Professional Documents

Culture Documents

1-GSP-82-3-E-005 - 0-Power House Gen-Set Test Run

Uploaded by

Mohd A IshakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-GSP-82-3-E-005 - 0-Power House Gen-Set Test Run

Uploaded by

Mohd A IshakCopyright:

Available Formats

Genting Sanyen Power Sdn Bhd

Doc Number: Created by Dept: Action by Dept: REV : 0

1-GSP-82-3-E-005_0 Maintenance Maintenance Derived from:

Dept Dept

Valid for: O&M GSP

Prepared by : Checked by: Approved by:

Wong Kok Loon Chok Yin Thong Sailesh Chander

ECI Engineer Maintenance Manager Senior Manager

Title :

Power House Gen-Set Test Run

Contents

1. Objective

2. Area of Application

3. Reference Document

4. Terminology, Definitions, Abbreviations

5. Responsibilities

6. Tools & Equipments

7. Procedure

8. Enclosures

Title : Power House Gen-Set Test Run Rev 00 Page 1 of 3

File: 505403297.doc

Genting Sanyen Power Sdn Bhd

Responsible Rev

Function

1. Objective

1. To establish standard engineering preventive maintenance

procedure to determine the health and functionality of the standby

generator set by performing weekly test run.

2. To ensure the condition of the electrical (batteries) and mechanical

(diesel engine) are in working condition and able to automatically

operate during sudden blackout so that all the connected emergency

equipment will be able to run.

2. Area of Application

Maintenance Department

3 Reference Document

None

4 Terminology, Definition, Abbreviations

None

5 Responsibilities

ECI technician is responsible to carry out the job.

ECI Supervisor is responsible to verify the data collected after the

job and highlight to the ECI Engineer if there is discrepancies

ECI Engineer is responsible to validate the collected data and

initiate action if required.

Title : Power House Gen-Set Test Run Rev 00 Page 2 of 3

File: 505403297.doc

Genting Sanyen Power Sdn Bhd

Responsible Rev

Function

6 Tools & Equipments

Checklist: ref GSP-ECI-PM-005_0, hydrometer, multimeter

7 Procedure

ECI Tech

1. Check Diesel Fuel Tank Level. Record into the checklist.

2. Check Engine Lube Oil Level (DD- 40). Ensure the level is near

the “MAX” indicator.

3. Check Engine Radiator Water Level

4. Switch ‘Off’ gen-set outgoing supply breaker (MCCB) at the

panel.

5. Check Battery Charger condition (DCA & DCV)

6. Battery Terminal and connections (Clean & Tighten)

7. Check Battery Water Level. Top up if necessary (Using distilled

water only).

8. Check battery water acid density with hydrometer.

9. Switch ‘Off” Battery Charger and Load test both batteries with

Battery tester.(Motorad BT100A). Check the indicator of the

tester should be in the GREEN region if healthy

10. Check Main Power Cable / Control condition.

11. Record down all the initial information

12. Make sure that the ‘on’ ‘off’ selector switch always in ‘on’

position, then only start the Gen-Set diesel engine by pushing

the start (green) button .

13. After the gen-set run for 30 minutes, stop the diesel engine by

selecting the selector switch to ‘off’ position.

14. When the diesel engine has completely stopped, switch back the

starter selector switch to ‘on’ position.

15. Switch ‘On’ the battery charger at the end of the testing.

16. Switch ‘On’ the gen. set Outgoing supply breaker (MCCB)

Switch at Panel after finished the test run.

17. Jot down any remarks if any.

8 Enclosures

Checklist ref: GSP-ECI-PM-005_0

Title : Power House Gen-Set Test Run Rev 00 Page 3 of 3

File: 505403297.doc

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- IgnitionDocument79 pagesIgnitionJM Llaban RamosNo ratings yet

- Cat Data Link Circuit - Test 01-02-2009Document7 pagesCat Data Link Circuit - Test 01-02-2009harikrishnanpd3327No ratings yet

- Moors Sovereign Dollarium 500 Gold Backed Dollarium PicautoDocument2 pagesMoors Sovereign Dollarium 500 Gold Backed Dollarium Picautoakil kemnebi easley elNo ratings yet

- CAT - G3516H Throttle Actuator - Test PDFDocument5 pagesCAT - G3516H Throttle Actuator - Test PDFwagner_guimarães_1No ratings yet

- Permaculture - Plants Suitable For Ground Cover (P) - Plants For A FutureDocument2 pagesPermaculture - Plants Suitable For Ground Cover (P) - Plants For A Futurecontadino_impazzitoNo ratings yet

