Professional Documents

Culture Documents

IAG water tank wall section design

Uploaded by

christopher0 ratings0% found this document useful (0 votes)

31 views1 pageOriginal Title

Design 1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views1 pageIAG water tank wall section design

Uploaded by

christopherCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

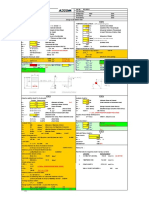

Company: IAG INTERNATIONAL LLC 2001 Techno Consultants

Address: Turbunka Avenue RC8007 Ver:010104

4th Floor the Gadoi Regency

Tel Fax: Made by Date Page No

Project: WATER TANK AT WTP1 @ FIRE STATION EEC 23 Febuary 21 1

Client: UNSOS Checked Job No Revision

Element: Wall Section Design 2001/45-4500

Liquid Retaining Reinforced Concrete Section to BS 8007& BS 8110

User Ref: Wall 300 Thick Datastore No 1150

Description: Wall fcu=30, W=0.2mm, h=300, c=40, dia=16, s=200, hs=150

Size & Material Properties:

2 2

Concrete strength, fcu 30 N/mm Steel strength, fy (Deformed Type 2) 460 N/mm

2

Crack width, W max 0.2 mm Steel modulus, Es 200000 N/mm

2

Restraint factor, R 0.5 Concrete modulus, Ec = 5,500 sqrt (fcu / 1.5) / 2 12298 N/mm

Section Thickness, h 300 mm Modular ratio, m = Es / Ec 16.3

2

Concrete cover, c 40 mm Average bond strength between concrete & steel, f b 2.4 N/mm

2

Bar size, f 12 mm Direct tensile strength of immature concrete, f ct 1.44 N/mm

Bar spacing, s 150 mm Effective depth, d = h - c - f / 2 254 mm

2

gms for steel 1.15 Steel area provided in b=1000 mm wide zone, A s 753 mm

Type of reinforcement Deformed

1 Type 2 Steel ratio provided over gross area, pg = As / (b h) 0.00251 0.0013

Plain Round

Serviceability Limit State:

Moment Capacity: Steel ratio provided, p = As / (b d) 0.002965

2

Neutral axis depth, x = [ - m p + sqrt {(m p) + 2 m p} ] d 67.6 mm

Lever Arm, z = d - x / 3 231.5 mm

2 2

Distance to nearest steel bar surface, acr =sqrt[(s/2) +(c+f/2) ] - f/2 82.0 mm

Strain due to the stiffening effect of concrete between cracks, as per Appendix B.4 of BS 8007:

2

e2=kb(h-x) /[3EsAs(d-x)] where k=1 when W max=0.2 & 1.5 when W max=0.1 0.000641

Average strain at the tension face, em=W max[1+2(acr-c)/(h-x)] / (3 acr) 0.001107

2

Stress in steel fs = Es (e2+em) (d-x) / (h-x) <= fy / gms 280.3 N/mm

Service Moment Capacity, Ms= fs As z 48.9 kNm/m

Applied M s 45 kNm/m < 48.9 kNm/m, Hence OK

Ultimate Limit State:

Moment Capacity: Neutral axis depth, x = fy As / (0.405 fcu b gms) <= 0.5 d 24.8 mm

Lever Arm z = (d - 0.45 x) <= 0.95 d 241.3 mm

Ultimate Moment Capacity, Mu = 0.405 fcu b x z 72.7 kNm/m

Applied M u 63 kNm/m < 72.7 kNm/m, Hence OK

2

Shear Capacity: Design concrete shear stress from Table 3.8 of BS 8110: Part 1, vc 0.502 N/mm

Ultimate Shear Capacity of concrete section alone, V c = vc b d 127.4 kN/m

Applied V u 52.78 kN/m < 127.4 kN/m, Hence OK

Minimum Reinforcement for the Control of Thermal & Shrinkage Cracking:

Concrete Surface Zone

Wall / Suspended-slab / Top of ground slab Bottom of ground slab

1.0

Wall/Suspended-slab/Top of ground slab: Surface Zone Depth, hs 150 mm

Coefficient of Thermal Expansion for mature concrete, a 1.00E-05

T1, fall in temperature between the hydration peak and ambient o

24 C

T2, fall in temperature because of seasonal variations o

20 C

Effective Strain, e = R a (T1+T2) 0.000220

Likely maximum spacing of cracks, Smax = W max / e 909.1 mm

Steel requirements in surface zone, as per Appendix A of BS 8007:

