Professional Documents

Culture Documents

Crack PDF

Uploaded by

ghansaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crack PDF

Uploaded by

ghansaCopyright:

Available Formats

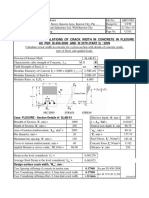

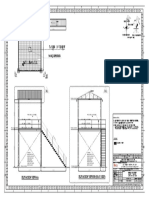

VERTICAL WALL-SOIL FACE- AT RL-1.

38M AT END OF HAUNCH

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1300 mm

Crack Width limit = 0.200 mm

Cover, Main Tension Steel = 62 mm

Cover, Cmin = 57 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 35 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 14.79 KN/mm2

Modular Ratio m 13.522

Design Service moment (Msls) = 1750 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 765 KN

Eccentricity (e) 2287.581699 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 72 20 120 2617.99388

Compression steel layer 2 ac2 = 114 0 120 0

Compression steel layer 3 ac3 = 146 0 120 0

Centroid of Compression steel d' = 72 Total Comp. Steel = 2617.99388

Tension steel layer 3 a1= 161.6 0 120 0

Tension steel layer 2 a2= 129.6 0.00 120 0

Tension steel layer 1 a3= 82.3 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 6E-05

dm= 1217.7 mm 1156.815

Calculation of neutral axis X

A0= -2E+08

A1= 1.6708E+05

A2= 2.8676E+02

A3= 5.8371E-02

X= F(X)= -8E-08

532.6406633

Stain Stress

(mm) (N/mm2)

Concrete 0.000473211 6.998889659 <0.45fcu O.K.

Compression steel 0.000409245 81.84894121 <0.8fy O.K.

Tensile steel layer 1 0.000538172 107.6343542 <0.8fy O.K.

Tensile steel layer 2 0.000566601 113.3202746 <0.8fy O.K.

Tensile steel layer 3 0.000608624 121.7247756 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000677299

e2 = 0.000132788

em =e1-e2 0.000544512

acr = 77.55341077 mm

Estimated crack width, Wcr = 0.1202 mm

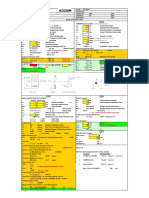

VERTICAL WALL-SOIL FACE- AT RL-1.38M AT END OF HAUNCH

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1000 mm

Crack Width limit = 0.200 mm

Cover, Main Tension Steel = 62 mm

Cover, Cmin = 57 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 1650 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 765 KN

Eccentricity (e) 2156.862745 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 72 20 120 2617.99388

Compression steel layer 2 ac2 = 114 0 120 0

Compression steel layer 3 ac3 = 146 0 120 0

Centroid of Compression steel d' = 72 Total Comp. Steel = 2617.99388

Tension steel layer 3 a1= 161.6 0 120 0

Tension steel layer 2 a2= 129.6 0.00 120 0

Tension steel layer 1 a3= 82.3 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 6E-05

dm= 917.7 mm 871.815

Calculation of neutral axis X

A0= -1E+08

A1= 1.5870E+05

A2= 3.2178E+02

A3= 6.4736E-02

X= F(X)= 0E+00

417.0187892

Stain Stress

(mm) (N/mm2)

Concrete 0.00067138 10.61544996 <0.45fcu O.K.

Compression steel 0.000555464 111.0927001 <0.8fy O.K.

Tensile steel layer 1 0.000678403 135.6806584 <0.8fy O.K.

Tensile steel layer 2 0.000729922 145.9843477 <0.8fy O.K.

Tensile steel layer 3 0.000806072 161.2144885 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000930522

e2 = 0.000104866

em =e1-e2 0.000825655

acr = 77.55341077 mm

Estimated crack width, Wcr = 0.1794 mm

VERTICAL WALL-SOIL FACE- AT RL-2.53M AFTER HAUNCH

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1000 mm

Crack Width limit = 0.200 mm

Cover, Compression Steel = 62 mm

Cover, Cmin = 57 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 1340 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 810 KN

Eccentricity (e) 1654.320988 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 72 20 120 2617.99388

Compression steel layer 2 ac2 = 114 0 120 0

Compression steel layer 3 ac3 = 146 0 120 0

Centroid of Compression steel d' = 72 Total Comp. Steel = 2617.99388

Tension steel layer 3 a1= 161.6 0 120 0

Tension steel layer 2 a2= 129.6 0.00 120 0

Tension steel layer 1 a3= 82.3 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 8E-05

dm= 917.7 mm 871.815

Calculation of neutral axis X

A0= -1E+08

A1= 1.5606E+05

A2= 2.7855E+02

A3= 8.0437E-02

X= F(X)= 7E-04

433.7094105

Stain Stress

(mm) (N/mm2)

Concrete 0.000555707 8.786491901 <0.45fcu O.K.

