Professional Documents

Culture Documents

7.7.1 Shear Transfer Check at Roof Slab & D Wall

Uploaded by

ghansaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7.7.1 Shear Transfer Check at Roof Slab & D Wall

Uploaded by

ghansaCopyright:

Available Formats

KNPCC-05-Design and Construction of Tunnel from start of elevated ramp (after Motijheel Station) to

end of Nayaganj station including four underground metro stations (viz. Chunniganj, Naveen Market,

Bada Chauraha and Nayaganj) and ramp including Architectural finishes, E&M, TVS, ECS etc. on

Corridor-1 of Kanpur MRTS Project at Kanpur, Uttar Pradesh, India

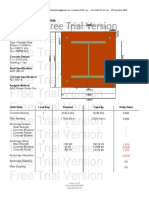

7.7.1 SHEAR TRANSFER CHECK AT ROOF SLAB & D WALL

Beam L/C Node Fx kN Fy kN Fz kN Mx kNm My kNm Mz kNm

Max Fx 2107 2101 239 957 1207 0 0 0 3492

Min Fx 2107 2004 239 483 572 0 0 0 1631

Max Fy 2107 2107 239 950 1209 0 0 0 3510

Min Fy 2107 14009 241 601 364 0 0 0 -50

Max Fz 2107 2001 239 495 572 0 0 0 1636

Min Fz 2107 2001 239 495 572 0 0 0 1636

Max Mx 2107 2001 239 495 572 0 0 0 1636

Min Mx 2107 2001 239 495 572 0 0 0 1636

Max My 2107 2001 239 495 572 0 0 0 1636

Min My 2107 2001 239 495 572 0 0 0 1636

Max Mz 2107 2107 239 950 1209 0 0 0 3510

Min Mz 2107 14009 241 601 364 0 0 0 -50

Max factored shear to be transferred at D

wall-Roof slab junction

Vu = 1209 KN/m

This shear shall be transferred through bearing, yeilding of coupler bars and friction between concrete surfaces

SHEAR TRANSFER CHECKS/Mu-data

KNPCC-05-Design and Construction of Tunnel from start of elevated ramp (after Motijheel Station) to

end of Nayaganj station including four underground metro stations (viz. Chunniganj, Naveen Market,

Bada Chauraha and Nayaganj) and ramp including Architectural finishes, E&M, TVS, ECS etc. on

Corridor-1 of Kanpur MRTS Project at Kanpur, Uttar Pradesh, India

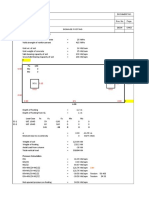

F1: Transfer of shear through bearing

Bearing area in D wall = 1000x75 mm2

= 75000 mm2

Allowable bearing stress = 0.45fck

= 0.45x40 Mpa

= 18 MPa

so, F1 = 1350000 N

= 1350 KN

F2: Transfer of shear through yielding of coupler bars

Ast provided = 7552 mm2 (Refer coupler design)

Ast required = 4847 mm2 (Refer coupler design)

Stress in provided steel = Ast required x0.87X500/Ast provided

279 mm2

Stress strength remaining for = 156 Mpa

yielding

Hence F2 = Ast provided x 156

= 1176675 N

1176.675 KN

F3: Transfer through friction

Coupler have been designed for pure bending

hence Tension in section = Compression due bending

Tension = Compression = Ast req x 0.87x500

= 2108445 N

Friction coef. Between = 0.5

concerte surfaces

Hence F3 = 1054222.5 N

= 1054.2225 KN

Therefore total available strength = F1+F2+F3

F = 3580.8975 KN

FOS = F/Vu

= 3.0 Safe

SHEAR TRANSFER CHECKS/Mu-data

KNPCC-05-Design and Construction of Tunnel from start of elevated ramp (after Motijheel Station) to

end of Nayaganj station including four underground metro stations (viz. Chunniganj, Naveen Market,

Bada Chauraha and Nayaganj) and ramp including Architectural finishes, E&M, TVS, ECS etc. on

