Professional Documents

Culture Documents

Lab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels..docx - 2 PDF

Lab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels..docx - 2 PDF

Uploaded by

Muhammad Adli Amin Mohd AmzukiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels..docx - 2 PDF

Lab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels..docx - 2 PDF

Uploaded by

Muhammad Adli Amin Mohd AmzukiCopyright:

Available Formats

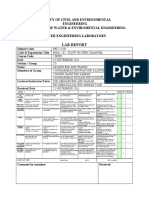

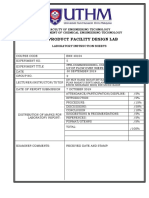

FACULTY OF CIVIL ENGINEERING DIPLOMA IN CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA LABORATORY MANUAL

COURSE WATER ENGINEERING LABORATORY

COURSE CODE ECW341

LEVEL OF OPENNESS 1

CATEGORY PARTIALLY OPEN

DEGREE OF OPEN ENDED 33%

PERIOD OF ACTIVITY 1 WEEK

LAB NO 3.2

DETERMINATION OF HYDRAULIC PARAMETERS IN UNIFORM

TITLE

FLOW FOR OPEN CHANNELS.

OBJECTIVES

1. To obtain appropriate coefficients to satisfy the Manning formula

of a corrugated and roughened bed on the depth of water at

different flow rates.

LEARNING OUTCOMES

At the end of the lesson, students should be able to:

1. Conduct the determination of hydraulic parameters in uniform flow

for open channels laboratory experiment. (CO1 – PO4)

2. Analyze and interpret the data based on obtained data. (CO2 –

PO6)

THEORITICAL BACKGROUND

For uniform flow in an open channel, the Manning formula states that:

PREAMBLE

2 1

1

𝑣 = 𝑛 𝑅3 𝑆 2

where

n = Coefficient of roughness (Dimensionless)

v = Mean fluid velocity (m/s)

R = Hydraulic mean radius (m)

= Flow area A / Wetted perimeter P

Where:

𝑑0 +𝑑1

𝐴 = 𝐵. ( 2

)

and

𝑑0 +𝑑1

𝑃 = 𝐵 + 2. ( 2

)

Where

B= channel width (m)

ECW341 – WATER ENGINEERING LABORATORY Page 1

FACULTY OF CIVIL ENGINEERING DIPLOMA IN CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA LABORATORY MANUAL

S= Slope of energy line

= sin θ = (d0 – d1)/x

with

x = Distance between level of measurements (m)

d0 = Upstream depth of flow (m)

d1 = Downstream depth of flow (m)

The actual fluid velocity can be calculated as:

𝑣 = 𝑄/𝐴

where:

v = Mean fluid velocity (m)

Q = volume of flow rate (m3)

A = Area of flow (m2)

= (Breadth of channel, b) x (depth of flow, h)

h = Average depth of flow above gravel bed (m)

(d0 + d1) / 2

The group is required to obtain the coefficient of roughness, n based on

the laboratory test on the two (2) type of different bed surface. Then need

PROBLEM STATEMENTS

to compare to the actual Manning coefficient publishes base on the two

(2) types of different bed flow rates.

APPARATUS

i. Self-contained glass sided tilting flume

ii. Rulers

iii. Paper

iv. Corrugated bed

v. Gravel bed

APPARATUS vi. Point gauge

Figure 1 Self contained glass sided tilting flume

ECW341 – WATER ENGINEERING LABORATORY Page 2

FACULTY OF CIVIL ENGINEERING DIPLOMA IN CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA LABORATORY MANUAL

Figure 2 Apparatus cross-section in corrugated bed

Figure 3 Apparatus cross-section in gravel bed

PROCEDURE/METHOD

1) Install the corrugated bed section at the bottom of the flume.

Position the hook and point level gauge on the instrument rails.

Use the top of the corrugations in the bed as a datum and measure

the datum height.

2) Ensure the downstream tilting overshot weir is at the bottom of its

water flow, open the flow control valve and admit the water into the

flume. Once a small head of flowing water has been achieved do

not adjust the flow control valve again, in order to maintain a

WAYS AND MEANS constant flow rate throughout the experiment.