Compression steel 0.000463454 92.69076506 <0.8fy O.K.

Tensile steel layer 1 0.000518525 103.7050164 <0.8fy O.K.

Tensile steel layer 2 0.000559526 111.9052578 <0.8fy O.K.

Tensile steel layer 3 0.000620131 124.0262397 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000719175

e2 = 0.00010236

em =e1-e2 0.000616815

acr = 77.55341077 mm

Estimated crack width, Wcr = 0.134 mm

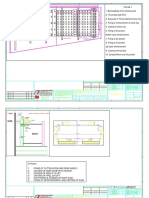

TOP SLAB-SOIL FACE- AT HAUNCH START

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1400 mm

Crack Width limit = 0.200 mm

Cover, Compression Steel = 66 mm

Cover, Cmin = 61 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 1500 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 225 KN

Eccentricity (e) 6666.666667 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 76 20 120 2617.99388

Compression steel layer 2 ac2 = 118 0 120 0

Compression steel layer 3 ac3 = 150 0 120 0

Centroid of Compression steel d' = 76 Total Comp. Steel = 2617.99388

Tension steel layer 3 a1= 165.6 0 120 0

Tension steel layer 2 a2= 133.6 0.00 120 0

Tension steel layer 1 a3= 82 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 2E-05

dm= 1318 mm 1252.1

Calculation of neutral axis X

A0= -2E+08

A1= 1.6393E+05

A2= 4.0954E+02

A3= 2.2879E-02

X= F(X)= 2E-05

491.0293055

Stain Stress

(mm) (N/mm2)

Concrete 0.000325812 5.151544858 <0.45fcu O.K.

Compression steel 0.000275384 55.07681635 <0.8fy O.K.

Tensile steel layer 1 0.000493248 98.64963916 <0.8fy O.K.

Tensile steel layer 2 0.000514481 102.8962263 <0.8fy O.K.

Tensile steel layer 3 0.000548719 109.7438481 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000599811

e2 = 0.000154347

em =e1-e2 0.000445464

acr = 80.74301064 mm

Estimated crack width, Wcr = 0.103 mm

TOP SLAB-SOIL FACE- AT END OF HAUNCH

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1100 mm

Crack Width limit = 0.200 mm

Cover, Compression Steel = 66 mm

Cover, Cmin = 61 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 1250 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 225 KN

Eccentricity (e) 5555.555556 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 78.5 25 120 4090.61543

Compression steel layer 2 ac2 = 123 0 120 0

Compression steel layer 3 ac3 = 155 0 120 0

Centroid of Compression steel d' = 78.5 Total Comp. Steel = 4090.61543

Tension steel layer 3 a1= 165.6 0 120 0

Tension steel layer 2 a2= 133.6 0.00 120 0

Tension steel layer 1 a3= 82 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 3E-05

dm= 1018 mm 967.1

Calculation of neutral axis X

A0= -1E+08

A1= 1.8014E+05

A2= 4.1550E+02

A3= 2.7669E-02

X= F(X)= -8E+06

387.8078122

Stain Stress

(mm) (N/mm2)

Concrete 0.000406047 6.420164829 <0.45fcu O.K.

Compression steel 0.000323855 64.77098552 <0.8fy O.K.

Tensile steel layer 1 0.000572299 114.4598141 <0.8fy O.K.

Tensile steel layer 2 0.000605804 121.1608137 <0.8fy O.K.