Corridor-1 of Kanpur MRTS Project at Kanpur, Uttar Pradesh, India

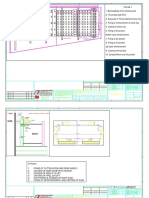

7.7.2 SHEAR TRANSFER CHECK AT CONCOURSE SLAB & D WALL

Beam L/C Node Fx kN Fy kN Fz kN Mx kNm My kNm Mz kNm

Max Fx 59 2206 53 1269 232 0 0 0 469

Min Fx 59 2109 53 -465 235 0 0 0 128

Max Fy 59 2007 53 377 290 0 0 0 427

Min Fy 59 14011 149 480 -25 0 0 0 -445

Max Fz 59 2001 53 403 32 0 0 0 -133

Min Fz 59 2001 53 403 32 0 0 0 -133

Max Mx 59 2001 53 403 32 0 0 0 -133

Min Mx 59 2001 53 403 32 0 0 0 -133

Max My 59 2001 53 403 32 0 0 0 -133

Min My 59 2001 53 403 32 0 0 0 -133

Max Mz 59 14040 53 190 228 0 0 0 759

Min Mz 59 14007 149 304 -17 0 0 0 -458

Max factored shear to be transferred

Vu = 290 KN/m

This shear shall be transferred through bearing, yeilding of coupler bars and friction between concrete surfaces

SHEAR TRANSFER CHECKS/Mu-data

KNPCC-05-Design and Construction of Tunnel from start of elevated ramp (after Motijheel Station) to

end of Nayaganj station including four underground metro stations (viz. Chunniganj, Naveen Market,

Bada Chauraha and Nayaganj) and ramp including Architectural finishes, E&M, TVS, ECS etc. on

Corridor-1 of Kanpur MRTS Project at Kanpur, Uttar Pradesh, India

F1: Transfer of shear through bearing

Bearing area in D wall = 700x50 mm2

= 35000 mm2

Allowable bearing stress = 0.45fck

= 0.45x40 Mpa

= 18 MPa

so, F1 = 630000 N

= 630 KN

F2: Transfer of shear through yielding of coupler bars

Ast provided = 6187 mm2 (Refer coupler design)

Ast required = 3487 mm2 (Refer coupler design)

Stress in provided steel = Ast required x0.87X500/Ast provided

245 mm2

Stress strength remaining for = 190 Mpa

yielding

Hence F2 = Ast provided x190

= 1174500 N

1174.5 KN

F3: Transfer through friction

Coupler have been designed for pure bending

hence Tension in section = Compression due bending

Tension = Compression = Ast req x 0.87x500

= 1516845 N

Friction coef. Between = 0.5

concerte surfaces

Hence F3 = 758422.5 N

= 758.4225 KN

Therefore total available strength = F1+F2+F3

F = 2562.9225 KN

FOS = F/Vu

= 8.8 Safe

SHEAR TRANSFER CHECKS/Mu-data

You might also like

- Introduction To Microelectronic Fabrication PDFDocument332 pagesIntroduction To Microelectronic Fabrication PDFChristy Moore92% (13)

- Off Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesDocument1 pageOff Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesFadi Ramadan100% (1)

- Column DesignDocument6 pagesColumn DesignKenneth CajefeNo ratings yet

- Ce133p-2 Working Stress DesignDocument29 pagesCe133p-2 Working Stress Designo100% (1)

- Column Beam Joint Check Validation Document - IS 13920-2016 PDFDocument30 pagesColumn Beam Joint Check Validation Document - IS 13920-2016 PDFompoc123No ratings yet

- COMBINED FOOTING ExcelDocument15 pagesCOMBINED FOOTING Excelyedida viswanadh100% (1)

- Final LUS EvaluationDocument36 pagesFinal LUS EvaluationNextgenNo ratings yet

- Flexural Capacity Check of PSC Box at L/2:-: Concrete Crushes Before Steel Strain Reaches To LimitDocument2 pagesFlexural Capacity Check of PSC Box at L/2:-: Concrete Crushes Before Steel Strain Reaches To LimitSachin DalalNo ratings yet

- Concrete Column DesignDocument2 pagesConcrete Column Designheherson juanNo ratings yet

- Raft DesignDocument14 pagesRaft DesignGautham AllimuthuNo ratings yet

- PILE FDN DESIGN For NMD TOWERDocument12 pagesPILE FDN DESIGN For NMD TOWERraj mNo ratings yet

- Base PlateDocument15 pagesBase PlatemaheshbandhamNo ratings yet

- Concrete Column DesignDocument2 pagesConcrete Column DesignGandhi HammoudNo ratings yet

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- XX2 PDFDocument3 pagesXX2 PDFgarysootetNo ratings yet

- Rawlplug-HPTIIZF-20160 23122022Document7 pagesRawlplug-HPTIIZF-20160 23122022Freddie KooNo ratings yet

