Professional Documents

Culture Documents

Facts at Your Fingertips-200912-Creating Installed Gain Graphs

Uploaded by

onizuka-t2263Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Facts at Your Fingertips-200912-Creating Installed Gain Graphs

Uploaded by

onizuka-t2263Copyright:

Available Formats

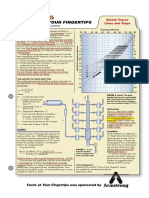

Creating Installed

Gain Graphs for

Department Editor: Scott Jenkins Control Valves

I

nstalled gain graphs can help improve the selection of control valves by using the equations in the ISA/IEC valve sizing standard (ANSI/

for chemical processing. The graphs are plotted to analyze together ISA-75.01.01).

control-valve flow characteristics and process-system flow character-

istics, and better illustrate the relationship between a control valve and Step 4: Express the flowrate in terms of

the system. Predicting installed gain can help to increase controllability percent process variable (%PV)

of the system and help avoid oversized valves. Installed gain graphs Use the range of the process-variable measurement device and its rela-

can reveal ranges of valve travel where the valve gain might impede tionship to flowrate to determine the %PV for the installed characteristic

controllability. They can also show the travels for which the control valve graph points. For example, if the process variable is flowrate, divide

will perform optimally. each flowrate on the curve by the full span of the flowmeter.

GENERATING AN INSTALLED GAIN GRAPH 2.2

Installed gain

2.0

Step 1: Determine the control valve’s inherent flow characteristic

1.8 Maximum

a) Inherent flow characteristic describes how the capacity of a control 1.6

gain

valve changes with valve travel. 1.4

b) The inherent flow characteristic plot has the same shape as valve

Gain

1.2 Minimum

gain

flow coefficient (CV) curve. Common curve shapes are: 1.0

Linear — Slope changes little over the normal working range of the valve 0.8

Quick-opening — Slope changes faster over first 25% of valve travel 0.6

and slower at high travels 0.4

Equal percentage — Slope 0.2

0

changes more slowly at 100 0 10 20 30 40 50 60 70 80 90 100

Percent of rated flow coefficient

low travels and faster at Valve travel, %

g

in

high travels

en

op

c) Plot CV versus valve travel. Step 5: Develop installed gain graph

ck

Find the slope of the installed flow characteristic graph at each valve

ui

ar

Q

ne

Step 2: Determine sys- travel. The plot of Δ%PV / Δ%travel for each percent travel increment is

Li

tem characteristic curve the installed gain graph.

e

ag

nt

The system curve defines

ce

er

piping head and friction Step 6: Interpret results

lp

losses. Plot flowrate vs. The installed gain graph can aid in the analysis of whether the control

ua

Eq

pressure. Assuming the valve inherent characteristic is suitable for the system. An installed gain

control valve is not un- 0

0 100 equal to one for the entire valve travel would indicate that the other

Percent of rated travel components of the control system would not have to compensate for the

dersized, it will have one

position that can fulfill both installed valve gain (that is, the control system tuning parameters used at

the flowrate and pressure conditions required by the system. one value of valve travel would allow equally acceptable controllability

at other travels).

System pressure characteristic It is more than likely the installed gain will not equal one across the

225 full valve travel. Guidelines for desirable installed gain values have

200

been established. In most cases, installed gain values of between 0.5

Maximum

and 2.0 should be the target.

175 Normal If the installed gain falls outside this range for valve travels that are

Pressure, psia

Minimum expected to be used for controlling the process, the controllability will

150

not be optimal. For example, controller tuning setpoints that function

125 P1 for valve well at low valve travel values might cause system instability if used at

travels with a high installed gain.