(Refer to Standard Methods for the 3) Measure the volume flow rate, Q, and the depth of flow d0 and d1

Examination of Water and above the roughened bed at each end.

4) Raise the downstream tilting overshot weir in small stages,

Wastewater

repeating the measurements at each stage.

5) Further sets of readings can be obtained by repeating the above

measurement with different flow rates but increasing the slope of

the flume.

6) Repeat the whole procedures with gravel bed section.

Students are asked to obtain the upstream and downstream flow depth

from the given discharges. The horizontal distances between upstream

and downstream location will be determined.

ECW341 – WATER ENGINEERING LABORATORY Page 3

FACULTY OF CIVIL ENGINEERING DIPLOMA IN CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA LABORATORY MANUAL

The group is required to submit the technical report of the laboratory

results highlighting the apparatus used, the procedures undertaken for the

RESULT, ANALYSIS

test, data acquisition process, analysis carried out and the relevancy of

CONCLUSION

the set-out output to address the given problem. Discuss the result

outcome in the experiment.

ECW341 – WATER ENGINEERING LABORATORY Page 4

You might also like

- Pluto Ufufy V2 0Document4 pagesPluto Ufufy V2 0tobi mania100% (1)

- Cable Trench Installation GuideDocument12 pagesCable Trench Installation Guideecruz_yhwhNo ratings yet

- Sharp Crested WeirDocument7 pagesSharp Crested WeirAizuddinNo ratings yet

- Impact of A Jet Lab ReportDocument3 pagesImpact of A Jet Lab ReportSaiful IslamNo ratings yet

- What Makes A MoatDocument5 pagesWhat Makes A MoatMohammed ShakilNo ratings yet

- Presentation On ShutteringDocument29 pagesPresentation On ShutteringMukul KumarNo ratings yet

- ASTM D36/D36M-09 Standard Test Method For Softening Point of Bitumen (Ring-and-Ball Apparatus)Document6 pagesASTM D36/D36M-09 Standard Test Method For Softening Point of Bitumen (Ring-and-Ball Apparatus)Nashrul3267% (3)

- Refresher Geotechnical Engineering 1 ExamDocument3 pagesRefresher Geotechnical Engineering 1 ExamMayya BonaNo ratings yet

- Autodesk Robot Structural Analysis ProfessionalDocument4 pagesAutodesk Robot Structural Analysis ProfessionalKay Chan Sotheara0% (1)

- Multilane Highway Capacity AnalysisDocument9 pagesMultilane Highway Capacity AnalysisIkhwan Z.100% (1)

- Tension Coefficient 2 ReportDocument10 pagesTension Coefficient 2 ReportMuhd ArifNo ratings yet

- Marketing Plan (Pizza Hut)Document13 pagesMarketing Plan (Pizza Hut)Anjali10183% (48)

- Experiment No - 1 Flow Through A Sluice GateDocument11 pagesExperiment No - 1 Flow Through A Sluice Gatesalman40% (5)

- Universiti Malaysia Sarawak: Faculty of EngineeringDocument22 pagesUniversiti Malaysia Sarawak: Faculty of EngineeringAyish Cehcter100% (1)

- Lab3 Experiment Hydraulic JumpDocument21 pagesLab3 Experiment Hydraulic JumpErin MarissaNo ratings yet

- Curriculum MapDocument9 pagesCurriculum MapJoyce Anne Tuala Yabut100% (1)

- Outflow MeterDocument5 pagesOutflow MeterFirash ImranNo ratings yet

- Student Code of Ethic (SCE)Document10 pagesStudent Code of Ethic (SCE)Rahim GenesisNo ratings yet

- Lab Soil UctDocument3 pagesLab Soil UctSyed Zulfaizzuan AljufriNo ratings yet

- Outflow LabDocument4 pagesOutflow LabNorhazerahYussop67% (3)

- Nitrite and Nitrate Lab ReportDocument14 pagesNitrite and Nitrate Lab ReportAlif ZakwanNo ratings yet