Tensile steel layer 3 0.000659831 131.9661756 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000740452

e2 = 0.00012434

em =e1-e2 0.000616113

acr = 80.74301064 mm

Estimated crack width, Wcr = 0.141 mm

TOP SLAB-SOIL FACE- AT 1.4M FROM CENTRE LINE OF WALL (CURTAILMENT POINT)

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1100 mm

Crack Width limit = 0.200 mm

Cover, Compression Steel = 66 mm

Cover, Cmin = 61 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 750 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 225 KN

Eccentricity (e) 3333.333333 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 78.5 25 120 4090.61543

Compression steel layer 2 ac2 = 123 0 120 0

Compression steel layer 3 ac3 = 155 0 120 0

Centroid of Compression steel d' = 78.5 Total Comp. Steel = 4090.61543

Tension steel layer 3 a1= 150 0 120 0

Tension steel layer 2 a2= 118 0.00 120 0

Tension steel layer 1 a3= 78.5 25.00 120 4090.61543

Total Tensile Steel (Ast) = 4090.61543

Effective depth (to the centroid of steel) (dm) Y= 4E-05

dm= 1021.5 mm 970.425

Calculation of neutral axis X

A0= -6E+07

A1= 9.0661E+04

A2= 3.6576E+02

A3= 4.3804E-02

X= F(X)= 2E-06

282.8918885

Stain Stress

(mm) (N/mm2)

Concrete 0.000325378 5.144674245 <0.45fcu O.K.

Compression steel 0.000235088 47.01766245 <0.8fy O.K.

Tensile steel layer 1 0.000767297 153.4594363 <0.8fy O.K.

Tensile steel layer 2 0.000804103 160.820615 <0.8fy O.K.

Tensile steel layer 3 0.000849535 169.9070698 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000934074

e2 = 0.000368303

em =e1-e2 0.000565771

acr = 82.38018761 mm

Estimated crack width, Wcr = 0.133 mm

TOP SLAB-EXCAVATION FACE- AT MIDDLE OF SPAN

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1100 mm

Crack Width limit = 0.300 mm

Cover, Compression Steel = 66 mm

Cover, Cmin = 61 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 1950 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 225 KN

Eccentricity (e) 8666.666667 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 78.5 25 120 4090.61543

Compression steel layer 2 ac2 = 123 0 120 0

Compression steel layer 3 ac3 = 155 0 120 0

Centroid of Compression steel d' = 78.5 Total Comp. Steel = 4090.61543

Tension steel layer 3 a1= 165.6 0 120 0

Tension steel layer 2 a2= 133.6 0.00 120 0

Tension steel layer 1 a3= 82 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 2E-05

dm= 1018 mm 967.1

Calculation of neutral axis X

A0= -1E+08

A1= 1.8289E+05

A2= 4.4428E+02

A3= 1.8246E-02

X= F(X)= 6E-04

394.7831176

Stain Stress

(mm) (N/mm2)

Concrete 0.000607665 9.608022362 <0.45fcu O.K.

Compression steel 0.000486835 97.36692066 <0.8fy O.K.

Tensile steel layer 1 0.000830598 166.119629 <0.8fy O.K.

Tensile steel layer 2 0.000879854 175.9707443 <0.8fy O.K.

Tensile steel layer 3 0.000959278 191.8556678 <0.8fy O.K.

CRACK WIDTH

e1 = 0.0010778

e2 = 0.00012328

em =e1-e2 0.000954519

acr = 80.74301064 mm

Estimated crack width, Wcr = 0.219 mm

BOTTOM SLAB-SOIL FACE- AT HAUNCH START

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1400 mm

Crack Width limit = 0.200 mm

Cover, Compression Steel = 86 mm

Cover, Cmin = 61 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 1450 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 225 KN

Eccentricity (e) 6444.444444 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 96 20 120 2617.99388

Compression steel layer 2 ac2 = 138 0 120 0

Compression steel layer 3 ac3 = 170 0 120 0

Centroid of Compression steel d' = 96 Total Comp. Steel = 2617.99388

Tension steel layer 3 a1= 165.6 0 120 0

Tension steel layer 2 a2= 133.6 0.00 120 0

Tension steel layer 1 a3= 102 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 2E-05

dm= 1298 mm 1233.1

Calculation of neutral axis X

A0= -2E+08

A1= 1.6393E+05

A2= 4.0784E+02

A3= 2.3666E-02

X= F(X)= 1E-05

487.8183826

Stain Stress

(mm) (N/mm2)

Concrete 0.000324423 5.129582873 <0.45fcu O.K.

Compression steel 0.000260579 52.11571346 <0.8fy O.K.

Tensile steel layer 1 0.000496514 99.30272639 <0.8fy O.K.

Tensile steel layer 2 0.000517795 103.5590423 <0.8fy O.K.

Tensile steel layer 3 0.000538811 107.7621543 <0.8fy O.K.