- Ancient Skies of Northern Europe: Stars, Constellations, and The Moon in Nordic MythologyDocument12 pagesAncient Skies of Northern Europe: Stars, Constellations, and The Moon in Nordic MythologyoldenglishblogNo ratings yet

- Level 2 M020 Pumps QA-QC ChecksDocument10 pagesLevel 2 M020 Pumps QA-QC ChecksAnurag KumbhareNo ratings yet

- FAT Procedure of PLC PanelDocument25 pagesFAT Procedure of PLC PanelDipti Bhanja83% (6)

- EMD Overhaul and Maintenance of MotorsDocument24 pagesEMD Overhaul and Maintenance of MotorssingenaadamNo ratings yet

- Cat 950GDocument10 pagesCat 950GManuel BarahonaNo ratings yet

- Capability Test Procedure For EDG, Rev01Document11 pagesCapability Test Procedure For EDG, Rev01Naresh PattanaikNo ratings yet

- Distance Relay BasicsDocument58 pagesDistance Relay Basicsaalamz93_854917254100% (1)

- 3500C Timing CalibrationDocument2 pages3500C Timing Calibrationharikrishnanpd3327100% (1)

- CAT - 3516H Coolant Pressure Is HighDocument3 pagesCAT - 3516H Coolant Pressure Is Highwagner_guimarães_1No ratings yet

- FAT ProcedureDocument13 pagesFAT ProcedureTapas Hira100% (1)

- MOTOR PROTECTION RELAYdocxDocument7 pagesMOTOR PROTECTION RELAYdocxPandrayar Maruthu100% (3)

- Grouding System Field Test ProcedureDocument9 pagesGrouding System Field Test Proceduremilton1987No ratings yet

- Low PowerPoor or No Response To ThrottleDocument5 pagesLow PowerPoor or No Response To ThrottleAxel G.FloresNo ratings yet

- Kitchen Window Herb GardenDocument2 pagesKitchen Window Herb GardenNevin SmithNo ratings yet

- ISO 8861 Blower Engine RoomDocument28 pagesISO 8861 Blower Engine Roommohammad choirul huda100% (1)

- Zombieworld PlaytestDocument30 pagesZombieworld PlaytestWellameGranaNo ratings yet

- Part 3 Omni SetupDocument19 pagesPart 3 Omni SetupReem AwwadNo ratings yet

- 2015 PVMRW 71 LawrenceDocument17 pages2015 PVMRW 71 Lawrencerabbit_39100% (1)

- Newton Papers Letter Nat Phil Cohen EdDocument512 pagesNewton Papers Letter Nat Phil Cohen EdFernando ProtoNo ratings yet

- Pm1 HT Motor & Panel: ECM Check List Doc No: ECM-02 Checking List No: 5 Genting Sanyen Rev.2 Electrical DepartmentDocument3 pagesPm1 HT Motor & Panel: ECM Check List Doc No: ECM-02 Checking List No: 5 Genting Sanyen Rev.2 Electrical DepartmentMohd A IshakNo ratings yet

- Transport of Dangerous GoodsDocument16 pagesTransport of Dangerous Goodskeaty100% (1)

- SP0518Document15 pagesSP0518NgigiDanielNo ratings yet

- DH3-31BB-T-SCT-0009 Commissioning Procedure of 6.6kv Transformer System REV.0Document8 pagesDH3-31BB-T-SCT-0009 Commissioning Procedure of 6.6kv Transformer System REV.0hungNo ratings yet

- The Thermoeconomics of Energy ConversionsFrom EverandThe Thermoeconomics of Energy ConversionsRating: 5 out of 5 stars5/5 (2)

- 1-GSP-82-3-E-012 - 0-Motor Starter General Health CheckDocument3 pages1-GSP-82-3-E-012 - 0-Motor Starter General Health CheckMohd A IshakNo ratings yet

- 1-GSP-82-3-E-013 - 0-Power Transformer CheckDocument3 pages1-GSP-82-3-E-013 - 0-Power Transformer CheckMohd A IshakNo ratings yet

- 1-GSP-82-3-E-011 - 0-Fire Alarm Panel CheckDocument3 pages1-GSP-82-3-E-011 - 0-Fire Alarm Panel CheckMohd A IshakNo ratings yet

- 1-GSP-82-3-E-002 - 0-Protection Relay ChecklistDocument3 pages1-GSP-82-3-E-002 - 0-Protection Relay ChecklistMohd A IshakNo ratings yet

