Professional Documents

Culture Documents

C.05 SL - SLW Girder Inspection Report

Uploaded by

Sami AjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C.05 SL - SLW Girder Inspection Report

Uploaded by

Sami AjCopyright:

Available Formats

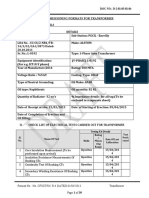

Bridge File #:

SL/SLW GIRDER Date:

INSPECTION REPORT By:

Page: 1 of 5

GIRDER SERIAL NO.

FAB. MARK NO.

GIRDER TYPE

CAST DATE

A. MATERIAL

1. REINFORCING STEEL

• Tack welding of reinforcing steel is not allowed.

Grade

Size

Bends

Cleanliness

2. STRAND

• Only low relaxation strand allowed.

Condition, cleanliness

E (Same as stressing Calcs)

3. VOIDS

• Splices in sonotubes are not allowed.

Diameter

Condition

4. CHANNEL CONNECTORS

• Anchors are properly welded.

Dimensions

Galvanizing

Slots deburred

5. BUFFER ANGLES

• Studs are properly welded.

Dimensions

Galvanizing

6. ANCHOR BOLTS

Assembly dimensions

Galvanizing

Revised December 2013 Appendix C.05

Bridge File #:

SL/SLW GIRDER Date:

INSPECTION REPORT By:

Page: 2 of 5

B. FORM SET-UP

• Prior to form set-up approved shop drawings, stressing calculations and mix design on hand.

• Forms clean, straight with mortar tight joints and sprayed with a form release agent.

• Serial number, loading, year of manufacture and fabricator's name cast into the girder.

1. FORM

Length

Width

Depth

Skew

Sweep

Bulkheads - braced

2. STRESSING

• Observe stressing operations, stressing records are maintained by plant's quality control personnel.

• Strand splices inside the member are not allowed.

• Elongation and gauge pressure must be within 5% (combined) of that specified in the approved stressing calcs.

• Strands are recessed 15 mm inside the girder.

Strand pattern, location

Elongation

Gauge pressure

3. REBAR

• Chairs shall be plastic or galvanized metal.

Spacing

Lap

Cover

4. CHANNEL CONNECTORS

Spacing

Securely held in position

5. VOIDS

• Hold downs shall be adequate to maintain the final location of voids.

Top cover

Sealed

Location

6. BUFFER ANGLES

5 mm recess

Revised December 2013 Appendix C.05

Bridge File #:

SL/SLW GIRDER Date:

INSPECTION REPORT By:

Page: 3 of 5

7. LIFTING HOOKS

Location

Pockets

Projection

8. PLINTHS

Anchor bolt spacing

Anchor bolt projection

9. DOWEL HOLES

Hole size & location

C. CASTING

1. CONCRETE

Unit weight

Air

Slump

Temperature

Release strength

28 days strength

2. PLACING

Drop

Vibration

3. VOIDS

Position

Cover

4. FINISH

Girder top

Finish around anchor bolts

5. INITIAL CURING

After 4 hours of final concrete

Curing temperature

Revised December 2013 Appendix C.05

Bridge File #:

SL/SLW GIRDER Date:

INSPECTION REPORT By:

Page: 4 of 5

D. REMOVAL FROM THE FORM

1. STRAND RELEASE SEQUENCE

As per approved sketch

2. CLEAN UP

Fin removal

Minor patching

(before steam curing)

3. GIRDER

Length

Width

Depth

Skew

Sweep

24 hours

7 days

Camber

14 days

shipping

Ends

Bearing area smooth & flat

Interior units (cavities

over 10 mm repaired)

Exterior units (all

cavities repaired)

Honey- In bearing area

comb At other locations

E. CURING

1. STEAMING

• Steam curing for four days with 95% - 100% relative humidity and 40° C to 50° C temperature.

Temperature

Relative Humidity

Date unit in

Day unit out

Revised December 2013 Appendix C.05

Bridge File #:

SL/SLW GIRDER Date:

INSPECTION REPORT By:

Page: 5 of 5

F. FINISHES

1. SEALER

Type

Application

2. GIRDER FINISHES

Top

Bottom

Sides

G. FINAL

1. CHANNEL CONNECTORS

Clean inside & outside

2. ANCHOR BOLTS

Bolt clean

Nuts free to spin

3. STORAGE

Safe

Blocking

Revised December 2013 Appendix C.05

You might also like

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- C.06 SLC Girder Inspection ReportDocument5 pagesC.06 SLC Girder Inspection ReportSami AjNo ratings yet

- Integrated Piling FormatDocument2 pagesIntegrated Piling Formatyash shah88% (34)

