Professional Documents

Culture Documents

Prestressing schedule and notes

Uploaded by

TriChandra MaharjanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prestressing schedule and notes

Uploaded by

TriChandra MaharjanCopyright:

Available Formats

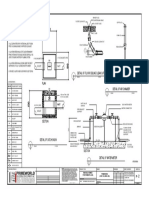

GENERAL NOTES:-

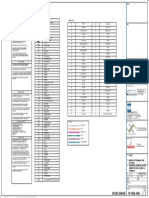

D. PRESTRESSING SCHEDULE:-

§ STRESSING OF CABLE (1-7), (2-8), (3-9), (4-10), (5-11), (6-12), (13-20), (14-19), (15-18) & (16-17) SHALL BE DONE IN ONE

STAGE AFTER 28 DAYS OF LAST CONCRETING OF BOX ELEMENTS

§ THE CABLE NO. D SHALL ACT AS DUMMY AND SHALL BE STRESSED IN CASE OF ANY SHORT FALL IN STRESSING. IF

THERE IS NO. SHORT FALL STRANDS IN CABLE NO. D SHALL BE TAKEN OUT AND GROUTED.

B. E. STRESSING PROCEDURE:-

§ STRESSING IS TO BE DONE FROM BOTH END. EXTENSION SHOWN ARE TOTAL EXTENSION INCLUDING EFFECT

§ INDIVIDUAL STRAND SIZE :15.2MM (CLASS 2 / SEVEN PLY) CONFIRMING IS 14268:1995

§ INDIVIDUAL STRAND AREA :140 SQ.MM

OF SLIP (10 MM) AT EACH END. HENCE NO EXTRA ALLOWANCE SHALL BE MADE FOR SLIP.

§ NORMAL EXTENSION SHALL BE OBTAINED AT SPECIFIED GAUGE PRESSURE. IN CASE EXTENSION IS NOT AT

§ UNIT WEIGHT :1.102 KG/M

§ MIN. BREAKING LOAD, UTS: 260.7 KN

SPECIFIED GAUGE PRESSURE, THE STRESSING SHALL BE CONTINUED TILL REQUIRED EXTENSION OBTAINED

§ MIN. YIELD LOAD @ 1% STRAIN 234.5 KN (0.90% OF UTS)

SUBJECT TO GAUGE PRESSURE NOT EXCEEDING 5% OF REQUIRED GAUGE PRESSURE.

§ IN CASE REQUIRED EXTENSION IS OBTAINED AT LOWER GAUGE PRESSURE THEN STRESSING , SHALL BE

§ MIN. ELONGATION : 3.5%

§ 1000HR RELAXATION : 2.50% @70% OF INITIAL STRESS

CONTINUED IN ORDER TO OBTAIN THE SPECIFIED GAUGE PRESSURE. HOWEVER THE EXTENSION SHALL NOT

§ MODULUS OF ELASTICITY: 205 KN/SQ.MM

EXCEED BY MORE THAN 5% OF REQUIRED EXTENSION.

§ ALL CABLES SATISFYING THE ABOVE CONDITION SHALL BE GROUTED.

§ ANCHORAGE TYPE : 19K15

§ IF IN CASE OF ANY CABLE REQUIRED EXTENSION AT ONE END IS NOT OBTAINED EVEN REACHING GAUGE

§ NO. OF STRAND PER DUCT : 19

§ TOTAL NO. OF TENDON : 20

PRESSURE OF 5% MORE THAN THE SPECIFIED GAUGE PRESSURE, THE BALANCE EXTENSION SHALL BE

§ APPLIED PRESTRESS FORCE 75% OF UTS :195.5 KN

OBTAINED BY STRESSING THE OTHER END.

§ ADDITIONAL EXTENSION AT EACH END TO ACCOUNT FOR EXTENSION IN GRIP LENGTH OF CABLE SHALL BE

§ SHEATHING SHALL BE OF CORRUGATED HDEP TYPE OF 100MM CONFIRMING IRC 18:2000.

§ JACK TYPE :K500

ADDED TO THE RESPECTIVE EXTENSION SHOWN IN THE TABLE.

