Professional Documents

Culture Documents

MECHANICAL

Uploaded by

Donita AcuinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MECHANICAL

Uploaded by

Donita AcuinCopyright:

Available Formats

GENERAL NOTES: STANDARD SPECIFICATIONS

AND PRECAUTIONS: UNIT

1. ALL MECHANICAL WORKS HEREIN INCLUDED SHALL

BE DONE ACCORDANCE WITH THE LATEST 1. WHEN INSTALLATION MADE EQUIPMENTS CHECK FOR THEIR LOAD OF

NO. DESCRIPTION HP WATTS

REQUIREMENTS OF THE PHILIPPINE BUILDING CODE REFRIGERANT.

AND LOCAL RELATION. 2. INSTALLATION SHOULD BE PROVIDED ON PIPES THE LIQUID PIPES AND SUCTION

PIPES IN ORDER TO MINIMIZE THE HEAT TRANSFER AND ELIMINATE

CONDENSATION,

2. THE LOCAL SCOPE OF WORKS SHALL INCLUDE WORKS

DESCRIBED IN THE GENERAL PROVISIONS OF THE

3. WRONG WIRING CONNECTION OCCUR IN POWER RTS-RTS, SCROLL COMPRESSOR IN

REVERSE CREATES NOISE,CHECK TO AVOID DAMAGES. 1 AIRCONDITIONING UNIT 2 1492

TECHNICAL SPECIFICATIONS FOR MECHANICAL WORKS. 4. CONSULT PROFESSIONAL MECHANICAL ENGINEER IN SYMBOLS OF OPERATION,

REMOTE CONTROL WITH THE WIRING

3. ALL WORKS SHALL BE EXECUTED IN CLOSE 5. DUCT SYSTEM ALLOW MOTOR SPECIFICATION DRIVES CARRIES PULLEY ON

COORDINATION WITH THE WORKS OF OTHER TRADES

COORDINATE WITH THE ARCHITECTURAL AND 6.

MAGNETIC WITH CONTRACTOR.

MOTOR PERFORMANCE TEST SHOULD IN ACCORDANCE WITH ASH-57 2 AIRCONDITIONING UNIT 2.5 1865

INSTALLED CAPACITY

ELECTRICAL THE EXACT LOCATION OF FANS. PIPE AND

AIR CONDITIONING UNIT. A.) COOLING CAPACITIES ON 27°C DB AND 19.5°C NB (INDOOR UNIT).

4. CONTRACTORS SHALL SUBMIT SHOP DRAWING,

7.

B) CONDENSING TEMPERATURES IS 50°C AND EVAPORATING TEMPERATURE IS 72°C.

ALWAYS CHECK INDICATED LOAD, ENTRANCE CONDUCTOR/SERVICE EQUIPMENT ON

3 AIRCONDITIONING UNIT 3T 3500

MANUFACTURED EQUIPMENT, SPECIFICATIONS,

INSULATIONS, FILTERS. ETC. BEFORE EXECUTION OF MODELS HAS ACT ON SIZING OF PIPES.

8. ALWAYS CONDUCT ON RECORD OF REFRIGERANT APPLICATION AND SHOULD FREE

WORKS.

5. CONTRACTOR/SUPPLIER SHALL INSTALL ALL 9.

BLOW OF AIR-COOLING SYSTEM BE ACCOMMODATED THE ENTIRE AREA AND

CAPACITY BE ACCUMULATED THE ENTIRE PLACE

THE AHU AND ACCU SHALL BE FIRMLY SECURED TO THE BASE FOUND.

4 AIRCONDITIONING UNIT 2 1492

EQUIPMENT IN ACCORDANCE WITH THE MANUFACTURER 10. ALL ACCU's INSTALLED ON THE SIDE OF THE BUILDING AND ELEVATED NO LESS

RECOMMENDATIONS COMPRESSOR SHALL PROVIDED THAN 5 FT. ABOVE THE GROUND LEVEL, SHALL BE PROVIDED SERVICE ACCESS

WITH DUAL PRESSURE CUT-OUT SWITCH TIME DELAY FROM WITHIN THE BUILDING OF SERVICE LADDER OUTSIDE THE BUILDING.

