Professional Documents

Culture Documents

P D L W P: UMP OWN AND Iner Iper Lugs

Uploaded by

Ghinet Teodor-ioanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P D L W P: UMP OWN AND Iner Iper Lugs

Uploaded by

Ghinet Teodor-ioanCopyright:

Available Formats

P UMP D OWN AND L INER WIPER P LUGS

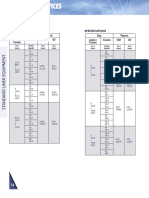

The Pump Down Plug (PDPC) The Liner Wiper Plug (LWPC)

prevents cement contamination in prevents cement contamination in the

the drill pipe during liner cement- liner during liner cementing opera-

ing operations. The PDPC is released tions. The LWPC is normally shear

from the cementing manifold at the pinned to the setting tool and pro-

surface after the cement is pumped. vides the seal bore for the PDPC. With

Traveling between the cement and the PDPC sealed and latched, the

the displacement fluid, it wipes LWPC shears off, wiping the cement

cement from the drill pipe. The from the inside of the liner and keep-

PDPC then seals and locks into the ing the cement separate from the

STANDARD LINER EQUIPMENT

liner wiper plug, to function as a displacing fluid. Following displace-

single plug. ment, the LWPC seals into the landing

collar, preventing backflow of cement.

PDPC

LWPC

D UAL L INER WIPER P LUG SYSTEM

The Dual Liner Wiper Plug FEATURES AND BENEFITS:

System (DPS) provides enhanced Prevents cement contamination in

cement contamination prevention. drill pipe and liners

The DPS uses two PDPC plugs and Locking system provides back

two LWPC plugs, matched to wipe pressure capability when locked

ahead of and behind the cement and sealed in the landing collar

column. The system has the same Elastomer selection for compat-

advantages as the traditional lead ibility with most drilling fluids

and following plugs in conventional PDC drillable

full string cementing. Anti-rotation feature reduces

drill-out times

DPS

31

You might also like

- Drilling A SS WellDocument61 pagesDrilling A SS WellWilliam EvansNo ratings yet

- Servco Mills HandbookDocument90 pagesServco Mills HandbookGhinet Teodor-ioan100% (1)

- Piping Study DrumsDocument31 pagesPiping Study Drumsradin202033% (3)

- DPT Well S & ADocument57 pagesDPT Well S & ABrahim Letaief100% (2)

- Reelwell Drilling Method Makes Use of Dual Conduit Drill StringDocument2 pagesReelwell Drilling Method Makes Use of Dual Conduit Drill Stringlulalala8888100% (1)

- Horizontal Directional Drilling HDD Operations White Paper-Riks and Mitigations For HDD HAZIDDocument21 pagesHorizontal Directional Drilling HDD Operations White Paper-Riks and Mitigations For HDD HAZIDVeena NageshNo ratings yet

- Pipeline Depth of CoverDocument18 pagesPipeline Depth of Coverallouche_abdNo ratings yet

- Well CompletionDocument29 pagesWell CompletionAkol MajookNo ratings yet

- 6 Well Control System CDocument64 pages6 Well Control System CHamid Reza BabaeiNo ratings yet

- 2011 - 11 - PCM Moineau Operating Manual Rev3 - ENDocument57 pages2011 - 11 - PCM Moineau Operating Manual Rev3 - ENMarwenNo ratings yet

- 45 Versalok Wireline Retrievable PackerDocument1 page45 Versalok Wireline Retrievable PackerGhinet Teodor-ioanNo ratings yet

- Training Manual-Piping: Piping Study Underground PipingDocument30 pagesTraining Manual-Piping: Piping Study Underground Pipingrazi khan100% (2)

- StrongholdBarricade ProductsheetDocument1 pageStrongholdBarricade Productsheeteddy hariyadieNo ratings yet

- Drilling Mud DesilterDocument4 pagesDrilling Mud DesilterkosunlucyNo ratings yet

- Stuck Pipe PDFDocument16 pagesStuck Pipe PDFcarlos801No ratings yet

- 39 Packer Comparison ChartDocument1 page39 Packer Comparison ChartGhinet Teodor-ioan100% (2)

- Saipem Pres2Document45 pagesSaipem Pres2alexrodriguezabcNo ratings yet

- Daf English 2009 PDFDocument2 pagesDaf English 2009 PDFAquasoul CoNo ratings yet

- Prefabricated Vertical Drains For: Soil ConsolidationDocument14 pagesPrefabricated Vertical Drains For: Soil ConsolidationFerry Yudha Mangiwa100% (1)

- MPD Techniques Address Problems in Drilling LimestoneDocument3 pagesMPD Techniques Address Problems in Drilling LimestonecafegrNo ratings yet

- Casing While Drilling PPT (2) - 1Document33 pagesCasing While Drilling PPT (2) - 1Sangam ShiralNo ratings yet

- DPS DPCDocument8 pagesDPS DPCMARCO ANTONIO100% (1)

- Agrifim Catalog PDFDocument48 pagesAgrifim Catalog PDFJhohan Steven Muñoz PinedaNo ratings yet