CRACK WIDTH

e1 = 0.00059002

e2 = 0.00015866

em =e1-e2 0.000431359

acr = 80.74301064 mm

Estimated crack width, Wcr = 0.100 mm

BOTTOM SLAB-SOIL FACE- AT HAUNCH END

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1100 mm

Crack Width limit = 0.200 mm

Cover, Compression Steel = 86 mm

Cover, Cmin = 61 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 1150 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 225 KN

Eccentricity (e) 5111.111111 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 98.5 25 120 4090.61543

Compression steel layer 2 ac2 = 143 0 120 0

Compression steel layer 3 ac3 = 175 0 120 0

Centroid of Compression steel d' = 98.5 Total Comp. Steel = 4090.61543

Tension steel layer 3 a1= 165.6 0 120 0

Tension steel layer 2 a2= 133.6 0.00 120 0

Tension steel layer 1 a3= 102 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 3E-05

dm= 998 mm 948.1

Calculation of neutral axis X

A0= -1E+08

A1= 1.7984E+05

A2= 4.1024E+02

A3= 2.9981E-02

X= F(X)= 9E-09

401.859613

Stain Stress

(mm) (N/mm2)

Concrete 0.000378963 5.991936381 <0.45fcu O.K.

Compression steel 0.000286075 57.21508993 <0.8fy O.K.

Tensile steel layer 1 0.000502198 100.4396921 <0.8fy O.K.

Tensile steel layer 2 0.000532375 106.4750469 <0.8fy O.K.

Tensile steel layer 3 0.000562175 112.4349597 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000634788

e2 = 0.000126306

em =e1-e2 0.000508481

acr = 80.74301064 mm

Estimated crack width, Wcr = 0.117 mm

BOTTOM SLAB-SOIL FACE- AT CURTAILMENT POINT

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1100 mm

Crack Width limit = 0.200 mm

Cover, Compression Steel = 86 mm

Cover, Cmin = 61 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 400 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 225 KN

Eccentricity (e) 1777.777778 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 98.5 25 120 4090.61543

Compression steel layer 2 ac2 = 143 0 120 0

Compression steel layer 3 ac3 = 175 0 120 0

Centroid of Compression steel d' = 98.5 Total Comp. Steel = 4090.61543

Tension steel layer 3 a1= 150 0 120 0

Tension steel layer 2 a2= 118 0.00 120 0

Tension steel layer 1 a3= 102 25.00 120 4090.61543

Total Tensile Steel (Ast) = 4090.61543

Effective depth (to the centroid of steel) (dm) Y= 7E-05

dm= 998 mm 948.1

Calculation of neutral axis X

A0= -5E+07

A1= 8.2575E+04

A2= 2.7581E+02

A3= 7.4880E-02

X= F(X)= 8E-09

311.2409842

Stain Stress

(mm) (N/mm2)

Concrete 0.000185249 2.929047887 <0.45fcu O.K.

Compression steel 0.000126622 25.32449813 <0.8fy O.K.

Tensile steel layer 1 0.000380187 76.0373069 <0.8fy O.K.

Tensile steel layer 2 0.000399233 79.84655853 <0.8fy O.K.

Tensile steel layer 3 0.000408756 81.75118434 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000454586

e2 = 0.0003691

em =e1-e2 8.54857E-05

acr = 82.38018761 mm

Estimated crack width, Wcr = 0.020 mm

BOT SLAB-EXCAVATION FACE- AT MIDDLE OF SPAN

Member Properties

Width,b = 1000 mm

Width at centriod of steel bars = 1000 mm

Overall depth, h = 1100 mm

Crack Width limit = 0.300 mm

Cover, Compression Steel = 66 mm

Cover, Cmin = 61 mm

Spacer Diameter = 32 mm

Material Properties

Concrete grade fcu 40 N/mm2

steel grade fy 500 N/mm2

Steel Modulus Es 200 KN/mm2

Concrete Modulus Ec, 28 15.81 KN/mm2

Modular Ratio m 12.649

Design Service moment (Msls) = 1550 KNm

Design Service axial force (N) (90% of the least loaded case LC1012) = 225 KN

Eccentricity (e) 6888.888889 mm

DESIGN FOR SLS LOADING AND CRACK WIDTH REQUIRMENTS

Prefered Bar Arrangement Steel Ratio

Cover to steel Bar Size Spacing As prov

Centroid (mm) (mm) (mm) (mm2)

