are

so reflective in the infrared that accurate tem- calibrators can tune the IR sensor’s internal

as combustion gases and flames

perature measurement is not always possible. measurement signal to known temperatures.

Within the CPI, IR thermometry is most ef- Tables listing emissivity values for various

fective and used most frequently in semicon- materials have been published, and are avail- Selection questions to consider

ductor and wafer processing, cement and able for reference (Table). Some IR thermom- When selecting an IR thermometer for a CPI

lime processing, rotating kiln shells, waste eters allow users to change emissivity values application, it is important to consider the fol-

incineration, glass processing, sintering and according to the material being measured, lowing questions:

heat treating, metals processing and drying while others have a pre-set emissivity value. • What is the required proximity to the target?

applications. While IR thermometers are gen- When using IR thermometry, it is important • What is the size of object to be measured,

erally more expensive than contact thermom- to consider that materials can have different and will it it the instrument’s FOV?

eters, they usually have longer lifetimes and emissivity values at different wavelengths. To • Are there any physical obstructions between

require less maintenance. determine an emissivity value, you can heat a the object to be measured and the measur-

A general knowledge of the key aspects of material to a known temperature, then adjust ing device

thermal radiation physics can help users apply the emissivity value of the instrument until the IR • Are smoke, dust or other particulate matter

and operate the devices more effectively. thermometer matches the known temperature. likely to be in the measurement area?

• What are the measurement control fre-

Stefan-Boltzmann law Field of view (FOV) quency requirements?

The energy radiated by an object per unit The FOV is the angle of vision at which the • Does the object have a shiny surface?

surface area per unit time is related to its instrument operates and is determined by the • What are the output/interface requirements?

temperature by the Stefan-Boltzmann law, which optics of the system. The optical system of the

states that irradiance (in J/s/m2) is proportional References

IR thermometer collects the IR energy from a

to the fourth power of the object’s temperature circular measurement spot, and focuses the 1. Young, A., IR Thermometry Finds CPI Niches,

multiplied by its emissivity. A constant of propor- energy on the detector. The optical resolution Chem. Eng., Feb. 2002, pp. 56–60.

tionality (the Stefan-Boltzmann constant) is re- of the instrument is determined by the ratio 2. Omega Engineering Inc. [Internet]. c2003–

quired for calculations. In a perfect (theoretical) between the distance from instrument to object 2010. Stamford (CT). [cited Feb. 2011].

blackbody radiator, emissivity equals one. and the size of the spot being measured Available from: http://www.omega.com/.

Lens assembly

Object Filter Recommended Incorrect

Field of view Aperture

Detector IR Thermometer

Amplifier

and electronics

Target greater Target equal Target smaller

D than spot size to spot size than spot size Backround

FIGURE 1. The optical system of an IR thermometer collects IR en- FIGURE 2. For accurate IR temperature measurement, the target area

ergy from a circular measurement spot, and focuses it on a detector should be greater than the instrument’s FOV by a factor of about 1.5

You might also like

- Thermal Imaging: SC, KF & GFDocument9 pagesThermal Imaging: SC, KF & GFooironicooNo ratings yet

- Rollers Pipes CylindersDocument1 pageRollers Pipes CylindersJoanna MarieNo ratings yet

- NDT ThermographyDocument30 pagesNDT ThermographyAshwini SinghNo ratings yet

- How Infrared Thermocouples WorkDocument13 pagesHow Infrared Thermocouples WorkKlingkling Magbanua DomiderNo ratings yet

- Resistance Temperature Detectors (RTDS)Document14 pagesResistance Temperature Detectors (RTDS)ramprabhakarjNo ratings yet

- Infrared Inspection Program for Fired Heater Integrity ManagementDocument21 pagesInfrared Inspection Program for Fired Heater Integrity Managementbarry nancoo100% (1)

- Infrared Non Contact ThermometersDocument8 pagesInfrared Non Contact ThermometersKaushik LanjekarNo ratings yet