1- Steel ratio to control crack widths, pcrw = fct f / (2 fb Smax) 0.003960

2- Critical Steel ratio to distribute cracking, p crit = fct / fy 0.003130

3- Minimum Steel ratio as per Table A.1 BS 8007, p min 0.003500

Hence, Steel ratio required, preq 0.003960

2

Required Steel Area in 1000mm x hs deep surface zone = 1000 preq hs 594 mm

< 753 provided, Hence OK

File: BS8007 RC WATER TANK DESIGN.xlsm Tab: RC8007 Date Printed: 2/24/2021

You might also like

- Wall Formwork Design CalculationsDocument7 pagesWall Formwork Design CalculationsJun Rey Morales100% (1)

- Keys For Prayer - Myles MunroeDocument35 pagesKeys For Prayer - Myles MunroeAnn Onimous100% (5)

- Keys For Prayer - Myles MunroeDocument35 pagesKeys For Prayer - Myles MunroeAnn Onimous100% (5)

- Project: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)Document8 pagesProject: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)pakbilal1100% (1)

- Faith Food Devotions - Kenneth E. HaginDocument325 pagesFaith Food Devotions - Kenneth E. HaginBereket100% (2)

- Swimming Pool Design Rev-0Document2 pagesSwimming Pool Design Rev-0Haytham Samir75% (4)

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document1 pageLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110James LaurentNo ratings yet

- 5.0 Design of Top Ring BeamDocument3 pages5.0 Design of Top Ring BeamJayNo ratings yet

- Crack WidthDocument21 pagesCrack WidthBalaji HariNo ratings yet

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Design of Valve-chamber-Vc- 08 & 12-13-04-23Document26 pagesDesign of Valve-chamber-Vc- 08 & 12-13-04-23desilcharpdmcNo ratings yet

- Behavior of Cantilever SlabsDocument1 pageBehavior of Cantilever Slabsatoz2033No ratings yet

- Imps - Short Wall (My - Vertical) : Calculation of SteelDocument12 pagesImps - Short Wall (My - Vertical) : Calculation of Steelpearl kachhawahNo ratings yet

- Maximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapDocument1 pageMaximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapsivaNo ratings yet

- Singly Reinforcrd BeamDocument2 pagesSingly Reinforcrd BeamLikith Gowda MNo ratings yet

- Crack Width - BS en 1992 Base SlabDocument3 pagesCrack Width - BS en 1992 Base SlabVinoth KumarNo ratings yet

- SLAB DESIGN-300mm THK. CENTER SLABDocument2 pagesSLAB DESIGN-300mm THK. CENTER SLABvoilNo ratings yet

- Calculation For Crack WidthDocument48 pagesCalculation For Crack Widthpearl kachhawahNo ratings yet

- Crack PDFDocument22 pagesCrack PDFghansaNo ratings yet

- Crack Width CalculationDocument7 pagesCrack Width CalculationSrinivas RegulavalasaNo ratings yet

- Design of square footing for 600 KN column loadDocument2 pagesDesign of square footing for 600 KN column loadVishwajith KadriNo ratings yet

- Annexure-2 (Section Design Calcs)Document107 pagesAnnexure-2 (Section Design Calcs)blisscutest beagleNo ratings yet

- 3-Stress Check - Rectangular AbutDocument6 pages3-Stress Check - Rectangular Abutsanjay vermaNo ratings yet

- Horizontal and vertical steel reinforcement design for rectangular water tankDocument4 pagesHorizontal and vertical steel reinforcement design for rectangular water tankMiko AbiNo ratings yet

- Fin plate connection design detailsDocument2 pagesFin plate connection design detailsSudhakar Krishnamurthy100% (1)

- Design of Precast BeamDocument4 pagesDesign of Precast BeamMUTHUKKUMARAMNo ratings yet

- Design Bottom slabDocument2 pagesDesign Bottom slabravi kulhariNo ratings yet

- RC Beam DesignDocument1 pageRC Beam DesignshiruhanNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- Aci Beam Crack Width Bot ZDocument2 pagesAci Beam Crack Width Bot ZParthiban ArivazhaganNo ratings yet