- Suzlon - S - PR - 444 - REV01 - 1Document4 pagesSuzlon - S - PR - 444 - REV01 - 1Shubham BaderiyaNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- NO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last CalibrationDocument39 pagesNO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last Calibrationmayur dhandeNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Cable Termination Inspection ReportDocument20 pagesCable Termination Inspection ReportReynante AlimNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Sis Book1Document99 pagesSis Book1Hamza AlamNo ratings yet

- Recent Findings and Developments in Chromium Plated Gun TubesDocument29 pagesRecent Findings and Developments in Chromium Plated Gun TubesycwbycwbNo ratings yet

- ENI - Casing Design ManualDocument134 pagesENI - Casing Design Manualwelltest2012100% (14)

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- G.U.C. & T.A.P.Document8 pagesG.U.C. & T.A.P.Lokesh BadgujarNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- General Injection Mould SpecsDocument19 pagesGeneral Injection Mould SpecsSalvador Tiño100% (1)

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Aboveground storage tank inspection checklistDocument7 pagesAboveground storage tank inspection checklistES RouzaNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- JBMMA F PE 38 01 - Static Check FormatsDocument13 pagesJBMMA F PE 38 01 - Static Check FormatsTarang ShandilyaNo ratings yet

- Mta B&T E&C in House ConsultantDocument10 pagesMta B&T E&C in House ConsultantrozakNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Inspection Check ListDocument6 pagesInspection Check ListNagesh RaoNo ratings yet

- Procedure Manual: FOR Underground FRP Storage TankDocument6 pagesProcedure Manual: FOR Underground FRP Storage Tankravi yemmadiNo ratings yet

- Cylinder Condition ReportDocument7 pagesCylinder Condition ReportThusitha Dalpathadu100% (2)

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Inspection Checklist Platformer Reactor Vessel PDFDocument5 pagesInspection Checklist Platformer Reactor Vessel PDFsebas_vNo ratings yet

- Valve BoxDocument79 pagesValve BoxAnu JosephNo ratings yet

- Hnager CalculationsDocument169 pagesHnager CalculationsNaveen RohiraNo ratings yet

- Construction equipment earthing checklistDocument1 pageConstruction equipment earthing checklisthrimklimNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- MS For Reinforcement WorksDocument9 pagesMS For Reinforcement WorksShan THALANo ratings yet

- Mold Design Review Checklist: Part InformationDocument5 pagesMold Design Review Checklist: Part InformationAbdul BasitNo ratings yet

- Bulk Carrier Condition Survey ReportDocument33 pagesBulk Carrier Condition Survey Reportalxgam100% (1)

- 410 CTDocument2 pages410 CTSARAVANAN ANo ratings yet

- All ChecklistDocument28 pagesAll Checklistitsumar632No ratings yet

- Radiographic Examination Report: Defect CodesDocument2 pagesRadiographic Examination Report: Defect CodesMuhammadZahirKhanNo ratings yet

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- G SM PPLT Pip 805Document12 pagesG SM PPLT Pip 805rokan123No ratings yet

- Reverse Engineering Pressure Vessel ChecklistDocument5 pagesReverse Engineering Pressure Vessel ChecklistES RouzaNo ratings yet

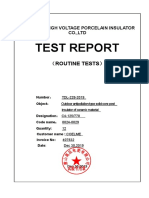

- Test Report: Routine TestsDocument6 pagesTest Report: Routine Testsgrigore mirceaNo ratings yet

- Inspection /record Sheet For Foundation Excavation DimentionDocument7 pagesInspection /record Sheet For Foundation Excavation DimentiondineshksenthilNo ratings yet

- Civil4M Aluminium Sliding Works ChecklistDocument1 pageCivil4M Aluminium Sliding Works ChecklistKishoreNo ratings yet

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- Top Head and NozzlesDocument4 pagesTop Head and NozzlesShamsul AffendiNo ratings yet

- Cylinder Condition ReportDocument5 pagesCylinder Condition ReportŞansal DikmenerNo ratings yet

- Resettlement Plan: July 2016Document61 pagesResettlement Plan: July 2016Sami AjNo ratings yet

- 002 SMR en - 0Document129 pages002 SMR en - 0Sami AjNo ratings yet

- Resettlement Plan: July 2016Document78 pagesResettlement Plan: July 2016Sami AjNo ratings yet

- Procedure Checklist AASHTO R-18: Quality Systems Manual: Management RequirementsDocument2 pagesProcedure Checklist AASHTO R-18: Quality Systems Manual: Management RequirementsSami AjNo ratings yet