- Unit-2-Thermal, Optical and PIR SensorDocument32 pagesUnit-2-Thermal, Optical and PIR SensorAnuj NikamNo ratings yet

- Non-Contact Temperature Measurement TechniquesDocument16 pagesNon-Contact Temperature Measurement TechniquesJoel EvertonNo ratings yet

- CHAPTER-2 Automation ComponentsDocument65 pagesCHAPTER-2 Automation ComponentsHimanshu JoshiNo ratings yet

- Measuring Building Losses & Applications of Infrared (Ir) ThermographyDocument6 pagesMeasuring Building Losses & Applications of Infrared (Ir) ThermographyArthur Maderse Ramo Jr.No ratings yet

- EGE Infrared DetectorsDocument12 pagesEGE Infrared DetectorsYing Kei ChanNo ratings yet

- 39 PDFDocument3 pages39 PDFMisdehRasmanNo ratings yet

- Thermography PPT 110405102354 Phpapp02 PDFDocument24 pagesThermography PPT 110405102354 Phpapp02 PDFvignesh88in2332No ratings yet

- Temperature Sensing TechniquesDocument66 pagesTemperature Sensing TechniquesEng RemoonNo ratings yet

- THERMOGRAPHDocument39 pagesTHERMOGRAPHBRajesh ReddyNo ratings yet

- Physics Project - OdtDocument22 pagesPhysics Project - OdtRitu AgrawalNo ratings yet

- L5 Slides 4 Temperature SensorsDocument64 pagesL5 Slides 4 Temperature Sensorspemadamunisel besjayaNo ratings yet

- Thermal Camera Implementation For Crack Detection in Pressure VesselsDocument5 pagesThermal Camera Implementation For Crack Detection in Pressure VesselsVinodNo ratings yet

- Emissivity UKDocument1 pageEmissivity UKMohamed-Hazem Mahmoud NadaNo ratings yet

- Syn A - Lecture Slides-Week No. 10Document22 pagesSyn A - Lecture Slides-Week No. 10Afaaq HussainNo ratings yet

- TR Induction Heating Systems - 201705 - enDocument4 pagesTR Induction Heating Systems - 201705 - enVanbeverNo ratings yet

- Principles of Infrared ThermometryDocument5 pagesPrinciples of Infrared ThermometrytrebeardNo ratings yet

- Thermocouple: Anand Bongir Girjashankar MishraDocument10 pagesThermocouple: Anand Bongir Girjashankar MishraПривет УлыбатьсяNo ratings yet

- Module 2 Part 1Document85 pagesModule 2 Part 1Sankaranarayanan ANo ratings yet

- Chapter 6 Temperature MeasurementDocument37 pagesChapter 6 Temperature MeasurementYasser ElshaerNo ratings yet

- MSL Technical Guide 2 Infrared Thermometry Ice Point: Introduction and ScopeDocument2 pagesMSL Technical Guide 2 Infrared Thermometry Ice Point: Introduction and ScopeEgemet SatisNo ratings yet

- Mini Project ReportDocument14 pagesMini Project ReportfatinNo ratings yet

- Sensor dan Aktuator: Temperature, Light, and AcousticDocument50 pagesSensor dan Aktuator: Temperature, Light, and AcousticCakra BhirawaNo ratings yet

- Important Considerations For Measuring Human Body Temperature With Infrared ThermometersDocument27 pagesImportant Considerations For Measuring Human Body Temperature With Infrared ThermometersSelyun E OnnajNo ratings yet

- Radiation Pyrometre NaveenaDocument27 pagesRadiation Pyrometre NaveenaRahul RaaghavNo ratings yet

- Lec14 PDFDocument24 pagesLec14 PDFharikiranNo ratings yet

- Thermocouple 110329060908 Phpapp02Document10 pagesThermocouple 110329060908 Phpapp02Eng-anwer kadhimNo ratings yet