- NDJ Drip Eng 160914Document48 pagesNDJ Drip Eng 160914CARLOS EDUARDONo ratings yet

- Hannegan 2015Document4 pagesHannegan 2015aidaNo ratings yet

- Compact Seal: DUOPAC Rubber Fabric Reinforced Compact Seals Type DPS and DPCDocument6 pagesCompact Seal: DUOPAC Rubber Fabric Reinforced Compact Seals Type DPS and DPCg.annibaliNo ratings yet

- GeneralbrochDocument18 pagesGeneralbrochRoberto CandidoNo ratings yet

- DSTconceptDocument17 pagesDSTconceptsyed shafqatNo ratings yet

- MPD Familiarization Presentation April 2016Document39 pagesMPD Familiarization Presentation April 2016Amr FathiNo ratings yet

- System Summary - Cardium Hanger OnlyDocument9 pagesSystem Summary - Cardium Hanger OnlyRahima RahoumaNo ratings yet

- Method Suggestion On Temporary Drainage SystemDocument2 pagesMethod Suggestion On Temporary Drainage SystemAhmad AfeeqNo ratings yet

- ANDRITZ TetrapackDocument18 pagesANDRITZ TetrapackClaudinei MayerNo ratings yet

- DBM PDFDocument6 pagesDBM PDFeguren_91No ratings yet

- Well Cementing 13cap IDocument43 pagesWell Cementing 13cap IWill OrtizNo ratings yet

- Catalogue Escodisc PDFDocument47 pagesCatalogue Escodisc PDFTEIUSANUNo ratings yet

- 36 Tamping Dog AssemblyDocument1 page36 Tamping Dog AssemblyGhinet Teodor-ioanNo ratings yet

- Polishing Process For Heatcure Fiber Optic Connectors: 1. GeneralDocument4 pagesPolishing Process For Heatcure Fiber Optic Connectors: 1. GeneralAbNo ratings yet

- Nsert EAL Ssembly: Ing Bushing (RCB) or Retrievable Landing Assembly (RLA) ProfileDocument1 pageNsert EAL Ssembly: Ing Bushing (RCB) or Retrievable Landing Assembly (RLA) ProfileGhinet Teodor-ioanNo ratings yet

- 37 Drillable Cementing BushingDocument1 page37 Drillable Cementing BushingGhinet Teodor-ioanNo ratings yet

- 2.1 RIV - BR - D5000-Brochure - R6 - EN - W17 - 0232-LRDocument8 pages2.1 RIV - BR - D5000-Brochure - R6 - EN - W17 - 0232-LRcristian elias portocarreroNo ratings yet

- API Plan 31 - ENDocument3 pagesAPI Plan 31 - ENarunima04No ratings yet

- Drilling Mud DesanderDocument3 pagesDrilling Mud DesanderkosunlucyNo ratings yet

- Lincoln Model 653 Grease Pump2 - P653S - Flyer PDFDocument6 pagesLincoln Model 653 Grease Pump2 - P653S - Flyer PDFAdi PutraNo ratings yet

- Section3 - Pipeline StoppersDocument22 pagesSection3 - Pipeline StoppersMelele MuNo ratings yet

- Donaldson Torit - Easy Duct Technical ManualDocument40 pagesDonaldson Torit - Easy Duct Technical ManualtylerstearnsNo ratings yet

- Variable Flow PICV - Case StudyDocument19 pagesVariable Flow PICV - Case StudySikander AahilNo ratings yet

- Cementing Application Well Drilling and Workover Presentation UP45 231023Document70 pagesCementing Application Well Drilling and Workover Presentation UP45 231023Dion SeranNo ratings yet

- 9.cable Trough of ZJ70DBS Rig USER'S MANUALDocument6 pages9.cable Trough of ZJ70DBS Rig USER'S MANUALKapil TiwariNo ratings yet

- Rivulis DriplinesDocument8 pagesRivulis DriplinesLeon SteynNo ratings yet

- Pi Ups 1002Document31 pagesPi Ups 1002JOEL ARNAO CORTEGANANo ratings yet

- Safe Cyanide Management: in Our OperationsDocument18 pagesSafe Cyanide Management: in Our OperationsjostinalejandroNo ratings yet

- Underbalance Drilling SeminarDocument4 pagesUnderbalance Drilling Seminarmin thantNo ratings yet

- Emp Appendix 6 - Deep Well SpecificationsDocument12 pagesEmp Appendix 6 - Deep Well SpecificationsMadhusudanan78No ratings yet

- Dike ProtectionDocument6 pagesDike ProtectionSTICK EDUARDO PINCAY SANCHEZNo ratings yet

- Single Tap Double Block and Bleed Isolation Cuts Costs of Pipeline Piggability ExpansionDocument4 pagesSingle Tap Double Block and Bleed Isolation Cuts Costs of Pipeline Piggability ExpansionAnonymous 7xbdR5No ratings yet

- WWT - Compatibilidade Dos Protetores Com MPD SystemsDocument4 pagesWWT - Compatibilidade Dos Protetores Com MPD SystemsGustavo TeixeiraNo ratings yet

