Professional Documents

Culture Documents

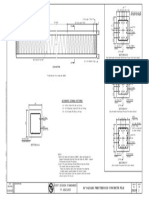

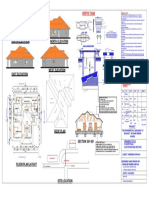

Typical Plan: Span

Uploaded by

Joem0989Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical Plan: Span

Uploaded by

Joem0989Copyright:

Available Formats

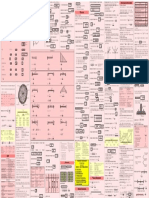

Note

"E "

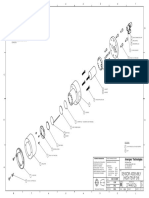

L Flare #4 transverse * Use staggered diaphragm beams when 0 < 65°. Provide 4 See Deck Plans for "FL"

Negative values for "F " End beam per

L conc. inserts in each girder web at each diaphragm beam

or "F " indicates that "FL" bars @ 18" max. � Span diaphragm beams project plans "EL" Pour this part of flange

R

ctrs. as required for exterior side of

corner of top slab extends

-0"

ange

beyond end of girder web. 2" dia. vent holes 1 2" exterior girders unless

2'

at diaphragm beams shown otherwise on

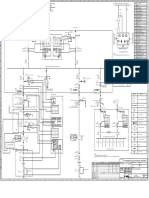

Girder min. #

fl

detail plans, typ. each end

6"

web

Type "a" spaces 0

6"

"ER" #4 "U" bars @ 12" max. ctrs. BI51 4 * Use in line diaphragm beams when 0 > 65°. Provide 4 "DL" "DR "

Chamfer corners when "ER"

each end of girder BI63 7 conc. inserts in exterior girder webs and 2" dia.

"FR " Negative Direction Positive Direction angle is less than 60° "F "

BI75 10 TYPICAL PLAN holes thru interior girder webs for 4-#6 x 5'-0" bars R � holes or inserts

6" 6"

2" 6@212" 9@4" "a" spaces @ 6" "b" spaces @ 12" 18" max. ctrs. 18" max. ctrs. 18" max. ctrs.

"D " and "D " = Girder spacing

L R

2 x tan 0

1'-3" #4 "U4" #4 "U4" stirrups #4 "U4" stirrups #4 "U4" stirrups (2 bars each stirrup, typ.) #4 "U4" stirrups #4"U4" stirrups

3"

7"

7-#5 "U5" stirrups each

end. Vary spacing to avoid Diaphragm �'s when 0 65°

11"

insert or hole locations

4"

1" dia. hole for cable restraint when 6" (typ.)

*CONCRETE INSERTS

4"

2-#5 x 4'-0" L-bars

Expanded coil concrete inserts with Alternate A restraint is used (typ.) 6" 6" 4-1" conc. inserts

(std. 90° hook) Strand c.g.

closed-back ferrule threaded to receive "x" = 0.50 girder depth (*) in exterior girder webs

1" dia. x 2'-3" rods, Gr36 (ASTM A307) and 4-2" dia. holes

4"

4"

threaded full length. thru int. girder webs for

51

6" to 2'-6" equal spacing

63

75

� dual hold downs

BI

-2" BI

-4" BI

4-#6 x 5'-0" bars

"x"

(deflected strands >14) Strand c.g. (unless shown otherwise,

"ye"

-4"

#4 "U" bars @ 12" max.

12"

on detail plans)

03-2017

ctrs. each end of girder

1'

1'

1'

� hold down

"yc"

� Bearing #3 "U3" bars Diaphragm �'s when 0 > 65° 812"

812" 0.4 Span Length (ctr. - ctr. bearing) ±2'-6"

2-#5 "U6" bars at

� Bearing

each end of girder Horizontal girder length "A" (add grade correction and estimated shortening allowance to "A" for fabrication length)

dgn

BACK END OF GIRDER Note AHEAD END OF GIRDER

(on stationing) Girder details are symmetrical (on stationing)

br300.

except as noted otherwise TYPICAL ELEVATION

514"

.

2'-0"

1"cl

Lower deflected strand Upper group contains

2-#5 cont.

group (14 max. except 16 deflected strands

614"

when the number of strands in excess of 14 unless

4-#6 cont.

7-#5 "U5" stirrups N is 58 or greater) shown otherwise

stagger splices

(2 bars each stirrup)

4"

2-#5 x 4'-0" L-bars Slant bars as

3"

o-o

2"

1

2" spacing

3

#4 "U1" bars @ 18" (std. 90° hook) required to fit

1'-10" 2" 3'-8" inside "U5" deflected

4"

134"

2" 3@ 1 4"=

stirrups strands at

2"

514"

BAR "U" midspan

3

4" 4"

6" web

(ASTM A706)

"yc"

c. g. strands

#4 "U4" stirrups

Note at midspan

51

63

1" min. cl.

75

(2 bars each stirrup)

912"

8"

3" 10"

-3" BI

-3" BI

Ensure ends of girders are vertical

-3"BI

unless shown 11"

7

when under full dead load unless

ected

strands @

otherwise (typ.) "hc" > 3" at midspan

758"

3

214" 4@134"=7" 1 4"

2"ctrs.

#3 "U3" bars shown otherwise on detail plans 1" (typ.)

4'

5'

6'

(#3 "U3a" bars

Defl

where deflected 2'-0" Chamfer soffit

312"

strands conflict) at 1'-10" BAR "U3a" corners 1" max.

each "U4" stirrup

9" BAR "U3" (Use in lieu of "U3" BULB DETAIL

and at alternate

c. g. strands bars when deflected

"he"

3"

"U5" stirrup

strands conflict).

"ye"

6"

6"

depth + 414"

2" dia. tight Accompanied by dwgs. BR350 and DET3305

See Bulb Detail 2-#5 "U6" bars at 2'-0" bend for #5

"m "

CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

each end of girder � Girder bars this bend only

rder

MIDSPAN SECTION Strand

6"

o-o

NOTE: All material and workmanship shall be in accordance with

END VIEW

Gi

the current Oregon Standard Specifications

4"

5'-0" DETENSIONING NOTE 8 1 2 7

The selection and use of this

Detension strands in a

9 3 10 1'-1" OREGON STANDARD DRAWINGS

4 Standard Drawing, while de-

BAR "U6" systematic order about o-o

END BLOCK NOTE girder � to limit 12 5 6 11 BAR "U4" or "U5" signed in accordance with BULB-I (PRECAST PRESTRESSED

When End Block is required, eccentricity. generally accepted engineer-

TYPICAL

see Girder Schedule for details CONCRETE GIRDERS)

BAR BENDING DETAILS ing principles and practices,

BR300

DETENSIONING ORDER

is the sole responsibility of

BULB-I GIRDER NOTES the user and should not be 2018

Girders designed for live loading and superimposed dead load as shown in the General Notes. Provide the class of concrete shown on the Girder Schedule.

used without consulting a DATE REVISION DESCRIPTION

Provide reinforcing steel as shown in the General Notes except as noted. Keep girders in an upright position with the support points - -

Provide12" dia. 7-wire low relaxation prestressing strands conforming to AASHTO within 2'-0" of the girder ends. Registered Professional En-

- -

M203 (ASTM A416), Grade 270, Supplement 1. Provide an initial tensioning (after harping Deflected strands may be bundled between hold down points. gineer. - -

Provide temporary diaphragm beams as required, see BR350. - -

deflected strands) of 31.0 kips per strand unless shown otherwise on the Girder Schedule.

- -

Effective Date:June 1, 2019 - November 30, 2019 BR300

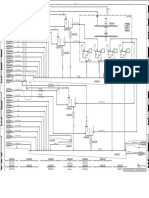

"FL"

End beam per project plans

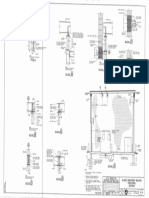

Note "EL" "EL"

Flare #3 transverse bars Use staggered diaphragm beams when

Negative values � Span See Deck Plans for "F "

0 < 65°. Provide 4 conc. inserts*in each

6"

@ 6" max. ctrs. as req'd L Pour this part of flange

diaphragm beams

-0"

for "FL" or "FR "

ange

girder web at each diaphragm beam. 1 2" for exterior side of

indicates that corner

4'

2" dia. vent holes exterior girders unless

fl

of top slab extends

web

shown otherwise on detail

6"

n.

Girder min. # at diaphragm beams. 0

beyond end of

12"

mi

plans, typ. each end

6"

girder web. "E " Type "a" spaces Use in line diaphragm beams when 0 > 65°. Provide 4

R

BT48 4 conc. inserts*in exterior girder webs and 2" dia. � holes or inserts

Chamfer corners when

#4 "U" bars @ 12" max. BT60 7 holes thru interior girder webs for 4-#6 x 5'-0" bars. "DL" "DR " "ER"

"FR " angle is less than 60°

each end of girder BT72 10 Negative Direction Positive Direction

TYPICAL PLAN "F

R"

BT84 13 "D " and "DR " = Girder spacing

7-#5 "U5" stirrups L

4-1" dia. conc. inserts

6" 6" 6" 6" 2 x tan 0

each end. Vary (*) in exterior girder webs and

2" 6@212" 9@4" "a" spaces @ 6" "b" spaces @ 12" 1'-6" max. 1'-6" max. 1'-6" max.

spacing to avoid 4-2" dia. holes thru interior

15" #4 "U4" #4 "U4" stirrups #4 "U4" stirrups #4 "U4" stirrups (2 bars each stirrup, typ.) #4 "U4" stirrups #4 "U4" stirrups

insert or hole locations girder webs for 4-#6 x 5'-0"

3"

Diaphragm �'s when 0 < 65°

bars (unless shown otherwise

8"

on detail plans)

2-#5 x 4'-0" L-bars

4"

1" dia. hole for cable restraint when

7"

(std. 90° hook) 6" 6"

4"

Alternate A restraint is used (typ.)

* CONCRETE INSERTS "x" = 0.50 girder depth.

Expanded coil concrete inserts with

closed-back ferrule threaded to receive

Strand c.g.

BT48

6" (typ.)