- Crack Width For MX - Outer - MaxDocument1 pageCrack Width For MX - Outer - Maxmhazarath murariNo ratings yet

- Design of foundation flexure reinforcement parametersDocument2 pagesDesign of foundation flexure reinforcement parameterswaquarstrNo ratings yet

- Fire Resistance of Partially Encased Composite BeamDocument46 pagesFire Resistance of Partially Encased Composite BeamvedranNo ratings yet

- Aci Beam Crack Width Top XDocument2 pagesAci Beam Crack Width Top XParthiban ArivazhaganNo ratings yet

- Shear Wall Sample Design CalculationsDocument2 pagesShear Wall Sample Design CalculationsRohan DharmadhikariNo ratings yet

- Lintal Beam and Wall OpeningDocument4 pagesLintal Beam and Wall Openingkc chanNo ratings yet

- Design of One Way Slab (Continuous) : Given DataDocument3 pagesDesign of One Way Slab (Continuous) : Given DataParwan ExceltechNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- Water Tank DesignDocument3 pagesWater Tank Designkiran raghukiranNo ratings yet

- BS5400 R.C Design With Crack WidthDocument9 pagesBS5400 R.C Design With Crack WidthWangTF100% (4)

- Two Way Slab DesignDocument1 pageTwo Way Slab DesignShakil AkhterNo ratings yet

- Short Wall - Vertical: Plate No.-961 L/C No. - 10Document12 pagesShort Wall - Vertical: Plate No.-961 L/C No. - 10pearl kachhawahNo ratings yet

- Design of Water Tank On The Ground According To Bs 8007:1987Document109 pagesDesign of Water Tank On The Ground According To Bs 8007:1987minov minovitchNo ratings yet

- Design of Two Way SlabDocument4 pagesDesign of Two Way Slabpepe wosNo ratings yet

- Check For Pressure Exerted by Water in Tank: Unit WT of Submerged Soil 8 KN/MDocument3 pagesCheck For Pressure Exerted by Water in Tank: Unit WT of Submerged Soil 8 KN/MzohaNo ratings yet

- Design steel tubular pile subject to axial & bending loadsDocument5 pagesDesign steel tubular pile subject to axial & bending loadsEdward Albert BañagaNo ratings yet

- Cantlver SlabDocument8 pagesCantlver SlabsheikNo ratings yet

- 8 Check For Crack Width: B) Bottom SlabDocument2 pages8 Check For Crack Width: B) Bottom SlabAnonymous jLLjBdrNo ratings yet

- 400mm THK Raft - T25-100Document2 pages400mm THK Raft - T25-100Ihab SorourNo ratings yet

- Design of Pile Cap: X Y XYDocument2 pagesDesign of Pile Cap: X Y XYvoilNo ratings yet

- Stress Check of Box CulvertDocument2 pagesStress Check of Box CulvertBRIDGE DESIGNCELLNo ratings yet

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 23-Nov-2020 34 CHG R68Document1 pageSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 23-Nov-2020 34 CHG R68Aung MayNo ratings yet

- G-Slab 2way SiemensDocument20 pagesG-Slab 2way SiemensRaghNo ratings yet

- Slab Thickness : 0.92 KN 8.825kN/mDocument6 pagesSlab Thickness : 0.92 KN 8.825kN/mhamza hanifNo ratings yet

- Crack Width Calculation in Reinforced Concrete BeamDocument1 pageCrack Width Calculation in Reinforced Concrete BeamGautham AllimuthuNo ratings yet

- Baja 1Document25 pagesBaja 1Ruddy ChoiruddynNo ratings yet

- S2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersDocument2 pagesS2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersMuhammed Sabah100% (1)

- Crack Width Calculation To Bs8110:Part 2:1985: Project Job RefDocument1 pageCrack Width Calculation To Bs8110:Part 2:1985: Project Job RefJonn MashNo ratings yet

- Crack Width Bs 8110 by CivilaxcomDocument3 pagesCrack Width Bs 8110 by CivilaxcomasdNo ratings yet

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- Structural Design of Bored Cast In-Situ PileDocument2 pagesStructural Design of Bored Cast In-Situ PilesathishNo ratings yet