§ ALL CABLE ARE TO BE STRESSED FROM BOTH ENDS SIMULTANEOUSLY.

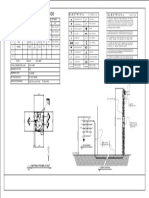

F. IMPORTANT N0TES:-

§ BUNCH TOGETHER ALL 12 STANDS INTO A GROUP BY BINDING WIRE TIGHTENED AROUND THE BUNCH AT ABOUT

1.0M INTERVALS.

§ ALL PRESTRESSING CABLES SHALL BE LAID TO SMOOTH PROFILES USING THE SPECIFIED PROFILE ORDINATES

GIVEN IN TABLE. SHORT 12MM DIA. CROSS BARS SHALL BE SPOT WELDED TO THE STIRRUP LEGS AT

APPROXIMATELY 1M CENTERS ALONG THE LENGTH OF CABLES TO GIVE THE NECESSARY PROFILE TO THE

CABLES.

§ BEFORE COMMENCEMENT OF PRESTRESSING, IT SHALL BE ENSURED THAT ALL THE CABLES/DUCTS ARE FREE

OF ANY CLOGS AND THAT THE STRUCTURE-MEMBERS ARE FREE TO ACCOMMODATE THE HORIZONTAL AND

VERTICAL MOVEMENTS DUE TO APPLICATION OF PRESTRESS, AND THAT THESE IS ENOUGH SPACE FOR THE

MOVEMENT OF THE JACK PISTON.

§ FOR TENSIONING A CABLE, THE INITIAL SLACK IN IT SHALL FIRST BE REMOVED BY APPLYING A RELATIVELY

SMALL INITIAL TENSION FROM EACH END AS REQUIRED TO REMOVE THIS SLACK SHALL BE TAKEN AS THE

STARTING POINT FOR MEASURING THE CABLE ELONGATIONS AND THE CORRECTION SHALL BE APPLIED AS PER

CLAUSE 12.2.1.3 OF IS1343:2012

§ THE SUPERSTRUCTURE IN A SPAN CAN BE LIFTED UPWARDS AT EACH OF ITS ENDS (WORK ONLY AT ONE END

AT A TIME)BY OPERATING THE APPROPRIATE-CAPACITY LIFTING JACKS APPLIED UNDER THE END

CROSS-GIRDER AT THAT END AS INDICATED IN THE DRAWING.

§ EACH OF THESE LIFTING JACKS SHALL HAVE A SAFE LIFTING CAPACITY OF 260 TONNES.

§ ALL JACKS MUST BE OPERATED SIMULTANEOUSLY, EQUALLY AND IN UNISON.

§ FOR MIX DESIGN OF M45 CONCRETE, IS10262:2009 GUIDELINE FOR CONCRETE MIX SHALL BE FOLLOWED.

§ REMOVAL OF FALSEWORK ONLY AFTER FULL PRESTRESSING

05

GENERAL

NOTES

1/1

You might also like

- Fluid Viscous Dampers & Lock-Up Devices Clevis - Base Plate ConfigurationDocument4 pagesFluid Viscous Dampers & Lock-Up Devices Clevis - Base Plate ConfigurationElmer Palma RomeroNo ratings yet

- General Notes-Layout1Document1 pageGeneral Notes-Layout1Akmal KhanNo ratings yet

- Structural SteelDocument15 pagesStructural Steelstudent999No ratings yet

- H001 76-10526-Detail Design: Drainage Legend Standard Drainage Notes: Abbreviation Designation AbbreviationsDocument1 pageH001 76-10526-Detail Design: Drainage Legend Standard Drainage Notes: Abbreviation Designation AbbreviationsMazen IsmailNo ratings yet

- General Notes: As-Built Plan of One Storey Abdulin Store BuildingDocument1 pageGeneral Notes: As-Built Plan of One Storey Abdulin Store BuildingMark Ruby OpawonNo ratings yet

- (4.) Beams & Slabs 5.reinforcement:: General NotesDocument1 page(4.) Beams & Slabs 5.reinforcement:: General NotesVirendra ChavdaNo ratings yet