- Radiation Temperature Measurement GuideDocument32 pagesRadiation Temperature Measurement GuideYatharth AgrawalNo ratings yet

- Helios-Quartz IR-LAMPS EngDocument24 pagesHelios-Quartz IR-LAMPS EngAlbertoNo ratings yet

- Measurement of TemperatureDocument21 pagesMeasurement of TemperatureCharitha RanwalaNo ratings yet

- RD Handbook PDFDocument48 pagesRD Handbook PDFManuelNo ratings yet

- Williamson Product Overview BrochureDocument12 pagesWilliamson Product Overview Brochuresunil_dharNo ratings yet

- IR Thermometer ManualDocument3 pagesIR Thermometer ManualAgus Athar yuliantoNo ratings yet

- Emissivity and AccuracyDocument9 pagesEmissivity and Accuracyalexander100% (1)

- Infrared Sensor Application Notes ZTPDocument22 pagesInfrared Sensor Application Notes ZTPilarionramahefarisoaNo ratings yet

- NDT UNIT 3-Complete NotesDocument59 pagesNDT UNIT 3-Complete Notesshriman100% (1)

- Thermal Imaging Tech Provides Night Vision for Emergency RespondersDocument2 pagesThermal Imaging Tech Provides Night Vision for Emergency RespondersLealyn AbaoNo ratings yet

- IRUltrasonicLDRsensorDocument30 pagesIRUltrasonicLDRsensorYatharth YatharthNo ratings yet

- Design Consideration of RTDDocument6 pagesDesign Consideration of RTDRavi LaguNo ratings yet

- CH - 2 - Sensors - Last PartDocument75 pagesCH - 2 - Sensors - Last PartAgtNo ratings yet

- Selecting The Correct Temperature SensorDocument5 pagesSelecting The Correct Temperature SensorRajeev PandeyNo ratings yet

- Pyro MetersDocument3 pagesPyro MetersNakul AhirraoNo ratings yet

- Fundamentals of Thermometry - Part 8Document15 pagesFundamentals of Thermometry - Part 8AntmavrNo ratings yet

- TG22 Version 3 MSL Technical GuideDocument9 pagesTG22 Version 3 MSL Technical GuideBalaMayurPriyanNo ratings yet

- MSL Tech Guide 22 - Calibration Infrared ThermometerDocument8 pagesMSL Tech Guide 22 - Calibration Infrared Thermometeracanis1016100% (2)

- TR Casting 201302 enDocument4 pagesTR Casting 201302 enVanbeverNo ratings yet

- Temperature MeasurementDocument25 pagesTemperature MeasurementPratik GhongadeNo ratings yet

- Non-Contact Temperature Measurement DevicesDocument14 pagesNon-Contact Temperature Measurement DevicesSubhajit ChaudhuriNo ratings yet

- Temperature Measurement: After Time, Temperature Is The Second Most Measured Physical UnitDocument40 pagesTemperature Measurement: After Time, Temperature Is The Second Most Measured Physical Unitanon_410770000No ratings yet

- Article About SensorDocument2 pagesArticle About SensorArjun NegiNo ratings yet

- Pocket Guide Thermography enDocument56 pagesPocket Guide Thermography enMárton SolymosiNo ratings yet

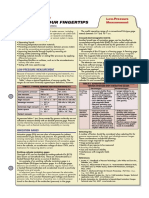

- Facts at Your Fingertips-201105-Pressure Measurement ConsiderationsDocument1 pageFacts at Your Fingertips-201105-Pressure Measurement Considerationsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201102-Control Valve Position SensorsDocument1 pageFacts at Your Fingertips-201102-Control Valve Position Sensorsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201012-Project Design Decision-Making Option ListsDocument1 pageFacts at Your Fingertips-201012-Project Design Decision-Making Option Listsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201104-Hopper Inserts For Improved Solids FlowDocument1 pageFacts at Your Fingertips-201104-Hopper Inserts For Improved Solids Flowonizuka-t2263No ratings yet