- RECTANGULAR BEAM DESIGNDocument1 pageRECTANGULAR BEAM DESIGNRavi Sharma BhandariNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Coronavirus Ppe Forward Facing StaffDocument4 pagesCoronavirus Ppe Forward Facing StaffchristopherNo ratings yet

- Critical Column C1Document2 pagesCritical Column C1christopherNo ratings yet

- Job Advert Junior Projects Engineer - ElectricalDocument3 pagesJob Advert Junior Projects Engineer - ElectricalchristopherNo ratings yet

- Critical BeamDocument16 pagesCritical BeamchristopherNo ratings yet

- EbDocument2 pagesEbBaugh Graphic DesignNo ratings yet

- B Stormwater Calculations ImppDocument12 pagesB Stormwater Calculations ImppFarman Ali KhaskheliNo ratings yet

- Mesicic5 BLZ Resp Annex17Document44 pagesMesicic5 BLZ Resp Annex17cherinet jaburaNo ratings yet

- RA3531 Initial IssueDocument8 pagesRA3531 Initial IssuechristopherNo ratings yet

- Wing WallDocument12 pagesWing WallWaheed AhmadNo ratings yet

- God's formula for attaining true successDocument47 pagesGod's formula for attaining true successchristopherNo ratings yet

- God's formula for attaining true successDocument47 pagesGod's formula for attaining true successchristopherNo ratings yet

- B Stormwater Calculations ImppDocument12 pagesB Stormwater Calculations ImppFarman Ali KhaskheliNo ratings yet

- Checklist For Pre ConcretingDocument4 pagesChecklist For Pre ConcretingIfeanyi IwuallaNo ratings yet

- Cemfis India PVT LTD Concrete Pour CardDocument1 pageCemfis India PVT LTD Concrete Pour CardchristopherNo ratings yet

- Mortar PDFDocument274 pagesMortar PDFbadar100% (1)

- Manual For Structural Design of Waterworks Structures: Water Supplies Department Special Administrative RegionDocument9 pagesManual For Structural Design of Waterworks Structures: Water Supplies Department Special Administrative RegionchristopherNo ratings yet

- Civil Engineering: 1 Mortar, Masonry, Concrete and Steel ReinforcementDocument50 pagesCivil Engineering: 1 Mortar, Masonry, Concrete and Steel ReinforcementZuhal ZaeemNo ratings yet

- Appendix A: Sample Inventory Support Form: E Q U Ipment Registry FormDocument5 pagesAppendix A: Sample Inventory Support Form: E Q U Ipment Registry FormchristopherNo ratings yet

- linkStudPSR Design Manual To BS8110 v2.0 - 1302185409 PDFDocument35 pageslinkStudPSR Design Manual To BS8110 v2.0 - 1302185409 PDFHemantha BalasuriyaNo ratings yet

- Chapter 4. Hospital HeliportsDocument46 pagesChapter 4. Hospital HeliportsErik VanNo ratings yet

- Supplemental Note For Checklist Item #14 - A Copy of The Engineering ContractDocument20 pagesSupplemental Note For Checklist Item #14 - A Copy of The Engineering ContractchristopherNo ratings yet

- Estimate Takeoff Example SheetDocument1 pageEstimate Takeoff Example Sheetzabiruddin786No ratings yet

- Concrete Pipe & Box Culvert: InstallationDocument99 pagesConcrete Pipe & Box Culvert: InstallationPol StephNo ratings yet

- 2018 5 3 4 MohammadDocument20 pages2018 5 3 4 MohammadsgondoschNo ratings yet

- Lots 3 - Annexure B 1b Appendix 3 - Structural CalculationsDocument95 pagesLots 3 - Annexure B 1b Appendix 3 - Structural CalculationschristopherNo ratings yet

- Concrete Pipe & Box Culvert: InstallationDocument99 pagesConcrete Pipe & Box Culvert: InstallationPol StephNo ratings yet

- Nucl510 L02Document21 pagesNucl510 L02Brittany TuckerNo ratings yet

- Atoms and Light InteractionsDocument252 pagesAtoms and Light InteractionsHundaol TesfayeNo ratings yet