RELAY, THERMAL OVERLOAD PROTECTION AND ALL 11. FOR THOSE EXPOSED TO THE WEATHER, INSULATION SHALL HAVE AN ADDITIONAL

PLASTIC TAPE COVERING OR METAL CLADDING ALL COPPER TUBES SHALL BE

REQUIRE ACCESSORIES.

BRAND NEW AND FREE FROM DEEP SCRATCHES, DENTS, KINKS AND BURNS, HARD

DRAWN TYPE K OR L IS RECOMMENDED REFRIGERANT LINES LARGE THAN 3/4

6. ALL FLOOR SLAB MOUNTED VIBRATING EQUIPMENT DIAMETER.

SHALL BE PROVIDED WITH VIBRATION ISOLATORS TO 12. AIR SHALL NOT BE RETICULATED IN AREAS OR SPACES WHERE THERE ARE

PREVENT VIBRATION AND NOISE TRANSMISSION. OBJECTIONABLE QUANTITIES OF TOXIC WASTE GASES FLAMMABLE VAPORS

BACTERIA AND DUST AND FOR UNDERGROUND PIPING, BOTH SUCTION AND

7. PIPE ALL EQUIPMENT CONDENSATE DRAIN UNDER TO DISCHARGES LINES SHALL BE ADEQUATELY PROTECTED AGAINST DAMAGES FROM

WATER AND OTHER FOREIGN MATERIALS THAT MAY HAVE A HARMFUL EFFECT ON

THE NEAREST FLOOR CATCH BASIN. USE MAX. 3/4 0 PVC

THE PERFORMANCE OF THE UNIT.

PIPE DRAIN LINE. 13. A SAFETY SWITCH AND OR CIRCUIT BREAKER SHALL BE INSTALLED BETWEEN THE

POWER SOURCE AND THE UNIT ALL CONDUCTOR SHALL ADEQUATELY PROTECTED

8. PITCH ALL HORIZONTAL REFRIGERANT LINE A MINIMUM AGAINST PHYSICAL DAMAGES AND WHEN RUN UNDERGROUND SHALL BE

1/2" IN FEET IN THE DIRECTION OF REFRIGERANT FLOW. INSTALLED IN A DUCT OF RIGID METALLIC CONDUITS SUITABLE FOR THE CONDITION,

DUCTS AND CONDUITS MADE ORDINARY STEEL BE COATED ON CORROSION

9. PROVIDE 20 MM THICK ELASTOMERIC RUBBER RESISTANCE.

14. ALWAYS INSTALL A DOUBLE-THROW CIRCUIT BREAKER WITH 500 AMPERES.

INSULATION TO ALL LINES WITH BLUE FILM TAPE FINISH

AS FINISHED.

10. PROVIDE AND INSTALL CONTROL WIRING FOR ALL PVC

AND VENTILATION EQUIPMENT.

11. THE EVAPORATORS SHOULD BE INSTALLED WITH STEEL

SUPPORT FREE FROM MY VIBRATION A RUBBER SHOULD

BE PROVIDED AND INSTALLED PROPERLY.

12. PROPER INCLINATION FOR DRAIN PIPE SHOULD BE

INSTALLED AT LINES TO PREVENT BACK FLOW.

13. ARMAFLEX AND AEROFLEX INSULATION SHOULD BE

INSTALLED AT LINES TO PREVENT.

14. 14. ELECTRICAL LINES FOR CONTROL AND SWITCHES

SHOULD NOT BE VISIBLE AND SHOULD BE IMBEDDED IN

CONCRETE WALL.