- Drilling Safety SystemDocument2 pagesDrilling Safety Systemvinky sulistyawatiNo ratings yet

- DAF Pump ENGLISH 2009Document2 pagesDAF Pump ENGLISH 2009PRO X VLOGER OF NRL TOWNSHIPNo ratings yet

- Well completion-ENI-3Document81 pagesWell completion-ENI-3Mohammed Khalid AbdullahNo ratings yet

- DWC - PPt-Alom - Double Walled - Corrugated Pipes For SwewrageDocument73 pagesDWC - PPt-Alom - Double Walled - Corrugated Pipes For Swewragenimm1962No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- 55 Sphinx Wireline PackerDocument1 page55 Sphinx Wireline PackerGhinet Teodor-ioanNo ratings yet

- SMITH CatalogDocument86 pagesSMITH CatalogGhinet Teodor-ioanNo ratings yet

- 56 RSBH Sphinx Hydraulic PackerDocument1 page56 RSBH Sphinx Hydraulic PackerGhinet Teodor-ioanNo ratings yet

- 44 Elite PI-75 PackerDocument1 page44 Elite PI-75 PackerGhinet Teodor-ioanNo ratings yet

- 41 M1-X Production Packer SpecificationsDocument2 pages41 M1-X Production Packer SpecificationsGhinet Teodor-ioanNo ratings yet

- 43 Mar 1Document1 page43 Mar 1Ghinet Teodor-ioanNo ratings yet

- 38 Inner String Circulating ToolsDocument1 page38 Inner String Circulating ToolsGhinet Teodor-ioanNo ratings yet

- 36 Tamping Dog AssemblyDocument1 page36 Tamping Dog AssemblyGhinet Teodor-ioanNo ratings yet

- 42 M Snap II Retrievable Isolation PackerDocument1 page42 M Snap II Retrievable Isolation PackerGhinet Teodor-ioanNo ratings yet

- Loat Quipment: The Float Collar (FC) Is NormallyDocument1 pageLoat Quipment: The Float Collar (FC) Is NormallyGhinet Teodor-ioanNo ratings yet

- 27 Tubing Seal AssemblyDocument1 page27 Tubing Seal AssemblyGhinet Teodor-ioanNo ratings yet

- 40 m1x Production PackerDocument2 pages40 m1x Production PackerGhinet Teodor-ioanNo ratings yet

- 37 Drillable Cementing BushingDocument1 page37 Drillable Cementing BushingGhinet Teodor-ioanNo ratings yet

- Nsert EAL Ssembly: Ing Bushing (RCB) or Retrievable Landing Assembly (RLA) ProfileDocument1 pageNsert EAL Ssembly: Ing Bushing (RCB) or Retrievable Landing Assembly (RLA) ProfileGhinet Teodor-ioanNo ratings yet

- 29 Retrievable Landing AssemblyDocument1 page29 Retrievable Landing AssemblyGhinet Teodor-ioanNo ratings yet

- Ress ILL Ssembly: Retrievable Landing Assembly (RLA) and Retrievable Cementing Bushing (RCB)Document1 pageRess ILL Ssembly: Retrievable Landing Assembly (RLA) and Retrievable Cementing Bushing (RCB)Ghinet Teodor-ioanNo ratings yet

- 22 Compression Set Isolation PackerDocument1 page22 Compression Set Isolation PackerGhinet Teodor-ioanNo ratings yet

- Ieback EAL Ipple: Tieback Seal Nipple (TSN), Orifi Ce Float Collar (OFC) and An ExistingDocument3 pagesIeback EAL Ipple: Tieback Seal Nipple (TSN), Orifi Ce Float Collar (OFC) and An ExistingGhinet Teodor-ioanNo ratings yet

- 24 Tieback ReceptacleDocument2 pages24 Tieback ReceptacleGhinet Teodor-ioanNo ratings yet

- 21 Float Shoe and Guide ShoeDocument1 page21 Float Shoe and Guide ShoeGhinet Teodor-ioanNo ratings yet

- Bowen Lead Seal Cementing-Type Casing Patches: Instruction ManualDocument12 pagesBowen Lead Seal Cementing-Type Casing Patches: Instruction ManualGhinet Teodor-ioanNo ratings yet

- Anding Ollars: The Landing Collar (LC) Acts AsDocument1 pageAnding Ollars: The Landing Collar (LC) Acts AsGhinet Teodor-ioanNo ratings yet

- Iner OP Acker: Liner Top Packers Are Run As AnDocument1 pageIner OP Acker: Liner Top Packers Are Run As AnGhinet Teodor-ioanNo ratings yet

- 15 HSDB Non-Rotating Hydraulic-Set Liner HangerDocument2 pages15 HSDB Non-Rotating Hydraulic-Set Liner HangerGhinet Teodor-ioanNo ratings yet

- 11 Hydraulic Rotating Pocket Slip Liner HangerDocument1 page11 Hydraulic Rotating Pocket Slip Liner HangerGhinet Teodor-ioanNo ratings yet

- 13 Double Spline Setting AdapterDocument1 page13 Double Spline Setting AdapterGhinet Teodor-ioanNo ratings yet