- AE 51 Thermodynamics and Heat Transfer For Agricultural Engineering Basic ConceptsDocument43 pagesAE 51 Thermodynamics and Heat Transfer For Agricultural Engineering Basic ConceptsYsmael Alongan B. MangorsiNo ratings yet

- ME 301 Homework 5 Static and Dynamic AnalysisDocument11 pagesME 301 Homework 5 Static and Dynamic Analysisjoseph beckhamNo ratings yet

- Pipe Mastery Part 1-Answer KeyDocument2 pagesPipe Mastery Part 1-Answer KeyLorence CardenasNo ratings yet

- Basic Engineering Thermodynamics A Venkatesh PDFDocument104 pagesBasic Engineering Thermodynamics A Venkatesh PDFRudresh J MattikalliNo ratings yet

- Four Bar ChainDocument11 pagesFour Bar ChaindxfdxNo ratings yet

- Melody Jones - Newton's 2nd Law LabDocument3 pagesMelody Jones - Newton's 2nd Law LabMelody JonesNo ratings yet

- ZahidDocument2 pagesZahidZahid ManzoorNo ratings yet

- Collision of Elastic BodiesDocument19 pagesCollision of Elastic Bodiesviveksp99No ratings yet

- FLUID ROTATION CIRCULATIONDocument22 pagesFLUID ROTATION CIRCULATIONAristyo Rahadian WijayaNo ratings yet

- 762X267X197Crane Gantry Girder Design (BS5950)Document5 pages762X267X197Crane Gantry Girder Design (BS5950)Ravindu Jayalath100% (1)

- Molecular Term SymbolsDocument5 pagesMolecular Term Symbols1jerushaNo ratings yet

- Dynamic Shear Rheometers For Asphalt: SmartpaveDocument7 pagesDynamic Shear Rheometers For Asphalt: SmartpaveMiguelNo ratings yet

- Application of ThermodynamicsDocument5 pagesApplication of ThermodynamicsRonald McJollibeeNo ratings yet

- Impulsive Force and Momentum DefinitionDocument15 pagesImpulsive Force and Momentum DefinitionCheah Chong ShengNo ratings yet

- Casing Design ExampleDocument42 pagesCasing Design ExampleFabio Ribera SaavedraNo ratings yet

- Soil Young's ModulusDocument1 pageSoil Young's ModulusAndre UlianovNo ratings yet

- Comparison of Theoretical & ANSYS FEADocument26 pagesComparison of Theoretical & ANSYS FEArbachalliNo ratings yet

- 05 Unit and Dimension SET (70 72)Document4 pages05 Unit and Dimension SET (70 72)lakshyaNo ratings yet

- Deep Xcav Waler Beams Theory ManDocument30 pagesDeep Xcav Waler Beams Theory Manharicv019100% (1)

- Flat Slab Punching Shear Check r1Document5 pagesFlat Slab Punching Shear Check r1Usama ChauguleNo ratings yet

- KTG & Thermodynamics Homework SheetDocument23 pagesKTG & Thermodynamics Homework SheetMayur S DhawaleNo ratings yet

- 4.4 Understanding The Gas Law: Property of Gas Volume, VDocument6 pages4.4 Understanding The Gas Law: Property of Gas Volume, VZalini AbdullahNo ratings yet

- Modal Space Articles 1998-2014 17years MACL tcm18-189938 PDFDocument225 pagesModal Space Articles 1998-2014 17years MACL tcm18-189938 PDFRamganesh TNo ratings yet

- By: Virwane Rose P. Abellera Hanz Raymond B. Consumo Bill Ervein P. RamientosDocument10 pagesBy: Virwane Rose P. Abellera Hanz Raymond B. Consumo Bill Ervein P. RamientosMareld Dyzelle EcijaNo ratings yet

- SURFACE TENSION MODULE NOTESDocument38 pagesSURFACE TENSION MODULE NOTESamjad_sharawiNo ratings yet

- Earthquake Engineering2Document147 pagesEarthquake Engineering2Mariz Ellaine Baltazar83% (6)

- 04 Concrete Column Slenderness Flowchart Equations CSA A23.3-19Document1 page04 Concrete Column Slenderness Flowchart Equations CSA A23.3-19hichem titouNo ratings yet

- Motion-Distance and DisplacementDocument41 pagesMotion-Distance and Displacementmjdemaala100% (1)