Professional Documents

Culture Documents

Tan Delta - TDM 4000: Benefits

Uploaded by

Hiro ItoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tan Delta - TDM 4000: Benefits

Uploaded by

Hiro ItoCopyright:

Available Formats

TAN DELTA - TDM 4000

Automatic Dielectric Constant Tan Delta & Resistance Bridge

Automatic Dielectric Constant

Tan Delta & Resistance Bridge

Benefits

Fully Automatic Dielectric

Constant, Dielectric

Dissipation Factor &

Resistivity Measurement.

Inbuilt Printer Facility for

Test Report Printing.

Easy Storage of Data.

PC Compatibility.

Fully Automatic Operation

Data Storage 250 test

results in inbuilt memory

The TDM-4000 is an automated instrument for measuring the

electrical characteristics of transformer oil, insulating liquids & other

insulating material samples. The TDM-4000 measures Capacitance,

Dielectric Constant (Î), Dielectric Loss, Tan Delta (Dissipation Factor),

Resistance & Resistivity of the test sample. The Tan Delta value gives

TDM 4000

an indication of the condition of the oil sample. There are several

reasons due to which the Tan Delta value may be affected – such as

moisture, dissolving of some of the transformer varnish, insulating

material deteoriating etc.

Oil sample dose - Start measuring - The result obtained

TDM-4000 is especially designed to work with the IEC & ASTM type oil cell

with a 2mm spacing and will apply a stress in the range of 100 - 1000

volts per mm as recognized by ASTM and other specifications.

DESCRIPTION

The model TDM-4000 is a versatile Test Set used for measuring the

Dielectric Constant, Tan Delta (DF), Resistivity of transformer oils & other

electrical insulating liquids or solid insulating materials in sheet form. The

TDM-4000 is only the measuring instrument to test insulating liquids, it

should be used with a three terminal oil test cell. A heater is required if

the oil is to be tested at temperatures specified in international or national

standards. A suitable solid dielectric test cell is required for testing

insulation in sheet form. When excited with an AC source, the TDM-4000

measures the Voltage, Capacitance, Dielectric Loss and Frequency.

Dissipation Factor (Tan Delta) or Power Factor is calculated from the

above measurements. To determine the Dielectric Constant (), the

measurements are carried on an empty and a full test cell. The

parameters of the test cell can also be entered manually, using the

keypad. The operating procedure is menu driven & simple. The AC &

DC test voltages are set using the front panel keypad. Tests can be

programmed for the AC test between 200 to 2500 volts and 100 to 1,000

volts for the DC test. After initial set-up, the oil test cell is filled with the

oil test sample & the test procedure is initiated. The test set performs all

the selected measurements automatically & the results are displayed on

the front panel.

Für weitere Informationen stehen wir Ihnen gerne zu Verfügung.

ENERGY SUPPORT GmbH

Sperberweg 47

D-41468 Neuss

T +49 - 2131 / 403 96 07

F +49 - 2131 / 403 96 08

info@energy-support.de

www.energy-support.de

www.energy-support.de

Oil sample dose - Start measuring - The result obtained

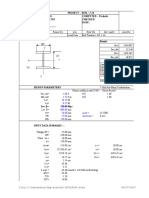

CAPACITANCE TAN DELTA & DIELECTRIC CONSTANT

Test Voltage : 0 - 3000 VAC in 1 volt steps requirement

( or as desired by Customer ).

Accuracy : ± 1% of output.

Capacitance : 0 -1600pF

Accuracy : ± 0.1% of reading, ± 0.1 pF.

Best Resolution : 0.01 pF

Dielectric Constant : 1 - 6 when using a typical oil test cell

(C=55pF±1pF)

Accuracy : ± 0.1%

Resolution : 0.001

Dissipation factor (DF) : 0-1.000

Accuracy : ± 1% of reading ± 0.0001 (1x10-4)

Resolution : 1 x 10e-5

Dielectric Loss : 0 - 10.00 watts.