- Cable Route MarkerDocument2 pagesCable Route Markersundareee96No ratings yet

- What is a Concrete Slab? Types and UsesDocument3 pagesWhat is a Concrete Slab? Types and Usesamit jainNo ratings yet

- Ce - 07Document1 pageCe - 07Arnulfo Jose Pi DiNo ratings yet

- Schedule of Loads and Design Computation:: LegendDocument1 pageSchedule of Loads and Design Computation:: LegendTraci ReyNo ratings yet

- 33 70 00-7 Generator Pad Detail PDFDocument1 page33 70 00-7 Generator Pad Detail PDFNadom MutlibNo ratings yet

- Legend: General Notes & SpecificationDocument1 pageLegend: General Notes & SpecificationShaunjay Dela CalzadaNo ratings yet

- File-1438261672 GatesDocument30 pagesFile-1438261672 Gatesterry fergusonNo ratings yet

- Structural Plan PDFDocument10 pagesStructural Plan PDFPaul Anjelo MilagrosaNo ratings yet

- Tubs Installation Harwil Q 12Document3 pagesTubs Installation Harwil Q 12Сергей ОтрошкоNo ratings yet

- 6312 e Civ DTR DC V I 002 Burnt Oil Pit Signed 23-09-2020Document1 page6312 e Civ DTR DC V I 002 Burnt Oil Pit Signed 23-09-2020manikandanNo ratings yet

- Woodman Gemini DrawingDocument13 pagesWoodman Gemini DrawingkhalidmahmoodqadriNo ratings yet

- Esr CyclosDocument12 pagesEsr CyclosSurendra KumarNo ratings yet

- 125 AMP /single Phase: General NotesDocument1 page125 AMP /single Phase: General NotesIvy Del GalvanNo ratings yet

- E6 Electrical SamplesDocument1 pageE6 Electrical Samplesgeneveve colasitoNo ratings yet

- Dwg. Number Connector P/N Customer P/N P400-S08-037 C10-749671-Z2S APPC, 474283A, 101Document1 pageDwg. Number Connector P/N Customer P/N P400-S08-037 C10-749671-Z2S APPC, 474283A, 101akoe ajaNo ratings yet

- Lighting & Power Layout Vicinity Map: Chedule of LoadsDocument1 pageLighting & Power Layout Vicinity Map: Chedule of Loadsjohndean urbanozoNo ratings yet

- Dual-Occupency House DrawingsDocument12 pagesDual-Occupency House DrawingsJiang TaoNo ratings yet

- Lap Lengths System of Units: Steel Grade Bar SizeDocument1 pageLap Lengths System of Units: Steel Grade Bar SizeKanz Ur RehmanNo ratings yet

- Pedestrian Bridge Design SpecificationsDocument13 pagesPedestrian Bridge Design SpecificationsyasirjurabaNo ratings yet

- Quality TrainingDocument39 pagesQuality TrainingSyed Mohammed ZakariaNo ratings yet

- KAM SR Sample Receiver: User GuidelinesDocument3 pagesKAM SR Sample Receiver: User GuidelinesGibran TorresNo ratings yet

- SR - No Comment Received ComplianceDocument2 pagesSR - No Comment Received Compliancepravin awalkondeNo ratings yet

- Specs Purchase To Winch Vendor From BuyerDocument1 pageSpecs Purchase To Winch Vendor From BuyerslipformNo ratings yet

- CSC To Crank Measuring InstructionDocument1 pageCSC To Crank Measuring InstructionparalocaliNo ratings yet

- 5990785459TDS - XBond Construction Adhesive Sealant PDFDocument2 pages5990785459TDS - XBond Construction Adhesive Sealant PDFelectrical engineeringNo ratings yet

- Precast Concete Panel: How Is It Made and Installed?: WaterproofingDocument3 pagesPrecast Concete Panel: How Is It Made and Installed?: WaterproofingharshitaNo ratings yet

- Installation Commissioning & Operators ManualDocument36 pagesInstallation Commissioning & Operators ManualSuman KumarNo ratings yet