- Project Administration Manual: Project Number: 48337-002 Loan Number: LXXXX November 2016Document81 pagesProject Administration Manual: Project Number: 48337-002 Loan Number: LXXXX November 2016Sami AjNo ratings yet

- Procedure Checklist FM 1 T-180: Moisture-Density Relations of Soils Using A 4.54 KG (10 LB) RammerDocument2 pagesProcedure Checklist FM 1 T-180: Moisture-Density Relations of Soils Using A 4.54 KG (10 LB) RammerSami AjNo ratings yet

- Equipment Checklist FM 1-T180: Moisture-Density Relations of Soils Using A 4.54Kg or 10lb Rammer and A 457mm or 18in DropDocument2 pagesEquipment Checklist FM 1-T180: Moisture-Density Relations of Soils Using A 4.54Kg or 10lb Rammer and A 457mm or 18in DropSami AjNo ratings yet

- SASEC Roads Project Environmental ReportDocument94 pagesSASEC Roads Project Environmental ReportSami AjNo ratings yet

- Procedure Checklist AASHTO T-265 Laboratory Determination of Moisture Content of SoilsDocument1 pageProcedure Checklist AASHTO T-265 Laboratory Determination of Moisture Content of SoilsSami AjNo ratings yet

- 002 EiaabDocument269 pages002 EiaabSami AjNo ratings yet

- Procedure Checklist AASHTO T-265 Laboratory Determination of Moisture Content of SoilsDocument1 pageProcedure Checklist AASHTO T-265 Laboratory Determination of Moisture Content of SoilsSami AjNo ratings yet

- Utility Accident Report: To: From: Project Sponsor Consultant's RepresentativeDocument3 pagesUtility Accident Report: To: From: Project Sponsor Consultant's RepresentativeSami AjNo ratings yet

- Procedure Checklist FM 1-R 090EW - Sampling of Earthwork: P F N/A A. Stockpiles (Manual Sampling - Board/Shovel Method)Document1 pageProcedure Checklist FM 1-R 090EW - Sampling of Earthwork: P F N/A A. Stockpiles (Manual Sampling - Board/Shovel Method)Sami AjNo ratings yet

- 002 SD 02Document2 pages002 SD 02Sami AjNo ratings yet

- Paperwork ReviewDocument1 pagePaperwork ReviewSami AjNo ratings yet

- Damage claim filed against contractorDocument1 pageDamage claim filed against contractorSami AjNo ratings yet

- Procedure Checklist AASHTO R-18: Quality Systems Manual: Management RequirementsDocument2 pagesProcedure Checklist AASHTO R-18: Quality Systems Manual: Management RequirementsSami AjNo ratings yet

- Utility Accident Report: To: From: Project Sponsor Consultant's RepresentativeDocument3 pagesUtility Accident Report: To: From: Project Sponsor Consultant's RepresentativeSami AjNo ratings yet

- A.c04 Damage Claim Letter CDocument1 pageA.c04 Damage Claim Letter CSami AjNo ratings yet

- A.c02 Damage Claim Letter ADocument1 pageA.c02 Damage Claim Letter ASami AjNo ratings yet

- As03 Accident-Motor Vehicle Traffic Collisions in Work Zones - OldDocument4 pagesAs03 Accident-Motor Vehicle Traffic Collisions in Work Zones - OldSami AjNo ratings yet

- As01 Saftey TAS OHS ReviewDocument2 pagesAs01 Saftey TAS OHS ReviewSami Aj0% (1)

- As05 Accident Notification (3rd Party)Document2 pagesAs05 Accident Notification (3rd Party)Sami AjNo ratings yet

- A.c01 Procedures For Damage ClaimsDocument2 pagesA.c01 Procedures For Damage ClaimsSami AjNo ratings yet

- As03 Accident-Motor Vehicle Traffic Collisions in Work Zones - OldDocument4 pagesAs03 Accident-Motor Vehicle Traffic Collisions in Work Zones - OldSami AjNo ratings yet

- As03 Accident-Motor Vehicle Traffic Collisions in Work Zones - OldDocument4 pagesAs03 Accident-Motor Vehicle Traffic Collisions in Work Zones - OldSami AjNo ratings yet

- Work Zone Crash ReportDocument4 pagesWork Zone Crash ReportSami AjNo ratings yet

- Old As02 A.s02 Traffic Accommodation Strategy Component ChecklistDocument2 pagesOld As02 A.s02 Traffic Accommodation Strategy Component ChecklistSami AjNo ratings yet

- Traffic Accommodation ChecklistDocument2 pagesTraffic Accommodation ChecklistSami AjNo ratings yet

