Professional Documents

Culture Documents

General Notes Special Inspections: Revision Date

Uploaded by

NirajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes Special Inspections: Revision Date

Uploaded by

NirajCopyright:

Available Formats

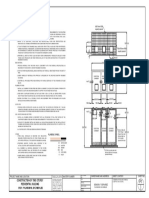

REVISION DATE

GENERAL NOTES SPECIAL INSPECTIONS

THE FOLLOWING NOTES APPLY EXCEPT WHERE SHOWN OTHERWISE WOOD ROOF TRUSSES

SHALL BE FACTORY FABRICATED TRUSSES WITH MINIMUM CAPACITY OF 43PSF. DESIGN AND FABRICATION SHALL CONFORM TO THE REQUIRED INSPECTIONS AND VERIFICATIONS FOR WOOD TRUSSES

CODE: INTERNATIONAL BUILDING CODE IBC (2015) REQUIREMENTS OF THE IBC AND THE DESIGN SPECIFICATIONS FOR LIGHT METAL PLATE CONNECTED WOOD TRUSSES PUBLISHED BY

THE TRUSS PLATE INSTITUTE. ENGINEERING DESIGN AND SHOP DRAWINGS BEARING THE STAMP OF A PROFESSIONAL ENGINEER TYPE CONTINUOUS PERIODIC REFERENCE STANDARD IBC REFERENCE

1. BUILDING DESIGN LOADS REGISTERED IN THE STATE OF WASHINGTON AND SHOWING ALL DETAILS OF CONSTRUCTION REQUIRED FOR A COMPLETE

A. LIVE LOAD INFORMATION INSTALLATION SHALL BE SUBMITTED TO THE ARCHITECT FOR REVIEW. TRUSSES SPANNING 60 FEET OR MORE: TEMPORARY

1. ROOF LIVE LOAD: 16 PSF INSTALLATION RESTRAINT/BRACING AND PERMANENT X

2. FLOOR LIVE LOAD: 40 PSF PRESERVATIVE TREATMENT 1705.2.4, 1705.5.2

INDIVIDUAL TRUSS RESTRAINT/BRACING

3. ATTIC LIVE LOAD: 20 PSF ALL LUMBER, TIMBER, PLYWOOD, GLUE-LAMINATED AND OTHER COMPOSITE LUMBER THAT IS IN CONTACT WITH CONCRETE OR

B. DEAD LOAD INFORMATION MASONRY OR EXPOSED TO WEATHER SHALL BE PRESERVATIVE TREATED IN ACCORDANCE WITH CURRENT AMERICAN WOOD-

1. ROOF DEAD LOAD: 12 PSF PRESERVERS ’ ASSOCIATION (AWPA) PRESERVATIVE (P) STANDARDS. THESE MEMBERS SHALL BE TREATED WITH AN APPROVED

2. FLOOR DEAD LOAD: 12 PSF PRESERVATIVE IN ACCORDANCE WITH CURRENT AWPA COMMODITY (C) STANDARDS AND THE AWPA USE CATEGORY SYSTEM (UCS). REQUIRED INSPECTIONS AND VERIFICATIONS FOR WOOD

C. WIND LOAD INFORMATION WHEREVER POSSIBLE, PRECUT ALL MATERIAL BEFORE TREATMENT. HANDLE TREATED LUMBER IN ACCORDANCE WITH AWPA M4

1. DESIGN WIND SPEED = 110 MPH STANDARDS. TYPE CONTINUOUS PERIODIC REFERENCE STANDARD IBC REFERENCE

2. WIND IMPORTANCE FACTOR (I W) = 1.0

3. RISK CATEGORY = II FIELD CUTS, HOLES (SUCH AS ANCHOR BOLT HOLES IN TREATED SILL PLATES) AND PENETRATION DAMAGE SHALL BE TREATED IN PLYWOOD DIAPHRAGMS WHERE PANEL EDGES HAVE

4. WIND EXPOSURE = B ACCORDANCE WITH THE CURRENT AWPA M4 STANDARDS. THE MOST COMMONLY AVAILABLE PRESERVATIVE MEETING THE MULTIPLE LINES OF FASTENERS: SPECIAL INSPECTOR

5. INTERNAL PRESSURE COEFFICIENT = +/- 0.18 REQUIREMENTS OF STANDARD M4 IS A COPPER NAPHTHENATE SOLUTION CONTAINING AT LEAST 2% COPPER. CERTAIN DAP, WM VERIFY WOOD PANEL THICKNESS AND GRADE, SIZE OF X 1705.5.1

6. COMPONENTS AND CLADDING = AS FOLLOWS BARR, CUPRINOL, BEHR, GREEN'S, JASCO, HENRY AND FIELDS PRESERVATIVE PRODUCTS CONTAIN THIS METAL CONTENT. FRAMING MEMBERS, NAIL DIAMETER AND LENGTH, NUMBER

7. WIND PRESSURES (NET, WIND PRESSURES ARE REPORTED AT ASD LEVEL) OF FASTENER LINES AND SPACING AND EDGE DISTANCE

a. ROOF ALL FASTENERS AND CONNECTORS IN CONTACT WITH PRESERVATIVE TREATED WOOD SHALL BE HOT-DIPPED GALVANIZED OR TYPE PLYWOOD DIAPHRAGMS AND SHEAR WALLS WITH 4" AND