- Precast Compound Wall DesignDocument1 pagePrecast Compound Wall DesignSumanNo ratings yet

- S021-GENERAL NOTES (SHEET 2 OF 3)Document1 pageS021-GENERAL NOTES (SHEET 2 OF 3)WNo ratings yet

- Electrical 2Document1 pageElectrical 2Rohan Siegfried BartolomeNo ratings yet

- SPE IADC - Stavanger - 2023 MarchDocument12 pagesSPE IADC - Stavanger - 2023 MarchPrakhil BilayeNo ratings yet

- Second Floor Genset Keyplan BDocument1 pageSecond Floor Genset Keyplan BIvan SantosNo ratings yet

- Designing Mep For A RoomDocument2 pagesDesigning Mep For A RoomdeddyNo ratings yet

- SFSDFDocument1 pageSFSDFbillNo ratings yet

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocument1 pageDetail of Floor/ Ceiling Clean Out: Plumbing NotesRODEAN HOPE LACSINo ratings yet

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocument1 pageDetail of Floor/ Ceiling Clean Out: Plumbing NotesHana YeppeodaNo ratings yet

- PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1Document1 pagePARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1irshad khanNo ratings yet

- Loose Cable ManualDocument9 pagesLoose Cable ManualHappy AaronNo ratings yet

- The Ve3Gk Plastic, 3 To 56 MHZ HF Mobile AntennaDocument3 pagesThe Ve3Gk Plastic, 3 To 56 MHZ HF Mobile AntennaDavid GallegoNo ratings yet

- Notes:: Plan End ViewDocument1 pageNotes:: Plan End Viewsowman tungNo ratings yet

- PLP Suspension AGS CatalogDocument48 pagesPLP Suspension AGS CatalogAlexandreinspetorNo ratings yet

- Baladna Farm2-Manure MGMT Renov-20190129Document11 pagesBaladna Farm2-Manure MGMT Renov-20190129AslamNo ratings yet

- 4151-SGEP-M-VD-002-34001_cedulaDocument35 pages4151-SGEP-M-VD-002-34001_cedulaAri Javier Martinez CoronaNo ratings yet

- Com XX E05 2002 001 01 Js1225 Uep 315 Kva Transformer Skid With LVDBDocument21 pagesCom XX E05 2002 001 01 Js1225 Uep 315 Kva Transformer Skid With LVDBbalaNo ratings yet

- Mmc111ac005a enDocument1 pageMmc111ac005a enКонстантин ГеоргиевNo ratings yet

- Plumbing Abbreviations Plumbing SpecificationsDocument3 pagesPlumbing Abbreviations Plumbing SpecificationsAriel DimacaliNo ratings yet

- Bat-Dwg-Dd-Me-00-Eg-6101 - R0 - Grounding, Earthing and Lightning Protection System Shematic DiagramDocument1 pageBat-Dwg-Dd-Me-00-Eg-6101 - R0 - Grounding, Earthing and Lightning Protection System Shematic DiagramCosphiiiNo ratings yet

- A. General Notes: B. Notes and Concrete Mixes and PlacingDocument1 pageA. General Notes: B. Notes and Concrete Mixes and Placingdomin domNo ratings yet

- LotDocument15 pagesLotOjo PreciousNo ratings yet

- Vacuum Circuit Breakers: For Out-Door Use Upto 36KvDocument4 pagesVacuum Circuit Breakers: For Out-Door Use Upto 36KvtoogooodNo ratings yet

- Vacuum Circuit Breakers: For Out-Door Use Upto 36KvDocument4 pagesVacuum Circuit Breakers: For Out-Door Use Upto 36KvdyeeuranNo ratings yet

- General Notes-1: Table 1: Lap Splices For RebarsDocument1 pageGeneral Notes-1: Table 1: Lap Splices For RebarsTanvir IslamNo ratings yet

- ShopDrawings - Part 1Document51 pagesShopDrawings - Part 1YapNo ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- 02Document1 page02TriChandra MaharjanNo ratings yet

- 01Document1 page01TriChandra MaharjanNo ratings yet

- General ArrangemetDocument1 pageGeneral ArrangemetTriChandra MaharjanNo ratings yet