- 1.deck SlabDocument3 pages1.deck SlabvibishnanNo ratings yet

- Tower Crane Foundation Design: Structural Design Report Prepared by Edifice Consultants PVT - LTDDocument15 pagesTower Crane Foundation Design: Structural Design Report Prepared by Edifice Consultants PVT - LTDkkgcNo ratings yet

- Catalog Motor EC90Flat 323772Document1 pageCatalog Motor EC90Flat 323772Lucas SuplinoNo ratings yet

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- Modification of Plot-279: Valid DesignDocument1 pageModification of Plot-279: Valid Designmukim0201004No ratings yet

- Concrete Column DesignDocument2 pagesConcrete Column Designheherson juanNo ratings yet

- Spreadsheets To BS 8110: Combined BaseDocument1 pageSpreadsheets To BS 8110: Combined BasemohammedNo ratings yet

- Elevator Wall 1Document588 pagesElevator Wall 1kanokoNo ratings yet

- 2-Col Bent On Bored PilesDocument17 pages2-Col Bent On Bored PilesabdurehimNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKSanjeev SanjeevNo ratings yet

- Deisel Tank AreaDocument21 pagesDeisel Tank AreaJanaka KarunarathnaNo ratings yet

- SlabDocument621 pagesSlabkanokoNo ratings yet

- Prokon - 6BDocument7 pagesProkon - 6BAzfarNo ratings yet

- Beam and Slab Type Combined FootingDocument6 pagesBeam and Slab Type Combined FootingAlphyl BalasabasNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)ery achjariNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UR6WTN2QF4XGQ2Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1UR6WTN2QF4XGQ2Samir RawatNo ratings yet

- 2-Col Bent On Bored PilesDocument17 pages2-Col Bent On Bored PileszxcNo ratings yet

- Foundation BoltDocument2 pagesFoundation BoltAnand N.B.No ratings yet

- 001 R0 RNT Design of Closed PortionDocument37 pages001 R0 RNT Design of Closed PortionrohanZorbaNo ratings yet

- 2-Col Bent On Bored PilesDocument29 pages2-Col Bent On Bored PilesHenry DiyokeNo ratings yet

- Design of Bearing For Beam B21: y X CK CKDocument7 pagesDesign of Bearing For Beam B21: y X CK CKMahadev D. BhandareNo ratings yet

- Foundation Design Joint Pit - R0Document29 pagesFoundation Design Joint Pit - R0ilham akbarNo ratings yet

- Combined Footing For TwoDocument15 pagesCombined Footing For Twoer.praveenraj30No ratings yet

- Corner ColumnDocument12 pagesCorner ColumnKelvine IjejiNo ratings yet

- Design of Water Tank Structural Design CalculationsDocument3 pagesDesign of Water Tank Structural Design CalculationsUzziel Abib GabiolaNo ratings yet

- Proposed Residential Development, Ruaka: Vemech Enterprises Critical Ground Floor Column, 300 X 300 5Document1 pageProposed Residential Development, Ruaka: Vemech Enterprises Critical Ground Floor Column, 300 X 300 5Kagwi MauriceNo ratings yet

- 29 - Monorail 800 2007Document7 pages29 - Monorail 800 2007Powerhouse ShaftNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Murthy GunaNo ratings yet

- Prokon - P1a - SeismicDocument5 pagesProkon - P1a - SeismicBrielle Ekira BermudezNo ratings yet

- EC - Pilegroup - BLK 226A - PC4F - 14HW31ZDocument2 pagesEC - Pilegroup - BLK 226A - PC4F - 14HW31ZJONHCENA13No ratings yet

- Design Calculation of Spherical MSM Fixed Bearing - 319 MTDocument7 pagesDesign Calculation of Spherical MSM Fixed Bearing - 319 MTChandan VatsNo ratings yet

- Pressure Table-Nvk Portion IsolatedDocument42 pagesPressure Table-Nvk Portion IsolatedVasanthakumarNo ratings yet

- Ribbed Slab Design-1Document2 pagesRibbed Slab Design-1HAITHAM ALI100% (2)

- Aisc360 Box Steel DesignDocument3 pagesAisc360 Box Steel DesignHattori HanzoNo ratings yet

- AISC360 Round Filled Composite MemberDocument2 pagesAISC360 Round Filled Composite MemberHattori HanzoNo ratings yet

- Analysis of Bush Bearing Using Ansys 11Document5 pagesAnalysis of Bush Bearing Using Ansys 11engineersaabNo ratings yet