- DCC30093 Dis 2020 Test 2Document3 pagesDCC30093 Dis 2020 Test 2BruhNo ratings yet

- LAB 1 - PARTICLE DENSITY & MOISTURE CONTENT (Level 1)Document6 pagesLAB 1 - PARTICLE DENSITY & MOISTURE CONTENT (Level 1)Muhd MuqhreyNo ratings yet

- LAB REPORT ECS238 3 Pin ArchDocument6 pagesLAB REPORT ECS238 3 Pin Archmarina zamriNo ratings yet

- Angularity NumberDocument5 pagesAngularity NumberSolankiNo ratings yet

- Sungai MelanaDocument53 pagesSungai MelanaFahrul 2394No ratings yet

- Recognize The Standard Safety Operational Procedure To Be Fulfilled Before Conducting This TestingDocument3 pagesRecognize The Standard Safety Operational Procedure To Be Fulfilled Before Conducting This TestingEzanie IzyanNo ratings yet

- Group 3 (Seksyen4)Document15 pagesGroup 3 (Seksyen4)alnzNo ratings yet

- HYDRAULIC Cqi QuestionsDocument2 pagesHYDRAULIC Cqi QuestionsJibul temulakNo ratings yet

- All Three Labs 2Document22 pagesAll Three Labs 2JaeNo ratings yet

- Nurul Nabilah Binti Baharin - 16dka19f2054 - Case StudyDocument25 pagesNurul Nabilah Binti Baharin - 16dka19f2054 - Case Studymoneesha sriNo ratings yet

- SofteningDocument2 pagesSofteningmaizansofiaNo ratings yet

- Turbidity TestDocument12 pagesTurbidity TestNazrul IzdhamNo ratings yet

- Flakiness IndexDocument6 pagesFlakiness IndexEagleLordNo ratings yet

- Politeknik MalayDocument6 pagesPoliteknik MalaybrianlaksonoNo ratings yet

- Skid ResistanceDocument5 pagesSkid ResistanceMoyashi Desu100% (2)

- Lab Report Turbine and PumpDocument12 pagesLab Report Turbine and PumpNOR IFFAH ALEYA LATIFFNo ratings yet

- AIV TestDocument3 pagesAIV TestismailNo ratings yet

- Uitm Lab ReportDocument4 pagesUitm Lab ReportShark MJNo ratings yet

- Sharp Crested WeirDocument7 pagesSharp Crested WeirMohamad Zahir Razak100% (1)

- Lab Report For Venturi MeterDocument9 pagesLab Report For Venturi MeterRichard Puni92% (12)

- Lab Report Vicat TestDocument2 pagesLab Report Vicat TestmanNo ratings yet

- Full Lab Report 5Document12 pagesFull Lab Report 5Siti SyuhadahNo ratings yet

- StrutsDocument7 pagesStrutsBatrisyialya RusliNo ratings yet

- OEL CEG552 Level 2 Surface DrainageDocument1 pageOEL CEG552 Level 2 Surface Drainagenur syafieraNo ratings yet

- Lab SprinklerDocument8 pagesLab Sprinklerida hadi0% (1)

- C4008 - Geotechnic 2 (Kertas Soalan Politeknik-Politeknik Malaysia Kejuruteraan Awam)Document7 pagesC4008 - Geotechnic 2 (Kertas Soalan Politeknik-Politeknik Malaysia Kejuruteraan Awam)Azil14100% (1)

- Specific Gravity Lab ReportDocument16 pagesSpecific Gravity Lab Reportimran shakirNo ratings yet

- Softening PointDocument6 pagesSoftening PointMohd Zairul Shafiq ZakariaNo ratings yet

- Flakiness & Elongation IndexDocument7 pagesFlakiness & Elongation IndexvinoNo ratings yet

- Lab Report Indeterminate BeamDocument9 pagesLab Report Indeterminate BeamFatin Samsudin60% (5)

- WRE 212 - EXP 5 Flow Through External Cylindrical MouthpieceDocument7 pagesWRE 212 - EXP 5 Flow Through External Cylindrical MouthpieceAshik AshikNo ratings yet