- 03Document1 page03TriChandra MaharjanNo ratings yet

- Box Girder - OuterDocument1 pageBox Girder - OuterTriChandra MaharjanNo ratings yet

- Final Report of Field Test and Laboratory Test For Upgrading of TU Gate To Chovar RoadDocument78 pagesFinal Report of Field Test and Laboratory Test For Upgrading of TU Gate To Chovar RoadTriChandra MaharjanNo ratings yet

- Hydrology of Mainawoti Khola Bridge DesignDocument12 pagesHydrology of Mainawoti Khola Bridge DesignTriChandra MaharjanNo ratings yet

- Geotechnical soil report for Bagdoghra Khola BridgeDocument1 pageGeotechnical soil report for Bagdoghra Khola BridgeTriChandra MaharjanNo ratings yet

- Sub Drawing - TopomapDocument1 pageSub Drawing - TopomapTriChandra MaharjanNo ratings yet

- Speed & Delay Survey: Form: 4CDocument1 pageSpeed & Delay Survey: Form: 4CTriChandra MaharjanNo ratings yet

- Cover Page 1Document1 pageCover Page 1TriChandra MaharjanNo ratings yet

- Bore LogDocument4 pagesBore LogTriChandra MaharjanNo ratings yet

- LAPTOPDocument1 pageLAPTOPTriChandra MaharjanNo ratings yet

- Mainawati Khola ReportDocument51 pagesMainawati Khola ReportTriChandra MaharjanNo ratings yet

- ललितपुर जिल्ला दर रेट २०७५ २०७६ PDFDocument171 pagesललितपुर जिल्ला दर रेट २०७५ २०७६ PDFTriChandra MaharjanNo ratings yet

- Tle"/ Lo "9'' '''''/'. .$ : CH Lu A/,/.-.LiDocument20 pagesTle"/ Lo "9'' '''''/'. .$ : CH Lu A/,/.-.LiTriChandra MaharjanNo ratings yet

- Ongoing Projects - Hulaki SadakDocument11 pagesOngoing Projects - Hulaki SadakTriChandra MaharjanNo ratings yet

- LAPTOPDocument1 pageLAPTOPTriChandra MaharjanNo ratings yet

- Origin-Destination Survey: Form: 4BDocument1 pageOrigin-Destination Survey: Form: 4BTriChandra MaharjanNo ratings yet

- Terre Armee India Company Profile PDFDocument24 pagesTerre Armee India Company Profile PDFTriChandra MaharjanNo ratings yet

- Form 4A Traffic Volume SurveyDocument1 pageForm 4A Traffic Volume SurveyTriChandra MaharjanNo ratings yet

- Sunsari Landslide Topo Map PDFDocument1 pageSunsari Landslide Topo Map PDFTriChandra MaharjanNo ratings yet

- 03 - RoadConditionDocument1 page03 - RoadConditionTriChandra MaharjanNo ratings yet

- 01 PDFDocument1 page01 PDFTriChandra MaharjanNo ratings yet

- Sunsari Landslide Topo Map PDFDocument1 pageSunsari Landslide Topo Map PDFTriChandra MaharjanNo ratings yet

- Sunsari Landslide Orthophoto A0Document1 pageSunsari Landslide Orthophoto A0TriChandra MaharjanNo ratings yet

- Pile Capacity - FB - Mid PierDocument2 pagesPile Capacity - FB - Mid PierTriChandra MaharjanNo ratings yet

- Sunsari Landslide Topo Map PDFDocument1 pageSunsari Landslide Topo Map PDFTriChandra MaharjanNo ratings yet

- 01 PDFDocument1 page01 PDFTriChandra MaharjanNo ratings yet

- Heat exchanger specification sheetDocument1 pageHeat exchanger specification sheetIdil Fitri100% (1)

- As'idatu Viddaroini - A - 195060401111009kelompok 5 LidDocument13 pagesAs'idatu Viddaroini - A - 195060401111009kelompok 5 LidAs'idatu ViddaroiniNo ratings yet