1. ZONE 1: -28.3 PSF STAINLESS STEEL. SEE THE "WOOD CONNECTORS" SECTION. CLOSER PANEL EDGE NAILING: SPECIAL INSPECTOR

2. ZONE 2: -37.2 PSF VERIFY NAIL SIZE AND SPACING, BOLTING, SHEAR WALL X 1705.11.1, 1705.12.2

3. ZONE 3: -46 PSF T & G DECKING ANCHORING AND HOLD-DOWNS, AND DRAG STRUTS OF

b. WALLS 2", 3” AND 4” T & G DECKING TO BE DOUGLAS-FIR OR HEMLOCK SELECT DECKING GRADE OR BETTER. DECKING SHALL BE LAYED UP LATERAL FORCE-RESISTING SYSTEM

1. ZONE 4 -23 PSF AND NAILED IN A “CONTROLLED RANDOM LAYUP ” CONFIGURATION PER AMERICAN WOOD COUNCIL ’S (AWC.ORG) “WOOD PLYWOOD DIAPHRAGMS AND SHEAR WALLS

2. ZONE 5 -28 PSF CONSTRUCTION DATA 2, TONGUE AND GROOVE ROOF DECKING ”. NOT REQUIRED NOT REQUIRED 17.05.11.1

WITH 6" OC PANEL EDGE NAILING

D. SEISMIC DESIGN INFORMATION

A. SEISMIC IMPORTANCE FACTOR (I e) = 1 SCOPE OF STRUCTURAL ENGINEERING SERVICES

B. SEISMIC DESIGN CATEGORY = C THE STRUCTURAL ENGINEER HAS PERFORMED THE STRUCTURAL DESIGN AND PREPARED THE STRUCTURAL WORKING

C. 0.2 SECOND SPECTRAL RESPONSE ACCELERATION (S S) = 0.514 DRAWINGS FOR THIS PROJECT. THE CONSTRUCTION MUST BE PERFORMED IN STRICT ACCORDANCE WITH THE STRUCTURAL

D. 1 SECOND SPECTRAL RESPONSE ACCELERATION (S 1) = 0.173 DRAWINGS. ANY DEVIATION FROM THE DRAWINGS MUST BE APPROVED IN WRITING BY THE STRUCTURAL ENGINEER. ERRORS

E. 0.2 SECOND DESIGN SPECTRAL RESPONSE ACCELERATION (S DS ) = 0.476 AND/OR OMISSIONS FOUND ON THE STRUCTURAL DRAWINGS MUST BE BROUGHT TO THE STRUCTURAL ENGINEER'S ATTENTION

F. 1 SECOND DESIGN SPECTRAL RESPONSE ACCELERATION (S D1 ) = 0.243 IMMEDIATELY.

YOGI ENGINEERING LLC

G. SITE CLASS = D

H. RESPONSE MODIFICATION COEFFICIENT (R) ARCHITECTURAL DRAWINGS ARE THE PRIME CONTRACT DRAWINGS. STRUCTURAL DRAWINGS SHALL BE USED IN CONJUNCTION

• LIGHT FRAMED WOOD WALLS SHEATHED W/ STRUCTURAL PANELS = 6.5 WITH ARCHITECTURAL DRAWINGS. PRIMARY STRUCTURAL ELEMENTS ARE DIMENSIONED ON THE STRUCTURAL PLANS AND

I. SEISMIC RESPONSE COEFFICIENT (C S) = 0.021 DETAILS. THE GENERAL CONTRACTOR SHALL VERIFY AND COORDINATE DIMENSIONS AMONG ALL DRAWINGS. ANY

DISCREPANCIES, CONTRADICTIONS, OR OMISSIONS SHALL BE REPORTED TO THE ARCHITECT FOR RESOLUTION PRIOR TO

J.

K.

DESIGN BASE SHEAR (V C) = C S. W

ANALYTICAL PROCEDURE = EQUIVALENT LATERAL FORCE PROCEDURE PROCEEDING WITH WORK OR FABRICATION OF THE ITEM(S) IN QUESTION. STRUCTURAL ABBREVIATIONS

E. SNOW LOAD = 25 PSF

238 Chittenden Rd, Clifton,

THE STRUCTURAL ENGINEER IS RESPONSIBLE FOR THE DESIGN OF THE PRIMARY STRUCTURAL SYSTEM, EXCEPT FOR ANY

COMPONENTS NOTED ABOVE. RESPONSIBILITY FOR ANY SECONDARY STRUCTURAL AND NON-STRUCTURAL SYSTEMS NOT

E: yogiengs@gmail.com

SHOP DRAWINGS A.BOLT ANCHOR BOLT LW LONG WAY

SHOP DRAWINGS SHALL BE SUBMITTED FOR REVIEW PRIOR TO FABRICATION. SHOP DRAWING SUBMITTALS PROCESSED BY THE ENGINEER ARE NOT SHOWN ON THE STRUCTURAL PLANS RESTS WITH SOMEONE OTHER THAN THE STRUCTURAL ENGINEER. ADDL ADDITIONAL MATL MATERIAL

CHANGE ORDERS. THE PURPOSE OF SHOP DRAWING SUBMITTALS BY THE CONTRACTOR IS TO DEMONSTRATE TO THE ENGINEER THAT THE CONTRACTOR ARCHT ARCHITECTURAL MAX MAXIMUM

New Jersey 07013

UNDERSTANDS THE DESIGN CONCEPT, BY INDICATING WHICH MATERIAL IS INTENDED TO BE FURNISHED AND INSTALLED, AND BY DETAILING THE THE STRUCTURE SHOWN ON THESE DRAWINGS IS STRUCTURALLY SOUND ONLY IN ITS COMPLETED FORM. THE CONTRACTOR BLDG BUILDING MECH MECHANICAL

SHALL PROVIDE ALL NECESSARY BRACING TO STABILIZE THE BUILDING DURING CONSTRUCTION.