-2" BT60

BT72

BT84

1" dia. x 2'-3" rods AASHTO M314,

4"

4"

6" to 2'-6" equal spacing

Gr36 (ASTM A307) threaded full length. #4 "U4"

03-2017

"x"

� dual hold downs Strand c.g. stirrups

"ye"

-4"

-4"

-6"

12"

#4 "U" bars @ 12" max. (deflected strands >14)

1'

1'

1'

1'

ctrs. each end of girder

� hold down

"yc"

� Bearing #3 "U3" bars Diaphragm �'s when 0 > 65° 812"

812" 0.4 Span Length (ctr. - ctr. bearing) ±2'-6"

2-#5 "U6" bars at

� Bearing

dgn

each end of girder Horizontal girder length "A" (add grade correction and estimated shortening allowance to "A" for fabrication length)

br310.

Note

BACK END OF GIRDER AHEAD END OF GIRDER

Girder details are symmetrical

(on stationing)

except as noted otherwise

TYPICAL ELEVATION (on stationing)

4'-0"

2"

Upper group contains

2"

Lower deflected strand

514"

4"

cl

4-#5 cont. 6"

1

group (14 max. except 16 deflected strands

when the number of strands in excess of 14 unless

N is 58 or greater). shown otherwise

#3 x 3'-10" @ 6"

2"

2-#5 x 4'-0" L-bars

2"

8-#3 x cont. @ 6" (or

2" 7-#5 "U5" stirrups (std. 90° hook) 1

6 x 6 - D12 x D12 2" spacing

Slant bars as

(2 bars each stirrup)

3"

o-o

welded wire fabric) Note deflected strands

required to fit

6" 1'-9"

2" 3@ 1 4"=

134"

Ensure ends of girders are at midspan

2"

3'-8" inside "U5"

web vertical when under full

514"

3

stirrups

-0"BT48

-0"BT60

-0"BT84

-0"BT72

#4 "U4" stirrups dead load unless shown

"yc"

BAR "U" c. g. strands

(2 bars each stirrup) otherwise on detail plans

(ASTM A706) at midspan

1" min. cl. unless

8"

912"

@ 2"ctrs.

4'

5'

shown otherwise (typ)

7

7'

ected

6'

3" 10"

strands

11" "hc" > 3" at midspan

#3 "U3" bars 214"

3

4@134" = 7" 1 4" 1" (typ.)

Defl

758"

(#3"U3a" bars

Chamfer soffit corners

where deflected

2'-0" 1" max.

strands conflict)

312"

at each "U4" stirrup 9" 1'-10"

BAR "U3a"

"he"

and at alternate c. g. strands

3"

"U5" stirrup BAR "U3"

(Use in lieu of "U3" BULB DETAIL

bars when deflected

"ye"

strands conflict).

6"

6"

Accompanied by dwgs. BR350 and DET3315

See Bulb Detail 2-#5 "U6" bars at

depth + 414"

2'-0" CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

each end of girder

MIDSPAN SECTION 2" dia. tight

� Girder NOTE: All material and workmanship shall be in accordance with

"m "

o-o

END VIEW

6"

bend for #5 the current Oregon Standard Specifications

rder

Strand

END BLOCK NOTE bars this bend only

The selection and use of this

Gi

When End Block is required, 5'-0" DETENSIONING NOTE OREGON STANDARD DRAWINGS

4"

8 1 2 7 Standard Drawing, while de-

see Girder Schedule for details Detension strands in a

BAR "U6" systematic order about signed in accordance with

9 4 3 10 1'-1" BULB-T (PRECAST

girder � to limit o-o

12 5 6 11 generally accepted engineer-

eccentricity.

BAR "U4" or "U5"

PRESTRESSED CONCRETE

ing principles and practices,

BR310

BULB-T GIRDER NOTES

TYPICAL is the sole responsibility of GIRDERS)

DETENSIONING ORDER BAR BENDING DETAILS

Girders designed for live loading and superimposed dead load as shown in the General Notes. the user and should not be 2018

Provide reinforcing steel as shown in the General Notes except as noted. used without consulting a DATE REVISION DESCRIPTION

Provide welded wire fabric conforming to ASTM A497. Provide the class of concrete shown on Girder Schedule. - -

Registered Professional En-

- -

Provide12" dia. 7-wire low relaxation prestressing strands conforming to AASHTO Keep girders in an upright position w/the support points within 2'-0" of the girder ends.

Deflected strands may be bundled between hold-down points. gineer. - -

M203 (ASTM A416), Grade 270, Supplement 1. Provide an initial tensioning (after harping - -

deflected strands) of 31.0 kips per strand unless shown otherwise on Girder Schedule. Provide temporary diaphragm beams as required, see BR350.

- -

Effective Date:June 1, 2019 - November 30, 2019 BR310

Note "EL" End beam per project plans

* Use staggered diaphragm beams when "EL"

Negative values "FL"

Flare #3 transverse bars 0 > 65°. Provide 4 conc. inserts in each

for "FL" or "FR " � Span See Deck Plans for "FL"

6"

@ 6" max. ctrs. as req'd girder web at each diaphragm beam. diaphragm beams Pour this part of flange

-0"

indicates that corner

ange

1 2" for exterior side of

of top slab extends

5'

exterior girders (unless

beyond end of 2" dia. vent holes

fl

shown otherwise on detail

web

6"

girder web. at diaphragm beams. 0

n.

plans), typ. each end

6"

12"

mi

* Use in line diaphragm beams when 0 > 65°. Provide 4

"ER"

conc. inserts in exterior girder webs and 2" dia. � holes or inserts

#4"U" bars @ 12" max. holes thru interior girder webs for 4-#7 x 6'-0" bars. "DL" "DR" "ER "

"FR"

Chamfer corners when

each end of girder

Negative Direction Positive Direction angle is less than 60° "FR "

Note: Provide "a" > 14 "DL" and "D

TYPICAL PLAN R " = Girder spacing 4-1" dia. conc. inserts

6" 6" 6" 6" 2 x tan 0

(*) in exterior girder webs and

2" 8@214" 9@4" "a" spaces @ 6" "b" spaces @ 12" 1'-6" max. 1'-6" max. 1'-6" max.

9-#5 "U5" stirrups

4-2" dia. holes thru interior

18" #4 "U4" #4 "U4" stirrups #4 "U4" stirrups #4 "U4" stirrups (2 bars each stirrup, typ.) #4 "U4" stirrups #4 "U4" stirrups

each end. Vary spacing

girder webs for 4-#7 x 6'-0"

8"

Diaphragm �'s when 0 < 65°

3"

to avoid insert or hole

bars (unless shown otherwise

locations

on detail plans)

7"

4"

1" dia. hole for cable restraint

*CONCRETE INSERTS

4"

Expanded coil concrete inserts with when Alternate A restraint is used

closed-back ferrule threaded to receive (typ.) "x" = 0.50 girder depth.

2-#5 x 4'-6" L-bars

1" dia. x 2'-3" rods AASHTO M314,

(std. 90° hook)

GR36 (ASTM A307) threaded full length.

6" 6"

6" to 2'-6"

06-2017

Strand c.g.

4"

equal spacing 6" typ.

4"

� dual hold downs #4 "U4"

"x"

(deflected strands > 14) Strand c.g. stirrups

"ye"

-6"

-6"

#4 "U" bars @ 12" max.

1'

1'

ctrs. each end of girder

dgn

"yc"

� Bearing #3 "U3" bars � hold down Diaphragm �'s when 0 > 65°

br321.

10" 0.4 Span Length (ctr. - ctr. bearing) ±2'-6" 10"

� Bearing

2-#5 "U6" bars at Horizontal girder length "A" (add grade correction and estimated shortening allowance to "A" for fabrication length)

each end of girder

BACK END OF GIRDER AHEAD END OF GIRDER

(on stationing)

TYPICAL ELEVATION TYPICAL (on stationing)

DETENSIONING ORDER

Upper group deflected Middle group deflected

Note

5'-0" DETENSIONING NOTE strands (10 max.) strands (10 max.)

Girder details are symmetrical � Girder

212"

412"

2"

Detension strands in a

514"

.

except as noted otherwise

cl

6" Strand

1

6-#5 bars cont. systematic order about

Lower deflected strand

2"

girder � to limit

8 1 2 7 group (10 max.)

eccentricity. 0.6" spacing

#3 x 4'-10" @ 6"

2"

2-#5 x 4'-6" L-bars 9 4 3 10 deflected strands

3"

3@ 2"=

9-#5 "U5" stirrups

2"

10-#3 x cont. @ 6" 3" (std. 90° hook) at midspan

12 5 6 11

(or 6 x 6 - D12 x D12 (2 bars each stirrup)

6"

welded wire fabric)

"yc"

6" 2'-3" 4'-4" 6" c. g. strands

web

rderdepth + 414"

at midspan

2"

#4 "U4" stirrups

o-o

3"

-6"BT90

(2 bars each stirrup) "hc" 3" at midspan

-0"BT96

ected

@ 2"ctrs.

Slant bars as required 214" 5@2"= 10" 0.9" (typ.)

strands

"m "

2" dia. tight

to fit inside "U5" stirrups.

Defl

bend for #5

#3 "U3" bars 234" 2'-6" Chamfer soffit

7'

BAR "U" this bend

8'

(#3 "U3a" bars 1" min. clr. unless corners 1" max.

(ASTM A706) only

4"

Gi

where deflected shown otherwise (typ)

strands conflict)

BULB DETAIL

1'-4"

at each "U4" stirrup

12"

and at alternate c. g. strands BAR "U4" or "U5"

Accompanied by dwgs. BR350 and DET3322

"he"

"U5" stirrup

1212"

4" 10"

CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

14"

"ye"

6" 4"

NOTE: All material and workmanship shall be in accordance with

858"

the current Oregon Standard Specifications

See Bulb Detail 2-#5" U6" The selection and use of this

312"

OREGON STANDARD DRAWINGS

6"

2'-6"

o-o

bars of each 2'-4" Standard Drawing, while de-

MIDSPAN SECTION end of girder END VIEW BAR "U3a"

END BLOCK NOTE (Use in lieu of "U3" bars signed in accordance with BT90 AND BT96 (PRECAST

5'-0" BAR "U3"

When End Block is required, when deflected strands conflict). generally accepted engineer-

see Girder Schedule for details PRESTRESSED CONCRETE

ing principles and practices,

BR321

NOTES BAR BENDING DETAILS

Provide all material and preform all work according to the current Oregon Standard Specifications.

is the sole responsibility of GIRDERS)

Girders designed for live loading and superimposed dead load as shown in the General Notes. the user and should not be 2018

Provide reinforcing steel as shown in the General Notes except as noted. Provide welded wire Provide the class of concrete shown on Girder Schedule.

used without consulting a DATE REVISION DESCRIPTION

fabric conforming to ASTM A497. Keep girders in an upright position w/the support points within 2'-0" of the girder ends. - -

Deflected strands may be bundled between hold-down points.