- GCE 4145 Foundry Engineering Lecture: Key Pattern Allowances for Casting DesignDocument18 pagesGCE 4145 Foundry Engineering Lecture: Key Pattern Allowances for Casting DesignAbdullah SubbirNo ratings yet

- Construction of Surface CAR Parking BoQDocument15 pagesConstruction of Surface CAR Parking BoQFANTASY 11No ratings yet

- Design Column Axial Loads Shear StressesDocument31 pagesDesign Column Axial Loads Shear Stressesrhoniel0% (2)

- Piling Installation Project Requirements and ConsiderationsDocument9 pagesPiling Installation Project Requirements and ConsiderationshugojameswoodNo ratings yet

- Chapter Five Shear Stress DistributionDocument15 pagesChapter Five Shear Stress DistributionAli AlabdalatheemNo ratings yet

- ACI 318M/318RM-02 Building Code RequirementsDocument1 pageACI 318M/318RM-02 Building Code RequirementsomidziaNo ratings yet

- Low NPSH Side Channel PumpsDocument20 pagesLow NPSH Side Channel PumpsAlexander Rivillas100% (1)

- Bill of Quantity - Forest Harmony Showroom Construction WorksDocument6 pagesBill of Quantity - Forest Harmony Showroom Construction WorksShaikh AafrinNo ratings yet

- Chapter 1Document76 pagesChapter 1Anonymous MdUlQq2hhNo ratings yet

- Doshi Steel Catalogue 2021 - EmailDocument12 pagesDoshi Steel Catalogue 2021 - EmailFLYNAS LOGISTICS100% (1)

- Design of Residential BuildingDocument57 pagesDesign of Residential BuildingShubhankar ThakurNo ratings yet

- Coupling BeamDocument2 pagesCoupling Beamwilliam6703100% (1)

- Anna Bhau Sathe Auditorium, YerwadaDocument17 pagesAnna Bhau Sathe Auditorium, YerwadaRadhika AgarwalNo ratings yet

- Energy Efficient Design: Assignment - 4Document8 pagesEnergy Efficient Design: Assignment - 4Gauri WaikarNo ratings yet

- Pendel Bearing Replacement at A9 Kessock Bridge, Scotland 2007Document9 pagesPendel Bearing Replacement at A9 Kessock Bridge, Scotland 2007정주호No ratings yet

- Wold Life-Safety Reports On Center Cass School District 66 SchoolsDocument8 pagesWold Life-Safety Reports On Center Cass School District 66 SchoolsDavid GiulianiNo ratings yet

- Hydraulics Secttion4Document7 pagesHydraulics Secttion4Rezeile RoxasNo ratings yet

- The History About Silver BridgeDocument4 pagesThe History About Silver Bridgethekrauser96No ratings yet

- PS 36 Effect Deflection On Floor FlatnessDocument1 pagePS 36 Effect Deflection On Floor Flatness081382991318No ratings yet

- W15 QDocument6 pagesW15 QRajeshNo ratings yet

- Carbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19Document17 pagesCarbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19Marija IvanovskaNo ratings yet

- ITP Clearing and GrubbingDocument12 pagesITP Clearing and GrubbingAntonio Tomas Gonzalez LosaNo ratings yet

- Structured Method Statement For Concrete Repair - 2Document10 pagesStructured Method Statement For Concrete Repair - 2m.umarNo ratings yet

- 44 Aux. Boiler, Exh. Gas EconomizerDocument132 pages44 Aux. Boiler, Exh. Gas EconomizerKrunal TandelNo ratings yet

- Pile SplicesDocument27 pagesPile Splicesfree4bruceNo ratings yet

- Reinforcement Calculation of Abutment (2) : A B A BDocument12 pagesReinforcement Calculation of Abutment (2) : A B A Bshashi rajhansNo ratings yet

- Slow Down, You're Moving Too FastDocument3 pagesSlow Down, You're Moving Too Fastcjp6124No ratings yet

- Construction Bill of Quantities for 9.7 km Road ProjectDocument18 pagesConstruction Bill of Quantities for 9.7 km Road ProjectUyavie ObonnaNo ratings yet