Professional Documents

Culture Documents

Classification of Aggregate

Uploaded by

wpt civilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Classification of Aggregate

Uploaded by

wpt civilCopyright:

Available Formats

Department of Civil Engineering 2020-21

Aggregate

In the construction industry, aggregate are used as filler material in the production

of concrete and mortar. Aggregate occupy around 70% to 80% of the volume of the

concrete, reduce shrinkage effects and minimize costs. The coarse aggregate form the

main matrix of concrete and the fine aggregates form the filler matrix between the

coarse aggregate.

Classification of Aggregate:

A. Based on Geological Origin:

On the basis of origin, aggregates can be classified into natural aggregates and artificial

aggregates.

Natural Aggregate:

The aggregates which are obtained crushing igneous, sedimentary or metamorphic

rocks are called natural aggregates. Aggregates obtained from igneous rocks have the

best engineering properties and hence they are most widely used aggregates.

Artificial Aggregate:

The aggregates which are obtained from manmade processes are called as artificial

aggregates. Surkhi, Blast furnace slag aggregate and synthetic aggregates are some kind

of examples of artificial aggregates.

Department of Collegiate & Technical Education Bengaluru 1

Department of Civil Engineering 2020-21

B. Based on Size:

According to size, aggregates can be classified as coarse aggregates and fine aggregates.

Coarse Aggregate:

The aggregates which pass through the 80 mm sieve and are retained on the 4.75 mm

sieve are called as coarse aggregates.

The size of the aggregate bigger than 4.75 mm is considered as the coarse aggregate

i.e. basically, all other aggregates which are retained on 4.75mm IS sieve while sieve

analysis is performed. According to sources of coarse aggregates, it can be further

classified as:

(a) Uncrushed Gravel or Stone:

It results from natural disintegration of rock.

(b) Crushed Gravel Stone:

It results from the crushing of gravel or hard stone.

Perhaps, 80 mm size is the maximum size that could be conveniently used for

concrete making. Usually, the 20 mm size of aggregates is generally considered

satisfactory for reinforced concrete work.

Department of Collegiate & Technical Education Bengaluru 2

Department of Civil Engineering 2020-21

Fine Aggregate:

All the aggregates which pass through the 4.75 mm sieve are called as fine aggregates.

Basically during sieve analysis, if the aggregates pass through 4.75mm IS sieve than

those types of aggregates falls into fine aggregates category. It means Fine

aggregates have a particle size less than 4.75mm. According to sources, fine

aggregates can be further classified as

(a) Natural Sand:

It is the fine aggregate resulting from the natural disintegration of rock. It is

deposited by streams or glacial agencies.

(b) Crushed Gravel Sand:

It is the fine aggregate which is produced by crushing hard gravel.

(c) Crushed Stone Sand:

It is the fine aggregate which is produced by crushing natural stone.

Department of Collegiate & Technical Education Bengaluru 3

Department of Civil Engineering 2020-21

C. Based on Shape:

Based on the shape of the aggregates, they are classified as rounded, irregular, angular

and flaky.

Rounded Aggregate:

The aggregates which are obtained from river or sea shores are generally close to

spherical in shape and are called as rounded aggregates. These aggregates have

minimum surface area to the volume and have poor interlocking bond, making them

unsuitable for the production of concrete.

Irregular Aggregate:

Theses aggregates are irregular in shape and require more cement paste compared to

rounded aggregates. Because of the irregularity in shape, these aggregates form good

interlocking bond and are suitable in the production of concrete.

Department of Collegiate & Technical Education Bengaluru 4

Department of Civil Engineering 2020-21

Angular Aggregate:

These aggregates are sharp and they have angular shape and rough texture. Those

aggregates are best suited for the preparation of high strength concrete.

Flaky Aggregates:

The aggregates whose thickness is less than 0.6 times the mean dimension are called as

flaky aggregates.

Elongated Aggregates:

The aggregates whose length is 1.8 times the mean dimension are called as elongated

aggregates.

Department of Collegiate & Technical Education Bengaluru 5

Department of Civil Engineering 2020-21

Grading of Aggregates

Grading is the particle-size distribution of an aggregate as determined by a sieve

analysis using wire mesh sieves with square openings. As per IS:2386(Part-1)

Fine aggregate―6 standard sieves with openings from 150 μm to 4.75 mm.

Coarse aggregate―5 sieves with openings from 4.75mm to 80 mm.

Gradation (grain size analysis)

Grain size distribution for concrete mixes that will provide a dense strong mixture.

Ensure that the voids between the larger particles are filled with medium particles. The

remaining voids are filled with still smaller particles until the smallest voids are filled

with a small amount of fines.

Good Gradation:

Concrete with good gradation will have fewer voids to be filled with cement paste

(economical mix) Concrete with good gradation will have fewer voids for water to

permeate (durability)

Ensure maximum density and strength using a maximum density curve

Testing of Coarse Aggregate.