15. DRAIN SHOULD PAN AND BE COATED WITH WEATHER

INSULATIONS.

16. HE CONTRACTOR SHALL BE RESPONSIBLE FOR ALL

TESTING, ALSO BALANCING AND COMMISSIONING OF

THE ENTIRE INSTALLATION.

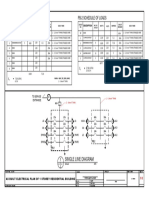

AS-BUILT PLAN OF 2-STOREY WAREHOUSE MR. & MRS. ANDREW NG M-1

WAREHOUSE

CR. CONFERENCE

ROOM 3T

ACU

CR.

1 1

OFFICE

OFFICE

2.5HP 2.0HP 2.0HP

ACU ACU ACU

STAIRS STAIRS

1 GROUND FLR. LAYOUT 2 SECOND FLR. LAYOUT

ME 02 SCALE NTS ME 02 SCALE NTS

AS-BUILT PLAN OF 2-STOREY WAREHOUSE MR. & MRS. ANDREW NG M-2

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- General Notes HvacDocument7 pagesGeneral Notes Hvacmilindskulkarni2005@yahoo.co.inNo ratings yet

- SEA JET Reel Brochure - Submersible Movable Pump With Hose SupportDocument4 pagesSEA JET Reel Brochure - Submersible Movable Pump With Hose SupportMohamed MostafaNo ratings yet

- Kitchen HoodDocument18 pagesKitchen HooddrahcirNo ratings yet

- 1301 Pme PDFDocument11 pages1301 Pme PDFCassie GraceNo ratings yet

- Lesson Exemplar COT of Bending PipesDocument2 pagesLesson Exemplar COT of Bending PipesHarold Vernon Martinez100% (2)

- Pec Wire Sizes CompilationDocument2 pagesPec Wire Sizes Compilationjay garciaNo ratings yet

- Wiring Methods and Materials: Summary of SAES-P-104Document7 pagesWiring Methods and Materials: Summary of SAES-P-104Afzal Asif100% (3)

- PQMS, MS, ITP, CHECKLIST, NCR, MOCKUP SAMPLES - Session 1,2 & 3 PDFDocument155 pagesPQMS, MS, ITP, CHECKLIST, NCR, MOCKUP SAMPLES - Session 1,2 & 3 PDFUma Mahesh Raju100% (1)

- YAY TAR SHAY - FIVE STORIES PROJECT - ACMV & FIRE FIGHTING DESIGN 12nd AUGUST UPDATE PDFDocument21 pagesYAY TAR SHAY - FIVE STORIES PROJECT - ACMV & FIRE FIGHTING DESIGN 12nd AUGUST UPDATE PDFHnin PwintNo ratings yet

- Company ProfileDocument32 pagesCompany ProfileShubhankar KunduNo ratings yet

- J0535-S001 - General Notes PDFDocument1 pageJ0535-S001 - General Notes PDFSaiful IslamNo ratings yet

- 1646-Fire Safety of Buildings Electrical Installations-2015Document21 pages1646-Fire Safety of Buildings Electrical Installations-2015kapilNo ratings yet

- Pipe CulvertDocument12 pagesPipe CulvertSajjad Khan100% (1)

- Drawing 5 of 6 - Fire Suppression and Fire Alarm v1Document9 pagesDrawing 5 of 6 - Fire Suppression and Fire Alarm v1Renz Albert TejadillaNo ratings yet

- Electrical General NotesDocument5 pagesElectrical General NotesjustineNo ratings yet

- Union Universal RAWELTDocument4 pagesUnion Universal RAWELTLuisDonairesNo ratings yet

- General NotesDocument7 pagesGeneral NotesAzzirrenNo ratings yet

- E6 Electrical SamplesDocument1 pageE6 Electrical Samplesgeneveve colasitoNo ratings yet