Accuracy : ± 1% of reading, ± (10-5 watts)

Best Resolution : 0.001 milli watts (10-6 watts)

Cell Constant : Any cell acceptable, oil test cell with 55 pF.

RESISTANCE & RESISTIVITY

Test Voltage : 100-1000 VDC SETTABLE.

Accuracy : ± 1% of setting.

Resistivity : 109 to 1015 Ω cm with a typical test cell of 1000

cm.

Resolution : 3 Digits

Accuracy : ± 2% of reading at 109 – 1013Ω cm

± 5% of reading at 1013 – 1014Ω cm

± 10% of reading above 1014Ω cm

ENERGY SUPPORT GmbH

Sperberweg 47

D-41468 Neuss

T +49 - 2131 / 403 96 07

F +49 - 2131 / 403 96 08

info@energy-support.de

www.energy-support.de

www.energy-support.de

Oil sample dose - Start measuring - The result obtained

CAPACITANCE TAN DELTA & DIELECTRIC CONSTANT

OIL TEST CELL

Construction : 3 Terminal Configuration.

Cell constant : 621.5 Nominal

Cell Capacitance : 55pf 1pF

Cell material : Stainless steel (SS : 316)

Insulation material : Teflon (PTFE)

Temperature range : upto 150° C

Electrode Spacing : 2 mm

Electrodes Max. applicable Voltage : 2 KV

Volume of the oil required : 60 ml. Approximately

OIL TEST CELL HEATER

Power Supply : 230VAC 10%, 50Hz.

Temperature range : 150° C

Temperature control : One set point over the entire range (at 90° C)

Test Temperature : Adjustable from 20 C (Room Temp.) to 150 C with

an accuracy 0.5 % Accuracy of temp. control: 2 C.

Indication : LCD Panel

Sensing probe : Solid state (PT-100)

Heating element : Induction Type Heater.

DISPLAY PRINTER & DATA STORAGE

Display : Alphanumeric LCD display

Keyboard : 20 Key keypad providing numeric and

soft function entries.

Printer : Inbuilt dot matrix printer.

PC Compatibility : RS 232 port

Data Storage : Capacity upto100 test results should be stored.

POWER SUPPLY, TEMP & HUMIDITY RANGE

Power Supply : 230VAC 10%, 50Hz Operating Temp: -10 to 50 C

Humidity : Ambient to 90% RH

STANDARD CALIBRATOR

Capacitance 1 value, Tan Delta 3 value & Resistivity 4 value standard calibrator with

traceable calibration certificate operating voltage 500VAC/DC.

CONNECTORS

Suitable HV, LV & Ground Leads, 6 Pin Safety Interlock & 3 Pin Mains chord.

ENERGY SUPPORT GmbH

Sperberweg 47

D-41468 Neuss

T +49 - 2131 / 403 96 07

F +49 - 2131 / 403 96 08

info@energy-support.de

www.energy-support.de

www.energy-support.de

You might also like

- Data Sheet: Automatic Dissipation Factor and Resistivity Test Equipment Dieltest DTLDocument4 pagesData Sheet: Automatic Dissipation Factor and Resistivity Test Equipment Dieltest DTLFany OchNo ratings yet

- Oil Tan Delta Manual - Oil Tan Delta Volume Resistivity MeterDocument1 pageOil Tan Delta Manual - Oil Tan Delta Volume Resistivity MeterAbvolt IndiaNo ratings yet

- Adtr 2K PLUS DS - 17Document4 pagesAdtr 2K PLUS DS - 17Jackson MokwatloNo ratings yet

- C & Tanδ Meter for Insulation MaterialsDocument4 pagesC & Tanδ Meter for Insulation MaterialsBash MatNo ratings yet

- Manual Equipo Gd6000aDocument21 pagesManual Equipo Gd6000aGiovanni TorresNo ratings yet

- 5025E DatasheetDocument3 pages5025E DatasheetDavid SigalinggingNo ratings yet

- Precision thermometry bridge for calibration labsDocument4 pagesPrecision thermometry bridge for calibration labslukasjoNo ratings yet