- Facts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)Document1 pageFacts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)onizuka-t2263No ratings yet

- Facts at Your Fingertips-201011-Viscosity MeasurementDocument1 pageFacts at Your Fingertips-201011-Viscosity Measurementonizuka-t2263No ratings yet

- Facts at Your Fingertips-201010-MSMPR Crystallization EquipmentDocument1 pageFacts at Your Fingertips-201010-MSMPR Crystallization Equipmentonizuka-t2263No ratings yet

- Facts at Your Fingertips-201006-Fluid MechanicsDocument1 pageFacts at Your Fingertips-201006-Fluid Mechanicsonizuka-t2263No ratings yet

- Steam Tracer Lines and Traps GuideDocument1 pageSteam Tracer Lines and Traps Guideonizuka-t2263No ratings yet

- CHE Facts 0410Document1 pageCHE Facts 0410gwinnruNo ratings yet

- Facts at Your Fingertips-201002-Positive Displacement PumpsDocument1 pageFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFDocument1 pageFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263No ratings yet

- Controlling membrane foulingDocument1 pageControlling membrane foulingonizuka-t2263No ratings yet

- Heat Transfer Fluids: System FiltrationDocument1 pageHeat Transfer Fluids: System Filtrationonizuka-t2263No ratings yet

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFDocument1 pageFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263No ratings yet

- Facts at Your Fingertips-201007-Conservation Economics Carbon Pricing ImpactsDocument1 pageFacts at Your Fingertips-201007-Conservation Economics Carbon Pricing Impactsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201002-Positive Displacement PumpsDocument1 pageFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263No ratings yet

- CHE Facts 0410Document1 pageCHE Facts 0410gwinnruNo ratings yet

- Facts at Your Fingertips-201001-Low-Pressure MeasurementDocument1 pageFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263No ratings yet

- Facts at Your Fingertips-201001-Low-Pressure MeasurementDocument1 pageFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263No ratings yet

- Steam Tracer Lines and Traps GuideDocument1 pageSteam Tracer Lines and Traps Guideonizuka-t2263No ratings yet

- Above and Underground Storage Tanks PDFDocument1 pageAbove and Underground Storage Tanks PDFrasik.kiraneNo ratings yet

- Facts at Your Fingertips-200912-Creating Installed Gain GraphsDocument1 pageFacts at Your Fingertips-200912-Creating Installed Gain Graphsonizuka-t2263No ratings yet

- Adsorption PDFDocument1 pageAdsorption PDFrasik.kiraneNo ratings yet

- Facts at Your Fingertips-200909-Heat Transfer System Design IIDocument1 pageFacts at Your Fingertips-200909-Heat Transfer System Design IIonizuka-t2263No ratings yet

- Facts at Your Fingertips-200907-Flowmeter SelectionDocument2 pagesFacts at Your Fingertips-200907-Flowmeter Selectiononizuka-t2263No ratings yet

- Facts at Your Fingertips-200910-Chemical Resistance of ThermoplasticsDocument1 pageFacts at Your Fingertips-200910-Chemical Resistance of Thermoplasticsonizuka-t2263No ratings yet

- Specialty metals guide corrosion resistance and propertiesDocument1 pageSpecialty metals guide corrosion resistance and propertiesonizuka-t2263No ratings yet

- Facts at Your Fingertips-200905-Choosing A Control SystemDocument1 pageFacts at Your Fingertips-200905-Choosing A Control Systemonizuka-t2263No ratings yet

- Engineering Thermodynamics: Experiment# 08 (Open Ended Lab)Document17 pagesEngineering Thermodynamics: Experiment# 08 (Open Ended Lab)kashmiri food and culture and bunkNo ratings yet