- V NotchDocument2 pagesV NotchRahul Kumar0% (1)

- Proposal PDFDocument52 pagesProposal PDFAfif AzharNo ratings yet

- Aggregate Crushing Value Test Lab ReportDocument2 pagesAggregate Crushing Value Test Lab ReportComr A Y ZarginaNo ratings yet

- Lab 6 Saturation Flow RateDocument4 pagesLab 6 Saturation Flow RateDhrubo Alam100% (4)

- Flow in Open ChannelDocument24 pagesFlow in Open ChannelSue IlaNo ratings yet

- Introduction Impact JetDocument4 pagesIntroduction Impact JetIniaan SaminathanNo ratings yet

- Lab 1 - Particle Density TestDocument6 pagesLab 1 - Particle Density Testeijal1179% (14)

- Softing PointDocument12 pagesSofting PointMUHAMMAD AKRAMNo ratings yet

- Exp.5 - Flow Over Wiers GROUP 2Document20 pagesExp.5 - Flow Over Wiers GROUP 2Gua HantuNo ratings yet

- Student Code of Ethic (SCE) : Department of Civil Engineering Centre For Diploma Studies UthmDocument13 pagesStudent Code of Ethic (SCE) : Department of Civil Engineering Centre For Diploma Studies UthmKerol Kerol Kerol0% (1)

- Full Report Bacterial CountDocument10 pagesFull Report Bacterial CountSuzeanni Jalil100% (1)

- Lab Manual 3.3 - LEVEL 1 - Measurement of Flow Over Broad Crestedsharp Crested Weir.Document4 pagesLab Manual 3.3 - LEVEL 1 - Measurement of Flow Over Broad Crestedsharp Crested Weir.Muhamad IzzanNo ratings yet

- Level 0 ECW437 Friction Loss in Pipe - MAC 2023Document3 pagesLevel 0 ECW437 Friction Loss in Pipe - MAC 20232022605212No ratings yet

- Review Module 23 Geotechnical Engineering 4 Part 1Document2 pagesReview Module 23 Geotechnical Engineering 4 Part 1Mark Daren Patrona RamonNo ratings yet

- 02 P FallingheadpermeabilitytestnewDocument8 pages02 P Fallingheadpermeabilitytestnewkavithrra krishnanNo ratings yet

- Ecw437/Ecw421 Laboratory Manual 2016Document3 pagesEcw437/Ecw421 Laboratory Manual 2016Syahir HamidonNo ratings yet

- JAWAPAN TEST 1 - Version PelajarDocument4 pagesJAWAPAN TEST 1 - Version PelajarMuhamad IzzanNo ratings yet

- Assignment ECS338 OCT2020-FEB2021 (Latest)Document5 pagesAssignment ECS338 OCT2020-FEB2021 (Latest)Muhamad IzzanNo ratings yet

- Performance of Bamboo Sticks As Steel Reinforcement in Reinforced Concrete Beam - Chapter 1 - FKASA-Tan Khye Fang-CD 10188Document3 pagesPerformance of Bamboo Sticks As Steel Reinforcement in Reinforced Concrete Beam - Chapter 1 - FKASA-Tan Khye Fang-CD 10188Muhamad IzzanNo ratings yet

- Izzan DotmyDocument1 pageIzzan DotmyMuhamad IzzanNo ratings yet

- Architectural PlansDocument1 pageArchitectural PlansMuhamad IzzanNo ratings yet

- NfoDocument1 pageNfoMuhamad IzzanNo ratings yet

- Lab Manual 2.3 - LEVEL 0 - Determination of Metacentric HeightDocument6 pagesLab Manual 2.3 - LEVEL 0 - Determination of Metacentric HeightMuhamad IzzanNo ratings yet

- Bernoulli Eqn Waste Water LabDocument10 pagesBernoulli Eqn Waste Water LabMuhamad IzzanNo ratings yet

- Lab Manual 2.4 - LEVEL 0 - Application of Bernoulli EquationDocument4 pagesLab Manual 2.4 - LEVEL 0 - Application of Bernoulli EquationMuhamad IzzanNo ratings yet