- Tan DeltaDocument4 pagesTan Deltasumonto majiNo ratings yet

- MO-1210 Instruction Manual LivretoDocument20 pagesMO-1210 Instruction Manual Livretoqhrnn4xf8xNo ratings yet

- mrp11 Catalogue PDFDocument3 pagesmrp11 Catalogue PDFab_s5036No ratings yet

- Tech Specs: Temperature ControllerDocument2 pagesTech Specs: Temperature Controllershruti JadhavNo ratings yet

- HZJQ-X1 80KV Transformer Oil BDV TesterDocument2 pagesHZJQ-X1 80KV Transformer Oil BDV TesterRafaela Ribeiro de OliveiraNo ratings yet

- Dielectric Constant Tan Delta & Resistivity TestDocument2 pagesDielectric Constant Tan Delta & Resistivity TestKANNA_2327No ratings yet

- Highlights: AM8010 Handheld Precision ThermometerDocument2 pagesHighlights: AM8010 Handheld Precision ThermometerValidaciones VicarNo ratings yet

- BXD17 Series Datasheet v1Document12 pagesBXD17 Series Datasheet v1Alexandre FerreiraNo ratings yet

- 525B 9001 Rev D PIE 525B Automated Thermocouple and RTD Calibrator Data SheetDocument8 pages525B 9001 Rev D PIE 525B Automated Thermocouple and RTD Calibrator Data Sheethugo_cortes5275No ratings yet

- 34405A Data SheetDocument9 pages34405A Data SheetcciproductsNo ratings yet

- Datasheet For Tan Delta and Capacitance Tester TDC3100 BDocument2 pagesDatasheet For Tan Delta and Capacitance Tester TDC3100 BCarlos SantosNo ratings yet

- FlukeDocument16 pagesFlukejohovitchNo ratings yet

- Operator'S Instruction Manual: 903-150NAS 903-150NBS 303-150NCS 903-150NDSDocument20 pagesOperator'S Instruction Manual: 903-150NAS 903-150NBS 303-150NCS 903-150NDSPhạm VinhNo ratings yet

- Fluke 45Document3 pagesFluke 45Jonatan BuitragoNo ratings yet

- At9205d PDFDocument3 pagesAt9205d PDFLuis Roa ZambranoNo ratings yet

- Digital Multimeter: Atten At9205DDocument3 pagesDigital Multimeter: Atten At9205DxspectroxNo ratings yet

- 8-channel temperature scannerDocument2 pages8-channel temperature scannermukul9040No ratings yet

- DT 6650Document3 pagesDT 6650maurleivaNo ratings yet

- PTC Thermistors As Limit Temperature Sensors: Motor Protection, Single SensorsDocument12 pagesPTC Thermistors As Limit Temperature Sensors: Motor Protection, Single SensorsshakibNo ratings yet

- PTC Motor Protection M1100Document12 pagesPTC Motor Protection M1100MalikAlrahabiNo ratings yet

- Agilent 34405A Multimeter 5.5 Digit Dual Display, Benchtop DMM More Capabilities at A Value PriceDocument9 pagesAgilent 34405A Multimeter 5.5 Digit Dual Display, Benchtop DMM More Capabilities at A Value PriceSergiu BadalutaNo ratings yet

- APPA A18 Clamp Multi MeterDocument4 pagesAPPA A18 Clamp Multi MeterLalo LeloNo ratings yet

- SMT2001Document10 pagesSMT2001Lavanya ReddyNo ratings yet

- TA-Smart EN LowDocument8 pagesTA-Smart EN LowRendiNo ratings yet

- Multi Vision™: Multivariable TransmitterDocument10 pagesMulti Vision™: Multivariable TransmitterRaja RamNo ratings yet

- FjcyjDocument6 pagesFjcyjAminah Symphos WeltrafNo ratings yet

- 5025C Multifunction CalibratorDocument3 pages5025C Multifunction CalibratorNicolas RamosNo ratings yet