Compression steel layer 1 ac1 = 78.5 25 120 4090.61543

Compression steel layer 2 ac2 = 123 0 120 0

Compression steel layer 3 ac3 = 155 0 120 0

Centroid of Compression steel d' = 78.5 Total Comp. Steel = 4090.61543

Tension steel layer 3 a1= 165.6 0 120 0

Tension steel layer 2 a2= 133.6 0.00 120 0

Tension steel layer 1 a3= 82 40.60 120 10788.491

Total Tensile Steel (Ast) = 10788.491

Effective depth (to the centroid of steel) (dm) Y= 2E-05

dm= 1018 mm 967.1

Calculation of neutral axis X

A0= -1E+08

A1= 1.8160E+05

A2= 4.3081E+02

A3= 2.2655E-02

X= F(X)= 9E-04

398.9646584

Stain Stress

(mm) (N/mm2)

Concrete 0.000485596 7.677945651 <0.45fcu O.K.

Compression steel 0.00039005 78.01008305 <0.8fy O.K.

Tensile steel layer 1 0.0006517 130.3399747 <0.8fy O.K.

Tensile steel layer 2 0.000690648 138.1296719 <0.8fy O.K.

Tensile steel layer 3 0.000753453 150.6905587 <0.8fy O.K.

CRACK WIDTH

e1 = 0.000847173

e2 = 0.000122646

em =e1-e2 0.000724527

acr = 80.74301064 mm

Estimated crack width, Wcr = 0.166 mm

You might also like

- 5.0 Design of Top Ring BeamDocument3 pages5.0 Design of Top Ring BeamJayNo ratings yet

- Imps - Short Wall (My - Vertical) : Calculation of SteelDocument12 pagesImps - Short Wall (My - Vertical) : Calculation of Steelpearl kachhawahNo ratings yet

- 3-Stress Check - Rectangular AbutDocument6 pages3-Stress Check - Rectangular Abutsanjay vermaNo ratings yet

- Calculation For Crack WidthDocument48 pagesCalculation For Crack Widthpearl kachhawahNo ratings yet

- Stress Check of Box CulvertDocument2 pagesStress Check of Box CulvertBRIDGE DESIGNCELLNo ratings yet

- Depth of Neutral Axis For Long Term Ec - (X) : Directly Under The Bar LocationDocument2 pagesDepth of Neutral Axis For Long Term Ec - (X) : Directly Under The Bar LocationUsama ChauguleNo ratings yet

- Design of Column Base PlateDocument12 pagesDesign of Column Base PlateBikal BastakotiNo ratings yet

- 6.0 Design of Cylindrical ContainerDocument3 pages6.0 Design of Cylindrical ContainerJayNo ratings yet

- Short Wall - Vertical: Plate No.-961 L/C No. - 10Document12 pagesShort Wall - Vertical: Plate No.-961 L/C No. - 10pearl kachhawahNo ratings yet

- Crack Width CalculationDocument7 pagesCrack Width CalculationSrinivas RegulavalasaNo ratings yet

- IAG water tank wall section designDocument1 pageIAG water tank wall section designchristopherNo ratings yet

- Middle Wall (All Intermediate Walls)Document3 pagesMiddle Wall (All Intermediate Walls)epe civilNo ratings yet

- Welding Design For Diaphragm ReinforcementDocument8 pagesWelding Design For Diaphragm ReinforcementmalithNo ratings yet

- Design of Valve-chamber-Vc- 08 & 12-13-04-23Document26 pagesDesign of Valve-chamber-Vc- 08 & 12-13-04-23desilcharpdmcNo ratings yet

- RevisedDocument11 pagesRevised128 SACHITA BANIYANo ratings yet

- Crack Width Calculation SpreadsheetDocument1 pageCrack Width Calculation SpreadsheetAkhilesh Kumar SinghNo ratings yet

- Calculation of Crack Width As Per Is:456-2000Document4 pagesCalculation of Crack Width As Per Is:456-2000Gautam DuttaNo ratings yet

- Design of foundation flexure reinforcement parametersDocument2 pagesDesign of foundation flexure reinforcement parameterswaquarstrNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- WALL DESIGN-400mm THK.Document2 pagesWALL DESIGN-400mm THK.voilNo ratings yet

- Water Tank Above GroundDocument5 pagesWater Tank Above GroundFranklyn GenoveNo ratings yet

- Foundation Design ReportDocument5 pagesFoundation Design ReportShashankSinghNo ratings yet

