Professional Documents

Culture Documents

Hazard Identification and Risk Assessment: Yes 1 5 Nanayesyesna 1 3

Uploaded by

Ruchin JainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Identification and Risk Assessment: Yes 1 5 Nanayesyesna 1 3

Uploaded by

Ruchin JainCopyright:

Available Formats

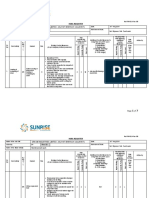

FLS/Safety/PR-06/Rev-2 Dated 14.02.

18

Task: Piling work Hazard Identification and Risk Assessment Date: 28-04-2020

ID: Site / HIRA No.: HIL-HIRA- 10 Rev. No.:

HIRA Team: Bidit Mahanta, Sandeep Kumar

Residual

Hazard Risk Assessment on

/NonRoutine(NR)

Risk

Legal (Yes/No)

Emergency , E

Routine(R)

Risk Level

Risk Level

Administrative

Substituition

Engineering

Elimination

Liklihood

Liklihood

Comtrols

Severity

Severity

No. Activity Sub activity OH/SH Existing Controls Proposed Controls Residual Risk Action By

Contols

PPE

Situation/ Source/Act Consequence

2 Piling Work Fitness inspection to be carried High

Inspection to be done before engaged Low

Unfit pile rig by inspection and Fit Pile rig to be engaged for

Pile rig Failure SH site activities NR Yes 1 5 NA NA Yes Yes NA to the work and valid gate pass will be 1 3 Acceptabe risk

Site

checklist provided after inspection/checking with engineer

authorized person

Selection of piling

7 rig Fitness inspection to be carried by High Low

competent person and Fit pile tig

Pile rig without competent

Pile rig Failure SH to be engaged for site activities NR Yes 1 5 NA NA Yes Yes NA Competent person to be checked 1 3 Acceptabe risk

Site

certification before engaged to the work engineer

9 1.Trained and experienced riggers High Medium

and workers to be deployed for

the same activities. Regarding

competency requirement to be

ensured Site

Unfit riggers & Workers Multiple Injury SH NR No 3 4 NA NA Yes Yes NA Experience person only engaged 2 3 Acceptabe risk

2.Medical fitness and working at engineer

height test to be conduct for the

riggers and workers before

engagement

Selection of riggers

10 Safety induction to be provided to the High Medium

& workers

Riggers and workers and sufficient All workmen should undergo in the

safety knowledge to be provided Site

Without safety induction Multiple Injury SH NR Yes 2 5 NA NA Yes Yes NA safety induction before issuing the 1 4 Acceptabe risk

engineer

valid gate pass

11 Special pep talk to be provided to High Low

the engaged team and briefly

In adequate knowledge of the Major injury / Multiple

SH explain the sequential NR No 1 5 NA NA Yes Yes NA Job specific Erection plan to be explain 1 3 Acceptabe risk

Site

sequential of erection activity injury methodology with all safety factor before start the work engineer

12 Sufficient PPE's has to be used Medium Low

PPE’s minimum stock to be maintain Site

Insufficient PPE's Body Injury SH R No 2 3 NA NA NA Yes Yes 1 2 Acceptabe risk

(10% of total worker) engineer

13 PPE's to be in good condition and Medium Low

as per standerd

PPE's for the Site

Damaged PPE's Body Injury SH R No 3 3 NA NA NA Yes Yes 2 2 Acceptabe risk

engaged workers engineer

14 Sufficient safety knowledge to be Low Low

shared to the workers via safety

In adequate knowledge of the training & pep talk Site

Human Injury SH R No 2 2 NA NA NA Yes Yes 1 1 Acceptabe risk

usage of PPE's engineer

15 Concern signature to be present 1 4 Medium Low

at PTW

Authorized person only can issue

Site

PTW without concern signature PTW failure SH the permit R Yes NA NA NA Yes NA 1 2 Acceptabe risk

engineer

PTW's for the

erection activity

16 Sufficient things to be mentioned Medium Low

on the PTW

In adequate information on All the erection procedure to be Site

PTW failure SH R Yes 1 4 NA NA NA Yes NA 1 2 Acceptabe risk

PTW display in the permit engineer

Breif discussion of PTW among

workmen before start the job.