A. Shape and Size Test:

The shape and size of aggregates can be determined by flakiness index and elongation

index tests.

B. Strength Test:

The strength of aggregates is based on three parameters – Aggregate Crushing Value

(ACV), Aggregate Impact Value (AIV) and Aggregate Abrasion Value (AAV).

Department of Collegiate & Technical Education Bengaluru 6

You might also like

- Civil V Transportation Engineering 1 U2Document11 pagesCivil V Transportation Engineering 1 U2Abhishek nNo ratings yet

- C. K. Pithawala College of Engineering & Technology: New-Mark's Influence Chart Westergaard's Formula, Contact PressureDocument14 pagesC. K. Pithawala College of Engineering & Technology: New-Mark's Influence Chart Westergaard's Formula, Contact PressureParth AnajwalaNo ratings yet

- Origin - Destination Survey: Definition, Objective and MethodologyDocument25 pagesOrigin - Destination Survey: Definition, Objective and MethodologyAbhishek SharmaNo ratings yet

- Aggregate PresentationDocument34 pagesAggregate PresentationRahsaan KirtonNo ratings yet

- Report On ENGINEERING COMPARISON BETWEEN FLEXIBLE AND RIGID PAVEMENTDocument35 pagesReport On ENGINEERING COMPARISON BETWEEN FLEXIBLE AND RIGID PAVEMENTTahmidul Islam FarabiNo ratings yet

- Mdterm Comprehensive QuizDocument2 pagesMdterm Comprehensive QuizMac KYNo ratings yet

- Brief Tutorial On: EpanetDocument26 pagesBrief Tutorial On: EpanetJayrold AsuncionNo ratings yet

- 02 Historical BackgroundDocument35 pages02 Historical BackgroundRohan PatilNo ratings yet

- Module No. 3 Planning and SchedulingDocument18 pagesModule No. 3 Planning and SchedulingAnghelo AlyenaNo ratings yet

- Pe Exam For ContractorDocument8 pagesPe Exam For ContractorMELCHOR JR ESPILOYNo ratings yet

- Hydrology in Civil EngineeringDocument5 pagesHydrology in Civil EngineeringAndrea MagtutoNo ratings yet

- Concrete Cylinder Curing MethodsDocument8 pagesConcrete Cylinder Curing Methodsjem guiNo ratings yet

- Submitted By: Garvit Goyal B.Tech 4 Year Civil BranchDocument23 pagesSubmitted By: Garvit Goyal B.Tech 4 Year Civil BranchAfghanistan AfghanNo ratings yet

- Highway Alignment: Premlatha K Naidu Assistant ProfessorDocument193 pagesHighway Alignment: Premlatha K Naidu Assistant ProfessorPremalata NaiduNo ratings yet

- Use of Glass Powder For Soil StabilisationDocument75 pagesUse of Glass Powder For Soil StabilisationKaushal RijalNo ratings yet

- Soil Testing and AnalysisDocument21 pagesSoil Testing and AnalysiskhemankarNo ratings yet

- Application of Multilinear Regression Analysis in Modeling of Soil Properties For Geotechnical Civil Engineering Works in Calabar SouthDocument7 pagesApplication of Multilinear Regression Analysis in Modeling of Soil Properties For Geotechnical Civil Engineering Works in Calabar SouthMasood AhmedNo ratings yet

- Permeability and SeepageDocument41 pagesPermeability and SeepageJayakumar JanardhananNo ratings yet

- Soil Erosion Measurement and Control TechniquesDocument12 pagesSoil Erosion Measurement and Control TechniquessezaitanyoluNo ratings yet

- Slump Cone TestDocument3 pagesSlump Cone TestAjay katkar100% (1)

- Road Construction & Maintenance Plus Road Survey & Design TrainingDocument68 pagesRoad Construction & Maintenance Plus Road Survey & Design TrainingshingkeongNo ratings yet

- Methods of Approximate Construction Cost Estimation PreparationDocument5 pagesMethods of Approximate Construction Cost Estimation PreparationcivilNo ratings yet

- Nepal Urban Road Standard - 2068Document24 pagesNepal Urban Road Standard - 2068Prabesh AdhikariNo ratings yet

- Retaining WallDocument7 pagesRetaining WallEdward SmithNo ratings yet

- Road ConstructionDocument91 pagesRoad ConstructionRA MagallanesNo ratings yet

- Construction Management-NotesDocument10 pagesConstruction Management-Notesprem galipelliNo ratings yet

- Sampling & Testing ProceduresDocument86 pagesSampling & Testing ProcedurescruzserNo ratings yet