P2 for valve

100

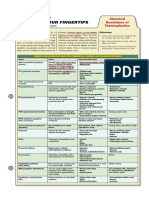

75 DEFINITIONS

100 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000

Flow, gal/min Valve gain — The change in flow for a given change in travel

Valve travel — The degree of openness of the valve; the valve stroke

Step 3: Determine installed flow characteristic graph Control range — The control range of an installed valve is the range of

a) Pressure conditions across a control valve are not constant. Values of travels for which the installed gain remains within the recommended 0.5

the liquid-pressure recovery factor and the pressure-drop ratio factor for to 2.0 range

control valves vary with valve travel. CV — The valve flow coefficient of a device (such as a valve) represents

b) For several values of valve travel, determine where on the system a relative measure of its efficiency at allowing fluid flow. It involves the

curve (flow versus pressure) the process will be operated and what the relationship between the pressure drop across a valve system and the

flowrate would be. The location on the system curve can be determined corresponding flowrate

Inherent flow characteristic — The relationship between control valve

Installed flow characteristic capacity and valve stem travel

3,000

Installed flow characteristic — Actual system flow plotted against valve

2,500 Maximum opening. Pressure drops vary with valve travel when valves are installed

with pumps, piping, fittings and other process equipment

2,000 Normal

Flow, gal/min

Minimum

1,500

References

1. Niesen, M., Using installed gain to improve valve selection. Chem. Eng.

1,000 October 2008, pp. 34–37.

500 2. Fitzgerald, B. and Linden, C., The control valve’s hidden impact on the

bottom line. Valve Manufacturer’s Association, Washington, D.C., 2003.

0 3. “Perry’s Chemical Engineer’s Handbook,” 8th ed., McGraw Hill, N.Y.,

0 10 20 30 40 50 60 70 80 90 100

Valve travel, % 2008.

You might also like

- Fuel Equivalent Factor - Marine Services PDFDocument9 pagesFuel Equivalent Factor - Marine Services PDFMax Kolonko100% (1)

- Develop, Implement and Maintain WHS Management System Task 2Document4 pagesDevelop, Implement and Maintain WHS Management System Task 2Harry Poon100% (1)

- Control Theory BasicsDocument19 pagesControl Theory BasicsVigneshRamakrishnanNo ratings yet

- Certificate of Incorporation Phlips India LimitedDocument1 pageCertificate of Incorporation Phlips India LimitedRam AgarwalNo ratings yet

- Creating Installed Gain Graphs for Control ValvesDocument1 pageCreating Installed Gain Graphs for Control Valvessulaiman_butt20058248No ratings yet

- Using Installed Gain CalcsDocument7 pagesUsing Installed Gain Calcschida mohaNo ratings yet

- Concepts of Instrumentation Control ValvesDocument140 pagesConcepts of Instrumentation Control ValvesSnehashis BoseNo ratings yet

- FC Mag - Characteristics and SizingDocument5 pagesFC Mag - Characteristics and SizingAhmed KhairiNo ratings yet

- EquiFlow AICD Data Sheet - H08364Document2 pagesEquiFlow AICD Data Sheet - H08364Cláudio VirgílioNo ratings yet

- Flow Control Valves DVE: Up To 350 Bar Up To 160 L/minDocument5 pagesFlow Control Valves DVE: Up To 350 Bar Up To 160 L/minVijay BhureNo ratings yet

- 1CEB120Document2 pages1CEB120ShaneNo ratings yet

- Integrated Advanced Digital Turbine Control For Steam TurbinesDocument4 pagesIntegrated Advanced Digital Turbine Control For Steam TurbinesJames IzquierdoNo ratings yet

- FE 2900 Pressure Losses From Fan AccessoriesDocument2 pagesFE 2900 Pressure Losses From Fan AccessoriesAvery OppegardNo ratings yet

- Cascade Control TutorialDocument12 pagesCascade Control Tutorialpleco4me100% (1)

- Lab 4 PneuDocument7 pagesLab 4 PneuhusainiNo ratings yet

- Pc210lc-11 Sen06695-01 Circuit DiagramsDocument26 pagesPc210lc-11 Sen06695-01 Circuit DiagramsdatphuongNo ratings yet