- Work Zone Crash ReportDocument4 pagesWork Zone Crash ReportSami AjNo ratings yet

- AML Biodiesel 1500 TPDDocument14 pagesAML Biodiesel 1500 TPDREALLY ?No ratings yet

- TheMinitestCookbook SampleDocument28 pagesTheMinitestCookbook SampleeveevansNo ratings yet

- Hilux Catalogue 2012 PDF-L0dxAt3980Document35 pagesHilux Catalogue 2012 PDF-L0dxAt3980Apal Vora100% (1)

- Company Profile Traya Lintas PersadaDocument24 pagesCompany Profile Traya Lintas PersadaAyu Catra KastaraNo ratings yet

- Mechanical Vibration WorksheetDocument6 pagesMechanical Vibration Worksheetduraiprakash83No ratings yet

- Final Cut Coach MC-6 Mid Term Exam QuestionsDocument10 pagesFinal Cut Coach MC-6 Mid Term Exam QuestionsVan CooperNo ratings yet

- Strongroom&safes PDFDocument3 pagesStrongroom&safes PDFAlbertNo ratings yet

- TWS Wheels ENGDocument12 pagesTWS Wheels ENGRaul MorenoNo ratings yet

- MODULE 3 - PSD (2 Files Merged)Document14 pagesMODULE 3 - PSD (2 Files Merged)joshNo ratings yet

- Parametric Study For Assessing The Effects of Coarseness Factor and Workability Factor On Concrete Compressive StrengthDocument9 pagesParametric Study For Assessing The Effects of Coarseness Factor and Workability Factor On Concrete Compressive StrengthJaga JayNo ratings yet

- It Is Best To Have A Quiet Moment ..Document5 pagesIt Is Best To Have A Quiet Moment ..Nuno AlvesNo ratings yet

- Cohesion and Adhesion in LiquidsDocument1 pageCohesion and Adhesion in LiquidsjmlagumbayNo ratings yet

- BIEN Introduction PDFDocument45 pagesBIEN Introduction PDFSneha SinghNo ratings yet

- Manual (For LP Series)Document25 pagesManual (For LP Series)Hùng Đinh TrọngNo ratings yet

- Introduction To The Project and Overview of Power System SecurityDocument9 pagesIntroduction To The Project and Overview of Power System Securitysalagasim100% (1)

- Journal of Loss Prevention in The Process Industries: Min-Soo Kim, Sang-Kwon LeeDocument5 pagesJournal of Loss Prevention in The Process Industries: Min-Soo Kim, Sang-Kwon LeeSrinivas GowdaNo ratings yet

- All the Java system variables and PACS propertiesDocument2 pagesAll the Java system variables and PACS propertiesfire316No ratings yet

- GeoTextiles PDFDocument6 pagesGeoTextiles PDFAsım DavulcuNo ratings yet

- 5 Sol To s2 Phy PressureDocument7 pages5 Sol To s2 Phy PressureShreyan KhetaniNo ratings yet

- Park To Playa Trail Feasibility Study and Wayfinding PlanDocument153 pagesPark To Playa Trail Feasibility Study and Wayfinding PlanEmpowerment Congress West Area Neighborhood Development CouncilNo ratings yet

- D4B805D88AC-Generic Scan Tool PDFDocument1,000 pagesD4B805D88AC-Generic Scan Tool PDFandrew smith100% (1)

- Data Sheet Hellenic 185mm 4 CoreDocument3 pagesData Sheet Hellenic 185mm 4 CoreNitesh GuptaNo ratings yet

- Compiler ObjectiveDocument26 pagesCompiler Objectiveamank114100% (1)

- Map 3 D 2015 InstallDocument15 pagesMap 3 D 2015 InstallHarrison HayesNo ratings yet

- Mitsubishi Lifts BrochureDocument28 pagesMitsubishi Lifts Brochurenaveenarora298040No ratings yet

- Theory of Anti Relativity" by E P DollardDocument16 pagesTheory of Anti Relativity" by E P DollardKWojtek100% (2)

- SMA and Sofar Inverter PricelistDocument3 pagesSMA and Sofar Inverter PricelistYuvaraj JeyachandranNo ratings yet

- Natural Ventilation PDFDocument7 pagesNatural Ventilation PDFDebasis DasguptaNo ratings yet

- SJ-20100510160815-008-ZXSDR BTS&Node B (V4.09.21) Performance Counter Reference - 325875Document413 pagesSJ-20100510160815-008-ZXSDR BTS&Node B (V4.09.21) Performance Counter Reference - 325875sndi1765100% (1)

- How To Setup KodiDocument20 pagesHow To Setup KodiGerardo RodríguezNo ratings yet