- B150 - Lift Roof Slab DesignDocument2 pagesB150 - Lift Roof Slab DesignGovendan GopalakrishnanNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- CrackWidth FlexureDocument2 pagesCrackWidth FlexureSahil OzaNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- Circular Section Crack Width Under Pure TensionDocument1 pageCircular Section Crack Width Under Pure TensionAbinash ModakNo ratings yet

- DBR-L2P9 2.5X2.5X.3 1000 Co-14 PDFDocument1 pageDBR-L2P9 2.5X2.5X.3 1000 Co-14 PDFRudra MehtaNo ratings yet

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document1 pageLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110James LaurentNo ratings yet

- Doubly Reinforced BeamDocument8 pagesDoubly Reinforced BeamKARTHIK SGNo ratings yet

- Beam DesignDocument2 pagesBeam DesignBilal A BarbhuiyaNo ratings yet

- Design of Inlet ChamberDocument2 pagesDesign of Inlet ChamberRaju SainiNo ratings yet

- Design of Pad Footings BS 8110Document4 pagesDesign of Pad Footings BS 8110thanigai veluNo ratings yet

- Concrete Beam Design ElementsDocument1 pageConcrete Beam Design Elementsp_ignatiusNo ratings yet

- RCC One Way SlabDocument2 pagesRCC One Way SlabAniket GunjalNo ratings yet

- Crack Width BS5400Document3 pagesCrack Width BS5400yuNo ratings yet

- Shell ReinDocument2 pagesShell ReinLatipKumar SharmaNo ratings yet

- Shear Wall Design (IS 13920-2016)Document8 pagesShear Wall Design (IS 13920-2016)Sahil OzaNo ratings yet

- Check For Requirement of Boundary ElementDocument9 pagesCheck For Requirement of Boundary ElementJai ThakkarNo ratings yet

- Shear Wall DesignDocument9 pagesShear Wall DesignJai ThakkarNo ratings yet

- Beam DesignDocument4 pagesBeam DesignPraYush RajbhandariNo ratings yet

- Design of A ShaftDocument2 pagesDesign of A ShaftSiddiqui RanaNo ratings yet

- Bolted Truss Column Connections - xlsx-29!14!2020Document34 pagesBolted Truss Column Connections - xlsx-29!14!2020Vineetha KrishnanNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Aisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANDocument5 pagesAisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANGousePeerzadeNo ratings yet

- SLAB DESIGN-300mm THK. CENTER SLABDocument2 pagesSLAB DESIGN-300mm THK. CENTER SLABvoilNo ratings yet

- Calculation of Moments and Shear: Input DataDocument3 pagesCalculation of Moments and Shear: Input DataARSENo ratings yet

- Beam and CorbelDocument14 pagesBeam and CorbelAkshay DuggalNo ratings yet

- Design of Singly Reinforced Beam SectionDocument6 pagesDesign of Singly Reinforced Beam SectionREVATHY GOPALNo ratings yet

- Crack Width Calculation BS 8110 FormulaDocument1 pageCrack Width Calculation BS 8110 Formulamvap2856No ratings yet

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- Concrete Grade (M) Steel Grade (Fe) Assume Depth: Design Balcony Cantilever SlabDocument1 pageConcrete Grade (M) Steel Grade (Fe) Assume Depth: Design Balcony Cantilever SlabAhmad MasoodNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- RCC Slab Bridge Design 10 M - 2022Document7 pagesRCC Slab Bridge Design 10 M - 2022erzahid ahmadNo ratings yet

- Assignment 5Document3 pagesAssignment 5Rohit KumarNo ratings yet

- Maximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapDocument1 pageMaximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapsivaNo ratings yet

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- RCC Slab Design for Toe Drain Span 800mm Thickness 100mmDocument4 pagesRCC Slab Design for Toe Drain Span 800mm Thickness 100mmManupriya KapleshNo ratings yet

- Septic Tank DesignDocument17 pagesSeptic Tank DesignPriya100% (1)

- Construction sequence for thrust bed slabDocument4 pagesConstruction sequence for thrust bed slabghansaNo ratings yet

- Secant Pile ReinforcementDocument8 pagesSecant Pile ReinforcementghansaNo ratings yet

- Labeshwar Chowk Station MDLDocument116 pagesLabeshwar Chowk Station MDLghansaNo ratings yet

- Comments P020c30ug01prb Dras Civstrdwg 10032 03 ADocument1 pageComments P020c30ug01prb Dras Civstrdwg 10032 03 AghansaNo ratings yet