- 1-GSP-82-3-E-003 - 0-Lead-Acid Battery InspectionDocument3 pages1-GSP-82-3-E-003 - 0-Lead-Acid Battery InspectionMohd A IshakNo ratings yet

- 1-GSP-82-3-E-010 - 0-Rain Water Drain Pump CheckDocument3 pages1-GSP-82-3-E-010 - 0-Rain Water Drain Pump CheckMohd A IshakNo ratings yet

- 1-GSP-82-3-E-008 - 0-ABS Submersible Pump MCU33 CheckDocument3 pages1-GSP-82-3-E-008 - 0-ABS Submersible Pump MCU33 CheckMohd A IshakNo ratings yet

- 1-GSP-82-3-E-004 - 0-Transformer Earthing MeasurementDocument3 pages1-GSP-82-3-E-004 - 0-Transformer Earthing MeasurementMohd A IshakNo ratings yet

- Dangatan, Lloyd C.-Ex 5 AsplanDocument7 pagesDangatan, Lloyd C.-Ex 5 AsplanMarnelyn DangatanNo ratings yet

- Low Voltage Motor PMDocument6 pagesLow Voltage Motor PMjustin cardinalNo ratings yet

- Qualification, Site Acceptance, and Surveillance TestingDocument40 pagesQualification, Site Acceptance, and Surveillance Testingsri_lntNo ratings yet

- Essais Des Cellules MVDocument8 pagesEssais Des Cellules MVKoffi BakanNo ratings yet

- Electrical Machines Laboratory - Ii: A Lab Manual On Subject Code: 15EEL47Document34 pagesElectrical Machines Laboratory - Ii: A Lab Manual On Subject Code: 15EEL47Gopinath B L NaiduNo ratings yet

- CAT - 3516H Engine Shutdown or Start Inhibit Initiated by Driven EquipmentDocument2 pagesCAT - 3516H Engine Shutdown or Start Inhibit Initiated by Driven Equipmentwagner_guimarães_1100% (1)

- Performance Monitoring Procedure - FinalDocument9 pagesPerformance Monitoring Procedure - FinalMuhammad Junaid KhanNo ratings yet

- 19-07-22 8.2 (E) (I) The Verification of Protection Level Settings of The Stator Earth FaultDocument7 pages19-07-22 8.2 (E) (I) The Verification of Protection Level Settings of The Stator Earth FaultsarmastNo ratings yet

- TP-GT01 GeneratorDocument10 pagesTP-GT01 Generatorوليد موسىNo ratings yet

- HEP-180011-3-MS-COMMISSIONING-HEPE-016 Test Procedure of Energizing SwitchyardDocument8 pagesHEP-180011-3-MS-COMMISSIONING-HEPE-016 Test Procedure of Energizing SwitchyardSalmanEjazNo ratings yet

- 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page - JSPDocument7 pages127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page - JSPkhaled fathyNo ratings yet

- Protection Relay Testing For Commissioning SWP: 1. Purpose and ScopeDocument15 pagesProtection Relay Testing For Commissioning SWP: 1. Purpose and Scopegosalhs9395No ratings yet

- DES-SE01 Reliability Test Report 20160413Document9 pagesDES-SE01 Reliability Test Report 20160413Edgar Franco PeraltaNo ratings yet

- Qualification, Site Acceptance and Surveillance TestingDocument22 pagesQualification, Site Acceptance and Surveillance TestingCarolinaNo ratings yet

- Videca Atp Lte Report Lim PQ 7 de AgosDocument13 pagesVideca Atp Lte Report Lim PQ 7 de AgosAlex Samuel Ludeña HuamaniNo ratings yet

- Sudarmawan: Key Skills Profile SummaryDocument3 pagesSudarmawan: Key Skills Profile SummaryHaidar MuttaqinNo ratings yet

- Troubleshooting Plan - Autosampler and BD Prover Repair 07 12 2021Document7 pagesTroubleshooting Plan - Autosampler and BD Prover Repair 07 12 2021Gilbert NdibeNo ratings yet

- NCRHA Low Voltage Motor PMDocument7 pagesNCRHA Low Voltage Motor PMjustin cardinalNo ratings yet

- Md. OriginalDocument4 pagesMd. OriginalMd. Tazir UddinNo ratings yet

- Specialist - Implementation Engineer, Powerstore Solutions Version 1.0Document4 pagesSpecialist - Implementation Engineer, Powerstore Solutions Version 1.0Nguyễn SơnNo ratings yet

- Lab Report: DJM3072 Programmable Logic ControllerDocument7 pagesLab Report: DJM3072 Programmable Logic ControllerManosh KumaarNo ratings yet