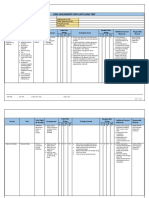

FLS/Safety/PR-06/Rev-2 Dated 14.02.18

Task: Piling work Hazard Identification and Risk Assessment Date: 28-04-2020

ID: Site / HIRA No.: HIL-HIRA- 10 Rev. No.:

HIRA Team: Bidit Mahanta, Sandeep Kumar

Residual

Hazard Risk Assessment on

/NonRoutine(NR)

Risk

Legal (Yes/No)

Emergency , E

Routine(R)

Risk Level

Risk Level

Administrative

Substituition

Engineering

Elimination

Liklihood

Liklihood

Comtrols

Severity

Severity

No. Activity Sub activity OH/SH Existing Controls Proposed Controls Residual Risk Action By

Contols

PPE

Situation/ Source/Act Consequence

18 The surface must be leveled and Medium Medium

compacted. Check the level of

outrigger during placement.

Safe distance from open

Imbalance of pile rig excavation and manholes at least Site

Uneven ground condition could result in toppling SH 3 m. R No 1 4 NA NA Yes NA NA 1 4 Acceptabe risk

engineer

while piling Outriggers must be fully extended

Placement of Pile

19 Equipment operators and drivers High Drivers / Operators are not allowing to Medium

rig and tools at site

shall follow site speed limit and use mobile phone during the operation

Serious Injury

Uncontrolled vehicle traffic signs. Site

Death SH R No 3 4 NA Yes NA NA of equipment. 2 3 Acceptabe risk

movement With out helper not permitted for engineer

Property damage

movement

20 Use trained flag man to control High Unauthorized entry should be restrict. Medium

Injury the equipment movement. With out helper not permitted for

Run over / Hitting people and Reverse horn in working condition Site

Fracture SH R No 3 4 NA NA Yes Yes NA movement 2 3 Acceptabe risk

vehicles by reversing engineer

Death

21 TBT given to workmen before Medium Pit depth should not be more than 1.5 Low

start the work. mtr.

Barrication provided Site

Fall of person inside the pit Physical injury SH R No 2 3 NA NA Yes Yes NA 2 2 Acceptabe risk

engineer

Making of bentonite

pit Pile bore to pit should be Medium Pit has to be cleaned or alternative pit Low

connected through proper to be prepare if one pit filled with mud

Slip & trip if slurry came out channel. & slurry. Site

Physical injury SH R No 3 2 NA Yes Yes NA NA 2 1 Acceptabe risk

near to approch engineer

Trained & experienced operator Medium Use mandatory PPE,s. Low

will be engaged

TBT/Training to workmen before Site

Lack of knowledge to operator Physical injury SH start the work. R No 1 4 NA NA Yes Yes Yes 1 2 Acceptabe risk

engineer

TBT given to workmen before Medium Ensure that no unwanted person Low

start the work. moving in working area.

Handling of drilling rod & other Physical injury to other Barrication provided in working Proper supervision. Site

SH area R No 2 3 NA NA Yes Yes Yes 1 2 Acceptabe risk

materials person due to hit engineer

Operation of pile rig

TBT given to workmen. Medium PPE’s minimum stock to be maintain Low

Safety goggles provided to (10% of total worker).