- 700 Series: 200 Amp Clamp MetersDocument12 pages700 Series: 200 Amp Clamp MetersTom BeanNo ratings yet

- Four Probe MethodDocument2 pagesFour Probe MethodlawilapNo ratings yet

- Four Probe Experiment Dfp 02 Basic ModelDocument2 pagesFour Probe Experiment Dfp 02 Basic Modelagarkarpallavi8No ratings yet

- Fluke 725 DatasheetDocument2 pagesFluke 725 DatasheetMilton MarinNo ratings yet

- Technical User Manual For Tan Delta Tester HYGS-10KVDocument21 pagesTechnical User Manual For Tan Delta Tester HYGS-10KVengenheiroigor100% (2)

- Fluke 36 Service ID10099Document13 pagesFluke 36 Service ID10099Gaspar GarciaNo ratings yet

- M4100 TechSpecs 12-08 US LRDocument2 pagesM4100 TechSpecs 12-08 US LRKinhNo ratings yet

- Closed Cup Flash Point TesterDocument6 pagesClosed Cup Flash Point TesterUzair BukhariNo ratings yet

- TC 305Document6 pagesTC 305DiegoNo ratings yet

- 5051 PlusDocument12 pages5051 PluspenityNo ratings yet

- AD711Document12 pagesAD711Ravi RathodNo ratings yet

- Fluke 111 CalibracionDocument16 pagesFluke 111 CalibracionMauricio Quevedo Millan100% (1)

- PROCESS CALIBRATOR Atek 830Document5 pagesPROCESS CALIBRATOR Atek 830BenabidNo ratings yet

- Medidas Eroelectronic PDFDocument4 pagesMedidas Eroelectronic PDFJuan Diego CondeNo ratings yet

- Manualportugues Txrail Usb Transmitter 4-20ma v20x B enDocument4 pagesManualportugues Txrail Usb Transmitter 4-20ma v20x B enLizandro FernandesNo ratings yet

- PESD1ETH1G-LS Nexperia Product ReliabilityDocument1 pagePESD1ETH1G-LS Nexperia Product ReliabilityCynthiaNo ratings yet

- TIM-94N / TIM-94N-B / TIM-94N-BN: DescriptionDocument5 pagesTIM-94N / TIM-94N-B / TIM-94N-BN: Descriptionluat1983No ratings yet

- EN Calibration Source M340 - DatasheetDocument2 pagesEN Calibration Source M340 - DatasheetMansour AchaourNo ratings yet

- Easy to operate general-purpose instrument that's as easy to affordDocument5 pagesEasy to operate general-purpose instrument that's as easy to affordakv_303No ratings yet

- Unilap 100 E: Installation TesterDocument4 pagesUnilap 100 E: Installation Testerchoban19840% (1)

- Product Specification: Research & DevelopmentDocument3 pagesProduct Specification: Research & DevelopmentGIL ENGINEERNo ratings yet

- Metravi: Digital T-Rms Multimeter With Wireless Usb PC InterfaceDocument2 pagesMetravi: Digital T-Rms Multimeter With Wireless Usb PC InterfaceefasaravananNo ratings yet

- Presys t25n t35n t50nDocument2 pagesPresys t25n t35n t50nNidia PerezNo ratings yet

- Model 1290 Strain Gage Installation ManualDocument32 pagesModel 1290 Strain Gage Installation ManualsunanNo ratings yet

- Kelman Minitrans GEA-17281C-E - 200214 - R003 - HRDocument2 pagesKelman Minitrans GEA-17281C-E - 200214 - R003 - HRHiro ItoNo ratings yet

- Thermasset 2: Fiber Optic Winding Hot Spot Temperature Monitor and Temperature Controller For Power TransformersDocument2 pagesThermasset 2: Fiber Optic Winding Hot Spot Temperature Monitor and Temperature Controller For Power TransformersHiro ItoNo ratings yet