- Jaya Teknik - Preventive Maintenance Rectifier System q2 - MSC Menara Mulia 99003Document7 pagesJaya Teknik - Preventive Maintenance Rectifier System q2 - MSC Menara Mulia 99003achmad basoriNo ratings yet

- HEP-180011-3-MS-COMMISSIONING-HEPE-017 Test Procedure of Energizing SST4Document8 pagesHEP-180011-3-MS-COMMISSIONING-HEPE-017 Test Procedure of Energizing SST4SalmanEjazNo ratings yet

- Commissining Chapter One LatestDocument60 pagesCommissining Chapter One Latestbisrat zerabirukNo ratings yet

- 2019 Technical Training Product BrochureDocument9 pages2019 Technical Training Product Brochurenurul azmiNo ratings yet

- Acceleration Is Poor or Throttle Response Is Poor: TroubleshootingDocument7 pagesAcceleration Is Poor or Throttle Response Is Poor: TroubleshootingEshop ManualNo ratings yet

- Protection Certification GuidelinesDocument14 pagesProtection Certification Guidelineskhalid EissaNo ratings yet

- Ensuring Healthiness and Availability of Black Start System of Gas StationsDocument12 pagesEnsuring Healthiness and Availability of Black Start System of Gas StationsAbhiroop AwasthiNo ratings yet

- Emc 00006Document31 pagesEmc 00006kiran loboNo ratings yet

- 2688 DerechoDocument4 pages2688 DerechoDiego CatariNo ratings yet

- Paddle Switch CombinedDocument10 pagesPaddle Switch CombinedPriyanshu GuptaNo ratings yet

- Load Bank Testing ProcedureDocument6 pagesLoad Bank Testing ProceduresabilNo ratings yet

- CHAPTER 7 - Optimal Dispatch of Generation 110511Document72 pagesCHAPTER 7 - Optimal Dispatch of Generation 110511Mohd A IshakNo ratings yet

- DF Series - SS Schaffer GaugeDocument1 pageDF Series - SS Schaffer GaugeMohd A IshakNo ratings yet

- WI-EI-064 Rotating Machinery MonitoringDocument2 pagesWI-EI-064 Rotating Machinery MonitoringMohd A IshakNo ratings yet

- CHAPTER 10 - Symmetrical Components Unbalanced FaultDocument68 pagesCHAPTER 10 - Symmetrical Components Unbalanced FaultMohd A IshakNo ratings yet

- CHAPTER 8 - Synchronous Machine Transient AnalysisDocument64 pagesCHAPTER 8 - Synchronous Machine Transient AnalysisMohd A IshakNo ratings yet

- DX Sealed Diaphragm GaugesDocument1 pageDX Sealed Diaphragm GaugesMohd A IshakNo ratings yet

- Eei PM1 El02Document61 pagesEei PM1 El02Mohd A IshakNo ratings yet

- Dublin City University LightingDocument6 pagesDublin City University LightingMohd A IshakNo ratings yet

- VR: Vaccuum Room PM1: PM1 Spare AreaDocument44 pagesVR: Vaccuum Room PM1: PM1 Spare AreaMohd A IshakNo ratings yet

- Pm2 Installed Motor List: Occ Pulper Pump To Dump ChestDocument23 pagesPm2 Installed Motor List: Occ Pulper Pump To Dump ChestMohd A IshakNo ratings yet

- Variable Speed Drives: AT Ascend Communications InternationalDocument2 pagesVariable Speed Drives: AT Ascend Communications InternationalMohd A IshakNo ratings yet

- Honeywell - CompressorDocument2 pagesHoneywell - CompressorMohd A IshakNo ratings yet

- Pm1 Install Motor List: C2 SB C1Document26 pagesPm1 Install Motor List: C2 SB C1Mohd A IshakNo ratings yet

- Inspection Checklist: PLC CubicleDocument2 pagesInspection Checklist: PLC CubicleMohd A IshakNo ratings yet

- 04 - QA Calibration Job Method For Packing Machine Check Weight 1Document3 pages04 - QA Calibration Job Method For Packing Machine Check Weight 1Mohd A IshakNo ratings yet

- Inspection Checklist: Earthing SystemDocument1 pageInspection Checklist: Earthing SystemMohd A IshakNo ratings yet

- Inspection Checklist: Control Gear Stage 2Document2 pagesInspection Checklist: Control Gear Stage 2Mohd A IshakNo ratings yet

- IC-EI-007 Control Panel. Stage 2Document2 pagesIC-EI-007 Control Panel. Stage 2Mohd A IshakNo ratings yet