- Framing PDFDocument4 pagesFraming PDFJizelle JumaquioNo ratings yet

- Bituminous Mixtures in Road ConstructionDocument42 pagesBituminous Mixtures in Road ConstructionThamiresGuerraNo ratings yet

- Dhanalakshmi College of Engineering, Chennai Department of Civil Engineering 2 Mark Questions With Answers Ce6502 - Foundation EngineeringDocument10 pagesDhanalakshmi College of Engineering, Chennai Department of Civil Engineering 2 Mark Questions With Answers Ce6502 - Foundation EngineeringDr J Logeshwari Asst. Prof., CIVIL Veltech, ChennaiNo ratings yet

- Construction Methods and EquipmentDocument9 pagesConstruction Methods and EquipmentAngelica GicomNo ratings yet

- Construction Method and Project Management ReportDocument4 pagesConstruction Method and Project Management Reportleselle quitanegNo ratings yet

- Role of Civil Engineers and Material Selection CriteriaDocument58 pagesRole of Civil Engineers and Material Selection CriteriaBhaskar Babi100% (1)

- Foundation Engineering I CE-325: Chapter 3: Bearing Capacity of Shallow FoundationsDocument17 pagesFoundation Engineering I CE-325: Chapter 3: Bearing Capacity of Shallow FoundationsRobert Prince100% (1)

- Cet402 Quantity Surveying and ValuationDocument13 pagesCet402 Quantity Surveying and ValuationdipinnediyaparambathNo ratings yet

- Construction Planning: Basic Concepts in The Development of Construction PlansDocument11 pagesConstruction Planning: Basic Concepts in The Development of Construction PlansAiswarya RajeevNo ratings yet

- Chapter 3: Geometric Design of Highways: D Ep Artm Ent of Civil Engineering, Ambo UniversityDocument27 pagesChapter 3: Geometric Design of Highways: D Ep Artm Ent of Civil Engineering, Ambo UniversityTarmok Hirpo100% (1)

- Stabilization of Black Cotton Soil With Marble DustDocument4 pagesStabilization of Black Cotton Soil With Marble DustIJRASETPublications100% (1)

- Soil Compaction: Standard and Modified Proctor TestsDocument31 pagesSoil Compaction: Standard and Modified Proctor TestsShamoyal KhanNo ratings yet

- Guidebook for Road Construction and Maintenance Management InspectionsDocument38 pagesGuidebook for Road Construction and Maintenance Management InspectionsElvin G. Tactac100% (1)

- CE181 CE Law, Contracts & Ethics: Lecture - 4 Contract DocumentDocument23 pagesCE181 CE Law, Contracts & Ethics: Lecture - 4 Contract DocumentYves Harvey Garcia Escarez100% (1)

- The Effects of Horseradish Seeds To The Compressive Strength of A Hollow BlockDocument58 pagesThe Effects of Horseradish Seeds To The Compressive Strength of A Hollow BlockRomy Cabhog JrNo ratings yet

- EERC Construction Plans and EstimatesDocument18 pagesEERC Construction Plans and EstimatesJOHN CARLO DE GUZMAN AMBAY (JCDGA)No ratings yet

- Field Tests of Building MaterialsDocument4 pagesField Tests of Building Materialssmartman3550% (2)

- H4140-CBR Test Method for In-Place CBR IndexDocument15 pagesH4140-CBR Test Method for In-Place CBR IndexIlman Isramdhani RahmanNo ratings yet

- Traffic Volume Survey ReportDocument36 pagesTraffic Volume Survey ReportMamunNo ratings yet

- Steel vs. Concrete MaterialDocument3 pagesSteel vs. Concrete MaterialGerald YasonNo ratings yet

- Civil II YearDocument75 pagesCivil II Yearsathya prakashNo ratings yet

- Introduction Importance of Materials TestingDocument61 pagesIntroduction Importance of Materials TestingJIENNY LOU TENGCONo ratings yet

- Claims Management Course ContentsDocument6 pagesClaims Management Course ContentsrajatNo ratings yet

- Peak Flow Calculation-LunugalaDocument3 pagesPeak Flow Calculation-LunugalakanishkaNo ratings yet

- Sanitary Engineering Important Formula Review by Sumit PaudelDocument2 pagesSanitary Engineering Important Formula Review by Sumit PaudelNirmal K.c.No ratings yet

- (E) Chapter 1 - Origin of Soil and Grain SizeDocument23 pages(E) Chapter 1 - Origin of Soil and Grain SizeLynas Beh TahanNo ratings yet

- Fresh ConcreteDocument15 pagesFresh ConcreteAlwyne ReyesNo ratings yet

- Cec 309 Note-1Document3 pagesCec 309 Note-1AbdulrafiuNo ratings yet

- CE 504 Foundation Engineering SettlementDocument18 pagesCE 504 Foundation Engineering SettlementIan Seguritan100% (1)