- General Notes Mounting Heights: Proposed Two (2) - Storey Residence Jason L. Herreria E-1/E-4Document1 pageGeneral Notes Mounting Heights: Proposed Two (2) - Storey Residence Jason L. Herreria E-1/E-4GigiNo ratings yet

- Electrical Sheets ColusaCoAdminOff - Elec - BidAdd3Document4 pagesElectrical Sheets ColusaCoAdminOff - Elec - BidAdd3Pinky CutNo ratings yet

- Final Abiera Duplexplan MechanicalDocument3 pagesFinal Abiera Duplexplan Mechanicalmarcelo serpa juanNo ratings yet

- Description REV Date Construction Drawing 0 JUNE'22Document1 pageDescription REV Date Construction Drawing 0 JUNE'22rajavelNo ratings yet

- C.7wy0.ih.74.86.1.uag Eiz100 S01 R00Document1 pageC.7wy0.ih.74.86.1.uag Eiz100 S01 R00JC DC AcostaNo ratings yet

- C.7wy0.ih.74.8244-Uag Eiz250 S01 R00Document1 pageC.7wy0.ih.74.8244-Uag Eiz250 S01 R00JC DC AcostaNo ratings yet

- Jak1 Aur El DWG A 0 0002 (C)Document1 pageJak1 Aur El DWG A 0 0002 (C)Budi HahnNo ratings yet

- El-15 Fire Alarm System DetailsDocument1 pageEl-15 Fire Alarm System DetailsEng Qais ShamikhNo ratings yet

- Exhibit 01 - Application - Plan Set - 03-09-2020Document5 pagesExhibit 01 - Application - Plan Set - 03-09-2020talhaNo ratings yet

- 13 PDFDocument1 page13 PDFRandy DonatoNo ratings yet

- A1.0 General NotesDocument1 pageA1.0 General NotesNguyen DuongNo ratings yet

- FDAS1Document1 pageFDAS1Donita AcuinNo ratings yet

- D-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021Document1 pageD-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021debapriyoNo ratings yet

- EXHIBIT B Part 2 of 2 PDFDocument16 pagesEXHIBIT B Part 2 of 2 PDFbelineNo ratings yet

- Cornell-Engineers-Sample-Drawings PAGE1Document1 pageCornell-Engineers-Sample-Drawings PAGE1mohanumaNo ratings yet

- Tañamor-Plate6 Eu1Document1 pageTañamor-Plate6 Eu1Hector TañamorNo ratings yet

- J1078-S001-General NotesDocument1 pageJ1078-S001-General Notesroy jackNo ratings yet

- Bhsarp 21 MTB ZZ Me DWG 320701 - D02Document1 pageBhsarp 21 MTB ZZ Me DWG 320701 - D02Jss Aircond & ElectricalNo ratings yet

- Plumbing NotesDocument1 pagePlumbing Notessergio.anacletoNo ratings yet

- J1273-S001-General NotesDocument1 pageJ1273-S001-General Notesroy jackNo ratings yet

- PV System: Sheet Index Scope of Work Construction NotesDocument5 pagesPV System: Sheet Index Scope of Work Construction NotesSAEL SOLARNo ratings yet

- J0673-S001 - General NotesDocument1 pageJ0673-S001 - General NotesEmon RayNo ratings yet

- Jn1252-S001-General NotesDocument1 pageJn1252-S001-General Notesroy jackNo ratings yet

- LG DVD DS9313CPM (3829RHP038B)Document48 pagesLG DVD DS9313CPM (3829RHP038B)videosonNo ratings yet

- Ductile Iron Piping Shall Be in Accordance With American Water Works AssociationDocument2 pagesDuctile Iron Piping Shall Be in Accordance With American Water Works AssociationKasuni LiyanageNo ratings yet

- D8834-Ga-Tk101 10-Sheet Tank Ga's (Signed)Document7 pagesD8834-Ga-Tk101 10-Sheet Tank Ga's (Signed)Santheep KumarNo ratings yet

