Professional Documents

Culture Documents

Ficha Tecnica de 5ELEM - Manguera Poliester UL FM

Uploaded by

JONY ROBERT SILVA AGUILAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica de 5ELEM - Manguera Poliester UL FM

Uploaded by

JONY ROBERT SILVA AGUILARCopyright:

Available Formats

Jiangyan Factory Shanghai Office

Machang Road, Jiangyan Economic Development Zone, Floor 1, Building 15, No. 481 Guiping Rd.

Jiangsu, China 225500 Caohejing Hi-Tech Park, Xuhui District,

Tel: +86-0523-88811133/7755 Shanghai, 200233, China

5Elem Hi-Tech Corporation Fax: +86-0523-88818855 Tel: +86-21-64907271

www.5elem.com www.chinafire.com Fax: +86-21-64901786

Flow Delivery Expert

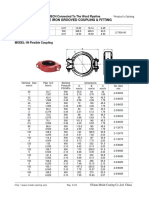

Datasheet of 5ELEM UL&FM Rack Hose - RBX series

Certificate Construction

TPU (Polyurethane)

Color: Transparent

& Polyester Single Jacket

Color: White or on request

* PU coating on request

Technical Characteristics

Item Φ 1-1/2" Features & Performace

Warp (Polyester Filament) ◎ Its jacket is woven evenly by high-tensity filament

Single Jacket Polyester as weft and warp, and shall be free of

Fabric defects, including knots, lumps, or unsightly

Weft (Polyester Filament) disfigurements that could jeopardize the integrity of

Jacket

the hose assembly.

Weft Density (picks/10cm) 54

Weaving Method (circular loom) Plain Woven ◎ Its lining is a single-ply extruded tube of TPU

compound, tightly adhered to the jacket to prevent

from delamination, which provides much better

Lining Material TPU resistance to punctures, mildew, solvents, and

aging compared to conventional rubber lined hose.

Lining Thickness (mm) 0.38±0.03

Lining Adhesion (under a force of 56N) <38mm/min ◎ It is certified by FM & UL both, with FM approval

No. 5ERR15-500FF, UL approval No.EX15595.

Both standards are observed in production and

Internal diameter (mm) 41 ± 1.0 assembly of this kind of hose to insure quality and

durability. All of our products are manufactured

Mass w/out couplings (g/m) 136 under the management system of ISO 9001:2015.

Mass w/out couplings (as per 100ft) 4.15kgs

◎ Performace remains at the temperature from -40℃

Max. Working Pressure (psi) 250 to 70℃.

Proof Test Pressure (psi) 500

◎ Available to assembled with Aluminum/Bronze

NST/NPSH threaded expansion ring coupling or

Burst Pressure (psi) 750 Aluminium quarter-turn couplings, forged couplings

with hard coating is recommended.

Pessure Loss due to friction (psi/m) ≤ 0.18

180 LPM flowing

Elongation Rate (%) ≤8

Dilatation Rate (%) ≤5

You might also like

- VK514 (k28)Document6 pagesVK514 (k28)carlos yepezNo ratings yet

- Safety Engineering: 1-1/2" BS 336 MaleDocument12 pagesSafety Engineering: 1-1/2" BS 336 Malewalid kawsarNo ratings yet

- Test & Drain TechDataDocument1 pageTest & Drain TechDatajhoger2012No ratings yet

- Rociador Cobertura Extendida k8.0Document6 pagesRociador Cobertura Extendida k8.0Anthony OneillNo ratings yet

- 5elem Lona - 250psi - Listada PDFDocument1 page5elem Lona - 250psi - Listada PDFChristian Ricra100% (1)

- FA 106R DatasheetDocument2 pagesFA 106R DatasheetPablo Jesús Huapaya ChumpitazNo ratings yet

- Manual Instalacion Detector de Humo EdwardsDocument2 pagesManual Instalacion Detector de Humo EdwardsMatiasNo ratings yet

- Ficha Técnica - FPPI - Val 3 Vías PDFDocument2 pagesFicha Técnica - FPPI - Val 3 Vías PDFDaniel AlvarezNo ratings yet

- Om Manual C0179439 PDFDocument154 pagesOm Manual C0179439 PDFAle AleNo ratings yet

- Ficha Tecnica Accesorios MechDocument40 pagesFicha Tecnica Accesorios MechTommylee golden retriever100% (1)

- Curva TD10E - 500GPMDocument2 pagesCurva TD10E - 500GPMElvis DiazNo ratings yet