- Lab Manual 3.3 - LEVEL 1 - Measurement of Flow Over Broad Crestedsharp Crested Weir.Document4 pagesLab Manual 3.3 - LEVEL 1 - Measurement of Flow Over Broad Crestedsharp Crested Weir.Muhamad IzzanNo ratings yet

- Lab Manual 2.3 - LEVEL 0 - Determination of Metacentric HeightDocument6 pagesLab Manual 2.3 - LEVEL 0 - Determination of Metacentric HeightMuhamad IzzanNo ratings yet

- Data TurbineDocument3 pagesData TurbineMuhamad IzzanNo ratings yet

- Lab Manual 2.1 - LEVEL 0 - Measurement of Fluid PropertiesDocument7 pagesLab Manual 2.1 - LEVEL 0 - Measurement of Fluid PropertiesMuhamad Izzan100% (1)

- Lesson Plan TechnologyDocument3 pagesLesson Plan Technologyapi-340918753No ratings yet

- WealthDocument1 pageWealthfredglass7No ratings yet

- JN0 104 QuestionsDocument3 pagesJN0 104 QuestionsOSAMAH ABU BAKERNo ratings yet

- Theobald Et Al. - 2017 - Student Perception of Group Dynamics Predicts IndiDocument16 pagesTheobald Et Al. - 2017 - Student Perception of Group Dynamics Predicts Indijunnoet21No ratings yet

- Class Sched of COEDocument19 pagesClass Sched of COEALNIE DAVE SEPOSONo ratings yet

- Chapter 12: Tropical Storms and HurricanesDocument24 pagesChapter 12: Tropical Storms and HurricanesSIDDHARTH MOHANTYNo ratings yet

- The Title of HapDocument2 pagesThe Title of HapArunava MisraNo ratings yet

- The Concept of Democracy: Session 5 © NU 2020Document19 pagesThe Concept of Democracy: Session 5 © NU 2020Hênry Stanley NkhuwaNo ratings yet

- Operation Manual: KQWS-2800-R306Document16 pagesOperation Manual: KQWS-2800-R306Wilman OngNo ratings yet

- An - Land Disposition With Survey ClaimantsDocument1 pageAn - Land Disposition With Survey ClaimantsGarry RocmaNo ratings yet

- Canso - Cyber Security and Risk Assessment GuideDocument3 pagesCanso - Cyber Security and Risk Assessment GuideleexyNo ratings yet

- Zzzzvers3.0Ethics TrstSftyRlblty HwCmptngChngeWhWAreNitsPDF PervsvAndAutonmsCmptng DmcrcyNFreedomofSpeechDocument143 pagesZzzzvers3.0Ethics TrstSftyRlblty HwCmptngChngeWhWAreNitsPDF PervsvAndAutonmsCmptng DmcrcyNFreedomofSpeechJosh PenascosasNo ratings yet

- Edith Branson: Modern Woman, Modernist ArtistDocument73 pagesEdith Branson: Modern Woman, Modernist ArtistPatricia Taylor Thompson100% (1)

- BGP Route Refresh CapabilityDocument11 pagesBGP Route Refresh CapabilityPalwasha GulNo ratings yet

- Annotated BibliographyDocument2 pagesAnnotated BibliographyAshley schewagaNo ratings yet

- IFRS 16 - by Zubair SaleemDocument34 pagesIFRS 16 - by Zubair SaleemAli OptimisticNo ratings yet

- Term Paper About MuslimDocument6 pagesTerm Paper About Muslimc5h4drzj100% (1)

- Cash Flow - The Coca-Cola Company (KO)Document1 pageCash Flow - The Coca-Cola Company (KO)vijayNo ratings yet

- Metering Guideline For LSSDocument8 pagesMetering Guideline For LSSAzree Mohd NoorNo ratings yet

- SDS Chevron HDD Antifreeze 50-50 GreenDocument9 pagesSDS Chevron HDD Antifreeze 50-50 Greengil_bar_tNo ratings yet

- Porte Cochere Repair SetDocument10 pagesPorte Cochere Repair SetjavierjimenezcholletNo ratings yet