TIEBACK S EAL N IPPLE

Tieback liners provide a new casing FEATURES AND BENEFITS:

string to cover intermediate casing Locator threaded to match tieback

worn by drilling or corrosion, protect liner / casing connection

a weak casing string from shut-in or Variety of seal materials available

excessive production pressure or to for compatibility with anticipated

isolate a leaking liner top. A typi- well conditions; Viton* / Aramid

cal tieback liner system includes a seal units standard

Tieback Seal Nipple (TSN), Orifice Mule shoe configuration aids in

Float Collar (OFC) and an existing stabbing and facilitates re-entry

Liner Tieback Receptacle (TBR). with wireline equipment

STANDARD LINER EQUIPMENT

Optional cementing ports available

The TSN consists of a locator, seal L80 and Q125 material grades

mandrel, seals or seal units and a are standard, with other material

half mule shoe bottom. This assem- grades available by special order

bly is made up to the tieback string

and is landed into the existing TBR.

OFC

O RIFICE FLOAT C OLLAR

The Orifice Float Collar (OFC) FEATURES AND BENEFITS:

reduces lost rig time and drilling Single poppet valve standard

fluids by allowing the tieback liner All internal parts are PDC drillable TBR

/ casing to fi ll as it is run. In addi- Orifice port allows tieback liner to

tion, when the Tieback Seal Nipple fi ll during run-in

(TSN) enters the tieback receptacle, Orifice prevents pressure lock by

displaced fluids flow through the providing a fluid path

orifice, preventing a pressure lock L80 and Q125 material grades are

during stabbing. The OFC is nor- standard, with other material grades

mally run one to two joints above available by special order

the TSN and provides a stop for the

cementing plug.

* Trademark of DuPont Company TSN

23

� TIEBACK R ECEPTACLE

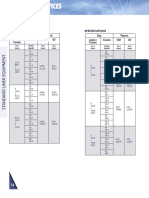

SPECIFICATIONS SPECIFICATIONS

SIZE TIEBACK SIZE TIEBACK

LINER X CASING OD ID LINER X CASING OD ID

CASING CASING

(in.) (lb/ft) (in.) (in.) (in.) (lb/ft) (in.) (in.)

(mm) (kg/M) (mm) (mm) (mm) (kg/M) (mm) (mm)

14 20

20.8 29.8

STANDARD LINER EQUIPMENT

15 23

22.3 34.2

3-1/2 17 26 5.82 5.25

88.9 25.3 5 38.7 147.82 133.35

4.375 3.75

X

111.25 95.25 127.0

5-1/2 20 29

X

139.7 29.8 43.2

7

23 177.8 32

34.2 47.6

26 35

38.7 52.1 5.625 5.125

14 38 143.00 130.18

4 20.8 56.5

101.6

15 4.625 4.125 24

X

22.3 117.60 104.78 35.7

5-1/2

139.7 17 26.4

25.3 39.3

20 5 29.7

29.8 127.0 44.2 5.82 5.25

X

23 33.7 147.82 133.35

7-5/8

34.2 193.7 50.1

26 39

4-1/2 38.7 58.0

114.3

29 5.625 5.00 55.3

X

43.2 143.00 127.00 82.3

7

177.8 32 24

47.6 35.7

35 26.4

52.1 5 39.3

127.0

38 29.7 6.25 5.25

X

56.5 44.2 158.75 133.35

7-5/8

193.7 33.7

50.1

39

58.0

24

�TIEBACK R ECEPTACLE

SPECIFICATIONS SPECIFICATIONS

SIZE TIEBACK SIZE TIEBACK

LINER X CASING CASING OD ID LINER X CASING CASING OD ID

(in.) (lb/ft) (in.) (in.) (in.) (lb/ft) (in.) (in.)

(mm) (kg/M) (mm) (mm) (mm) (kg/M) (mm) (mm)

20 32

5-1/2 29.8 47.6

STANDARD LINER EQUIPMENT

139.7

23 6.06 5.562 36

X

34.2 153.92 141.27 53.6

7

177.8 26 40 8.38 7.75

38.7 7-5/8 59.5 212.85 196.85

193.7

24 43

X

35.7 64.0

9-5/8

26.4 244.5 47

5-1/2 39.3 69.9

139.7

29.7 6.38 5.75 53.5

X

44.2 162.05 146.05 79.6 8.25 7.75

7-5/8

193.7 33.7 53.5 SD 209.55 196.85

50.1 79.6

39 42

58.0 62.5

32 47

47.6 9-5/8 69.9

244.5

36 54 10.38 9.875

X

53.6 80.4 263.65 250.83

11-3/4

40 298.5 60

59.5 89.3

7

177.8 43 8.25 65

7.375

X 64.0 209.55 96.7

9-5/8 47 48

244.5 66.9 71.4

53.5 54

79.6 80.4

53.5 SD 61

79.6 9-5/8 90.8

244.5

58 8.12 7.375 68 11.5 10.375

X

86.30 206.25 187.33 101.2 292.10 263.53

13-3/8

339.7 72

107.1

77

114.6

85

126.5

25