- Section 8 - Control Valve Flow CharacteristicsDocument6 pagesSection 8 - Control Valve Flow CharacteristicshammamiNo ratings yet

- INDUSTRIAL AUTOMATION - Controller TuningDocument7 pagesINDUSTRIAL AUTOMATION - Controller TuningPatil Amol PandurangNo ratings yet

- Balance of Plant - IntroductionDocument20 pagesBalance of Plant - IntroductionSwapanbasuNo ratings yet

- FE2900 - Pressure Losses From Fan AccessoriesDocument2 pagesFE2900 - Pressure Losses From Fan AccessoriesAhmad NilNo ratings yet

- Control Tutorials For MATLAB and Simulink - Introduction - Frequency Domain Methods For Controller DesignDocument12 pagesControl Tutorials For MATLAB and Simulink - Introduction - Frequency Domain Methods For Controller DesigncesarinigillasNo ratings yet

- Improving Control Valve PerformanceDocument5 pagesImproving Control Valve PerformanceBramJanssen76No ratings yet

- Pid Algorithm and Tuning Methods: Process Control SolutionsDocument33 pagesPid Algorithm and Tuning Methods: Process Control SolutionsTrần Ngọc MẩnNo ratings yet

- Chapter 1Document22 pagesChapter 1Guido Wilder Algarañaz MonteroNo ratings yet

- Basic Control Valve Sizing and SelectionDocument53 pagesBasic Control Valve Sizing and SelectionAtul TripathiNo ratings yet

- Section 8 - Control Valve Flow Characteristics PDFDocument6 pagesSection 8 - Control Valve Flow Characteristics PDFMahmoud Ahmed Ali AbdelrazikNo ratings yet

- System Engineering Management - 2016 - Blanchard - Appendix A Functional Analysis Case Study ExamplesDocument7 pagesSystem Engineering Management - 2016 - Blanchard - Appendix A Functional Analysis Case Study Examplescalvin suNo ratings yet

- Indoor Ventilation Study Sample - 2019.11.26Document2 pagesIndoor Ventilation Study Sample - 2019.11.26Akshay Kumar GuptaNo ratings yet

- PC210 (LC) - 10M0 Sen06701-C0 Standard Value TableDocument47 pagesPC210 (LC) - 10M0 Sen06701-C0 Standard Value Tabledatphuong100% (1)

- E After: New Design Method For Valves Internals (Trim), To Optimize ProcessDocument4 pagesE After: New Design Method For Valves Internals (Trim), To Optimize ProcessIan MannNo ratings yet

- Urban Micro Wind Turbines: Kent Hogan Onslow College Fellowship GoalsDocument34 pagesUrban Micro Wind Turbines: Kent Hogan Onslow College Fellowship GoalsFebriNo ratings yet

- Vlsi Design2011 LP Tutorial TechpaDocument127 pagesVlsi Design2011 LP Tutorial TechpaSaiPranav GootyNo ratings yet

- Hydraulic Excavator PC210-10M0, PC210LC-10M0 Abbreviation ListDocument112 pagesHydraulic Excavator PC210-10M0, PC210LC-10M0 Abbreviation Listdatphuong100% (1)

- Proc Calc Alumnos CapDocument26 pagesProc Calc Alumnos Capabigail muñozNo ratings yet

- Primer Distillation Column Loop TuningDocument6 pagesPrimer Distillation Column Loop TuningErick PachasNo ratings yet

- Priorety and Orbitrol CircuitDocument8 pagesPriorety and Orbitrol CircuitIslam ShoukryNo ratings yet

- Midea Commercial Air Conditioner VRF System Technical ManualDocument182 pagesMidea Commercial Air Conditioner VRF System Technical ManualJuan Manuel Silva DiazNo ratings yet