Registered Professional En-

Provide 0.6" dia. 7-wire low relaxation strands conforming to AASHTO M203 (ASTM A416), - -

Grade 270, Supplement 1. Provide an initial tension (after harping deflected strands) of Provide temporary diaphragm beams as required, see BR350. gineer. - -

- -

43.9 kips per strand unless shown otherwise on Girder Schedule. Ensure girder ends are plumb in their final position under full dead load.

- -

Effective Date:June 1, 2019 - November 30, 2019 BR321

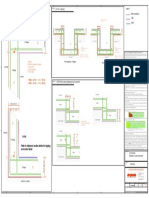

PRETENSIONING STEEL

Provide12" dia. 7-wire low relaxation strands conforming to

Interior Girder Exterior Girder

"D" � inserts for 1" dia. x 2'-3" AASHTO M203 (ASTMA416), Grade 270, Supplement 1.

"D"

threaded rods @ exterior girders

Provide an initial tension (after harping deflected strands)

of 31.0 kips per strand unless shown otherwise. Deflected

strands may be bundled between hold down points.

Provide the same tension as the straight strands after deflecting.

0 2"

0

� 112" dia. holes Detension strands alternately about the girder � to limit prestress

"C" ± 2'-0" 4" "C" ± 2'-0" eccentricity.

and diaphragm

2"

TYPICAL PLAN

Note: Provide "a" 6 6" MILD STEEL REINFORCEMENT

6"

Provide reinforcing steel as specified in the General Notes for the

2" cl. 1'-2" "a"spcs @ 6" "b" spcs @ 12" Equal spaces @ "e" maximum ctrs. "b" spcs @ 12" "a"spcs @ 6" 1'-2" 2"

project unless shown otherwise.

#4 "U1" bars #4 "U1" bars #4 "U1" bars #4 "U1" bars #4 "U1" bars cl.

5 sets of #5 2-#3 bars "U3" and

"U1" bars ea. end. 2-#6 bars x cont. 2-#3 x 12" bars 2" HANDLING PRESTRESSED CONCRETE GIRDERS

5"±

Midspan

4"

Vary spacing to exterior girders only 2" Keep girders in an upright position with the support points within

avoid insert or

2'-0" of the girder ends.

-6"

hole locations

8"±

Provide temporary diaphragm beams as required, see BR350.

Strand

Add #4 "U1" stirrups at

-2" 1'

1" dia. hole for cable restraint when

c.g.

"ye"

each transverse beam DIAPHRAGM BEAMS

Alternate A restraint is used (typ.),

-2"

locate at12 girder depth See structure plans for diaphragm beam locations.

1'

1'

Pour transverse beams a minimum of three days before deck pour.

1-#6 "U5" bar 3-112" dia. holes Provide structural concrete inserts:

03-2017

at each end 6" 6" Expanded coil concrete inserts with closed-back ferrule

each end of girder

of girder � Bearing � strand hold down threaded to receive 1" dia. x 2'-3" rods AASHTO M314,

"F" Gr. 36 (ASTM A307) threaded full length.

"E" "f" tubes

"G" Brace prestressed girders to prevent lateral deflection during

"g" tubes diaphragm pour.

712" "B" 712"

dgn

� Bearing

br325.

"A" 6"

10"

BACK END OF GIRDER TYPICAL ELEVATION

2"

Note Note AHEAD END OF GIRDER

11

(on stationing)

-412"

Girder details are symmetrical about These sections for dimensions only. (on stationing)

1

412"

midspan unless shown otherwise. See Figures on the Girder Schedule

6"

3'

Sheet for the actual strand

arrangements to be used.

4"

6"

1'-4"

4"

10" BAR "U2a" o-o

1'-0"

o-o (Use in lieu of "U2" when BAR "U2"

.

deflected strands conflict)

2"cl

BAR "U1"

514"

1" 1"

ected strands

2-#6 cont.

2-#4 "U4" bars

5"

4"

o-o

5"±

o-o

6"

2-#3 x 12"

@ 2"ctrs.

and 2-#3 "U3"

1'-3" 3'-0"

3"

bars at each o-o

8"±

o-o

Defl

upper insert

3" BAR "U3" BAR "U4"

4-#4 "U6" bars

6" web

#4 "U1" bars c.g. strands

Lower deflected strand

3"

6"

o-o

o-o

Upper group at end

-0"

1" min. cl. unless group (14 max. except 16 contains

*

3'

shown otherwise (typ) when the number of strands deflected strands 4'-10" 3'-8"

#3 "U2" bar, Tube strand when needed,

o-o

"he"

N is 46 or greater) in excess of 14 o-o

1 at each set see Girder Schedule.

6" BAR "U5"

1 unless shown BAR "U6"

of "U1" bars 2-#4 2" spacing Do not tube strand in bottom layer.

otherwise

6"

"U3" bars deflected Accompanied by dwgs. BR350 and DET3345

-2"

c.g. strands

"ye"

ea. hole strands at

2"

3@ 2"

3@ 2"

2"

2"

at midspan

1'

CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

midspan

"yc"

6"

NOTE: All material and workmanship shall be in accordance with

"hc" 3" the current Oregon Standard Specifications

at midspan

212"

212"

The selection and use of this

2"

2"

Chamfer soffit #6 "U5" bar 3@2" 3@2" 3@2" 3@2" OREGON STANDARD DRAWINGS

1'-6" Standard Drawing, while de-

corners 1" max. 1" 1"

(typ) END VIEW signed in accordance with TYPE II - PRESTRESSED

* � 112" dia. holes in internal girders. MIDSPAN SECTION END VIEW generally accepted engineer-

MIDSPAN SECTION Inserts in exterior girders.

CONCRETE GIRDERS

ing principles and practices,

BR325

STRAND ARRANGEMENTS is the sole responsibility of

the user and should not be 2018

used without consulting a DATE REVISION DESCRIPTION

- -

Registered Professional En-

- -

gineer. - -

- -

- -

Effective Date:June 1, 2019 - November 30, 2019 BR325

PRETENSIONING STEEL

� inserts for 1" dia. x 2'-3" Provide12" dia. 7-wire low relaxation strands conforming to

Interior Girder Exterior Girder

threaded rods @ exterior girders AASHTO M203 (ASTMA416), Grade 270, Supplement 1.

"D" "D"

Provide an initial tension (after harping deflected strands)

of 31.0 kips per strand unless shown otherwise. Deflected

strands may be bundled between hold down points.

Provide the same tension as the straight strands after deflecting.

0 2"

0 � 112" dia. holes Detension strands alternately about the girder � to limit prestress

"C" ± 2'-0" 4" "C" ± 2'-0" eccentricity.

and diaphragm

2"

Note: Provide "a" 8

TYPICAL PLAN MILD STEEL REINFORCEMENT

6"

6" Provide reinforcing steel as specified in the General Notes for the

project unless shown otherwise.

2" cl. 1'-2" "a" spcs @ 6" "b" spcs @ 12" Equal spaces @ "e" maximum ctrs. "b" spcs @ 12" "a" spcs @ 6" 1'-2" 2" cl.

#4 "U1" bars #4 "U1" bars HANDLING PRESTRESSED CONCRETE GIRDERS

5 sets of #5 #4 "U1" bars 2-#3 bars "U3" and #4 "U1" bars #4 "U1" bars

2-#6 x cont. 2-#3 x 12" bars Keep girders in an upright position with the support points within

"U1" bars ea. end. 2"

5"±

4"

Midspan exterior girders only 2'-0" of the girder ends.

Vary spacing to

2" Provide temporary diaphragm beams as required, see BR350.

avoid insert or

hole locations

DIAPHRAGM BEAMS

12"±

-1"

1" dia. hole for cable restraint when Add #4 "U1" stirrups at See structure plans for diaphragm beam locations.

2'

Alternate A restraint is used (typ.), Strand each transverse beam Pour transverse beams a minimum of three days before deck pour.

c.g.

locate at12 girder depth

"ye"

Provide structural concrete inserts:

-4"

-4"

Expanded coil concrete inserts with closed-back ferrule

1'

1'

threaded to receive 1" dia. x 2'-3" rods AASHTO M314,

03-2017

Gr. 36 (ASTM A307) threaded full length.

1-#6 "U5" bar 3-112" dia. holes

6" 6" Brace prestressed girders to prevent lateral deflection during

at each end each end of girder

diaphragm pour.

� Bearing � strand hold down

of girder "F"

"E" "f" tubes

"G"

dgn

6"

"g" tubes

712" "B" 712"

br330.

10"

� Bearing

"

"A"

2

-112"

'-

1

7"

BACK END OF GIRDER Note

412"

AHEAD END OF GIRDER

4'

(on stationing) Girder details are symmetrical about

(on stationing)

5"

TYPICAL ELEVATION

5"

midspan unless shown otherwise.

Note

712"

1'-8" o-o

These sections for dimensions only.

1'-012"

BAR "U2a"

2-#3 bars x 1'-0" See Figures on the Girder Schedule BAR "U2"

o-o

and 2 - #3 "U3" Sheet for the actual strand (Use in lieu of "U2" when

bars @ each upper arrangements to be used. deflected strands conflict)

1'-4" BAR "U1"

insert

.

2"cl

4"

o-o

o-o

5"

514" 1" 1"

2 - #6 x cont.

ected strands

1'-3" 3'-0"

412" 7"

2 - #4 "U4" bars o-o o-o

@ 2"ctrs.

BAR "U3"

BAR "U4"

4 - #4 "U6" bars

� 112" dia. holes

2 - #6 x cont. Lower deflected strand

Defl

412" in internal girders.