- Anchor Bolt Design (AISC) - Tt100Document2 pagesAnchor Bolt Design (AISC) - Tt100Jennifer HudsonNo ratings yet

- Core Wall DesignDocument10 pagesCore Wall Designhala_azhari50% (2)

- Pile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterDocument22 pagesPile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterShuvam SarkarNo ratings yet

- LN2 SYNC REVIEW OF FLEXURAL ANALYSIS OF BEAMS - PART 1 MarkedDocument10 pagesLN2 SYNC REVIEW OF FLEXURAL ANALYSIS OF BEAMS - PART 1 MarkedRalph Denver RomanoNo ratings yet

- Example 2 To Start ExplainationDocument8 pagesExample 2 To Start ExplainationsamehNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)RalfNo ratings yet

- Diaphragms For Gravity Loads (AASHTO)Document14 pagesDiaphragms For Gravity Loads (AASHTO)FAIZAN AHMEDNo ratings yet

- MOS Integrated Circuit DesignFrom EverandMOS Integrated Circuit DesignE. WolfendaleNo ratings yet

- Comments P020c30ug01prb Dras Civstrdwg 10032 03 ADocument1 pageComments P020c30ug01prb Dras Civstrdwg 10032 03 AghansaNo ratings yet

- Sustainability 13 02733Document12 pagesSustainability 13 02733ghansaNo ratings yet

- D-EUGP1-TPT-F-LCS-CST-FWG-1106 - R2 - Concourse-1 - Part PlanDocument1 pageD-EUGP1-TPT-F-LCS-CST-FWG-1106 - R2 - Concourse-1 - Part PlanghansaNo ratings yet

- Secant Pile ReinforcementDocument8 pagesSecant Pile ReinforcementghansaNo ratings yet

- Labeshwar Chowk Station MDLDocument116 pagesLabeshwar Chowk Station MDLghansaNo ratings yet

- D Eugp1 TPT F KPS CST FWG 1103 R0Document1 pageD Eugp1 TPT F KPS CST FWG 1103 R0ghansaNo ratings yet

- 00202-M-3-008a-B-R0 - Supporting A&d of Agitator Crude Pac Tank (A-002 A, B) PDFDocument1 page00202-M-3-008a-B-R0 - Supporting A&d of Agitator Crude Pac Tank (A-002 A, B) PDFghansaNo ratings yet

- Final Case B - On Permanent Base SlabDocument1 pageFinal Case B - On Permanent Base SlabghansaNo ratings yet

- Kolkata Construction Drawings PDFDocument4 pagesKolkata Construction Drawings PDFghansaNo ratings yet

- 04 Settlement PDFDocument1 page04 Settlement PDFghansaNo ratings yet

- Case A - On Temporary Base SlabDocument1 pageCase A - On Temporary Base SlabghansaNo ratings yet

- Indicative FQP-for Structural SteelDocument14 pagesIndicative FQP-for Structural SteelghansaNo ratings yet

- Floatation PDFDocument6 pagesFloatation PDFghansaNo ratings yet

- 05 - 02 - Nashrullaganj - Soil Investigation Report STPDocument66 pages05 - 02 - Nashrullaganj - Soil Investigation Report STPghansaNo ratings yet

- Design Calculation Report For CCT Tank: TitleDocument1 pageDesign Calculation Report For CCT Tank: TitleghansaNo ratings yet

- PC04 DMRC Ceg DBR 001 R0Document46 pagesPC04 DMRC Ceg DBR 001 R0ghansaNo ratings yet

- Arch Bridge Code-ACS-8 PDFDocument8 pagesArch Bridge Code-ACS-8 PDFshobhit mohtaNo ratings yet

- IS 9012 (1978) - Recommended Practice For Shotcreting PDFDocument24 pagesIS 9012 (1978) - Recommended Practice For Shotcreting PDFdeepak925No ratings yet

- Design Calculation Report For CCT Tank: TitleDocument15 pagesDesign Calculation Report For CCT Tank: TitleghansaNo ratings yet

- Staging MJ RUB 5Document6 pagesStaging MJ RUB 5ghansaNo ratings yet

- Pile DesignDocument32 pagesPile DesignghansaNo ratings yet

- PC04 DMRC Ceg DBR 001 R0Document46 pagesPC04 DMRC Ceg DBR 001 R0ghansaNo ratings yet