- 9.1 Definition of Indexes of Performance For Servo DrivesDocument16 pages9.1 Definition of Indexes of Performance For Servo DrivesChinh Hoang QuangNo ratings yet

- The K FactorDocument11 pagesThe K FactorSOURAV PRASADNo ratings yet

- Brief Review of Control TheoryDocument19 pagesBrief Review of Control TheoryMuhammad SofyanNo ratings yet

- Elysia Niveau Filter Manual enDocument6 pagesElysia Niveau Filter Manual enSchmooNo ratings yet

- FSG Ss 003 eDocument2 pagesFSG Ss 003 eduongbk24 luu quang duongNo ratings yet

- Abb Jacking ControlDocument4 pagesAbb Jacking ControlAleksey Bondar100% (1)

- PC210 (LC) - 10M0 Sen06701-C0 Circuit DiagramsDocument40 pagesPC210 (LC) - 10M0 Sen06701-C0 Circuit DiagramsdatphuongNo ratings yet

- 2000 07 Cascaded Pos Vel LoopsDocument4 pages2000 07 Cascaded Pos Vel LoopsKaren NaranjoNo ratings yet

- 2020R1 FluentDocument65 pages2020R1 Fluentagrbovic100% (1)

- Control Valves 1678169882Document22 pagesControl Valves 1678169882Myo Myint MaungNo ratings yet

- Basic Control Valve - Sizing & SelectionDocument38 pagesBasic Control Valve - Sizing & SelectionViệt Đặng XuânNo ratings yet

- FCV Series Fixed Cone Valves from WWW.VSIVALVE.COMDocument11 pagesFCV Series Fixed Cone Valves from WWW.VSIVALVE.COMRofi Trianto SNo ratings yet

- Brochure Echometer Well AnalyzerDocument3 pagesBrochure Echometer Well AnalyzermiguelNo ratings yet

- KFlopManual PDFDocument306 pagesKFlopManual PDFandrea772No ratings yet

- PC210LC-11 Sen06695-01 SpecificationsDocument16 pagesPC210LC-11 Sen06695-01 SpecificationsdatphuongNo ratings yet

- Design and Flow Coefficient Analysis of Globe Valve As Control Valve Using MATLABDocument5 pagesDesign and Flow Coefficient Analysis of Globe Valve As Control Valve Using MATLABInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- FACTS Controllers Optimize Transmission InterconnectionsDocument20 pagesFACTS Controllers Optimize Transmission InterconnectionsSiri AggarapuNo ratings yet

- HUAWEI BSC6000 Base Station Subsystem BSS Feature Description (V900R008C01) - Flow ControlDocument31 pagesHUAWEI BSC6000 Base Station Subsystem BSS Feature Description (V900R008C01) - Flow ControlHanumareddy VanukuriNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- Trane Engineers Newsletter - Mar2021Document8 pagesTrane Engineers Newsletter - Mar2021Raheem_kaNo ratings yet

- Modeling Performance of Butterfly Valves Using Machine Learning Methods - XGBoostDocument10 pagesModeling Performance of Butterfly Valves Using Machine Learning Methods - XGBoostJesús NavarroNo ratings yet

- ARTECHE DS adaTECH-OSC ENDocument4 pagesARTECHE DS adaTECH-OSC ENl3hrtcNo ratings yet

- Priorety and Orbitrol CircuitDocument8 pagesPriorety and Orbitrol CircuitIslam ShoukryNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Facts at Your Fingertips-201012-Project Design Decision-Making Option ListsDocument1 pageFacts at Your Fingertips-201012-Project Design Decision-Making Option Listsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201104-Hopper Inserts For Improved Solids FlowDocument1 pageFacts at Your Fingertips-201104-Hopper Inserts For Improved Solids Flowonizuka-t2263No ratings yet

- Facts at Your Fingertips-201103-Infrared Temperature MeasurementDocument1 pageFacts at Your Fingertips-201103-Infrared Temperature Measurementonizuka-t2263No ratings yet