- D-EUGP1-TPT-F-LCS-CST-FWG-1106 - R2 - Concourse-1 - Part PlanDocument1 pageD-EUGP1-TPT-F-LCS-CST-FWG-1106 - R2 - Concourse-1 - Part PlanghansaNo ratings yet

- 04 Settlement PDFDocument1 page04 Settlement PDFghansaNo ratings yet

- 00202-M-3-008a-B-R0 - Supporting A&d of Agitator Crude Pac Tank (A-002 A, B) PDFDocument1 page00202-M-3-008a-B-R0 - Supporting A&d of Agitator Crude Pac Tank (A-002 A, B) PDFghansaNo ratings yet

- Sustainability 13 02733Document12 pagesSustainability 13 02733ghansaNo ratings yet

- D Eugp1 TPT F KPS CST FWG 1103 R0Document1 pageD Eugp1 TPT F KPS CST FWG 1103 R0ghansaNo ratings yet

- Arch Bridge Code-ACS-8 PDFDocument8 pagesArch Bridge Code-ACS-8 PDFshobhit mohtaNo ratings yet

- Floatation PDFDocument6 pagesFloatation PDFghansaNo ratings yet

- Case A - On Temporary Base SlabDocument1 pageCase A - On Temporary Base SlabghansaNo ratings yet

- Final Case B - On Permanent Base SlabDocument1 pageFinal Case B - On Permanent Base SlabghansaNo ratings yet

- Indicative FQP-for Structural SteelDocument14 pagesIndicative FQP-for Structural SteelghansaNo ratings yet

- Design Calculation Report For CCT Tank: TitleDocument1 pageDesign Calculation Report For CCT Tank: TitleghansaNo ratings yet

- 05 - 02 - Nashrullaganj - Soil Investigation Report STPDocument66 pages05 - 02 - Nashrullaganj - Soil Investigation Report STPghansaNo ratings yet

- Design Calculation Report For CCT Tank: TitleDocument15 pagesDesign Calculation Report For CCT Tank: TitleghansaNo ratings yet

- (For 0-2.5m Soil) (For 2.5-21m Soil) (For 2.5-21m Soil) (For Soil 2.5m To 21m) (For Soil 21m To 40)Document4 pages(For 0-2.5m Soil) (For 2.5-21m Soil) (For 2.5-21m Soil) (For Soil 2.5m To 21m) (For Soil 21m To 40)ghansaNo ratings yet

- Pile DesignDocument32 pagesPile DesignghansaNo ratings yet

- PC04 DMRC Ceg DBR 001 R0Document46 pagesPC04 DMRC Ceg DBR 001 R0ghansaNo ratings yet

- IS 9012 (1978) - Recommended Practice For Shotcreting PDFDocument24 pagesIS 9012 (1978) - Recommended Practice For Shotcreting PDFdeepak925No ratings yet

- Staging MJ RUB 5Document6 pagesStaging MJ RUB 5ghansaNo ratings yet

- Drawing List - Design & Drawing NumberingDocument8 pagesDrawing List - Design & Drawing NumberingghansaNo ratings yet

- PC04 DMRC Ceg DBR 001 R0Document46 pagesPC04 DMRC Ceg DBR 001 R0ghansaNo ratings yet

- Drawing List - Design & Drawing Numbering-DANAPUR STATIONDocument1 pageDrawing List - Design & Drawing Numbering-DANAPUR STATIONghansaNo ratings yet

- 7.7.1 Shear Transfer Check at Roof Slab & D WallDocument4 pages7.7.1 Shear Transfer Check at Roof Slab & D WallghansaNo ratings yet

- DeflectionDocument22 pagesDeflectionrobertantoreniNo ratings yet

- Overturning Moment Due To Earth PressureDocument2 pagesOverturning Moment Due To Earth PressureghansaNo ratings yet

- GENERAL ARRANGEMENT LOADING & UNLOADING GANTRY FOR DAY TANKS - B-198-M1-115-Rev.1 - 27-9-2021Document1 pageGENERAL ARRANGEMENT LOADING & UNLOADING GANTRY FOR DAY TANKS - B-198-M1-115-Rev.1 - 27-9-2021ghansaNo ratings yet

- Hypo Building-Fdn DWG Sheet 1 of 6-r1Document1 pageHypo Building-Fdn DWG Sheet 1 of 6-r1ghansaNo ratings yet