Mud water splash on face Eye injury workmen Proper supervison. Site

SH R No 4 2 NA NA NA Yes Yes 3 1 Acceptabe risk

during bore engineer

Trained & experienced person to Low Proper supervision. Low

Drill rod hit to person be engaged.

during fixing without TBT givent to workmen before Site

Holding of drilling rod SH start the activity. R No 2 2 NA NA Yes Yes NA 2 2 Acceptabe risk

proper holding engineer

arrangment/tools

FLS/Safety/PR-06/Rev-2 Dated 14.02.18

Task: Piling work Hazard Identification and Risk Assessment Date: 28-04-2020

ID: Site / HIRA No.: HIL-HIRA- 10 Rev. No.:

HIRA Team: Bidit Mahanta, Sandeep Kumar

Residual

Hazard Risk Assessment on

/NonRoutine(NR)

Risk

Legal (Yes/No)

Emergency , E

Routine(R)

Risk Level

Risk Level

Administrative

Substituition

Engineering

Elimination

Liklihood

Liklihood

Comtrols

Severity

Severity

No. Activity Sub activity OH/SH Existing Controls Proposed Controls Residual Risk Action By

Contols

PPE

Situation/ Source/Act Consequence

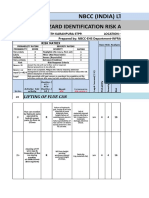

TBT given to workmen. Medium Tag line shall be used to control the Low

Trained person to be engaged. cage.

Cage hit to person during Proper supervison. Site

Holding of cage SH No 2 3 NA Yes NA Yes NA 1 2 Acceptabe risk

holding engineer

Flammable / Cumbustible Fire House keeping done before Medium Proper supervision Low

materials present in working welding operation Keep fire extinguisher near hot work

area area. Site

SH Yes R No 2 3 NA NA NA Yes NA 1 2 Acceptabe risk

engineer

Improper cable joint Fire / cable melt due Inspection prior to start the work Medium Use cable joint connecter to avoid fire Low

heat hazard

Site

SH Yes R No 2 3 NA NA Yes Yes NA 1 2 Acceptabe risk

engineer

Poor cable routing slip / fall TBT / Training done High Keep the cable over head to avoid slip Low

and trip

Lowring of

Site

reinforcement cage SH R No 4 3 NA NA Yes Yes NA 2 2 Acceptabe risk

engineer

& wedling

Exposure to injurious rays Eye injury Welding Helmet with adequate Low

filter glass is being used.

Site

SH Yes R No 1 3 NA NA NA NA Yes Acceptabe risk

engineer

Exposure to Electrical Energy Electric Shock causing All electrical hand tools including High Only Certified welder is being engaged. Low

serious injury welding machine are being Daily inspection shall be carried out

certified by the electrical engineer with supervisor as per checklist Site

SH ELCB provided in welding machine Yes R No 1 5 NA NA Yes Yes NA All PPEs Like welding shield, Leather 1 3 Acceptabe risk

engineer

apron ,Hand gloves, hand sleeves, leg

sleeves are being used

Overlapping of gas cutting Fire Proper supervision Medium Welding cables and cutting hoses to be Low

hoses and welding cables kept sepratley to avoid fire hazard

Site

SH Yes R No 3 2 NA Yes NA Yes NA 1 2 Acceptabe risk

engineer

23 TBT given to workmen before Low Ensure that no unwanted person Low

start the work. moving in working area.

Barrication provided in working Proper supervision.

Physical injury to other Site

Handling of tremie pipe SH area R No 1 2 NA NA Yes Yes Yes 1 3 Acceptabe risk

person due to hit engineer

25 Jerk load toward lifting Physical injury TBT / Training done Low Proper supervisoin required during Low

Fixing and removing equipment during removing of Concreting & removing of tremie pouring of concrete through tremie

of tremie pipe pipe pipe in continues manner. pipe.

Before initial setting of concrete

pipe has to be removed.