- Aries Netlink™ Configuration Tool (ACT8000) : User's GuideDocument178 pagesAries Netlink™ Configuration Tool (ACT8000) : User's GuideGilberto GuerreroNo ratings yet

- Bomba Proteccion Contra IncendioDocument9 pagesBomba Proteccion Contra IncendioYairton Vargas MuñozNo ratings yet

- Manual GST-M200Document2 pagesManual GST-M200Mauricio Fuentes Abarzua100% (1)

- Photoelectric Smoke Detectors Mir-338 Series: FeaturesDocument2 pagesPhotoelectric Smoke Detectors Mir-338 Series: FeaturesCesar MuñozNo ratings yet

- Aftk 25 ChartDocument1 pageAftk 25 ChartDiego Francisco Ancajima CuevaNo ratings yet

- Maintenance Schedule Checklist: Check and Correct As NecessaryDocument1 pageMaintenance Schedule Checklist: Check and Correct As NecessaryLeonardo RamirezNo ratings yet

- Engine Model Alternator Model LL2014H Engine Build: 1104D-44TG3 RGDocument2 pagesEngine Model Alternator Model LL2014H Engine Build: 1104D-44TG3 RGIbrahim AwadNo ratings yet

- Cámara de Espuma - Certificado UL PDFDocument3 pagesCámara de Espuma - Certificado UL PDFvivicastedoNo ratings yet

- 84-878752-010 Suppression System AbortDocument2 pages84-878752-010 Suppression System AbortAlexander TiopanNo ratings yet

- Bases Detector NOTIFIER B501Document2 pagesBases Detector NOTIFIER B501Tai KucingNo ratings yet

- 06 356 2Document128 pages06 356 2Jaime Eduardo Bolaños RaadNo ratings yet

- Ficha Tecnica Cable TeldorDocument2 pagesFicha Tecnica Cable TeldorRafael Enrique GonzalezNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidAntonio ChavezNo ratings yet

- Manual de Servicios Simplex 4010Document72 pagesManual de Servicios Simplex 4010Eduardo MegoNo ratings yet

- Ficha Tecnica Motobomba 1500gpm@150psiDocument2 pagesFicha Tecnica Motobomba 1500gpm@150psiPercy Valdera GuerreroNo ratings yet

- Tuberia Hdpe FM IscoDocument13 pagesTuberia Hdpe FM IscoJose Alonso AguilarNo ratings yet

- Cylinder Fm200 AllDocument56 pagesCylinder Fm200 Allwiwiqi100% (1)

- Curva e Info Tecnica de La Bomba PDFDocument8 pagesCurva e Info Tecnica de La Bomba PDFfelix uscangaNo ratings yet

- Panel de Control XLS200Document2 pagesPanel de Control XLS200Carlos AlbertoNo ratings yet

- Transmisor Indicador de Presion - Microcyber NCS-PT105 II DPDocument6 pagesTransmisor Indicador de Presion - Microcyber NCS-PT105 II DPAnonymous E4y5Pw1dOCNo ratings yet

- Notifier FRM 1 Relay Control Module PDFDocument2 pagesNotifier FRM 1 Relay Control Module PDFFRANKNo ratings yet

- L-Series Horns Strobes HornStorbes Wall PDFDocument4 pagesL-Series Horns Strobes HornStorbes Wall PDFAlhexander ValegaNo ratings yet

- Ansul: System ComponentsDocument1 pageAnsul: System ComponentsingjfhpNo ratings yet

- FMM - 4-20ma I56-2991-002Document2 pagesFMM - 4-20ma I56-2991-002Elias RangelNo ratings yet

- AAMI NFPA-99 - Hospital PDFDocument3 pagesAAMI NFPA-99 - Hospital PDFSusilo Ari WibowoNo ratings yet

- Eaton - FD120 Diesel Engine Fire Pump ControllerDocument2 pagesEaton - FD120 Diesel Engine Fire Pump ControllerAlejandro Chumpitaz MarchanNo ratings yet

- LPG Inert 2019 Sapphire PlusDocument8 pagesLPG Inert 2019 Sapphire PluskidmuNo ratings yet

- EMVcatalogApr13LR PDFDocument32 pagesEMVcatalogApr13LR PDFfirda8587No ratings yet

- FMDS0823Document31 pagesFMDS0823Diego MosoNo ratings yet

- FM Patterson Driveshaft IOMDocument22 pagesFM Patterson Driveshaft IOMeaywdjw2070No ratings yet