- TESSA® Asset Performance Management (Onepager)Document1 pageTESSA® Asset Performance Management (Onepager)Hiro ItoNo ratings yet

- Cispr15 2018Document161 pagesCispr15 2018Hiro ItoNo ratings yet

- TESSA® APM - FunctionsDocument15 pagesTESSA® APM - FunctionsHiro ItoNo ratings yet

- 40-0236-01 TOTUS Installation ManualDocument33 pages40-0236-01 TOTUS Installation ManualHiro Ito100% (2)

- Doble Prime PD Guard - Data SheetDocument2 pagesDoble Prime PD Guard - Data SheetHiro ItoNo ratings yet

- 1412i-T Manual BE6025-15Document202 pages1412i-T Manual BE6025-15Hiro ItoNo ratings yet

- Doble IDD Bushing Monitor Detects FailuresDocument2 pagesDoble IDD Bushing Monitor Detects FailuresHiro ItoNo ratings yet

- CG-060 - DGA 900 DNP3 Objects - IO Points Index - Rev 2.2Document18 pagesCG-060 - DGA 900 DNP3 Objects - IO Points Index - Rev 2.2Hiro ItoNo ratings yet

- Totus Certificate of Conformity and Calibration: TOTUS Serial Number: TST002-000788Document3 pagesTotus Certificate of Conformity and Calibration: TOTUS Serial Number: TST002-000788Hiro ItoNo ratings yet

- TCM Commissioning ChecklistDocument4 pagesTCM Commissioning ChecklistHiro ItoNo ratings yet

- Item Energisa 690878 - CoreTec 4.2 - ConcentradorDocument2 pagesItem Energisa 690878 - CoreTec 4.2 - ConcentradorHiro ItoNo ratings yet

- Item Energisa 690878 - TXpert - BM - Monitor de BuchasDocument2 pagesItem Energisa 690878 - TXpert - BM - Monitor de BuchasHiro ItoNo ratings yet

- Dissolved Gas Analysis in Tap-Changer Oil: Product InformationDocument4 pagesDissolved Gas Analysis in Tap-Changer Oil: Product InformationHiro ItoNo ratings yet

- DGA900 - DNP3 Installation Guide - Rev 1.4 Jun 2019Document31 pagesDGA900 - DNP3 Installation Guide - Rev 1.4 Jun 2019Hiro ItoNo ratings yet

- Kelman™ DGA 900: Installation ManualDocument68 pagesKelman™ DGA 900: Installation ManualHiro ItoNo ratings yet

- APM Utilities Brochure - 9AKK106930A8037-US-webDocument8 pagesAPM Utilities Brochure - 9AKK106930A8037-US-webHiro ItoNo ratings yet

- Temperature Monitor and Voltage RegulatorDocument24 pagesTemperature Monitor and Voltage RegulatorHiro ItoNo ratings yet

- Sigma 2000 - Tensión InterfacialDocument2 pagesSigma 2000 - Tensión InterfacialJorge EspinozaNo ratings yet

- BAB Messko PDFDocument1 pageBAB Messko PDFHiro ItoNo ratings yet

- Pocket TitratorDocument2 pagesPocket TitratorHiro ItoNo ratings yet

- RMC30 Hardware-Installation-Guide ENDocument38 pagesRMC30 Hardware-Installation-Guide ENHiro ItoNo ratings yet

- BAB Messko PDFDocument1 pageBAB Messko PDFHiro ItoNo ratings yet

- Column Is800Document4 pagesColumn Is800rammohanNo ratings yet

- Surface Chemistry of Solid Catalysts PDFDocument37 pagesSurface Chemistry of Solid Catalysts PDFCorby TranNo ratings yet

- Introduction To Basic Gas LawsDocument39 pagesIntroduction To Basic Gas LawsjosethompsonNo ratings yet

- Jawapan Latihan Fizik T4 2021Document34 pagesJawapan Latihan Fizik T4 2021KHAIRINA NAZIHAH BINTI KAMARUL RIZAM MoeNo ratings yet