- (For 0-2.5m Soil) (For 2.5-21m Soil) (For 2.5-21m Soil) (For Soil 2.5m To 21m) (For Soil 21m To 40)Document4 pages(For 0-2.5m Soil) (For 2.5-21m Soil) (For 2.5-21m Soil) (For Soil 2.5m To 21m) (For Soil 21m To 40)ghansaNo ratings yet

- DeflectionDocument22 pagesDeflectionrobertantoreniNo ratings yet

- Drawing List - Design & Drawing NumberingDocument8 pagesDrawing List - Design & Drawing NumberingghansaNo ratings yet

- Drawing List - Design & Drawing Numbering-DANAPUR STATIONDocument1 pageDrawing List - Design & Drawing Numbering-DANAPUR STATIONghansaNo ratings yet

- Hypo Building-Fdn DWG Sheet 1 of 6-r1Document1 pageHypo Building-Fdn DWG Sheet 1 of 6-r1ghansaNo ratings yet

- Overturning Moment Due To Earth PressureDocument2 pagesOverturning Moment Due To Earth PressureghansaNo ratings yet

- GENERAL ARRANGEMENT LOADING & UNLOADING GANTRY FOR DAY TANKS - B-198-M1-115-Rev.1 - 27-9-2021Document1 pageGENERAL ARRANGEMENT LOADING & UNLOADING GANTRY FOR DAY TANKS - B-198-M1-115-Rev.1 - 27-9-2021ghansaNo ratings yet

- FIGMADocument22 pagesFIGMACessNo ratings yet

- Economics - Economics - Cheat - SheetDocument1 pageEconomics - Economics - Cheat - SheetranaurNo ratings yet

- Very Hungry Caterpillar Clip CardsDocument5 pagesVery Hungry Caterpillar Clip CardsARTGRAVETO ARTNo ratings yet

- V13 D03 1 PDFDocument45 pagesV13 D03 1 PDFFredy Camayo De La CruzNo ratings yet

- Module 5Document14 pagesModule 5shin roseNo ratings yet

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasNo ratings yet

- Carbohydrates StainsDocument43 pagesCarbohydrates StainssupahvyNo ratings yet

- Embedded Software Development ProcessDocument34 pagesEmbedded Software Development ProcessAmmar YounasNo ratings yet

- IoT Security Checklist Web 10 17 r1Document39 pagesIoT Security Checklist Web 10 17 r1SubinNo ratings yet

- Week 3 Alds 2202Document13 pagesWeek 3 Alds 2202lauren michaelsNo ratings yet

- Sistemas de Mando CST Cat (Ing)Document12 pagesSistemas de Mando CST Cat (Ing)Carlos Alfredo LauraNo ratings yet

- Construction Claims and Contract Admin CPDDocument40 pagesConstruction Claims and Contract Admin CPDCraig FawcettNo ratings yet

- The Philippine GovernmentDocument21 pagesThe Philippine GovernmentChristel ChuchipNo ratings yet

- 3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideDocument6 pages3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideYuukinoriNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentAditya ShanbhagNo ratings yet

- All About TarlacDocument12 pagesAll About TarlacAnonymous uLb5vOjXNo ratings yet

- S4 Computer Sciences Exercises PDFDocument2 pagesS4 Computer Sciences Exercises PDFHenriette Desanges UwayoNo ratings yet

- Introduction: Meaning of HypothesisDocument8 pagesIntroduction: Meaning of HypothesisMANISH KUMARNo ratings yet

- PV Power To Methane: Draft Assignment 2Document13 pagesPV Power To Methane: Draft Assignment 2Ardiansyah ARNo ratings yet

- Fellows (Antiques)Document90 pagesFellows (Antiques)messapos100% (1)

- A Vocabulary of Latin Nouns and AdnounsDocument129 pagesA Vocabulary of Latin Nouns and Adnounsthersitesslaughter-1No ratings yet

- Group Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanDocument18 pagesGroup Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanNurul Hana BalqisNo ratings yet

- Uniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFDocument64 pagesUniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFtradosevic4091No ratings yet

- Product Handbook Arendal 1961 Series SubwoofersDocument44 pagesProduct Handbook Arendal 1961 Series SubwoofersDomagoj KovacevicNo ratings yet

- Questions 1 To 3 Are Based On The Following TextDocument7 pagesQuestions 1 To 3 Are Based On The Following TextHokage KumNo ratings yet

- Essay On Stem CellsDocument4 pagesEssay On Stem CellsAdrien G. S. WaldNo ratings yet

- Zillah P. Curato: ObjectiveDocument1 pageZillah P. Curato: ObjectiveZillah CuratoNo ratings yet