- Facts at Your Fingertips-201105-Pressure Measurement ConsiderationsDocument1 pageFacts at Your Fingertips-201105-Pressure Measurement Considerationsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)Document1 pageFacts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)onizuka-t2263No ratings yet

- Controlling membrane foulingDocument1 pageControlling membrane foulingonizuka-t2263No ratings yet

- Facts at Your Fingertips-201010-MSMPR Crystallization EquipmentDocument1 pageFacts at Your Fingertips-201010-MSMPR Crystallization Equipmentonizuka-t2263No ratings yet

- Facts at Your Fingertips-201102-Control Valve Position SensorsDocument1 pageFacts at Your Fingertips-201102-Control Valve Position Sensorsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201011-Viscosity MeasurementDocument1 pageFacts at Your Fingertips-201011-Viscosity Measurementonizuka-t2263No ratings yet

- Facts at Your Fingertips-201001-Low-Pressure MeasurementDocument1 pageFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263No ratings yet

- Heat Transfer Fluids: System FiltrationDocument1 pageHeat Transfer Fluids: System Filtrationonizuka-t2263No ratings yet

- Facts at Your Fingertips-201006-Fluid MechanicsDocument1 pageFacts at Your Fingertips-201006-Fluid Mechanicsonizuka-t2263No ratings yet

- Facts at Your Fingertips-201007-Conservation Economics Carbon Pricing ImpactsDocument1 pageFacts at Your Fingertips-201007-Conservation Economics Carbon Pricing Impactsonizuka-t2263No ratings yet

- CHE Facts 0410Document1 pageCHE Facts 0410gwinnruNo ratings yet

- Steam Tracer Lines and Traps GuideDocument1 pageSteam Tracer Lines and Traps Guideonizuka-t2263No ratings yet

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFDocument1 pageFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263No ratings yet

- Facts at Your Fingertips-201002-Positive Displacement PumpsDocument1 pageFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263No ratings yet

- Facts at Your Fingertips-200909-Heat Transfer System Design IIDocument1 pageFacts at Your Fingertips-200909-Heat Transfer System Design IIonizuka-t2263No ratings yet

- Facts at Your Fingertips-201002-Positive Displacement PumpsDocument1 pageFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263No ratings yet

- Steam Tracer Lines and Traps GuideDocument1 pageSteam Tracer Lines and Traps Guideonizuka-t2263No ratings yet

- CHE Facts 0410Document1 pageCHE Facts 0410gwinnruNo ratings yet

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFDocument1 pageFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263No ratings yet

- Above and Underground Storage Tanks PDFDocument1 pageAbove and Underground Storage Tanks PDFrasik.kiraneNo ratings yet

- Facts at Your Fingertips-201001-Low-Pressure MeasurementDocument1 pageFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263No ratings yet

- Facts at Your Fingertips-200912-Creating Installed Gain GraphsDocument1 pageFacts at Your Fingertips-200912-Creating Installed Gain Graphsonizuka-t2263No ratings yet

- Adsorption PDFDocument1 pageAdsorption PDFrasik.kiraneNo ratings yet

- Facts at Your Fingertips-200910-Chemical Resistance of ThermoplasticsDocument1 pageFacts at Your Fingertips-200910-Chemical Resistance of Thermoplasticsonizuka-t2263No ratings yet

- Facts at Your Fingertips-200907-Flowmeter SelectionDocument2 pagesFacts at Your Fingertips-200907-Flowmeter Selectiononizuka-t2263No ratings yet

- Facts at Your Fingertips-200905-Choosing A Control SystemDocument1 pageFacts at Your Fingertips-200905-Choosing A Control Systemonizuka-t2263No ratings yet

- Specialty metals guide corrosion resistance and propertiesDocument1 pageSpecialty metals guide corrosion resistance and propertiesonizuka-t2263No ratings yet