- ECM Check List Genting Sanyen Doc No: ECM-03 Check List No:1 Electrical Department Rev.2Document3 pagesECM Check List Genting Sanyen Doc No: ECM-03 Check List No:1 Electrical Department Rev.2Mohd A IshakNo ratings yet

- ECM Check List Doc No: ECM-13 Check List No:3 Rev.1 Genting Sanyen Electrical DepartmentDocument4 pagesECM Check List Doc No: ECM-13 Check List No:3 Rev.1 Genting Sanyen Electrical DepartmentMohd A IshakNo ratings yet

- Inspection Checklist: General LoadDocument2 pagesInspection Checklist: General LoadMohd A IshakNo ratings yet

- Guide To The Weekly Testing of Fire Alarm SystemsDocument2 pagesGuide To The Weekly Testing of Fire Alarm SystemsMohd A IshakNo ratings yet

- ECM Check List Doc No: ECM-27 Checking List No:2 Genting Sanyen Rev.0 Electrical DepartmentDocument4 pagesECM Check List Doc No: ECM-27 Checking List No:2 Genting Sanyen Rev.0 Electrical DepartmentMohd A IshakNo ratings yet

- GD - 202011 - G2 Inverter - Sungrow Single Phase Inverter Commissioning Guide - V1.0Document13 pagesGD - 202011 - G2 Inverter - Sungrow Single Phase Inverter Commissioning Guide - V1.0AbbasNo ratings yet

- Rundown ICTSD 2018 - (Latest)Document9 pagesRundown ICTSD 2018 - (Latest)Annisa Farida HayuningsihNo ratings yet

- 4K Resolution: The Future of ResolutionsDocument15 pages4K Resolution: The Future of ResolutionsRavi JoshiNo ratings yet

- 10069-9-V01-Ef00-00039 Fire Alarm SystemDocument49 pages10069-9-V01-Ef00-00039 Fire Alarm Systemahffg nnffNo ratings yet

- Bubble Slabs Burned at 800 °C With Different Periods: IOP Conference Series: Materials Science and EngineeringDocument10 pagesBubble Slabs Burned at 800 °C With Different Periods: IOP Conference Series: Materials Science and Engineeringshilpa jacobNo ratings yet

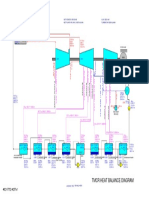

- 01 TMCR Heat Balance DiagramDocument1 page01 TMCR Heat Balance DiagramPrescila PalacioNo ratings yet

- Assignment 3 - NTFP&SLE (HNM AgFE IITKGP) - RERUN 2 (3) .NewDocument13 pagesAssignment 3 - NTFP&SLE (HNM AgFE IITKGP) - RERUN 2 (3) .NewDebasish Datta Research Scholar, Dept. of Biochem. Engg., IIT (BHU)No ratings yet

- Unit 2Document9 pagesUnit 2Quinn LilithNo ratings yet

- DS-7204HI-VS Net DVR - V2.0 (080909)Document88 pagesDS-7204HI-VS Net DVR - V2.0 (080909)ANTONIO PEREZNo ratings yet

- Numerical WindingDocument12 pagesNumerical Windingsujal jhaNo ratings yet

- Alfa Laval Energy Balance Casestory enDocument2 pagesAlfa Laval Energy Balance Casestory enHélder FernandoNo ratings yet

- Training Schedule April 2021 To March 22 - 0Document18 pagesTraining Schedule April 2021 To March 22 - 0sanrexiNo ratings yet

- Roberto Del RosarioDocument19 pagesRoberto Del RosarioCarl llamasNo ratings yet

- TrerwtsdsDocument167 pagesTrerwtsdsvinicius gomes duarteNo ratings yet

- Mita Lifestyle Agenda ContentDocument263 pagesMita Lifestyle Agenda Contentnacentral13517No ratings yet

- 7383 - AdmissionTech - Aiub 19 SummerDocument5 pages7383 - AdmissionTech - Aiub 19 SummerdeshidhongbdNo ratings yet

- Group 3 Aia ReportDocument26 pagesGroup 3 Aia ReportNAVAS E VNo ratings yet

- 7th Chemistry DLP Study Package FinalDocument101 pages7th Chemistry DLP Study Package FinalAdityaNo ratings yet

- IM300-20 (LCMass RHE 14) PDFDocument40 pagesIM300-20 (LCMass RHE 14) PDFLazzarus Az GunawanNo ratings yet

- Língua Inglesa: Reported SpeechDocument3 pagesLíngua Inglesa: Reported SpeechPatrick AlmeidaNo ratings yet