Concrete should not be single Site

SH R No 1 3 NA NA Yes Yes NA 1 2 Acceptabe risk

pourd more than 2 mtr depth. engineer

You might also like

- Risk Assessment - Grouting WorksDocument5 pagesRisk Assessment - Grouting Worksabhinav dj100% (5)

- Hirac (Manhole Installation)Document7 pagesHirac (Manhole Installation)tanaNo ratings yet

- Electrical HiraDocument114 pagesElectrical HiraVENKATESAN M100% (1)

- RISK ASSESSMENT AND ANALYSISDocument6 pagesRISK ASSESSMENT AND ANALYSISabhinav dj50% (2)

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie100% (1)

- HIRA For Civil WorkDocument11 pagesHIRA For Civil WorkYogesh Nath100% (1)

- JSA For Concrete Pouring Using Crane and Bucket3Document8 pagesJSA For Concrete Pouring Using Crane and Bucket3Mohammed Minhaj100% (1)

- All HiraDocument40 pagesAll Hirarameese muhammed100% (1)

- Risk Assessment for MBARARA- NKENDA 160 KV OHTL and Substation ProjectDocument50 pagesRisk Assessment for MBARARA- NKENDA 160 KV OHTL and Substation Projectvijay100% (2)

- K - Birth Plan ChecklistDocument2 pagesK - Birth Plan ChecklistPatrick LinNo ratings yet

- Risk Assessment - Breaking ConcreteDocument2 pagesRisk Assessment - Breaking Concretednmule100% (4)

- JSA-003 Excavation & BackfillingDocument3 pagesJSA-003 Excavation & Backfillingba ratnaparkhe100% (1)

- EHS Risk Assessment for Hyderabad Metro Rail Project ActivitiesDocument2 pagesEHS Risk Assessment for Hyderabad Metro Rail Project ActivitiesRohit Singh92% (12)

- Risk Assessment of Concrete PouringDocument13 pagesRisk Assessment of Concrete PouringAbdul MujeebNo ratings yet

- Block Work Risk AssessmentDocument5 pagesBlock Work Risk AssessmentJamal Khawaldeh0% (1)

- Risk Assessment High Strain Dynamic Testing of PilesDocument4 pagesRisk Assessment High Strain Dynamic Testing of PilesYaba88% (8)

- Risk Assessment For Concrete WorksDocument3 pagesRisk Assessment For Concrete WorksMario Marasigan86% (35)

- Job Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Document7 pagesJob Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Sanjay Kumar GhadaiNo ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- Master Hazard Identification & Risk Assesment (Hira) : Document No: Rev. 0 DateDocument2 pagesMaster Hazard Identification & Risk Assesment (Hira) : Document No: Rev. 0 DateHARSHADNo ratings yet

- 7-Asphalt Road Cutting PDFDocument3 pages7-Asphalt Road Cutting PDFAhmed ZaiNo ratings yet

- Sample Questions Emergency)Document14 pagesSample Questions Emergency)sonmarv100% (3)

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Document3 pagesHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- Hazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted CraneDocument1 pageHazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted Cranesaravanan .b90% (10)

- Aastha Hirac - Facade WorkDocument13 pagesAastha Hirac - Facade Workimran ahemadNo ratings yet

- Vehicular Movement Job Safety Analysis (JSA)Document2 pagesVehicular Movement Job Safety Analysis (JSA)sudam kumar raut100% (2)

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (3)

- Erection & Dismantle Risk AssessmentDocument5 pagesErection & Dismantle Risk Assessment287100% (4)

- Risk assessment manual excavationDocument1 pageRisk assessment manual excavationChandru100% (1)

- Risk Assessment for Anti-Termite WorksDocument3 pagesRisk Assessment for Anti-Termite WorksVictor81% (26)

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Concrete Pumping Risk AssessmentDocument1 pageConcrete Pumping Risk Assessmentqoci5ko50% (2)

- Risk Assesment For CompactionDocument12 pagesRisk Assesment For CompactionAzhar MushtaqNo ratings yet

- Denial Action Training: Welcome To AllDocument25 pagesDenial Action Training: Welcome To Allbraney miller100% (6)

- Job Safety Analysis For Highmast ErectionDocument8 pagesJob Safety Analysis For Highmast ErectionSantoshkumar Gupta100% (3)