312"

group (14 max. except 16

6"

o-o

o-o

7" web Inserts in exterior Upper group c.g. strands at end

-7"

when the number of strands

-9"

girders. 2-#4 "U3" bars contains

1'

N is 54 or greater) 4'-10" 3'-8"

3'

at ea. hole deflected strands o-o

1 c.g. strands o-o

712" 2" spacing in excess of 14 Tube strand when needed,

"he"

at midspan BAR "U5"

#3 "U2" bars at ea. pair of deflected unless shown see Girder Schedule. BAR "U6"

#4 "U1" bars

"ye"

712"

"U1" bars on "Elevation" #4 "U1" bars strands at otherwise Do not tube strand in bottom layer.

2"

2"

midspan

g

Accompanied by dwgs. BR350 and DET3345

2"

spc'

"yc"

7"

7"

1" cl. (typ.) "hc" 3" CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

at midspan

#3 "U2" bar at ea.

212"

2"

1" 1" NOTE: All material and workmanship shall be in accordance with

pair of "U1" bars Chamfer soffit corner the current Oregon Standard Specifications

1'-10" #6 "U5" bar

1" max. typ. 2" Spc'g @ 2" 2"

2" Spc'g @ 2" 2" The selection and use of this

END VIEW OREGON STANDARD DRAWINGS

MIDSPAN SECTION Standard Drawing, while de-

MIDSPAN SECTION END VIEW

signed in accordance with TYPE III - PRESTRESSED

generally accepted engineer-

STRAND ARRANGEMENTS CONCRETE GIRDERS

ing principles and practices,

BR330

is the sole responsibility of

the user and should not be 2018

used without consulting a DATE REVISION DESCRIPTION

- -

Registered Professional En-

- -

gineer. - -

- -

- -

Effective Date:June 1, 2019 - November 30, 2019 BR330

PRETENSIONING STEEL

� inserts for 1" dia. x 2'-3"

Interior Girder Exterior Girder Provide12" dia. 7-wire low relaxation strands conforming to

"D" threaded rods @ exterior girders

"D" AASHTO M203 (ASTMA416), Grade 270, Supplement 1.

Provide an initial tension (after harping deflected strands)

of 31.0 kips per strand unless shown otherwise. Deflected

strands may be bundled between hold down points.

0 2" Provide the same tension as the straight strands after deflecting.

"C" ±2'-0"

0

� 112" dia. holes Detension strands alternately about the girder � to limit prestress

"C" ±2'-0"

2" eccentricity.

and diaphragm

Note: Provide "a" 10 4" MILD STEEL REINFORCEMENT

6" TYPICAL PLAN 6"

Provide reinforcing steel as specified in the General Notes for the

2" cl. 1'-2" "a" spaces @ 6" "b" spaces @ 12" Equal spaces @ "e" maximum ctrs. "b" spaces @ 12" "a" spaces @ 6" 1'-2" 2" cl. project unless shown otherwise.

6 sets of #5 #4 "U1" bars #4 "U1" bars #4 "U1" bars #4 "U1" bars #4 "U1" bars

HANDLING PRESTRESSED CONCRETE GIRDERS

2-#6 x cont. 2-#3 bars "U3" and

"U1" bars ea. end. 2" 2-#6 x cont.

5"±

Keep girders in an upright position with the support points within

4"

Midspan 2-#3 x 12" bars

Vary spacing to

exterior girders only 2" 2'-0" of the girder ends.

avoid insert or

Provide temporary diaphragm beams as required, see BR350.

hole locations

12"±

Add #4 "U1" stirrups at

-7"

DIAPHRAGM BEAMS

1" dia. hole for cable restraint when each transverse beam

2'

Alternate A restraint is used (typ.), See structure plans for diaphragm beam locations.

Strand

locate at12 girder depth Pour transverse beams a minimum of three days before deck pour.

c.g.

Provide structural concrete inserts:

"ye"

-7"

-7"

1-#6 "U5" bar

Expanded coil concrete inserts with closed-back ferrule

1'

at each end

1'

03-2017

threaded to receive 1" dia. x 2'-3" rods AASHTO M314,

of girder

Gr.36 (ASTM A307) threaded full length.

� 2nd strand hold down 6" 6" 3-112" dia. holes

10'-0"± � Bearing Brace prestressed girders to prevent lateral deflection during

(if required) � 1st strand hold down each end of beam "F"

� Bearing diaphragm pour.

"E"

"G" "f" tubes

812" "B" "g" tubes 812" 6"

dgn

"A"

br335.

10"

BACK END OF GIRDER Note AHEAD END OF GIRDER

"

(on stationing) (on stationing)

5

Note

-1012"

'-

These sections for dimensions only.

1

TYPICAL ELEVATION

812"

Girder details are symmetrical about

See Figures on the Girder Schedule

412"

midspan unless shown otherwise

4'

Sheet for the actual strand

6"

arrangements to be used.

6"

2-#3 bars x 1'-0"

and 2 - #3 "U3"

bars @ each upper 9" 2'-0"

insert 1'-8" 1'-3" o-o

.

2"cl

o-o BAR "U2a"

BAR "U2"

514"

2 - #6 x cont. 1" 1" BAR "U1" (Use in lieu of "U2" when

deflected strands conflict)

8"

2 - #4 "U4" bars

5"

o-o

5"

ected strands

o-o

6"

2 - #6 x cont. 4 - #4 "U6" bars

1'-3" 3'-0"

at2"ctrs.

2-#4 "U3" bars o-o o-o

6"

at ea. hole

BAR "U3" BAR "U4"

-11"

Defl

Lower deflected strand

-6"

#4 "U1" bars

412"

8" web

6"

o-o

o-o

group (14 max. except 16 Upper group

1'

4'

c.g. strands at end

* when the number of strands contains

9" N is 66 or greater) deflected strands 4'-10" 3'-8"

#4 "U1" #3 "U2" bars o-o

1 c.g. strands in excess of 14 Tube strand when needed, o-o

bars at ea. pair of 2" spacing

at midspan unless shown see Girder Schedule. BAR "U5"

"he"

"U1" bars on deflected BAR "U6"

9"

otherwise Do not tube strand in bottom layer.

"Elevation" strands at

"ye"

Accompanied by dwgs. BR350 and DET3345

2"

midspan

g

2"

spc'

CALC. BOOK NO. - 20-April-2018

"yc"

8"

1" cl. typ. BASELINE REPORT DATE

"hc" 3"

at midspan NOTE: All material and workmanship shall be in accordance with

#3 "U2" bar at ea.

2"

the current Oregon Standard Specifications

pair of "U1" bars. Chamfer soffit corner 1" 1"

2'-2" #6 "U5" bar The selection and use of this

1" max. typ. Spc'g @ 2"

3" 3" 3" Spc'g @ 2" 3" OREGON STANDARD DRAWINGS

END VIEW Standard Drawing, while de-

signed in accordance with TYPE IV - PRESTRESSED

MIDSPAN SECTION * � 112" dia. holes in internal girders. MIDSPAN SECTION END VIEW

Inserts in exterior girders. generally accepted engineer-

STRAND ARRANGEMENTS CONCRETE GIRDERS

ing principles and practices,

BR335

is the sole responsibility of

the user and should not be 2018

used without consulting a DATE REVISION DESCRIPTION

- -

Registered Professional En-

- -

gineer. - -

- -

- -

Effective Date:June 1, 2019 - November 30, 2019 BR335

� inserts for 1" dia.

PRETENSIONING STEEL

Interior Girder Exterior Girder x 2'-3" threaded

"D" "D" Provide12" dia. 7-wire low relaxation strands conforming to

rods @ exterior girders

AASHTO M203 (ASTMA416), Grade 270, Supplement 1.

Provide an initial tension (after harping deflected strands)

of 31.0 kips per strand unless shown otherwise. Deflected

strands may be bundled between hold down points.

0 2"

0 Provide the same tension as the straight strands after deflecting.

"C" ±2'-0" � 112" dia. holes 4" "C" ±2'-0"

Detension strands alternately about the girder � to limit prestress

and diaphragm 2"

Note: Provide "a" 12

TYPICAL PLAN eccentricity.

6" 6" MILD STEEL REINFORCEMENT

2"cl. 1'-2" "a" spaces @ 6" "b" spaces @ 12" Equal spaces @ "e" maximum ctrs. "b" spaces @ 12" "a" spaces @ 6" 1'-2" 2"cl. Provide reinforcing steel as specified in the General Notes for the

6 sets of #5 "U1" #4 "U1" bars #4 "U1" bars #4 "U1" bars #4 "U1" bars #4 "U1" bars project unless shown otherwise.

2-#3 bars "U3" and

bars ea. end. Vary 2-#6 bars x cont. HANDLING PRESTRESSED CONCRETE GIRDERS

2"

2-#3 x 12" bars

5"±

4"

spc'g. to avoid insert Midspan

exterior girders only 2" Keep girders in an upright position with the support points within

or hole locations

2'-0" of the girder ends.

Provide temporary diaphragm beams as required, see BR350.

12"±

-4"

DIAPHRAGM BEAMS

Add #4 "U1" stirrups at

1" dia. hole for cable restraint each transverse beam See structure plans for diaphragm beam locations.

3'

when alternate A restraint is used Pour transverse beams a minimum of three days before deck pour.

(typ.) locate at12 girder depth Strand Provide structural concrete inserts:

c.g. Expanded coil concrete inserts with closed-back ferrule

-7"

"ye"

-7"

threaded to receive 1" dia. x 2'-3" rods AASHTO M314,

03-2017

1'

1'

Gr. 36 (ASTM A307) threaded full length.

Brace prestressed girders to prevent lateral deflection during

1-#6 "U5" bar at 3-112" dia. holes diaphragm pour.

each end of girder � 2nd strand hold down 6" 6"

each end of girder � Bearing

10'-0"± � 1st strand hold down

(if required) "F"

� Bearing 6"

"E" "f" tubes

dgn

"G"

10"

"g" tubes

br340.

812" "B" 812"

"

"A"

5

'-

-712"

1

812"

BACK END OF GIRDER

AHEAD END OF GIRDER

TYPICAL ELEVATION

412"

Note

5'

(on stationing) Note (on stationing)

2-#3 bars x 12" Girder details are symmetrical about These sections for dimensions only.

6"

6"

and 2 - #3 "U3" midspan unless shown otherwise

See Figures on the Girder Schedule

bars @ each upper

insert 1'-8" Sheet for the actual strand

9" 2'-0"

.

arrangements to be used.