M: 55.232.4302

INTENDED FABRICATION AND INSTALLATION METHODS. IF DEVIATIONS, DISCREPANCIES, OR CONFLICTS BETWEEN SHOP DRAWING SUBMITTALS AND THE BLKG BLOCKING MFR MANUFACTURER

CONTRACT DOCUMENTS ARE DISCOVERED EITHER PRIOR TO OR AFTER SHOP DRAWING SUBMITTALS ARE PROCESSED BY THE ENGINEER, THE DESIGN BM BEAM MIN MINIMUM

DRAWINGS AND SPECIFICATIONS SHALL CONTROL AND SHALL BE FOLLOWED. THE STRUCTURAL ENGINEER IS NOT RESPONSIBLE FOR, AND WILL NOT HAVE CONTROL OF, CONSTRUCTION MEANS, METHODS, BOD BOTTOM OF DECK MISC MISCELLANEOUS

TECHNIQUES, SEQUENCES OR PROCEDURES, OR FOR SAFETY PRECAUTIONS AND PROGRAMS IN CONNECTION WITH THE BOT BOTTOM (N) NEW

TIMBER CONSTRUCTION WORK, NOR WILL HE BE RESPONSIBLE FOR THE CONTRACTOR'S FAILURE TO CARRY OUT THE CONSTRUCTION BSMT BASEMENT NIC NOT IN CONTRACT

STRUCTURAL TIMBER AND LUMBER TO BE STRESS GRADE HEM-FIR OR DOUGLAS FIR AS FOLLOWS: WORK IN ACCORDANCE WITH THE CONTRACT DOCUMENTS. BTWN BETWEEN NOM NOMINAL

C CAMBER NTS NOT TO SCALE

USE SPECIES GRADE FB FIELD MEASUREMENTS AND THE VERIFICATION OF FIELD DIMENSIONS ARE NOT PART OF THE STRUCTURAL ENGINEER'S CAP CAPACITY OC ON CENTER

4 X BEAMS DOUGLAS FIR NO. 2 900 PSI RESPONSIBILITY. THE CONTRACTOR MUST CHECK ALL (ASSUMED) EXISTING CONDITIONS SHOWN ON THESE DRAWINGS FOR CC CENTER TO CENTER OD OUTSIDE DIAMETER

6 X BEAMS DOUGLAS FIR NO. 1 1350 PSI ACCURACY AND NOTIFY THE STRUCTURAL ENGINEER OF ANY DISCREPANCIES. CIP CAST IN PLACE OF OUTSIDE FACE

EXTERIOR & BEARING WALL STUDS DOUGLAS-FIR NO. 2 900 PSI CJ CONSTRUCTION OR CONTROL JOINT OPNG OPENING

SHEAR WALL STUDS, PLATES, AND BLOCKING DOUGLAS FIR NO. 2 900 PSI OMISSIONS FROM THE DRAWINGS OR SPECIFICATIONS OR THE INADVERTENT MISLABELING OF DETAILS OF WORK WHICH ARE CL CENTERLINE OPP OPPOSITE

ROOF JOISTS, FLOOR JOISTS DOUGLAS-FIR NO. 2 900 PSI MANIFESTLY NECESSARY TO CARRY OUT THE INTENT OF THE DRAWINGS AND SPECIFICATIONS, OR WHICH ARE CUSTOMARILY CMU CONCRETE MASONRY UNIT OVS OVERSIZE

INTERIOR STUDS AT NON-BEARING WALLS HEM-FIR STANDARD 550 PSI PERFORMED, SHALL NOT RELIEVE THE CONTRACTOR FROM PERFORMING SUCH OMITTED OR INADVERTENT MISLABELED DETAILS CNTR CENTER PEN PENETRATION

ALL OTHER LUMBER HEM-FIR STANDARD/BETTER --- OF THE WORK BUT THEY SHALL BE PERFORMED AS IF FULLY AND CORRECTLY SET FORTH AND DESCRIBED IN THE DRAWINGS CLR CLEAR PERP PERPENDICULAR

AND SPECIFICATIONS. COL COLUMN PL PLATE

WOOD AND WOOD BASED MATERIALS USED IN CONTACT WITH SOIL, CONCRETE OR MASONRY, INSTALLED WITHIN 1 ” OF CONCRETE OR MASONRY, OR CONC CONCRETE PLWD PLYWOOD

EXPOSED TO MOISTURE EITHER INTERIOR OR EXTERIOR, SHALL BE TREATED WITH AN APPROVED PRESERVATIVE PER THE “PRESERVATIVE TREATMENT ” DEFERRED SUBMITTALS CONN CONNECTION PNL PANEL

SECTION BELOW. SOLID BLOCKING OF NOT LESS THAN 2" NOMINAL THICKNESS SHALL BE PROVIDED AT ENDS AND AT ALL SUPPORTS OF JOISTS AND THE FOLLOWING ITEMS ARE CONSIDERED TO BE DEFERRED SUBMITTALS UNDER SECTION 107.3.4.1 OF THE INTERNATIONAL CONT CONTINUOUS PP PARTIAL PENETRATION

RAFTERS. BETWEEN SUPPORTS PROVIDE BLOCKING OR BRIDGING AT 8'-0" OC. BUILDING CODE AND MUST BE SUBMITTED TO THE ARCHITECT OR THE ENGINEER FOR REVIEW. THESE ITEMS WILL THEN BE CONTR CONTRACTOR PSI POUNDS PER SQUARE INCH