- HIRA For DPP-2 Project in I BlockDocument20 pagesHIRA For DPP-2 Project in I BlockSiddharth PNo ratings yet

- False CeilingDocument1 pageFalse CeilingChandru67% (3)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- JSA-Vertical Load On Test Pile - REV 0Document8 pagesJSA-Vertical Load On Test Pile - REV 0Sanjay Kumar GhadaiNo ratings yet

- HIRA for Loading, Unloading, Handling, Lifting & Shifting at Tata SmartFoodzDocument47 pagesHIRA for Loading, Unloading, Handling, Lifting & Shifting at Tata SmartFoodzNaresh Kumar83% (6)

- 1 RA 1410 Demolition & Site ClearanceDocument11 pages1 RA 1410 Demolition & Site ClearanceMuhammad Shahid Iqbal100% (5)

- Example Risk Assessment For Excavations Updated 21-11-12Document3 pagesExample Risk Assessment For Excavations Updated 21-11-12rishi100% (3)

- Height Work - HIRADocument1 pageHeight Work - HIRARuchin Jain91% (11)

- Passenger Hoist LiftDocument1 pagePassenger Hoist LiftGyanendra Narayan Nayak100% (2)

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- SS 6e Manager Sample-ChapterDocument32 pagesSS 6e Manager Sample-ChapterIrmita Prameswari Wijayanti100% (2)

- 04 HIRA For Reinforcement WorkDocument7 pages04 HIRA For Reinforcement WorkMithlesh Singh100% (1)

- Risk Assessment For Plate Load TestDocument4 pagesRisk Assessment For Plate Load TestShah Jan100% (7)

- Back FillingDocument2 pagesBack FillingChandruNo ratings yet

- HIRA For Loading or Unloading ActivityDocument4 pagesHIRA For Loading or Unloading ActivityMD Abdullah100% (2)

- Job Safety Analysis for Shuttering and Deshuttering Form WorkDocument3 pagesJob Safety Analysis for Shuttering and Deshuttering Form Workba ratnaparkhe83% (12)

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- Drug Related ProblemDocument34 pagesDrug Related ProblemERONADIAULFAH SUGITONo ratings yet

- Job Safety Analysis for Rohan Builders Construction ProjectsDocument9 pagesJob Safety Analysis for Rohan Builders Construction Projectsradeep100% (1)

- Dismantling of WallDocument1 pageDismantling of WallChandruNo ratings yet

- Module 7 Mental Health and Well-Being in Middle and Late AdolescenceDocument22 pagesModule 7 Mental Health and Well-Being in Middle and Late AdolescenceFaith CubillaNo ratings yet

- Mivan Risk AssessmentDocument3 pagesMivan Risk AssessmentBineeshNo ratings yet

- Barbending HiracDocument2 pagesBarbending HiracJohn Ha71% (7)

- Tower Crane HiraDocument3 pagesTower Crane HiraVikas YamagarNo ratings yet

- Risk Assessment For Anti Termite WorksDocument7 pagesRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Job Safety Measures for RMC Pump ConcretingDocument6 pagesJob Safety Measures for RMC Pump ConcretingRakeshkasarla100% (2)

- HIRA, TCS-ACP Sheet FixingDocument2 pagesHIRA, TCS-ACP Sheet FixingGowtham Kishore75% (4)

- NBCC (INDIA) LTD. HAZARD IDENTIFICATION RISK ASSESSMENTDocument6 pagesNBCC (INDIA) LTD. HAZARD IDENTIFICATION RISK ASSESSMENTAmit kumar Gupta100% (1)

- HIRA For Concrete Pouring of Diaphragm WallDocument4 pagesHIRA For Concrete Pouring of Diaphragm WallLoc Nguyen0% (1)

- GROUP RISK ASSESSMENTDocument3 pagesGROUP RISK ASSESSMENTJacob ChirayilNo ratings yet