- Foam Liquid Concentrates - Ul Product Iq SolbergDocument15 pagesFoam Liquid Concentrates - Ul Product Iq SolbergLuis Alberto Serrano MesaNo ratings yet

- Manual Programación Edwards Vigilant VS-2 Fire Alarm Control PanelDocument365 pagesManual Programación Edwards Vigilant VS-2 Fire Alarm Control Panelvizion2k4No ratings yet

- KFS ECS FM-200 Software ManualDocument62 pagesKFS ECS FM-200 Software Manualgalandar1356No ratings yet

- Pentax Bombas 50hz GC Rev 34Document520 pagesPentax Bombas 50hz GC Rev 34Fabiola barriosNo ratings yet

- X Ls 200 System SpecificationsDocument4 pagesX Ls 200 System SpecificationsCarlos AlbertoNo ratings yet

- Diametro de Tuberias NTP - 399.006 - 2003Document1 pageDiametro de Tuberias NTP - 399.006 - 2003Frank CruzNo ratings yet

- Ultrasonic Level Transmitter: AREA: 3510Document9 pagesUltrasonic Level Transmitter: AREA: 3510JHONATAN RODRIGUEZ VENTONo ratings yet

- 06 369 CheetahXi 50 Install Manual Rev 6Document76 pages06 369 CheetahXi 50 Install Manual Rev 6victor sagastumeNo ratings yet

- SIGA SB Detector Base Installation SheetDocument2 pagesSIGA SB Detector Base Installation SheetAlberyt099100% (1)

- EST QS1 v2.0 Technical Reference Manual PDFDocument126 pagesEST QS1 v2.0 Technical Reference Manual PDFDaniel GarridoNo ratings yet

- Manual de Mantenimiento y Operacion AriesDocument296 pagesManual de Mantenimiento y Operacion AriesJaime Eduardo Bolaños RaadNo ratings yet

- Kidde Aegis ManualDocument90 pagesKidde Aegis ManualAgustin Rosas100% (1)

- Operation Manual: High Pressure Water-Based Mist Fire Fighting SystemDocument44 pagesOperation Manual: High Pressure Water-Based Mist Fire Fighting SystemBARIS BILMEZ50% (2)

- Pqs BC 150 Lbs Con Ruedas MODELO 150-CDocument4 pagesPqs BC 150 Lbs Con Ruedas MODELO 150-CtremendousNo ratings yet

- Mangueras Contra Incendio-5elem RBX Series Ul-FmDocument1 pageMangueras Contra Incendio-5elem RBX Series Ul-Fmjhoger2012No ratings yet

- 【Hail Netting】-Technical DATA SHEET - Raschel -TriangleDocument1 page【Hail Netting】-Technical DATA SHEET - Raschel -TriangleVipul AgrawalNo ratings yet

- Cold Room Panel Specification and DataDocument9 pagesCold Room Panel Specification and DataRobert R. TiinNo ratings yet

- DF EspumaDocument1 pageDF EspumaAndre MoutelaNo ratings yet

- UL 521 SUN Rev 7 1 2019 ED 7 1 2021Document2 pagesUL 521 SUN Rev 7 1 2019 ED 7 1 2021JONY ROBERT SILVA AGUILARNo ratings yet

- Mech Acople Flexible Mod 1nDocument1 pageMech Acople Flexible Mod 1nJONY ROBERT SILVA AGUILARNo ratings yet

- Silent Knight SK Brand Overview - 070207Document33 pagesSilent Knight SK Brand Overview - 070207JONY ROBERT SILVA AGUILARNo ratings yet

- A7B Standard Equipment: (Technical Communication N° A-033)Document3 pagesA7B Standard Equipment: (Technical Communication N° A-033)JONY ROBERT SILVA AGUILARNo ratings yet

- JTPR Acople FlexDocument1 pageJTPR Acople FlexJONY ROBERT SILVA AGUILARNo ratings yet

- FLOWCOM Colgador Gota y ClevisDocument4 pagesFLOWCOM Colgador Gota y ClevisJONY ROBERT SILVA AGUILARNo ratings yet

- Acople Flexible DLDocument1 pageAcople Flexible DLJONY ROBERT SILVA AGUILARNo ratings yet

- Brochure - Modular Front Patching SystemDocument8 pagesBrochure - Modular Front Patching SystemJONY ROBERT SILVA AGUILARNo ratings yet