- Spec TransrecDocument9 pagesSpec TransrecSinaNo ratings yet

- General NotesDocument4 pagesGeneral NotesAarth CadavosNo ratings yet

- Btech SpecificationDocument5 pagesBtech SpecificationCaryll ChuaNo ratings yet

- A000 TRAB 1 - MergedDocument7 pagesA000 TRAB 1 - MergedRodrigo Ibañez GreilbergerNo ratings yet

- Symbol: Jjam Mall (5 Storey Mall)Document1 pageSymbol: Jjam Mall (5 Storey Mall)john benedict orbeNo ratings yet

- D Eugp1 TPT G 000 Gen FWG 001 R01Document1 pageD Eugp1 TPT G 000 Gen FWG 001 R01debapriyoNo ratings yet

- 0815STFRANCISSCH3SPECv2-WINDOWS NAT. & MEC. VENT 0815 3 SP1006Document1 page0815STFRANCISSCH3SPECv2-WINDOWS NAT. & MEC. VENT 0815 3 SP1006Philip MelemuriyilNo ratings yet

- ITB-KEOH-2016-009 - Section V - Annex D (Ii) - Electrical Works DrawingsDocument29 pagesITB-KEOH-2016-009 - Section V - Annex D (Ii) - Electrical Works DrawingsSefaNo ratings yet

- Harger LPS ChecklistDocument6 pagesHarger LPS ChecklisttelecttNo ratings yet

- 7.5.2 13 LGA Sprinkler StandardsDocument16 pages7.5.2 13 LGA Sprinkler StandardsWinarkoNo ratings yet

- Designing Mep For A RoomDocument2 pagesDesigning Mep For A RoomdeddyNo ratings yet

- ISETAN ELECTRICAL REPAIR WORKS ASBUILT-Model P1Document1 pageISETAN ELECTRICAL REPAIR WORKS ASBUILT-Model P1Smart Lte SuperlagNo ratings yet

- Legend and General NotesDocument1 pageLegend and General NotesKiesha SantosNo ratings yet

- General Notes PDFDocument1 pageGeneral Notes PDFNeneng KunaNo ratings yet

- Muizzah MorayoDocument21 pagesMuizzah MorayoOgunsina AdebayoNo ratings yet

- 2 Storey 23Document1 page2 Storey 23Nick Ivan Coz FailagaoNo ratings yet

- General Notes: Legends: Abbreviations:: Reference DrawingsDocument1 pageGeneral Notes: Legends: Abbreviations:: Reference DrawingsmuthuvelaaNo ratings yet

- Daewoo cn-071Document49 pagesDaewoo cn-071Joel Jácome SantosNo ratings yet

- J-S001-General NotesDocument1 pageJ-S001-General Notesroy jackNo ratings yet

- LG dv-8000Document65 pagesLG dv-8000ValeriiNo ratings yet

- Legends, Symbols and General NotesDocument1 pageLegends, Symbols and General NotesJaybee CorderoNo ratings yet

- Fdas PlansDocument3 pagesFdas PlansDonita AcuinNo ratings yet

- Dry Storage: Entry EntryDocument1 pageDry Storage: Entry EntryDonita AcuinNo ratings yet

- FP PlansDocument4 pagesFP PlansDonita AcuinNo ratings yet

- Pb-2 Schedule of Loads Pb-1 Schedule of Loads: To Service EntranceDocument1 pagePb-2 Schedule of Loads Pb-1 Schedule of Loads: To Service EntranceDonita AcuinNo ratings yet

- This Site: General Notes/ SpecificationsDocument1 pageThis Site: General Notes/ SpecificationsDonita AcuinNo ratings yet