2"cl

1'-3" o-o

514"

1" 1" BAR "U2a"

2 - #6 x cont. o-o

BAR "U2"

BAR "U1" (Use in lieu of "U2" when

8"

2 - #4 "U4" bars deflected strands conflict)

6"

5"

5"

o-o

o-o

2 - #6 x cont. 4 - #4 "U6" bars

ected strands

6" 2-#4 "U3" bars 1'-3" 3'-0"

o-o o-o

at ea. hole

BAR "U3"

at2"ctrs.

BAR "U4"

-8"

8" web #4 "U1" bars

-3"

� 112"

2'

dia. holes

412"

5'

Defl

6"

o-o

o-o

in internal girders. Lower deflected strand

Inserts in exterior group (14 max. except 16 Upper group 4'-10"

girders. c.g. strands at end 3'-8"

when the number of strands contains o-o o-o

9" N is 66 or greater) Tube strand when needed,

#4 "U1" bars #3 "U2" bars deflected strands BAR "U5"

see Girder Schedule. BAR "U6"

at ea. pair of 1 c.g. strands in excess of 14

2" spacing

at midspan Do not tube strand in bottom layer.

"U1" bars on unless shown

deflected

"he"

9"

"Elevation" otherwise Accompanied by dwgs. BR350 and DET3345

"ye"

strands at

2"

midspan CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

g

spc'

2"

"yc"

1" cl. (typ.)

8"

NOTE: All material and workmanship shall be in accordance with

"hc" 3"

the current Oregon Standard Specifications

#3 "U2" bar at ea. at midspan

2"

pair of "U1" bars. Chamfer 1" The selection and use of this

2'-2" #6 "U5" bar OREGON STANDARD DRAWINGS

soffit corner Standard Drawing, while de-

3" Spc'g @ 2" 3" 3" Spc'g @ 2" 3"

1" max. typ.

signed in accordance with TYPE V - PRESTRESSED

MIDSPAN SECTION END VIEW MIDSPAN SECTION END VIEW generally accepted engineer-

CONCRETE GIRDERS

ing principles and practices,

BR340

STRAND ARRANGEMENTS is the sole responsibility of

the user and should not be 2018

used without consulting a DATE REVISION DESCRIPTION

- -

Registered Professional En-

- -

gineer. - -

- -

- -

Effective Date:June 1, 2019 - November 30, 2019 BR340

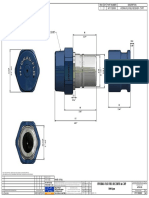

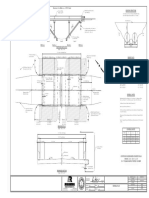

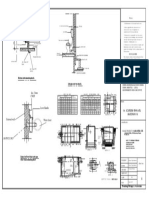

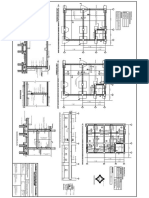

2"

134" 312" 134"

� exterior girder � first interior girder 2"

1

2"

3

4" 138" dia. holes

PL12 x 6" x 7" Girder Spacing 2-118" dia. holes for 1" dia. x 1 1

PL12 x 7" x 1012" 3 4" 4"

7" bolts Slide Unit only. (Fixed PL14 16

3

Unit similar except for bolts) 16 3

16

2"

� Upper Brace

4"

2"

3"

3"

(similar to lower brace)

1

Snug outer nuts first typ.

3

-0"

412"

16

4"

on upper brace

1'

Upper Connection Plate Detail TS4 x 4 x 0.1875x 8"

� 2-1" dia. holes through

2"

Snug inner nuts first

3

girder spaced 4" apart

2"

6" on lower brace PL 114 (A36) typ.3

16

-

2' s

for34" dia. x 9" bolts ho

e

l

2-114" dia. x 1'-2" 16

out � 4-1" dia. holes thru 814" 3" min., 7" max.

th

e

ol

s wi threaded adjusting rods 412"

2-12" dia. x 212" bolts into a.h � Lower Brace

girder spaced 4" apart bwtn. base plates

1 "di (A449) each brace with

ferrule inserts. (Recess inserts 1 8 for34" dia. x 9" bolts

1 " 4 nuts each rod

1", patch holes after temporary 3" 32 TS4 x 4 x 0.1875

@ SLIDE UNIT DETAILS

diaphragms are removed) 3" Fixed Unit FIXED UNIT SIMILAR

Slide Unit

2-#4 x 3'-0" TS312x 312x 0.3125

3

Brace End Detail

4" dia. holes 114" dia.

Add 3 extra #4 "U3a" @ 4" PL 1 (A36) hole for 118"

"t" "t" =316" for TS4 x 4 x 0.1875

(Middle bar on temporary Lower Connection Plate Detail

3" 4 2" 3"

5

16 dia. x 612" bolt "t" "t" =14" for TS312 x 312 x 0.3125

diaphragm beam �)

6"

03-2017

1012"

16

1

TEMPORARY DIAPHRAGM BEAM 3

16

(Bulb-I shown, other girders similar) 3

16

214" R 3

16" for TS4 x 4 x 0.1875

1

1" 114" dia. x 21516" 4" for TS312 x 312 x 0.3125

dgn

3" 3" 3"

1" long E.S. pipe. Tight fit

br350.

112" 112" into connection plate.

2" 4" 3" 118" dia. holes @ 312" ctrs. in

7"

Drill 2" dia. TS314 x 314x 0.3125 only

hole thru end

UPPER CONNECTION PLATE DETAIL plate

Cut from

"t" TS4 x 4 x 0.1875

Brace End Detail TS12 x 4 x12 "t" TS312 x 312 x 0.3125

Lower Connection as required.

TEMPORARY DIAPHRAGM BEAM GENERAL NOTES

Plate Detail

Install temporary diaphragm beams at exterior girders between end beams and BRACE END DETAIL

permanent diaphragms prior to pouring permanent diaphragms and end beams.

LOWER CONNECTION DETAIL Space temporary diaphragms as needed to resist construction loads but not at

more than 25 ft. apart. Assume the deck finishing machine carriage is at the most

TYPE II thru TYPE V GIRDERS

adverse position when computing construction loads. Remove temporary diaphragms

after removing the deck overhang brackets.

Provide pipe conforming to ASTM Specification A53, Grade A or B. Provide structural

tubing conforming to ASTM Specification A500, Grade A or B (or ASTM A513 with

the strength and elongation characteristics of A500, Grade A or B).

Provide other steel conforming to AASHTO Specification M183 (ASTM A36).

Provide mechanically galvanized high strength bolts conforming to ASTM Specification

A325 unless shown otherwise. Provide mechanically galvanized threaded rods

conforming to ASTM Specification A449.

Tighten but do not torque high strength bolts and rods.

Hot-dip Galvanize all structural steel after fabrication.

Approved alternate designs prepared by a registered Professional Engineer may be used

for temporary diaphragms.

PL 1 (A36) 112"

3 5 112" CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

4" dia.

2"

8" dia. holes

1

114" 21516"

2"

holes dia. x long

All material and workmanship shall be in accordance with

3" R 114" 21516" NOTE:

1

dia. x long

E.S. pipe (sch 80). Tight the current Oregon Standard Specifications

E.S. pipe. Tight fit into

2"

2 fit into connection plate 2"

" 3 connection plate The selection and use of this

1

2"

3 16

16

3" OREGON STANDARD DRAWINGS

3

1

3

3 3 16 16 Standard Drawing, while de-

" 3" R 16 PL34 x 5 x 7 3

typ.

PL 1 (A36) 16 signed in accordance with TEMPORARY DIAPHRAGM BEAM

314" 1" 3 (A36) 1"

16

typ. generally accepted engineer-

312" 3

FOR PRESTRESSED CONCRETE

16 314" 312"

PL34 x 5 x 7 ing principles and practices,

BR350

7"

(A36)

7" is the sole responsibility of GIRDERS

the user and should not be 2018

LOWER CONNECTION used without consulting a DATE REVISION DESCRIPTION

LOWER CONNECTION PLATE DETAIL - -

Registered Professional En-

- -

TYPE II thru TYPE V GIRDERS PLATE DETAIL gineer. - -

- -

BULB-I and BULB-T GIRDERS - -

Effective Date:June 1, 2019 - November 30, 2019 BR350

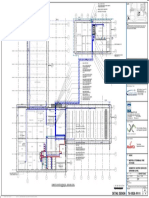

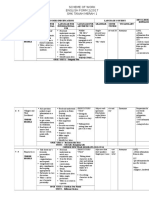

Notes

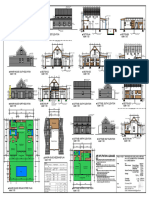

� Diaphragm Girders are designed for live loading and superimposed dead

Use in line diaphragm beams when

load as shown in the General Notes.

Extend #4 bars (A706) � Diaphragm 0 65°. Provide 2 concrete inserts* Symm. about Use staggered diaphragm beams Provide the class of concrete shown on the Girder Schedule.

"f" (1'-0" min. -

e in exterior girder webs and 2" dia.

a distance sin 0 "

e" 3'-6" max.) � of span when 0 65°. Provide 4 concrete Provide concrete strength at transfer of prestress not less than

holes thru interior girder webs for

beyond edge of flange Edge conn. plate @ 5'-0" o.c.

unless noted. inserts*in each girder web at that shown on the Girder Schedule.

and add std. 90° hk. 2-#6x5'-0" bars (unless shown

(interior flanges only) each diaphragm beam. Provide12" dia. 7-wire low relaxation prestressing strands

12"

otherwise on detail plans).

conforming to AASHTO M203 (ASTM A416) Grade 270,

0 Supplement 1.

6" 0

Tension straight strands initially to 31.0 kips, Ensure

-0"

0

0 deflected strands have the same tension after deflecting.

"W "

2'

Provide reinforcing steel as shown in the General Notes,

12"

except as noted.

Maintain girders in an upright position at all times with

the support points within 2'-0" of the girder ends.

"D "

L

�Bear

ing "

d" 6" dia. blockout thru girder flanges. Provide a transverse broom finish on tops of girders.

"DR"

(Interior flange only on exterior girders. Provide general finish for all other surfaces, except as shown

Negative Positive Girder Spacing

Both flanges on interior girders) "D " or "D " = in the General Notes.

L R 2xTan 0

Direction Direction Deflected strands may be bundled between hold-down points.

Provide temporary diaphragm beams as required, see BR350.