- Paul Ramesh Forensic Neuro Psychological InterviewDocument43 pagesPaul Ramesh Forensic Neuro Psychological Interviewnonam2100% (2)

- 3.4 Linearization of Nonlinear State Space Models: 1 F X Op 1 F X Op 2 F U Op 1 F U Op 2Document3 pages3.4 Linearization of Nonlinear State Space Models: 1 F X Op 1 F X Op 2 F U Op 1 F U Op 2Ilija TomicNo ratings yet

- CSIR NET December 2019 Admit CardDocument1 pageCSIR NET December 2019 Admit CardDevendra Singh RanaNo ratings yet

- Regular expressions chapter 3 key conceptsDocument3 pagesRegular expressions chapter 3 key conceptsNabeel Ahmed0% (1)

- Characterization in Compound Semiconductor ProcessingDocument27 pagesCharacterization in Compound Semiconductor ProcessingMomentum PressNo ratings yet

- Lun Mapping DisksDocument11 pagesLun Mapping DisksKarn GusainNo ratings yet

- Hydro Distillation Method Extraction of Eucalyptus Oil Lemongrass OilDocument9 pagesHydro Distillation Method Extraction of Eucalyptus Oil Lemongrass OilSIVANESAN JOTHIVELNo ratings yet

- Enterprise Architecture Roadmap: Sustain EA Best PracticesDocument1 pageEnterprise Architecture Roadmap: Sustain EA Best PracticesChen YooNo ratings yet

- SpinView Getting StartedDocument16 pagesSpinView Getting StartedRicardo SequeiraNo ratings yet

- Spru I 11444Document24 pagesSpru I 11444aalvarcaNo ratings yet

- HYDRAULICSDocument1 pageHYDRAULICSOrland Son FactorNo ratings yet

- Intro To Factor AnalysisDocument52 pagesIntro To Factor AnalysisRawnak JahanNo ratings yet

- Introduction To Globalization: Module DescriptionDocument3 pagesIntroduction To Globalization: Module DescriptionyowNo ratings yet

- Part 1Document3 pagesPart 1Jester NavarquezNo ratings yet

- Travel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteDocument1 pageTravel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteMark Levin Munar100% (1)

- IPPD Presentation Roll OutDocument34 pagesIPPD Presentation Roll OutGracel Alingod Galay100% (1)

- 07 FSM PDFDocument25 pages07 FSM PDFnew2trackNo ratings yet

- Cover Letter and Resume for Electrical Engineer PositionDocument4 pagesCover Letter and Resume for Electrical Engineer Positiongrabani77No ratings yet

- FINAL Please Be Informed That Your Termination From Office Is Not Intended To Be PersonalDocument9 pagesFINAL Please Be Informed That Your Termination From Office Is Not Intended To Be PersonalShareff ChamplainNo ratings yet

- Arduino PWM To DC Voltage Op Amp Converter - Henry's BenchDocument8 pagesArduino PWM To DC Voltage Op Amp Converter - Henry's BenchAlan A. TorresNo ratings yet

- Howden PDFDocument24 pagesHowden PDFskb2550% (2)

- Homework1 SKKK1113 1112-2Document1 pageHomework1 SKKK1113 1112-2Khairul Anwar Abd HamidNo ratings yet

- 5S ManualDocument60 pages5S ManualMun Hein ZawNo ratings yet

- Unit 3 Nis 22620Document6 pagesUnit 3 Nis 22620Komal JadhavNo ratings yet

- Mobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryDocument19 pagesMobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryJoaquim OliveiraNo ratings yet

- Sleep Hygiene Sleep QualityandDocument8 pagesSleep Hygiene Sleep QualityandVriddhi AgrawalNo ratings yet

- Technical Report Writing For Ca2 ExaminationDocument6 pagesTechnical Report Writing For Ca2 ExaminationAishee DuttaNo ratings yet