- Slip Form Construction Safety AnalysisDocument5 pagesSlip Form Construction Safety Analysisputrasejahtra50% (2)

- Virtual Simulation Learning among Student Nurses in PACUDocument4 pagesVirtual Simulation Learning among Student Nurses in PACUJessa BorreNo ratings yet

- Dhama 2021Document18 pagesDhama 2021Share linkNo ratings yet

- Hipertensi KebidananDocument77 pagesHipertensi KebidananNINING ALKOMAHNo ratings yet

- Localizing the SDGs for a Sustainable Cauayan CityDocument7 pagesLocalizing the SDGs for a Sustainable Cauayan CityAlyssa Marie M. ObenarNo ratings yet

- Clinical Pharmacy Thesis TopicsDocument6 pagesClinical Pharmacy Thesis Topicsbsk561ek100% (2)

- Mental health effects of distance learningDocument7 pagesMental health effects of distance learningJohn Patrick GarciaNo ratings yet

- Nursing ResponsibilitiesDocument4 pagesNursing ResponsibilitiesMaureen Joy Cascayan EspirituNo ratings yet

- Self-Assessment of Nursing Standards of PracticeDocument32 pagesSelf-Assessment of Nursing Standards of Practiceapi-242114301No ratings yet

- Assignment DNHEDocument9 pagesAssignment DNHEmohitNo ratings yet

- Intake of Carbohydrate-Protein Supplements by Recreational Users at Gym Body Composition ImprovedDocument9 pagesIntake of Carbohydrate-Protein Supplements by Recreational Users at Gym Body Composition ImprovedJuan Camilo MendietaNo ratings yet

- Kozier FundamentalDocument50 pagesKozier FundamentalgkixNo ratings yet

- The Wisdom of Life - Arthur Schopenhauer PDFDocument65 pagesThe Wisdom of Life - Arthur Schopenhauer PDFAachal PatelNo ratings yet

- Harry Guess, Linda Engel, Arthur Kleinman, John Kusek Science of The Placebo Toward An Interdisciplinanary Research Agenda Evidence-Based Medicine Workbks. 2002Document345 pagesHarry Guess, Linda Engel, Arthur Kleinman, John Kusek Science of The Placebo Toward An Interdisciplinanary Research Agenda Evidence-Based Medicine Workbks. 2002rockspirit02No ratings yet

- Annemarie Mol Mind Your PlateDocument19 pagesAnnemarie Mol Mind Your PlateantonadiaborgesNo ratings yet

- Chapter-5 Summary and Conclusion: 5.1 Summary of The StudyDocument29 pagesChapter-5 Summary and Conclusion: 5.1 Summary of The StudySumit SinghNo ratings yet

- Hormonal TherapiesDocument39 pagesHormonal TherapiesJalal EltabibNo ratings yet

- Self-Care refer-WPS OfficeDocument7 pagesSelf-Care refer-WPS OfficeLyka Maun trinidadNo ratings yet

- Gordon'S Functional Health PatternDocument10 pagesGordon'S Functional Health PatternDave SapladNo ratings yet

- ASALEXU Volume 21 Issue 2 Pages 69-82Document14 pagesASALEXU Volume 21 Issue 2 Pages 69-82احمد العايديNo ratings yet

- Health 10 - Q2 - WK5Document2 pagesHealth 10 - Q2 - WK5graceNo ratings yet

- Evaluation of Standard Growth Curves for Indian WomenDocument7 pagesEvaluation of Standard Growth Curves for Indian WomenPrashanth GuvvalaNo ratings yet

- MBBS-BDS Stray - Round - SelectionList R4Document462 pagesMBBS-BDS Stray - Round - SelectionList R4Lakshmi ManasaNo ratings yet

- Build Healthy Plate MyPlate Dietary GuidelinesDocument15 pagesBuild Healthy Plate MyPlate Dietary GuidelinesRommel SegoviaNo ratings yet

- Respiratory SystemDocument104 pagesRespiratory SystemKatisha JosephNo ratings yet