6 @ 212"

TYPICAL PLAN Notes See dwg. DET3380 for "a", "b", "d", "e", "f" and "0" values.

#5 "U5" See Detail Plans for diaphragm locations. Provide welded wire fabric conforming to ASTM A497.

Girder details are symmetrical except as

"U4" and "U5" 13 @ 4" "b" @ 12" #4 "U4" @ 18" max. Symm. about

"a" @ 6" noted otherwise. MINIMUM DECK REINFORCEMENT FOR INTERIOR GIRDERS

stirrup spcg. #4 "U4" #4 "U4" #4 "U4" � of span

03-2017

TOP FLANGE WIDTH "W" (in)

12"

unless noted

2"cl. � Diaphragm BAR

60 to 72 72 to 84 84 to 102

-0"

8"

"A" Spacing (in) 7 6 5

-0"

12"

12"

3'

# U"b

4" as

r Additional top deck reinforcement may be required for

2'

#5 "U7"

(2) each end exterior girders depending on specified bridge rail type.

10"

-2"

dgn

10"

2" dia. hole thru girder

"W" - 4"

1'

web for 2-#6 x 5'-0" bars

br360.

2-#3 "U3a" bars @

2'-6" 2'-6" 2'-0" 2'-0"

(unless shown otherwise on � 1st hold-down each diaphragm, typ.

�Bear

ing � 2nd hold-down max. max.

5"

detail plans). Adjust "U5" stirrups (deflected strands>14) 2" dia. x 1'-0" hole at pinned,

to avoid insert or hole locations.

hinged or fixed end of girder 6"

� hold-down

712" 0.4 span length (center-to-center bearing) ± 2'-6" 712" BAR "C"

(unless shown otherwise)

Horizontal girder length "A" (add grade correction and estimated shortening allowance to "A" for fabrication length)

o-o

3"

END OF GIRDER *CONCRETE INSERTS

TYPICAL ELEVATION END OF GIRDER

5'-0"

-734"

(Back on Station) Expanded coil concrete inserts with closed-back

ferrule threaded to receive 1" dia. x 2'-3" rods (Ahead on Station) BAR "U"

Blockouts thru girder flanges, 2" dia. tight

(ASTM A706)

2'

(ASTM A307) threaded full length. see Plan for location bend for #5

10"

Edge conn. plate bars this

Interior #6 bar "A" (epoxy coated) 11" 912"

Interior bend only.

Top flange width "W"

312"

flange flange Interior Exterior Lower deflected

3"

Slope 0.02 max. or tilt girder normal

.

2"cl

4"

7"

flange flange strand group (14

#4 @ 8" max. Upper group contains

to roadway surface, 0.02 max.

312"

strands max. except

(epoxy coated) deflected strands in

16 when the number 1'-1"

n.

excess of 14 unless 1'-10" BAR "U3a"

6"

of strands N is

-1"

mi

shown otherwise (Use in lieu of "U3" bars when BAR "U4"

58 or greater) BAR "U3"

1'

and

4"

1 deflected strands conflict)

2" spcg. deflected

-0"DKBT36

.

2"

134"

ected

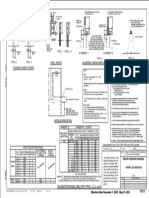

1"cl

#4@12"max. BAR "U5"

3@ 134"

ng

strands

3" 5'-0"

1

strands at midspan

2"

spaci

514"

#4@10"max.

@ 2"

1"min. cl. 3 c.g. strands

Defl

4" drip v-groove,

-3"

"U"bars

6"

o-o

@ 612"

1'-6" 3" 6" unless shown at midspan

"y "

#5 "U7" #4 "U4" stirrups exterior flange of

c

1'

otherwise, typ.

(2 bars each stirrup) exterior girders 3'-0"

8"

c.g. strands

3'

9" BAR "U6"

2"

7

at end of (omit shear key)

5"

o-o

See Bulb Detail 1"

6" 3"

"

"h " 3"

"y "

girder

"he

#3 "U3" bars or c

10"

Chamfer soffit typ. at midspan

#3 "U3a" bars at 134"

corners 1" max. BAR "U7"

each "U4" and every Accompanied by dwgs. BR350 and DET3380

other "U5" stirrup 214" 4@134"

Recess strands 1" CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

2-#5 "U6" 2'-0"

and epoxy patch,

bars at each NOTE: All material and workmanship shall be in accordance with

2'-0" typ., unless girder the current Oregon Standard Specifications

end of girder

end is embedded

MIDSPAN SECTION BULB DETAIL The selection and use of this

in concrete.

OREGON STANDARD DRAWINGS

END VIEW Standard Drawing, while de-

signed in accordance with 36" DECK BULB-T (PRECAST

generally accepted engineer-

PRESTRESSED CONCRETE)

ing principles and practices,

BR360

is the sole responsibility of GIRDER

the user and should not be 2018

used without consulting a DATE REVISION DESCRIPTION

- -

Registered Professional En-

- -

gineer. - -

- -

- -

Effective Date:June 1, 2019 - November 30, 2019 BR360

Notes

� Diaphragm Girders are designed for live loading and superimposed dead

Use in line diaphragm beams when

load as shown in the General Notes.

Extend #4 bars (A706) � Diaphragm 0 65°. Provide 2 concrete inserts* Symm. about Use staggered diaphragm beams

"f" (1'-0" min. - Provide the class of concrete shown on the Girder Schedule.

e

a distance sin 0 "

e" in exterior girder webs and 2" dia. � of span when 0 65°. Provide 4 concrete Provide concrete strength at transfer of prestress not less than

3'-6" max.)

beyond edge of flange holes thru interior girder webs for unless noted. inserts*in each girder web at

Edge conn. plate @ 5'-0" o.c. that shown on the Girder Schedule.

and add std. 90° hk. 2-#6x5'-0" bars (unless shown each diaphragm beam.

(interior flanges only) Provide12" dia. 7-wire low relaxation prestressing strands

12"

otherwise on detail plans).

conforming to AASHTO M203 (ASTM A416) Grade 270,

0 Supplement 1.

6" 0

Tension straight strands initially to 31.0 kips, Ensure

-0"

0

"W "

0 deflected strands have the same tension after deflecting.

2'

Provide reinforcing steel as shown in the General Notes,

except as noted.

Maintain girders in an upright position at all times with

12"

the support points within 2'-0" of the girder ends.

"D "

�Bear

ing "

d" 6" dia. blockout thru girder flanges. L Provide a transverse broom finish on tops of girders.

"D " Provide general finish for all other surfaces, except as shown

(Interior flange only on exterior girders. R

Positive Girder Spacing

Both flanges on interior girders) Negative "D " or "D " = in the General Notes.

L R 2xTan 0

Direction Direction Deflected strands may be bundled between hold-down points.

6 @ 212"

Provide temporary diaphragm beams as required, see BR350.

#5 "U5" TYPICAL PLAN Notes See dwg. DET3380 for "a", "b", "d", "e", "f" and "0" values.

"U4" and "U5" Symm. about See Detail Plans for diaphragm locations. Provide welded wire fabric conforming to ASTM A497.

15 @ 4" "a" @ 6" "b" @ 12" #4 "U4" @ 18" max.

stirrup spcg. � of span Girder details are symmetrical except as

#4 "U4" #4 "U4" #4 "U4"

unless noted. noted otherwise.

12"

2"cl. � Diaphragm MINIMUM DECK REINFORCEMENT FOR INTERIOR GIRDERS

03-2017

TOP FLANGE WIDTH "W" (in)

-9"

-5"

BAR

-8"

-8"

-9"

# U"b

4" as

r 60 to 72 72 to 84 84 to 102

3'

1'

1'

1'

2'

"A" Spacing (in) 7 6 5

#5 "U7"

(2) each end Additional top deck reinforcement may be required for

-2"

10"

10"

2" dia. hole thru girder

exterior girders depending on specified bridge rail type.

dgn

1'

web for 2-#6 x 5'-0" bars 2-#3 "U3a" bars @

2'-6" 2'-6"

� 1st hold-down

br365.

(unless shown otherwise on each diaphragm, typ. "W" - 4"

�Bear

ing � 2nd hold-down max. max.

detail plans). Adjust "U5" stirrups (deflected strands>14)

2" dia. x 1'-0" hole at pinned, 2'-0" 2'-0"

to avoid insert or hole locations.

hinged or fixed end of girder

5"

712" � hold-down

0.4 span length (center-to-center bearing) ± 2'-6" 712" 6"

(unless shown otherwise)

Horizontal girder length "A" (add grade correction and estimated shortening allowance to "A" for fabrication length) BAR "C"

3"

o-o

*CONCRETE INSERTS

END OF GIRDER END OF GIRDER

Expanded coil concrete inserts with closed-back TYPICAL ELEVATION

(Back on Station) (Ahead on Station) 6'-3"

ferrule threaded to receive 1" dia. x 2'-3" rods

-434"

(ASTM A307) threaded full length. Blockouts thru girder flanges, BAR "U" 2" dia. tight

(ASTM A706) bend for #5

3'

see Plan for location

10"

Edge conn. plate bars this

Interior Interior

#6 bar "A" (epoxy coated) Lower deflected 11" 912"

bend only.

Top flange width "W"

312"

flange flange Interior Exterior strand group

.

3"

Upper group contains

2"cl

Slope 0.02 max. or tilt girder normal

4"

flange (14 strands max.

7"

#4 @ 8" max. flange

deflected strands in

312"

to roadway surface, 0.02 max. except 16 when the

(epoxy coated) excess of 14 unless

number of strands 1'-1"

n.

shown otherwise 1'-10" BAR "U3a"

4" 6"

N is 58 or

-1"

mi

(Use in lieu of "U3" bars

greater) BAR "U3" BAR "U4"

1'

1 when deflected strands conflict)

2" spcg. deflected and

.

134"

2"

1"cl

#4@12"max. 3" strands at midspan BAR "U5"

3@ 134"

5'-0"

2"

#4@10"max.

ected

514"

1"min. cl.

-9"DKBT45

3 c.g. strands

4" drip v-groove,

6"

ng

strands

o-o

1'-6" 3" unless shown at midspan

"y "

#4 "U4" stirrups 6"

spaci

exterior flange of

-0"

c

@ 2"

Defl

otherwise, typ.