- Fatigue Crack Initiation Mechanisms: December 2016Document24 pagesFatigue Crack Initiation Mechanisms: December 2016sunil ugadiNo ratings yet

- Engineering Electromagnetics: The Steady Magnetic FieldDocument71 pagesEngineering Electromagnetics: The Steady Magnetic FieldSandeep RajputNo ratings yet

- Exercise - Moon MissionDocument14 pagesExercise - Moon Missional3ssi086No ratings yet

- A New Safety Philosophy for CWR TrackDocument6 pagesA New Safety Philosophy for CWR TrackAli Mubarack CKNo ratings yet

- Laser and IPL Technology in Dermatology and Aesthetic MedicineDocument434 pagesLaser and IPL Technology in Dermatology and Aesthetic MedicineMauricio MontemayorNo ratings yet

- 12.1 and 12.2 Quiz 1Document1 page12.1 and 12.2 Quiz 1DoraemonNo ratings yet

- Electronics and Communication MG University Syllabus.Document77 pagesElectronics and Communication MG University Syllabus.Anil RVNo ratings yet

- Experiment 6Document7 pagesExperiment 6swamyNo ratings yet

- Chem Notes Full PDFDocument35 pagesChem Notes Full PDFVishal Kunnathur Senthilkumar100% (2)

- 3rd Quarter PHYSICAL SCIENCE ExamDocument19 pages3rd Quarter PHYSICAL SCIENCE ExamZhering RodulfoNo ratings yet

- LQR Controller for Two Link Rigid ManipulatorDocument4 pagesLQR Controller for Two Link Rigid ManipulatorshivaNo ratings yet

- Student Exploration: Energy Conversions Part 2Document2 pagesStudent Exploration: Energy Conversions Part 2yareliNo ratings yet

- Prof InternDocument15 pagesProf InternPratyushAgarwalNo ratings yet

- Low Cost AFM Piezo BusserDocument11 pagesLow Cost AFM Piezo Busserjast_80No ratings yet

- Circular MotionDocument15 pagesCircular MotionARUNESH PRATAP SINGHNo ratings yet

- BSC Information Booklet PNG 21-5-2022Document30 pagesBSC Information Booklet PNG 21-5-2022UrvishNo ratings yet

- Diffusion TutorialDocument9 pagesDiffusion TutorialVishnuNo ratings yet

- SoilThermalResistivity PDFDocument29 pagesSoilThermalResistivity PDFgnklol3No ratings yet

- Hammerhead Tower CraneDocument15 pagesHammerhead Tower CraneMark Pamular100% (1)

- Enthalpy of Moist Air (Total Heat) Dry Bulb TemperatureDocument6 pagesEnthalpy of Moist Air (Total Heat) Dry Bulb Temperatureammar100% (1)

- Contoh Soal Heat Exchanger dan Cooling TowerDocument9 pagesContoh Soal Heat Exchanger dan Cooling TowerLuthfy AditiarNo ratings yet

- Orifice Under Varying Head: Experiment No.: 5Document4 pagesOrifice Under Varying Head: Experiment No.: 5KshitizNo ratings yet

- Nanocharacterisation, 2007, p.319 PDFDocument319 pagesNanocharacterisation, 2007, p.319 PDFArunmaalaNo ratings yet

- 2016 Book StochasticAndInfiniteDimension PDFDocument304 pages2016 Book StochasticAndInfiniteDimension PDFJhoan Sebastian Tenjo Garcia100% (1)

- NCERT Solutions For Class 11 Physics 15may Chapter 11 Thermal Properties of MatterDocument17 pagesNCERT Solutions For Class 11 Physics 15may Chapter 11 Thermal Properties of Mattermhar tsangNo ratings yet

- Entry Exam - PhD Chemical EngineeringDocument5 pagesEntry Exam - PhD Chemical Engineeringhiba thamirNo ratings yet