FORWARDED TO THE BUILDING OFFICIAL FOR APPROVAL. THE DEFERRED SUBMITTAL ITEMS SHALL NOT BE INSTALLED UNTIL

38 POPLAR AVENUE, POMPTON

CP COMPLETE PENETRATION PSF POUNDS PER SQUARE FOOT

ALL SILL PLATES AT SHEAR WALLS TO BE 3X_ PRESERVATIVE TREATED DOUGLAS-FIR #2, U.N.O. ON THE PLANS. SILL PLATES SHALL HAVE A MOISTURE THEIR DESIGN AND SUBMITTAL DOCUMENTS HAVE BEEN APPROVED BY THE BUILDING OFFICIAL. DBL DOUBLE PSL PARALLAM

CONTENT OF NOT GREATER THAN 19% BEFORE BEING COVERED WITH INSULATION, INTERIOR WALL FINISH, FLOOR COVERING OR OTHER MATERIAL. DET DETAIL PT POST TENSION

38 POPLAR

DF DOUGLAS FIR RC REINFORCED CONCRETE

AVENUE

ALL STUD WALL SILL AND TOP PLATE MEMBERS SHALL BE SURFACE-DRIED (S-DRY) LUMBER (MOISTURE CONTENT = 19% OR LESS DURING FRAMING). ALL DIA DIAMETER REINF REINFORCING

PLAINS NJ 07444

STUDS AND POSTS MAY BE SURFACE-GREEN (S-GREEN) LUMBER (MOISTURE CONTENT = 19% TO 23% DURING FRAMING) OR S-DRY LUMBER. THE DIAG DIAGONAL REQD REQUIRED

MOISTURE CONTENT OF THE FRAMING SHALL BE LESS THAN 12 % PRIOR TO INSTALLATION OF GYPSUM WALLBOARD SHEATHING. DO DITTO RO ROUGH OPENING

DWG DRAWING SC SLIP CRITICAL

WOOD SHRINKAGE EA EACH SCHED SCHEDULE

WOOD MEMBERS WERE EVALUATED USING SURFACE DRIED (S-DRY) LUMBER (MOISTURE CONTENT = 19% OR LESS). THE FLOOR-TO-FLOOR COMPRESSION EF EACH FACE SECT SECTION

OF SUCH WOOD MEMBERS (PLATES AND STUDS) DUE TO A MOISTURE CONTENT CHANGE OF 11% (BASED ON AN EQUILIBRIUM MOISTURE CONTENT, EMC = ELEV ELEVATION SEOR STRUCTURAL ENGINEER OF

8%) WILL BE APPROXIMATELY 1/10 INCH PER FLOOR. ADDITIONAL FLOOR-TO-FLOOR COMPRESSION OF WOOD STUDS DUE TO FULL COMPRESSIVE LOAD EQ EQUAL RECORD

WILL BE APPROXIMATELY 1/32 INCH PER FLOOR. ADDITIONAL COMPRESSION OF WOOD FRAMING MAY OCCUR DUE TO FRAMING TECHNIQUES AND LOCAL EW EACH WAY SHTG SHEATHING

STRESS CONCENTRATIONS. ALL FULL BUILDING HEIGHT ELECTRICAL, MECHANICAL AND PLUMBING SYSTEMS SHOULD BE DESIGNED TO ACCOMMODATE (E) EXISTING SHT SHEET

THESE MOVEMENTS. USE OF WOOD STUDS AND PLATES WHICH WILL HAVE MOISTURE CONTENT CHANGES GREATER THAN 11% WILL EXPERIENCE EXP EXPANSION SIM SIMILAR

GREATER MOVEMENT. THE VALUES ARE BASED ON THE ASSUMPTION THAT ALL FLOORS ARE FRAMED WITH MANUFACTURED WOOD MATERIALS, SUCH AS EXT EXTERIOR SOG SLAB ON GRADE

THE TJI AND LVL, AND THAT THEY ARE PROTECTED FROM THE WEATHER DURING CONSTRUCTION. FDN FOUNDATION SPC SPACING

FIN FINISH SPEC SPECIFICATION

WOOD CONNECTORS FLR FLOOR SQ SQUARE

SILL BOLTS TO BE 3/4" DIAMETER EMBEDDED 8" INTO THE CONCRETE. MAXIMUM SPACING OF SILL BOLTS SHALL BE 48 ” O.C. AT DESIGNATED SHEARWALLS FS FAR SIDE SSL SHORT SLOTTED HOLES

SILL BOLT SPACING SHALL BE PER THE PLANS. USE GALVANIZED 3" X 3" X 1/4" PLATE WASHERS, WITH HOLES NO GREATER THAN 3/16 ” LARGER THAN THE FT FOOT/FEET STD STANDARD

BOLT DIAMETER AT ALL SHEARWALL SILL BOLTS. PROVIDE A MINIMUM OF TWO BOLTS EACH PIECE. PROVIDE ONE BOLT AT EACH END OF EACH PIECE, NOT FTG FOOTING STIFF STIFFENER

LESS THAN 6 ” AND NOT MORE THAN 12 ” FROM THE END. GA GAGE STL STEEL

GALV GALVANIZED STRUCT STRUCTURAL

BOLT HEADS AND NUTS BEARING AGAINST WOOD TO BE PROVIDED WITH MALLEABLE IRON WASHERS EXCEPT ON STEEL BEAM NAILERS USE CUT GC GENERAL CONTRACTOR SUPP SUPPORT

WASHERS. NAILERS TO STEEL BEAMS SHALL BE ATTACHED WITH 5/8" BOLTS AT 3' - 0" OC STAGGERED. GEN GENERAL SW SHORT WAY OR SHEARWALL