"U"bars

@ 11"

(2 bars each stirrup) exterior girders

8"

3'-0"

2'

#5 "U7" BAR "U6"

7

2"

(omit shear key)

5"

o-o

1" "hc" 3"

3'

typ. at midspan

c.g. strands Chamfer soffit 134"

9" #3 "U3" bars or BAR "U7"

at end of corners 1" max. Accompanied by dwgs. BR350 and DET3380

See Bulb Detail

6" 3"

#3 "U3a" bars at 214" 4@134"

"

girder

"y "

10"

"he

e

each "U4" and every CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

other "U5" stirrup 2'-0"

NOTE: All material and workmanship shall be in accordance with

the current Oregon Standard Specifications

Recess strands 1"

2-#5 "U6"

and epoxy patch,

BULB DETAIL The selection and use of this

bars at each OREGON STANDARD DRAWINGS

2'-0" typ., unless girder Standard Drawing, while de-

end of girder

end is embedded

MIDSPAN SECTION signed in accordance with 45" DECK BULB-T (PRECAST

in concrete.

generally accepted engineer-

END VIEW PRESTRESSED CONCRETE)

ing principles and practices,

BR365

is the sole responsibility of GIRDER

the user and should not be 2018

used without consulting a DATE REVISION DESCRIPTION

- -

Registered Professional En-

- -

gineer. - -

- -

- -

Effective Date:June 1, 2019 - November 30, 2019 BR365

Notes

� Diaphragm Girders are designed for live loading and superimposed dead

Use in line diaphragm beams when load as shown in the General Notes.

Extend #4 bars (A706) "f" (1'-0" min. - � Diaphragm 0 65°. Provide 2 concrete inserts* Symm. about Use staggered diaphragm beams Provide the class of concrete shown on the Girder Schedule.

a distance

e "

e" in exterior girder webs and 2" dia. � of span when 0 65°. Provide 4 concrete Provide concrete strength at transfer of prestress not less than

sin 0 3'-6" max.)

beyond edge of flange holes thru interior girder webs for unless noted inserts*in each girder web at that shown on the Girder Schedule.

Edge conn. plate @ 5'-0" o.c.

2-#6x5'-0" bars (unless shown

and add std. 90° hk. (interior flanges only) each diaphragm beam. Provide12" dia. 7-wire low relaxation prestressing strands

12"

otherwise on detail plans).

conforming to AASHTO M203 (ASTM A416) Grade 270,

0 Supplement 1.

6" 0

Tension straight strands initially to 31.0 kips, Ensure

0

-0"

0

"W "

deflected strands have the same tension after deflecting.

2'

Provide reinforcing steel as shown in the General Notes,

except as noted.

Maintain girders in an upright position at all times with

12"

the support points within 2'-0" of the girder ends.

"D "

L Provide a transverse broom finish on tops of girders.

�Bea " 6" dia. blockout thru girder flanges.

r

ing d"

"D "

(Interior flange only on exterior girders. R Provide general finish for all other surfaces, except as shown

Negative Positive Girder Spacing

Both flanges on interior girders) "D " or "D " = in the General Notes.

L R 2xTan 0

Direction Direction Deflected strands may be bundled between hold-down points.

6 @ 212" TYPICAL PLAN Provide temporary diaphragm beams as required, see BR350.

#5 "U5" Notes

See dwg. DET3380 for "a", "b", "d", "e", "f" and "0" values.

See Detail Plans for diaphragm locations.

21 @ 4" "a" @ 6" "b" @ 12" #4 "U4" @ 18" max. Symm. about Provide welded wire fabric conforming to ASTM A497.

"U4" and "U5" Girder details are symmetrical except as

stirrup spcg. #4 "U4" #4 "U4" � of span

#4 "U4" noted otherwise.

unless noted.

12"

MINIMUM DECK REINFORCEMENT FOR INTERIOR GIRDERS

2"cl. � Diaphragm

03-2017

TOP FLANGE WIDTH "W" (in)

BAR

60 to 72 72 to 84 84 to 102

-0"

-0"

-2"

-6"

-6"

"A" Spacing (in) 7 6 5

5'

4'

2'

2'

2'

# U"b

4" as

r

Additional top deck reinforcement may be required for

#5 "U7"

exterior girders depending on specified bridge rail type.

(2) each end

dgn

10"

-2"

10"

2" dia. hole thru girder

"W" - 4"

br375.

1'

web for 2-#6 x 5'-0" bars 2-#3 "U3a" bars @

2'-6" 2'-6" 2'-0" 2'-0"

(unless shown otherwise on each diaphragm, typ.

�Bear

ing � 2nd hold-down � 1st hold-down

5"

detail plans). Adjust "U5" stirrups max. max.

(deflected strands>14) 2" dia. x 1'-0" hole at pinned,

to avoid insert or hole locations.

hinged or fixed end of girder 6"

� hold-down 712"

712" 0.4 span length (center-to-center bearing) ± 2'-6" BAR "C"

(unless shown otherwise)

o-o

3"

Horizontal girder length "A" (add grade correction and estimated shortening allowance to "A" for fabrication length)

*CONCRETE INSERTS

TYPICAL ELEVATION 8'-0"

-734"

END OF GIRDER Expanded coil concrete inserts with closed-back END OF GIRDER

BAR "U" 2" dia. tight

(Back on Station) ferrule threaded to receive 1" dia. x 2'-3" rods (Ahead on Station)

Blockouts thru girder flanges,

4'

(ASTM A706) bend for #5

(ASTM A307) threaded full length.

10"

see Plan for location

bars this

Edge conn. plate 11" 912"

Interior Interior Lower deflected bend only.

312"

Top flange width "W" #6 bar "A" (epoxy coated)

Interior strand group

312" 3"

flange flange Exterior

Slope 0.02 max. or tilt girder normal to

.

7"

4"

2"cl

flange flange (14 strands max.

#4 @ 8" max.

roadway surface, 0.02 max. Upper group contains

except 16 when the

(epoxy coated)

deflected strands in 1'-1"

number of strands 1'-10" BAR "U3a"

n.

excess of 14 unless

4" 6"

N is 58 or

mi

-1"

(Use in lieu of "U3" bars

shown otherwise BAR "U4"

greater) BAR "U3" when deflected strands conflict).

1'

and

1

.

2" spcg. deflected

134"

5'-0"

1"cl

BAR "U5"

2"

#4@12"max.

3"

3@ 134"

strands at midspan

2"

ected

#4@10"max.

514"

o-o

6"

ng

strands

3 c.g. strands

3" 4" drip v-groove,

spaci

1'-6" at midspan

"y "

@ 2"

exterior flange of

Defl

c

1"min. cl. 3'-0"

8"

exterior girders BAR "U6"

-0"DKBT60

unless shown

2"

6"

o-o

5"

#4 "U4" stirrups (omit shear key)

otherwise, typ. 1" "hc" 3"

(2 bars each stirrup)

-3"

"U"bars

typ. at midspan

@ 12"

#5 "U7" Chamfer soffit 134" BAR "U7"

3'

corners 1" max. Accompanied by dwgs. BR350 and DET3380

5'

214" 4@134"

CALC. BOOK NO. - BASELINE REPORT DATE 20-April-2018

"he"

2'-0"

#3 "U3" bars or All material and workmanship shall be in accordance with

NOTE:

c.g. strands #3 "U3a" bars at

9"

at end of

BULB DETAIL the current Oregon Standard Specifications

See Bulb Detail each "U4" and every

6" 3"

The selection and use of this

"y "

girder other "U5" stirrup

e

OREGON STANDARD DRAWINGS

10"

Standard Drawing, while de-

signed in accordance with 60" DECK BULB-T (PRECAST

Recess strands 1" generally accepted engineer-

2-#5 "U6" PRESTRESSED CONCRETE)

and epoxy patch, ing principles and practices,

BR375

bars at each

2'-0" typ., unless girder MIDSPAN SECTION is the sole responsibility of GIRDER

end of girder

end is embedded

the user and should not be 2018

END VIEW in concrete.

used without consulting a DATE REVISION DESCRIPTION

- -

Registered Professional En-

- -

gineer. - -

- -

- -

Effective Date:June 1, 2019 - November 30, 2019 BR375

You might also like

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- Fdot Design Standards: 20624 1 24" Square Prestressed Concrete PileDocument1 pageFdot Design Standards: 20624 1 24" Square Prestressed Concrete Pilearkiriz23No ratings yet

- A4Document1 pageA4Nefritiri BlanceNo ratings yet

- Load schedule for multi-function areaDocument1 pageLoad schedule for multi-function areaGilbert ObiasNo ratings yet

- Tiger Moth Sheet 2 of 2: DihedralDocument1 pageTiger Moth Sheet 2 of 2: DihedralFarooq AhmadNo ratings yet

- 4.plinth & Roof Details (With Diensions)Document1 page4.plinth & Roof Details (With Diensions)barathshyamNo ratings yet

- M Plusteam Sterilizer - Drain Pipe Line Installation Sheet Rev.3.4Document1 pageM Plusteam Sterilizer - Drain Pipe Line Installation Sheet Rev.3.4Casamed ServiceNo ratings yet

- HF1113Z0005 ReceiverDocument1 pageHF1113Z0005 ReceivergianninacostaNo ratings yet

- Double box culvert specifications and modelsDocument10 pagesDouble box culvert specifications and modelsSami AjNo ratings yet

- Robinson Pagadian - Bended Roof 9Document1 pageRobinson Pagadian - Bended Roof 9Cesar DuriasNo ratings yet

- Building Sections and ElevationsDocument1 pageBuilding Sections and ElevationsfrancisNo ratings yet

- Pole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SPDocument1 pagePole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SPDina ShresthaNo ratings yet

- Wa0000.Document3 pagesWa0000.nmarozhe_225151671No ratings yet

- Lateral Expansion Joints: LA2SH / ID No. 88Document7 pagesLateral Expansion Joints: LA2SH / ID No. 88adfafad gfadfNo ratings yet

- HITW-DH002 White Tank DetailsDocument1 pageHITW-DH002 White Tank DetailsArsalan Ullah KhanNo ratings yet

- Val2 Art HLS SHD SST 40 2 Cov 002 ADocument24 pagesVal2 Art HLS SHD SST 40 2 Cov 002 AAnh KyNo ratings yet