- HoI, NO, HDO - Engineering & Non-AICTE CollegesDocument56 pagesHoI, NO, HDO - Engineering & Non-AICTE CollegesAnuradha Sinha100% (1)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- Wastewater TreatmentDocument46 pagesWastewater TreatmentOsmanNo ratings yet

- Understanding The Results of An Intelligent Pig InspectionDocument18 pagesUnderstanding The Results of An Intelligent Pig InspectionLeonardo VazNo ratings yet

- 6324 ECO Prim Grip en LRDocument4 pages6324 ECO Prim Grip en LRdraganugNo ratings yet

- Phase Equilibria 200 SoftwareDocument29 pagesPhase Equilibria 200 SoftwareSuraj NairNo ratings yet

- Proposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)Document2 pagesProposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)John Axl LajomNo ratings yet

- UntitledDocument1 pageUntitledamitiffco0% (1)

- Idea Lesson ExemplarDocument3 pagesIdea Lesson Exemplareleonor ataatNo ratings yet

- Syllabus 3rd SemDocument6 pagesSyllabus 3rd Sem083Rahul SinghNo ratings yet

- Behavior of Prestressed Concrete I-Girders Strengthened in Shear With Externally Bonded Fiber-Reinforced-Polymer SheetsDocument20 pagesBehavior of Prestressed Concrete I-Girders Strengthened in Shear With Externally Bonded Fiber-Reinforced-Polymer SheetsmarkicivanNo ratings yet

- Mto Lab Manuals - All ExperimentsDocument121 pagesMto Lab Manuals - All ExperimentsAnmol JainNo ratings yet

- 2.3.1 Magnetite AnodesDocument3 pages2.3.1 Magnetite AnodesSoltani AliNo ratings yet

- Phenolic: The Offshore FRP Grating StandardDocument2 pagesPhenolic: The Offshore FRP Grating StandardBirendra2706No ratings yet

- Solid waste management challenges in BhutanDocument7 pagesSolid waste management challenges in BhutanSherub PhuntshoNo ratings yet

- Synthesis and Characterization of Expandable GraphiteDocument66 pagesSynthesis and Characterization of Expandable GraphitequiqueNo ratings yet

- Parker ValvesDocument64 pagesParker ValvesJaime PiedraNo ratings yet

- Group 5 Lab 2 - Q&ADocument2 pagesGroup 5 Lab 2 - Q&AChocolocoSampayanNo ratings yet

- Edexcel AS Chemistry Note 3 - Different Types of ReactionDocument7 pagesEdexcel AS Chemistry Note 3 - Different Types of ReactionSajaniNo ratings yet

- Marine Sandwich Composites for High PerformanceDocument12 pagesMarine Sandwich Composites for High Performancecarlos ivan carvajal ortizNo ratings yet

- Aislador Polimérico - Sediver - IECDocument6 pagesAislador Polimérico - Sediver - IECdaniel carhuamacaNo ratings yet

- ICorr CED CT06 ApplicationOfIntumescentCoatings Issue1 PDFDocument17 pagesICorr CED CT06 ApplicationOfIntumescentCoatings Issue1 PDFJoe Gaffney100% (1)

- Determination of Coefficient of Linear Expansion of A Metal RodDocument5 pagesDetermination of Coefficient of Linear Expansion of A Metal RodJustas Petrauskas50% (2)

- Excellence in Professional Engineering Review and Training SolutionsDocument3 pagesExcellence in Professional Engineering Review and Training SolutionsGlaiza Marie100% (1)

- Lattice Steel Towers and Steel PolesDocument7 pagesLattice Steel Towers and Steel Polesyudha_hermawan_kinoy0% (1)

- International Indian School, Dammam. Boys Middle Section Class: Viii Social Science Geo. Lesson - 5 IndustriesDocument4 pagesInternational Indian School, Dammam. Boys Middle Section Class: Viii Social Science Geo. Lesson - 5 IndustriesShaheem MuhammedNo ratings yet

- Chem 121-1Document45 pagesChem 121-1Zechariah NggitaNo ratings yet

- Leads Institute of Technology & EngineeringDocument22 pagesLeads Institute of Technology & EngineeringAladdin Narzo100% (2)

- Fumanite - Maximum Asset UptimeDocument256 pagesFumanite - Maximum Asset UptimePranpath NarupantawartNo ratings yet

- Polymer Blends and CompositesDocument25 pagesPolymer Blends and CompositesHamza ChelaliNo ratings yet

- r134 - r22-r404A-R290 (Diagramas de Molier 1)Document4 pagesr134 - r22-r404A-R290 (Diagramas de Molier 1)Miguel Carlin Jimenez100% (2)

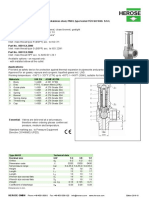

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed RaafatNo ratings yet