GLB GLUED LAMINATED BEAM SYM SYMMETRICAL

NAILS SHALL CONFORM TO REQUIREMENTS OF ASTM F1667 AND HAVE A MINIMUM BENDING STRENGTH OF 90 KSI FOR SHANK DIAMETERS BETWEEN .142 ” GR GRADE TOC TOP OF CONCRETE

AND .177” ALL WOOD-TO-WOOD NAILING SHALL BE PER IBC TABLE 2304.9.1. IF PLANS AND DETAILS SPECIFY 8D, 10D OR 16D NAILS, THEY SHALL HAVE THE GWB GYPSUM WALL BOARD TOP&BOT TOP AND BOTTOM

FOLLOWING PROPERTIES: HORIZ HORIZONTAL T&G TONGUE & GROOVE

8D = 0.131” DIA X 2-1/2” HSS HOLLOW STRUCTURAL SECTION TRANS TRANSVERSE

10D = 0.148” DIA X 3” IBC INTERNATIONAL BUILDING CODE TRTD TREATED

16D = 0.162” DIA X 3-1/2” IF INSIDE FACE (TYP) TYPICAL

ALL SUBSTITUTIONS SHALL HAVE THE WRITTEN APPROVAL OF THE ENGINEER OF RECORD PRIOR TO USE. IN INCH (ES) UBC UNIFORM BUILDING CODE

INT INTERIOR UNO UNLESS NOTED OTHERWISE

LIGHT GAUGE METAL FRAMING CONNECTORS AND THEIR REQUIRED FASTENERS SHALL BE “STRONG-TIE” BY SIMPSON COMPANY, OR APPROVED EQUAL. JT JOINT VERT VERTICAL

INSPECTIONS AND

LF LINEAL FOOT W/ WITH

ALL FASTENERS AND CONNECTORS IN CONTACT WITH PRESERVATIVE TREATED WOOD SHALL BE HOT-DIPPED GALVANIZED STEEL WITH A G185 LLH LONG LEG HORIZONTAL WF WIDE FLANGE

ABBREVIATIONS

SPECIFICATION OR TYPE 304 & 316 STAINLESS STEEL. TYPE 304 AND 316 STAINLESS STEEL SHOULD BE USED FOR ALL CONNECTORS AND FASTENERS IN

NOTES,SPECIAL

LLV LONG LEG VERTICAL W/O WITHOUT

CONTACT WITH AZCA TREATED WOOD AND SOME VARIATIONS OF ACQ TREATED WOODS. HOT-DIPPED GALVANIZED STEEL SHOULD NEVER COME IN LSL LAMINATED STRAND LUMBER WP WORK POINT

CONTACT WITH STAINLESS STEEL. LVL LAMINATED VENEER LUMBER WT STRUCTURAL TEE

WWF WELDED WIRE FABRIC

STRUCTURAL GLUED-LAMINATED LUMBER

SHALL BE FABRICATED TO THE REQUIREMENTS OF PRODUCT STANDARD PS 56. LUMBER SHALL BE VISUALLY GRADED WESTERN SPECIES, COMBINATION

24F-V4 FOR SIMPLE BEAMS, 24F-V8 FOR CANTILEVER BEAMS, COMBINATION 2 FOR COLUMNS, AND COMBINATION 5 FOR TRUSS MEMBERS PER 2015 NDS

SUPPLEMENT, TABLE 5A (BEAMS) AND 5B (COLUMNS). LAMINATED MEMBERS TO BE AITC CERTIFIED. USE WATERPROOF GLUE.

GENERAL

SHEET CONTENTS:

LAMINATED VENEER LUMBER (LVL)

LVL SHOWN ON PLANS TO BE TRUS JOIST MACMILLANS' MICROLLAM™ OR APPROVED EQUAL. LVL MATERIAL SHALL BE OF WESTERN SPECIES. MODULUS

OF ELASTICITY (E) SHALL BE 1,900 KSI MINIMUM, WITH CORRESPONDING BASE FB = 2,600 PSI FOR THICKNESSES UP TO 1-3/4 ” AND 2345 PSI FOR

THICKNESSES GREATER THAN OR EQUAL TO 1-7/8 ” (NOT INCLUDING SIZE & REPETITIVE MEMBER FACTORS PER REPORT ER-4979; LOAD APPLIED PARALLEL

TO WIDE FACE OF STRAND) AND FV = 285 PSI. LVL ASSEMBLY TO BE TESTED UNDER IBC TESTING PROCEDURES. LVL MANUFACTURER SHALL PROVIDE ALL

SPECIALTY ITEMS FOR A NORMAL AND COMPLETE INSTALLATION OF THE MEMBERS. ALL LVL'S OTHER THAN MICROLLAM SHALL HAVE ICC APPROVALS

SUBMITTED TO THE ARCHITECT FOR REVIEW.

PARALLEL STRAND LUMBER (PSL)

PSL SHOWN ON PLANS TO BE TRUS JOIST MACMILLANS' PARALLAM™ OR APPROVED EQUAL. MODULUS OF ELASTICITY (E) SHALL BE 2,000 KSI MINIMUM,

WITH CORRESPONDING BASE FB = 2,900 PSI (NOT INCLUDING SIZE & REPETITIVE MEMBER FACTORS PER REPORT ER-4979; LOAD APPLIED PARALLEL TO

WIDE FACE OF STRAND) AND FV = 290 PSI. PSL ASSEMBLY TO BE TESTED UNDER IBC TESTING PROCEDURES. PSL MANUFACTURER SHALL PROVIDE ALL

SPECIALTY ITEMS FOR A NORMAL AND COMPLETE INSTALLATION OF THE MEMBERS. ALL PSL'S OTHER THAN PARALLAM SHALL HAVE ICC APPROVALS JOB No.

SUBMITTED TO THE ARCHITECT FOR REVIEW.