- FW SstdeDocument1 pageFW SstdeJan Michael VecillesNo ratings yet

- EMAT Probe Exploded ViewDocument1 pageEMAT Probe Exploded ViewBernardo FariasNo ratings yet

- Construction Details For Nordic Lam™: Product WarrantyDocument2 pagesConstruction Details For Nordic Lam™: Product WarrantyhahaerNo ratings yet

- BR340Document1 pageBR340Ali HassanNo ratings yet

- Mama Structure-Structure 3Document1 pageMama Structure-Structure 3Saugat ThapaNo ratings yet

- Crne 7.5tDocument1 pageCrne 7.5tAdam SniffNo ratings yet

- Type 1 Structural DrawingDocument23 pagesType 1 Structural Drawingmyoaung.clickNo ratings yet

- Suction Head Calculation: Local Factors of FittingsDocument1 pageSuction Head Calculation: Local Factors of Fittingsmohamad azipNo ratings yet

- Birch-King Flow DirectionDocument4 pagesBirch-King Flow DirectionBruceNo ratings yet

- TM570Document1 pageTM570nim coNo ratings yet

- PSK1-E0000-0000-DDI - Single Line Diagram-Rev-ADocument1 pagePSK1-E0000-0000-DDI - Single Line Diagram-Rev-AAsep SaepudinNo ratings yet

- Entrance Level (0.00) Building Outdoor Equipotential Bus (S) Termination Conductor With The Loop Earth Electrode ConductorDocument1 pageEntrance Level (0.00) Building Outdoor Equipotential Bus (S) Termination Conductor With The Loop Earth Electrode ConductorsartajNo ratings yet

- Come Together: John Lennon, Paul Mccartney Arr. Silvio HenriqueDocument2 pagesCome Together: John Lennon, Paul Mccartney Arr. Silvio HenriqueSílvio HenriqueNo ratings yet

- Nakaz 279 FL DispatchDocument2 pagesNakaz 279 FL DispatchSergey DNo ratings yet

- PRINYANKADocument1 pagePRINYANKAApna gharNo ratings yet

- Construction notes and typical details for structural drawingsDocument1 pageConstruction notes and typical details for structural drawingsHailley DensonNo ratings yet

- Bachelor View KitchenDocument1 pageBachelor View KitchenAmrish TyagiNo ratings yet

- Schedule of openings for steel doorsDocument1 pageSchedule of openings for steel doorsAbdullah FrastNo ratings yet

- Standard Ductile Detailing, Beam & Slab Reinforcement DetailsDocument2 pagesStandard Ductile Detailing, Beam & Slab Reinforcement Detailsmohan890No ratings yet

- Arvin: Vintage 50Document14 pagesArvin: Vintage 50rodrigoNo ratings yet

- Project S-302: Inking, Length Measure, Area MeasureDocument2 pagesProject S-302: Inking, Length Measure, Area MeasureNoviantoNo ratings yet

- Locking ConnectorsDocument2 pagesLocking ConnectorsDieabsolute NullimBettNo ratings yet

- Stormwater Drainage System DesignDocument1 pageStormwater Drainage System DesignAhmad Farhad MadaniNo ratings yet

- SEC_TE_01A_Sections 1 and 2Document1 pageSEC_TE_01A_Sections 1 and 2erniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Openfoam Simulation of The Flow in The Hoelleforsen Draft Tube ModelDocument15 pagesOpenfoam Simulation of The Flow in The Hoelleforsen Draft Tube ModelAghajaniNo ratings yet

- R.C Wall Block Wall Vent Pipe Low Level CisternDocument1 pageR.C Wall Block Wall Vent Pipe Low Level CisternAmadi HenryNo ratings yet

- Power House - PlanDocument4 pagesPower House - PlanChristian Jeremiah TevesNo ratings yet

- Layout Plan 132kV SubstationDocument1 pageLayout Plan 132kV SubstationShuhan Mohammad Ariful Hoque0% (1)

- Piles ExtensionDocument1 pagePiles ExtensionmrmerajNo ratings yet

- Final Floor PlanDocument1 pageFinal Floor Plansafwanmohammad52No ratings yet

- Shed Struc DrawingsDocument7 pagesShed Struc Drawingsfinddict0% (1)

- A-22 Second Floor Sewerage PlanDocument1 pageA-22 Second Floor Sewerage PlandoctorahmadtanveerNo ratings yet

- 240K C2 3400 25J 005 2Document1 page240K C2 3400 25J 005 2Benny Gomez CNo ratings yet

- Washing Area: Avah EngineeringDocument1 pageWashing Area: Avah EngineeringrashalNo ratings yet

- Cable Voltage Drop CalculationDocument2 pagesCable Voltage Drop CalculationVaibhav ThoratNo ratings yet

- H-11 Double Bottom in Cargo Hold (2-2)Document19 pagesH-11 Double Bottom in Cargo Hold (2-2)최우종No ratings yet

- Block B: 164'-0" Wide Road 164'-0" Wide RoadDocument1 pageBlock B: 164'-0" Wide Road 164'-0" Wide RoadNikita DhingraNo ratings yet

- Underground water pipe planDocument1 pageUnderground water pipe planMazen IsmailNo ratings yet

- Plan LayoutDocument1 pagePlan LayoutmaxNo ratings yet

- ISO-5167 Table 3Document1 pageISO-5167 Table 3Prasad RamanNo ratings yet

- CIVIL ROCKET? CHART Civil Ki Goli (Civil Junction)Document1 pageCIVIL ROCKET? CHART Civil Ki Goli (Civil Junction)MR. PRANAV KUMAR67% (3)

- Arc Doc 2Document1 pageArc Doc 2Sultan MahmudNo ratings yet

- JIB FMME Ae 02CL 304.000Document1 pageJIB FMME Ae 02CL 304.000MoustafaNo ratings yet

- Pavement Design Parameters and Catch Basin DimensionsDocument1 pagePavement Design Parameters and Catch Basin DimensionsrickNo ratings yet

- Operations ManagementDocument132 pagesOperations ManagementECNo ratings yet

- UI 2230SE C HQ - Rev - 3Document3 pagesUI 2230SE C HQ - Rev - 3jhvghvghjvgjhNo ratings yet

- Faculty of Engineering, UNIMASDocument4 pagesFaculty of Engineering, UNIMASjohnNo ratings yet

- Simplicity SE Controls - 5127914-UTG-A-0515Document61 pagesSimplicity SE Controls - 5127914-UTG-A-0515Mario LozanoNo ratings yet

- AFI Data Sheet Heavy Density Pipe Insulation PI No Pix 1Document3 pagesAFI Data Sheet Heavy Density Pipe Insulation PI No Pix 1Mostafa ElsammanNo ratings yet

- 04-Chap5-Internal MemoryDocument37 pages04-Chap5-Internal Memoryabdul shakoorNo ratings yet

- Properties of Recurisve and Recursively Enumerable Languages PDFDocument2 pagesProperties of Recurisve and Recursively Enumerable Languages PDFBelex ManNo ratings yet

- Webnavigator Wincc Client SiemensDocument156 pagesWebnavigator Wincc Client SiemensEder Rinas0% (1)

- Computer Engineering Syllabus Sem IV - Mumbai UniversityDocument28 pagesComputer Engineering Syllabus Sem IV - Mumbai UniversityDaivik ChaulkarNo ratings yet

- HTZ 121 DVDDocument96 pagesHTZ 121 DVDtoyioriginalNo ratings yet

- Earthing Calculation: A General Design DataDocument14 pagesEarthing Calculation: A General Design Dataمحمد الأمين سنوساوي100% (1)

- Data ONTAP 81 Upgrade and RevertDowngrade GuideDocument157 pagesData ONTAP 81 Upgrade and RevertDowngrade GuidePurushothama GnNo ratings yet

- Analytic and Harmonic FunctionsDocument54 pagesAnalytic and Harmonic FunctionsATCNo ratings yet

- PrePoMax-v1 3 3-ManualDocument43 pagesPrePoMax-v1 3 3-ManualMarcelo ResendeNo ratings yet

- Parts Shutter CompletoDocument158 pagesParts Shutter CompletofaelofNo ratings yet

- Surface Vehicle Standard: Rev. AUG2005Document58 pagesSurface Vehicle Standard: Rev. AUG2005Leonardo Gonçalves GomideNo ratings yet

- MIR - Silencers - Catalog Miratech Marine Self SubSeaDocument60 pagesMIR - Silencers - Catalog Miratech Marine Self SubSeaFernando BarbosaNo ratings yet

- Tda 7850Document18 pagesTda 7850Adrian AguilarNo ratings yet

- Scheme of Work Form 2 English 2017Document8 pagesScheme of Work Form 2 English 2017Atikah AmaranNo ratings yet

- Covid 19 ImpactDocument38 pagesCovid 19 ImpactNavneet NandaNo ratings yet

- Lesson 13 StsDocument11 pagesLesson 13 StsJasmin Lloyd CarlosNo ratings yet

- Day 3 Multiplying Polynomials Homework Assignment OnlyDocument2 pagesDay 3 Multiplying Polynomials Homework Assignment Onlyapi-316619857No ratings yet

- Valtek Handwheels and Limit Stops (Flow Serve)Document12 pagesValtek Handwheels and Limit Stops (Flow Serve)dharmendrabholeNo ratings yet

- V2 Progression Pathways by CS IT and DL-with-CT-refs PDFDocument1 pageV2 Progression Pathways by CS IT and DL-with-CT-refs PDFsramsahaNo ratings yet

- 7 Steps Prevent Communication GapsDocument5 pages7 Steps Prevent Communication GapssmartisaacNo ratings yet

- History of Computer: Basic Computing Periods: Week 3 Living in The IT Era Maria Michelle VinegasDocument41 pagesHistory of Computer: Basic Computing Periods: Week 3 Living in The IT Era Maria Michelle VinegasMary Ianne Therese GumabongNo ratings yet

- Modern Reloading 1st Edition by Richard Lee TextDocument512 pagesModern Reloading 1st Edition by Richard Lee TextLorenzodasio1989No ratings yet

- Cloud Strategy Tds ExtractDocument14 pagesCloud Strategy Tds ExtractkkNo ratings yet

- E-895 EL Est R0 STG 0 05 1711Document20 pagesE-895 EL Est R0 STG 0 05 1711sultanprinceNo ratings yet

- Illustration 7Document18 pagesIllustration 7Jeh UbaldoNo ratings yet