- 4-13 TC Instrument Engineer HandbookDocument24 pages4-13 TC Instrument Engineer Handbooknabil mahmudNo ratings yet

- Tutorial 5Document1 pageTutorial 5sakinah azizanNo ratings yet

- Applied Thermodynamics - II: Gas Turbines - Shaft Power Ideal CyclesDocument34 pagesApplied Thermodynamics - II: Gas Turbines - Shaft Power Ideal CyclesSandeep BadinehalNo ratings yet

- Marine HVAC SystemsDocument58 pagesMarine HVAC SystemsSiti Aishah Hussien100% (3)

- Thermodynamic 1Document312 pagesThermodynamic 1Daniel Wang100% (5)

- 40 DensityandSpecificHeat Sp12Document11 pages40 DensityandSpecificHeat Sp12fernandoribeiromocNo ratings yet

- Thermo - ch.1Document42 pagesThermo - ch.1Dr.Ahmed Faiq Al-AlawyNo ratings yet

- Energetic and Financial Investigation of A Stand-Alone Solar-Thermal Organic Rankine Cycle Power PlantDocument24 pagesEnergetic and Financial Investigation of A Stand-Alone Solar-Thermal Organic Rankine Cycle Power PlantAdda Dà DY RerriballahNo ratings yet

- Tab Ept Acud DCP P&id-03 r00Document1 pageTab Ept Acud DCP P&id-03 r00Tarek KhafagaNo ratings yet

- MPP 1013Document9 pagesMPP 1013Ainul Mardiah AhmadNo ratings yet

- 61 66Document6 pages61 66Khiet80% (5)

- Daftar Pustaka Pratikum PTKDocument2 pagesDaftar Pustaka Pratikum PTKLopen JelinNo ratings yet

- Diffusion Flames, Droplet Evaporation and Droplet CombustionDocument9 pagesDiffusion Flames, Droplet Evaporation and Droplet Combustiontomotomotomo2No ratings yet

- 9 PsychrometryDocument71 pages9 PsychrometryPratyush NagareNo ratings yet

- Chapter - 2 - Finale ConductionDocument24 pagesChapter - 2 - Finale ConductioneirinaNo ratings yet

- Me 126Document2 pagesMe 126all workNo ratings yet

- Chapter - 2 DistillationDocument75 pagesChapter - 2 DistillationJACOB DAVENo ratings yet

- Exercise 1 & 2Document10 pagesExercise 1 & 2mohammadNo ratings yet

- Act 3 ConclusionDocument13 pagesAct 3 ConclusionVon A. DamirezNo ratings yet

- GCSE - AQA - Changes of State and The Particle Model - QPDocument19 pagesGCSE - AQA - Changes of State and The Particle Model - QPV-academy MathsNo ratings yet

- Equilibrium ProblemsDocument35 pagesEquilibrium ProblemsMichal Krawczyk0% (1)

- Advanced Fire-Tube Boiler ProjectDocument10 pagesAdvanced Fire-Tube Boiler ProjectRonnieldNo ratings yet

- Water (H2O) Data Page - WikipediaDocument19 pagesWater (H2O) Data Page - Wikipediadillan.aryianNo ratings yet

- PhaseTransformationII PDFDocument116 pagesPhaseTransformationII PDFBrian Renso Mamani VargasNo ratings yet

- Supplementary ProblemsDocument18 pagesSupplementary ProblemsVon A. DamirezNo ratings yet

- EthyleneDocument59 pagesEthyleneNauman100% (3)

- ESS Booklet Topic 1 PDF PDFDocument27 pagesESS Booklet Topic 1 PDF PDFTushar MalhotraNo ratings yet

- ME 131 Thermodynamics BasicsDocument34 pagesME 131 Thermodynamics BasicsMian AsimNo ratings yet

- Example 1: Solution 740 MM of HGDocument3 pagesExample 1: Solution 740 MM of HGBadresh JellaNo ratings yet