DWN BY: FP

LAMINATED STRAND LUMBER (LSL)

LSL SHOWN ON PLANS TO BE TRUS JOIST MACMILLANS' TIMBERSTRAND™ OR APPROVED EQUAL. MODULUS OF ELASTICITY (E) SHALL BE 1,500 KSI

MINIMUM, WITH CORRESPONDING BASE FB = 2,250 PSI (NOT INCLUDING SIZE & REPETITIVE MEMBER FACTORS PER REPORT ER-4979) AND FV = 400 PSI. LSL CHKD BY: SNP

ASSEMBLY TO BE TESTED UNDER IBC TESTING PROCEDURES. LSL MANUFACTURER SHALL PROVIDE ALL SPECIALTY ITEMS FOR A NORMAL AND COMPLETE

INSTALLATION OF THE MEMBERS. ALL LSL'S OTHER THAN TIMBERSTRAND SHALL HAVE ICC APPROVALS SUBMITTED TO THE ARCHITECT FOR REVIEW. DATE: 01/15/21

PLYWOOD/ OSB

PLYWOOD/OSB ROOF, FLOOR AND WALL SHEATHING TO BE APA RATED C-D EXPOSURE 1 PER APA "PLYWOOD DESIGN SPECIFICATION" (Y510). MAXIMUM SHEET No.

FASTENER SPACING SHALL BE 6" OC AT ALL SUPPORTED PANEL EDGES, AND 12" OC AT INTERMEDIATE SUPPORTS. FASTENERS INTO WOOD MEMBERS

SHALL BE 10D NAILS PER THE "WOOD CONNECTORS" SECTION. FASTENERS INTO COLD-FORMED STEEL MEMBERS SHALL BE #10 SCREWS PER THE "COLD-

FORMED STEEL CONNECTORS" SECTION.

STAGGER END LAPS AT ROOF AND FLOOR SHEATHING. ALL PANEL EDGES TO BE BLOCKED AT SHEAR WALLS. SUPPORT SHALL BE SUPPLIED TO ALL

PLYWOOD EDGES WITH PLYCLIPS, BLOCKING, TONGUE AND GROOVE PLYWOOD JOINTS OR OTHER APPROVED METHODS PER APA RECOMMENDATION.

S1.0

PLYCLIPS ARE NOT ALLOWED FOR FLOOR SHEATHING.

You might also like

- The Rocket Mass Heater Builder's GuideDocument298 pagesThe Rocket Mass Heater Builder's GuideIoan Novac100% (5)

- Shanghai Tower PDFDocument14 pagesShanghai Tower PDFFaisal Nasim0% (1)

- General Notes: FC' 3000 Psi Fy 60000 Psi Lap Length Location FC' 3000 Psi Fy 40000 PsiDocument1 pageGeneral Notes: FC' 3000 Psi Fy 60000 Psi Lap Length Location FC' 3000 Psi Fy 40000 PsiUsama EjazNo ratings yet

- SPA CombinedDocument24 pagesSPA CombinedMarielle Anne SantiagoNo ratings yet

- Define Abbrev: Issue Date: Drawn By: Checked By: Issue Date Author CheckerDocument2 pagesDefine Abbrev: Issue Date: Drawn By: Checked By: Issue Date Author Checkerdnl_vicarsNo ratings yet

- Ce - 07Document1 pageCe - 07Arnulfo Jose Pi DiNo ratings yet

- KC CombinedDocument10 pagesKC CombinedMarielle Anne SantiagoNo ratings yet

- General Notes: Contract Drawing Notes:: Commonwealth of PennsylvaniaDocument8 pagesGeneral Notes: Contract Drawing Notes:: Commonwealth of PennsylvaniawalidNo ratings yet

- General Note SampleDocument13 pagesGeneral Note SampleShyam AwalNo ratings yet

- General NotesDocument1 pageGeneral NotesWee RenNo ratings yet

- E:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntDocument2 pagesE:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntHoang Nguyen HuyNo ratings yet

- Detailed SpecificationDocument1 pageDetailed Specificationkishorkn2001No ratings yet

- General Notes TunnelDocument3 pagesGeneral Notes TunnelEnglish for KidsNo ratings yet

- General Notes FBDocument3 pagesGeneral Notes FBEnglish for KidsNo ratings yet

- Ae00000055 - Symbols, Abbreviations and General NotesDocument1 pageAe00000055 - Symbols, Abbreviations and General NotesKatherine GuivencanNo ratings yet

- Short BridgeDocument306 pagesShort BridgeChowdhury PriodeepNo ratings yet

- Rapid Initiator - 102806970 - 102806970Document3 pagesRapid Initiator - 102806970 - 102806970Syed HumzaNo ratings yet

- General Notes and SpecificationsDocument1 pageGeneral Notes and SpecificationsPrince QuimnoNo ratings yet

- Binder Latest GA 2020.01.13 PDFDocument30 pagesBinder Latest GA 2020.01.13 PDFABHINAY MUVVALANo ratings yet

- Design Criteria: Reinforcing SteelDocument12 pagesDesign Criteria: Reinforcing SteelALL-ROUNDER CIVIL ENGINEERS ENGLISHNo ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- Plumbing DWGDocument3 pagesPlumbing DWGJamillette NovesterasNo ratings yet

- Civil / Structural Construction Notes: Nearest Faultline Site Location FromDocument1 pageCivil / Structural Construction Notes: Nearest Faultline Site Location FromVince Bagsit PolicarpioNo ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- STRUCDocument5 pagesSTRUCEdward D. SarcoNo ratings yet