- FDAS1Document1 pageFDAS1Donita AcuinNo ratings yet

- Chapter 6Document24 pagesChapter 6Donita AcuinNo ratings yet

- Chapter 1-3Document28 pagesChapter 1-3Donita AcuinNo ratings yet

- Chapter 5Document15 pagesChapter 5Donita AcuinNo ratings yet

- Republic Act No. 8981: SECTION 1. Title. - This Act Shall Be Called The "PRC Modernization Act of 2000."Document8 pagesRepublic Act No. 8981: SECTION 1. Title. - This Act Shall Be Called The "PRC Modernization Act of 2000."Donita AcuinNo ratings yet

- Code of EthicalDocument7 pagesCode of EthicalDonita AcuinNo ratings yet

- BP 344Document25 pagesBP 344Donita AcuinNo ratings yet

- q4 Ia Eim 9 Week 1Document4 pagesq4 Ia Eim 9 Week 1Ann JennyNo ratings yet

- Gi Conduit LayingDocument5 pagesGi Conduit LayingPrasad PanchatsaramNo ratings yet

- Cable Handling Equipment Catalogue - G.V. Kinsman (Pty) LTDDocument34 pagesCable Handling Equipment Catalogue - G.V. Kinsman (Pty) LTDjeb13No ratings yet

- Sensepoint XCD Gas Detector Technical ManualDocument70 pagesSensepoint XCD Gas Detector Technical ManualYugandhar YuguNo ratings yet

- Kidde WHDR Part ListDocument20 pagesKidde WHDR Part ListAhamed KyanaNo ratings yet

- Indent JSBayDocument7 pagesIndent JSBayTallapureddy SarweswarareddyNo ratings yet

- E1 PDFDocument1 pageE1 PDFEdward Jade EmolagaNo ratings yet

- Schneider Select Product Catalog TechnicalDocument64 pagesSchneider Select Product Catalog Technicaldom007thyNo ratings yet

- TCI Library: WWW - Telephonecollectors.infoDocument22 pagesTCI Library: WWW - Telephonecollectors.infoMarlon BiagtanNo ratings yet

- Electrical WiringDocument52 pagesElectrical Wiringbharti dhoteNo ratings yet

- Eim Diagnostic1Document2 pagesEim Diagnostic1Michael Angelo ChuaNo ratings yet

- Los Angles Street LightDocument34 pagesLos Angles Street LightDin AjeNo ratings yet

- LES Cable Entry SystemsDocument26 pagesLES Cable Entry SystemsVasudev AgrawalNo ratings yet

- Bullitt Center As Built Product List Jan 20141Document19 pagesBullitt Center As Built Product List Jan 20141FABIUS IHINDULIZANo ratings yet

- Installation Chapter OneDocument16 pagesInstallation Chapter Oneassefa0% (1)

- Is 1646 1997 PDFDocument24 pagesIs 1646 1997 PDFamitabha0107No ratings yet

- LM Electrical 9Document65 pagesLM Electrical 9Raymond Alvarez ArabejoNo ratings yet

- Bs7211 Basec Lsoh CableDocument9 pagesBs7211 Basec Lsoh Cableapi-3803155No ratings yet

- General Notes: Legend and Symbols Power & Lighting SystemDocument1 pageGeneral Notes: Legend and Symbols Power & Lighting SystemkitnaNo ratings yet

- Industrial FittingsDocument160 pagesIndustrial FittingsAllamNo ratings yet

- External Cage Displacer Actuated: Liquid Level SwitchesDocument28 pagesExternal Cage Displacer Actuated: Liquid Level Switcheshoracio mondragonNo ratings yet

- Installation Instructions R 410A Ductless Split System Air Conditioner and Heat PumpDocument20 pagesInstallation Instructions R 410A Ductless Split System Air Conditioner and Heat PumpPauloNo ratings yet

- FE-326B Legacy-Performer Pump 120V Control - 240V 1-Phase Motor PDFDocument3 pagesFE-326B Legacy-Performer Pump 120V Control - 240V 1-Phase Motor PDFNasynCastroNo ratings yet