- Ishihara Test For Color BlindnessDocument5 pagesIshihara Test For Color BlindnessAnupama NagrajNo ratings yet

- Yarn Consumption + Costing CalculationDocument113 pagesYarn Consumption + Costing CalculationSALIMNo ratings yet

- Shostakovich Jazz Waltz 2 OrchestraDocument11 pagesShostakovich Jazz Waltz 2 OrchestraLi XianjiNo ratings yet

- Badura Skoda MozartDocument28 pagesBadura Skoda MozartDarioZanconi75% (8)

- Acta Hyperborea 12 2009-LibreDocument32 pagesActa Hyperborea 12 2009-LibreGermanikNo ratings yet

- Local Arts in Bulacan: Pabalat Puni Arts Buntal Waving Singkaban CapizDocument15 pagesLocal Arts in Bulacan: Pabalat Puni Arts Buntal Waving Singkaban Capizmylene castilloNo ratings yet

- Archaeological Sites in TaxilaDocument5 pagesArchaeological Sites in TaxilaLaraibmalik 674No ratings yet

- History of Arts ReportDocument30 pagesHistory of Arts ReportLakan Magiting Bayot BatiNo ratings yet

- Olympic Games Team ChartDocument4 pagesOlympic Games Team ChartAesha TaliaNo ratings yet

- Summary of Kinney, Introduction To 'Cambridge Companion To English Literature, 1500-1600'Document2 pagesSummary of Kinney, Introduction To 'Cambridge Companion To English Literature, 1500-1600'emasumiyatNo ratings yet

- Grade 3: Exam Structure SongsDocument6 pagesGrade 3: Exam Structure SongsnadiahNo ratings yet

- The Sound of Stevie Wonder - His Words and Music, by James E. Perone.Document212 pagesThe Sound of Stevie Wonder - His Words and Music, by James E. Perone.Pedro78% (9)

- Stan Henning BioDocument3 pagesStan Henning Bio12ab34cd8969No ratings yet

- The Beginning of Modern ArchitectureDocument11 pagesThe Beginning of Modern ArchitectureChicken NoodlesNo ratings yet

- FINAL DEMO 2 FestivalDocument7 pagesFINAL DEMO 2 FestivalKelvin Pineda BernelNo ratings yet

- 4th Grading TLEDocument4 pages4th Grading TLEBalacan NHS Balanacan NHSNo ratings yet

- Contemporary Philippine Arts From The RegionsDocument19 pagesContemporary Philippine Arts From The RegionsWinstone PinedaNo ratings yet

- Gcse Film Studies Amelie - Lesson 1Document11 pagesGcse Film Studies Amelie - Lesson 1Koulla TheodoulouNo ratings yet

- Lou ReedDocument14 pagesLou Reeddon100% (1)

- Maya The Bee Willy Pattern: Designed by Vanja GrundmannDocument34 pagesMaya The Bee Willy Pattern: Designed by Vanja GrundmannVanessa Martínez SuárezNo ratings yet

- A Lovely Night: ModeratelyDocument15 pagesA Lovely Night: ModeratelyLily J. T. Nguyen0% (1)

- Artapp 02.BDocument106 pagesArtapp 02.BHahahahahahahahahaNo ratings yet

- Rhetorical Analysis Final Draft-5Document5 pagesRhetorical Analysis Final Draft-5api-549245914No ratings yet

- A Guide To The Paintings in The Florentine Galleries 1000128552Document330 pagesA Guide To The Paintings in The Florentine Galleries 1000128552José Rubio RuizNo ratings yet

- Autumn Leaves Improv StudyDocument14 pagesAutumn Leaves Improv StudyCezanne GarciaNo ratings yet

- Down BeatDocument99 pagesDown Beatslusar100% (1)

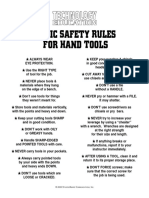

- Hand Tool SafetyDocument1 pageHand Tool SafetymardyNo ratings yet

- Amit Dixit (Raam Ji)Document4 pagesAmit Dixit (Raam Ji)SudhanshuMishraNo ratings yet

- IPO Definitions of Utility Model and Industrial DesignDocument2 pagesIPO Definitions of Utility Model and Industrial DesignArianne MarzanNo ratings yet

- Sewing Tools and Equipment: Lesson 1 Grade 8 LOYALTYDocument40 pagesSewing Tools and Equipment: Lesson 1 Grade 8 LOYALTYSusaly Danis100% (2)