- General Plumbing Notes and Specifications:: Manhole Detail Septic Vault DetailDocument1 pageGeneral Plumbing Notes and Specifications:: Manhole Detail Septic Vault DetailLab Dema-alaNo ratings yet

- A. General Notes: B. Notes and Concrete Mixes and PlacingDocument1 pageA. General Notes: B. Notes and Concrete Mixes and Placingdomin domNo ratings yet

- 1) General Notes: 9) Design Consideration: AS Civil Engg ServicesDocument4 pages1) General Notes: 9) Design Consideration: AS Civil Engg ServicesCivil Engineering projectNo ratings yet

- Wa0000.Document4 pagesWa0000.سلطان السواعيرNo ratings yet

- 04 Structural DrawingsDocument10 pages04 Structural DrawingszeipoibjasNo ratings yet

- Hvac Notes & AbbreviationsDocument1 pageHvac Notes & AbbreviationsShrikant SomvanshiNo ratings yet

- Typical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsDocument1 pageTypical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsRenel GarciaNo ratings yet

- LMW Engineering Group, LLC.: Revision Comment No. DateDocument16 pagesLMW Engineering Group, LLC.: Revision Comment No. DatenelsonNo ratings yet

- Irc 2018 With SC Modifications - Load Table: General Structural NotesDocument6 pagesIrc 2018 With SC Modifications - Load Table: General Structural Notespriya giriNo ratings yet

- Structural Engineering 1 344 Rock HollowDocument5 pagesStructural Engineering 1 344 Rock HollowDANIEL LOUISSE STA. MARIANo ratings yet

- bsd-10218 B Tennis Rebound Wall - General Notes - Sheet 1 of 3Document1 pagebsd-10218 B Tennis Rebound Wall - General Notes - Sheet 1 of 3Retaj AzizNo ratings yet

- Weight by Drawing Sheet: RevisionDocument1 pageWeight by Drawing Sheet: RevisionOseni MomoduNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- M-0.1 - Mechanical SpecificationsDocument1 pageM-0.1 - Mechanical SpecificationsAbdellatif AlhNo ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- Plumbing Permit Drawings PDFDocument3 pagesPlumbing Permit Drawings PDFJeremy BoyceNo ratings yet

- General Structural Notes: AbbreviationsDocument2 pagesGeneral Structural Notes: AbbreviationsCivix VarixNo ratings yet

- Road Concreting Design Criteria DrawingsDocument7 pagesRoad Concreting Design Criteria DrawingsUreshiii AnimeNo ratings yet

- Fire Protection Specifications Fire Protection General Notes Fire Protection AbbreviationsDocument8 pagesFire Protection Specifications Fire Protection General Notes Fire Protection Abbreviationsjaja riveraNo ratings yet

- Ground Water Tank Structural DrawingDocument8 pagesGround Water Tank Structural DrawingMonish Lakhey ShresthaNo ratings yet

- 1) General Notes:: Karthikeyan AssociatesDocument12 pages1) General Notes:: Karthikeyan AssociatesSLV GROUPNo ratings yet

- 7 Septic VaultDocument1 page7 Septic VaultB R PAUL FORTINNo ratings yet

- 2018 1206 Fairfield County Auditor Drawings VOL 2 PDFDocument40 pages2018 1206 Fairfield County Auditor Drawings VOL 2 PDFAr Hanz Gerome SuarezNo ratings yet

- FP-01 Front PageDocument1 pageFP-01 Front PageBerlin Andrew SionNo ratings yet

- 398 BALIDO SiteDocument2 pages398 BALIDO Siteothmane rihaniNo ratings yet

- SpecificationDocument1 pageSpecificationdanielsu87No ratings yet

- Revised Structural PlansDocument46 pagesRevised Structural Plansangelandlucifergabriel009No ratings yet

- General Notes: D.P.W.HDocument1 pageGeneral Notes: D.P.W.HJemil Rose SamosNo ratings yet

- Treehouse, Waiheke Island: Structural Steelwork NotesDocument12 pagesTreehouse, Waiheke Island: Structural Steelwork NotesKesavan DhuraiNo ratings yet

- 1.Rc Details Industrial Building Details-Rev-1Document7 pages1.Rc Details Industrial Building Details-Rev-1Civil StructureNo ratings yet

- MECHANICALDocument2 pagesMECHANICALDonita AcuinNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- General Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailDocument53 pagesGeneral Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailbetojulioNo ratings yet

- P011-0004, Symbols & General NotesDocument1 pageP011-0004, Symbols & General NotesMubashir fareedNo ratings yet

- Design Criteria: GeneralDocument1 pageDesign Criteria: GeneralRolly Marc G. SoteloNo ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- NDT Techniques Applied For The Inspection of Flare Stacks: Carlos - Martin@uca - EsDocument18 pagesNDT Techniques Applied For The Inspection of Flare Stacks: Carlos - Martin@uca - EsNirajNo ratings yet

- (N) RC Beam To (E) RC WallDocument3 pages(N) RC Beam To (E) RC WallNirajNo ratings yet

- Design of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserDocument11 pagesDesign of Isolated Pad Foundation: All The Cells That Have Border Are To Be Filled by The UserNirajNo ratings yet

- Sample Connection ReportDocument14 pagesSample Connection ReportNirajNo ratings yet

- Pole Footing Embedded in Soil: General InformationDocument1 pagePole Footing Embedded in Soil: General InformationNirajNo ratings yet

- Rajpura Jind Ub Weld 'SP 02 R00Document2 pagesRajpura Jind Ub Weld 'SP 02 R00NirajNo ratings yet

- Seismic 1 Z - 3640 Seismic 1 - Z Seismic 2 X Seismic 2 - X Seismic 2 Z Seismic 2 - ZDocument5 pagesSeismic 1 Z - 3640 Seismic 1 - Z Seismic 2 X Seismic 2 - X Seismic 2 Z Seismic 2 - ZNirajNo ratings yet

- RAJPURA TPS (2x700MW) : Data Sheet Moment Connection For B-C Bay Main Beams (WPB Rolled Section) G18 G19Document2 pagesRAJPURA TPS (2x700MW) : Data Sheet Moment Connection For B-C Bay Main Beams (WPB Rolled Section) G18 G19NirajNo ratings yet

- Typical Sketch of Shear Connections With Angle Cleat (Beam To Beam)Document26 pagesTypical Sketch of Shear Connections With Angle Cleat (Beam To Beam)NirajNo ratings yet

- Bill of Material: Vbr1 One - V - Brace - Vbr1Document8 pagesBill of Material: Vbr1 One - V - Brace - Vbr1NirajNo ratings yet

- Blutex - Part 2 - Slab Design - One Way - 2021 - 05 - 01Document24 pagesBlutex - Part 2 - Slab Design - One Way - 2021 - 05 - 01Niraj100% (1)

- Form 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Document4 pagesForm 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961NirajNo ratings yet

- ATC Hazards by LocationDocument2 pagesATC Hazards by LocationNirajNo ratings yet

- Rebar Tonnage For ABT wind/SSI Grav LoadingDocument4 pagesRebar Tonnage For ABT wind/SSI Grav LoadingNirajNo ratings yet

- Revised Kang Vanity Cutting ListDocument2 pagesRevised Kang Vanity Cutting ListDante Augusto JongoyNo ratings yet

- Specifications For Oil, Gas, Water, Sewer PipesDocument3 pagesSpecifications For Oil, Gas, Water, Sewer PipesShams TabrezNo ratings yet

- CS 457 Revision 1 The Assessment of Composite Highway Bridges and Structures-WebDocument137 pagesCS 457 Revision 1 The Assessment of Composite Highway Bridges and Structures-Webasaad biqaiNo ratings yet

- Solenoid Lifting Lug AnalysisDocument4 pagesSolenoid Lifting Lug AnalysisGiuliano PaoliniNo ratings yet

- Roduct ATA Heet: Crystalline Waterproofing CoatingDocument2 pagesRoduct ATA Heet: Crystalline Waterproofing CoatingdamithNo ratings yet

- The Dow Chemical Company Engineering Specification Process Containment K9S-1000-01 Ol2K 7-JAN-2005 Page 1 of 17Document17 pagesThe Dow Chemical Company Engineering Specification Process Containment K9S-1000-01 Ol2K 7-JAN-2005 Page 1 of 17maheshNo ratings yet

- Carrier 58MXA-10SMDocument16 pagesCarrier 58MXA-10SMMichael MartinNo ratings yet

- Inspection Electrical Storage Check ListDocument2 pagesInspection Electrical Storage Check ListZaini AchmadNo ratings yet

- Floor FinishesDocument20 pagesFloor FinishesFidha SulfiNo ratings yet

- B31 1interpretacion PDFDocument223 pagesB31 1interpretacion PDFGabriel PatrunoNo ratings yet

- DK DIN Bite Type Tube FittingDocument62 pagesDK DIN Bite Type Tube FittingLuisFranciscoMarinMedranoNo ratings yet

- Technical Data Sheet: 35% Silicone EmulsionDocument1 pageTechnical Data Sheet: 35% Silicone EmulsionJeet VekariyaNo ratings yet

- Method StatementDocument4 pagesMethod StatementNajib GombakNo ratings yet

- MTFDocument12 pagesMTFCupido Jr. SabatinNo ratings yet

- Thermal InsulationDocument10 pagesThermal InsulationNykha AlentonNo ratings yet

- ISA RP60 1 1990 Control Center FacilitiesDocument22 pagesISA RP60 1 1990 Control Center FacilitiesDaniel Arrieta DarrásNo ratings yet

- NSCV - ElectricalDocument38 pagesNSCV - Electricalphankhoa83-1No ratings yet

- Pile CalculationDocument1 pagePile Calculationepe civil1No ratings yet

- Machine Design GATE Book 2019Document256 pagesMachine Design GATE Book 2019NAMAN GARG CO18139No ratings yet

- 4.3.1 Chamber Wall Uls CheckDocument81 pages4.3.1 Chamber Wall Uls CheckSasinath MshNo ratings yet

- 28 Transmission Lines and CablesDocument7 pages28 Transmission Lines and CablesIlyas HussainNo ratings yet

- EE002 Report #1Document29 pagesEE002 Report #1JM RaagasNo ratings yet

- Capacity 7000KW Heavy Oil Fired Thermal Oil Boiler Quotation From Henan Yuanda Boiler FactoryDocument11 pagesCapacity 7000KW Heavy Oil Fired Thermal Oil Boiler Quotation From Henan Yuanda Boiler Factorykariem noweerNo ratings yet

- Catalogue DARCO Flottant ENDocument20 pagesCatalogue DARCO Flottant ENScipp ZengNo ratings yet

- MasterProject IST VeraOliveiraMachadoDocument116 pagesMasterProject IST VeraOliveiraMachadotheoNo ratings yet

- 12 PAPYEX Flexible Graphite Mersen 21Document14 pages12 PAPYEX Flexible Graphite Mersen 21ayushNo ratings yet

- Tribology Case Study ProjectDocument17 pagesTribology Case Study ProjectKeyredin SelmanNo ratings yet

- Ag31 Ag 41Document8 pagesAg31 Ag 41Fahmi HaidiNo ratings yet