Professional Documents

Culture Documents

33 70 00-7 Generator Pad Detail PDF

Uploaded by

Nadom MutlibOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

33 70 00-7 Generator Pad Detail PDF

Uploaded by

Nadom MutlibCopyright:

Available Formats

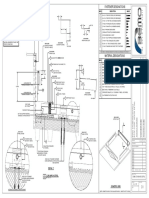

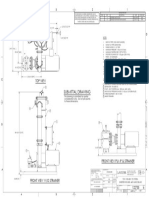

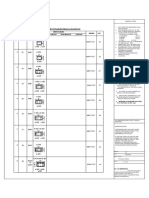

GENERATOR PAD GENERAL NOTES

1. THE TOP 12" OF SUBGRADE BENEATH THE SLAB SHALL BE

THOROUGHLY COMPACTED TO 90% OF MAXIMUM DENSITY

PER ASTM D698. IF TOP 36" OF SUBGRADE IS SUBJECT TO

HIGH WATER TABLE OR PERIODIC SATURATION, COMPACT

SUBGRADE TO 90% PER ASTM D2039 AND D1556. NO

FROZEN BACKFILL SHALL BE USED.

2. SLAB TO BE MADE OF FIBER REINFORCED POLYMER (FRP)

CONCRETE WITH MINIMUM 28 DAY STRENGTH OF 3,500 PSI

WITH 2 INCH LENGTH OF MONOFILAMENT

Facilities Planning & Construction

NOTE: MACROSYNTHETIC FIBERS AT APPROXIMATELY 4 LB/YD^3

L: LENGTH OF GENERATOR (LONGEST SIDE) DOSAGE. ADD AIR-ENTRAINING ADMIXTURE CONFORMING

W: WIDTH OF THE GENERATOR (SHORTEST SIDE) TO ASTM C260/C260M.

Standard Detail

3. TOP OF PAD TO BE SMOOTH, LEVEL AND CLEARED OF ALL

FRAMING MATERIAL AFTER CONCRETE SETS.

EDGE TO CL OF #6, EQUALLY SPACED, MIN. 4. NO WALLS SHALL BE BUILT AROUND GENERATOR, NOR

LENGTH OF THE PAD SPACING @ 7-1/2" CENTER CANOPIES ABOVE GENERATOR.

18"

TO CENTER

5. ALL CONDUIT ENTERING SLAB TO BE VERTICAL AND AT A

GROUND ROD, SEE NOTE 12 90° ANGLE WITH TOP OF SLAB. STUB ALL CONDUITS 1"

ABOVE TOP OF CONCRETE PAD. PROVIDE ALL SPARE

12"

#6, EQUALLY SPACED,

(W) + 24" MIN. SPACING @ 14-5/8" CONDUITS WITH PULLSTRINGS AND PLASTIC CAPS.

12" CENTER TO CENTER

6. COORDINATE WITH UNL UTILITIES TO ALLOW ANY AND ALL

INSPECTIONS BEFORE, DURING AND AFTER

CONDUIT STUB UP AREA. CONSTRUCTION OF PAD.

VERIFY EXACT SIZE AND

12" LOCATION WITH GENSET. 7. PROPER REBAR SPACERS SHOULD BE USED TO KEEP THE

(L) + 24" REBAR AT PLACE. USE OF CONCRETE BRICKS AS

#4 CIRCULAR REBAR

SUBSTITUTE OF SPACERS IS NOT PERMITTED.

PLAN VIEW 8. ALL REBAR SHOULD AT LEAST HAVE 3" COVER FROM THE

SCALE: NO SCALE

SIDES OTHERWISE NOTED.

BOND GROUND ROD TO REBAR IN SLAB 9. REVIEW GENERATOR INSTALLATION INSTRUCTIONS

AND TO GENERATOR FRAME. SEE NOTE 12. BEFORE FORMING THE CONDUIT STUB UP AREA. PROVIDE

AREA PER MANUFACTURER REQUIREMENTS.

3/4" CHAMFER

(TYP-ALL SIDES) 10. PILES OR RE-BAR DETAILS CAN NOT BE ALTERED WITHOUT

8"

12"

3" 7 1/2" WRITTEN CONSENT FROM A CIVIL ENGINEER.

FINAL GRADE

April 2021

N.T.S.

33 70 00 - 07

11. A 48 HOUR INSPECTION NOTICE SHALL BE GIVEN BEFORE

#4 REBAR EQUALLY SCHEDULED POUR WHICH INCLUDES EMAILING THE

#6 REBAR, LOCATED

SPACED AT 3" UNIVERSITY INSPECTOR, ELECTRICAL ENGINEER, AND

AT CENTER OF

CIVIL ENGINEER.

5'-0" MIN.

THICKNESS OF PAD 1'-0" TYP.

3" MIN.

#6 REBAR,

4 NOS. 12. BOND GROUNDING ROD TO REBAR IN SLAB AND TO

(1) 5/8" DIA. X 10' LONG CU

Detail No.:

GENERATOR FRAME. STUB ROD UP 6" ABOVE TOP OF

GROUND ROD. BOND TO

Scale:

Date:

CONCRETE PAD. SIZE BOND PER NEC 250-66

PAD REBAR WITH UL

REQUIREMENTS BASED ON PHASE CONDUCTOR SIZE.

SECTION VIEW LISTED CONNECTOR.

PROVIDE BRAIDED, BARE CU BOND CABLE FROM GROUND

SCALE: NO SCALE

BAR TO PAD REINFORCING AND TO FRAME. LEAVE

SUFFICIENT LACK ABOVE PAD TO TIE TO GENSET FRAME,

GENERATOR PAD DETAIL

Generator Pad Detail

1 MINIMUM OF 24" COIL.

E1.01 SCALE: NO SCALE

Detail Title:

You might also like

- Structural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1Document1 pageStructural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1roger100% (2)

- Structural - AOBDocument21 pagesStructural - AOBMr. Mark B.No ratings yet

- Roof Framing PlanDocument1 pageRoof Framing PlanZandie GarciaNo ratings yet

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyFrom EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyNo ratings yet

- 1) General Notes: 9) Design Consideration: AS Civil Engg ServicesDocument4 pages1) General Notes: 9) Design Consideration: AS Civil Engg ServicesCivil Engineering projectNo ratings yet

- Toaz - Info Tappi Handbook of Pulping and Papermaking PRDocument14 pagesToaz - Info Tappi Handbook of Pulping and Papermaking PRJepri MarpaungNo ratings yet

- A0.01 General NotesDocument1 pageA0.01 General NotesAblaze AllNo ratings yet

- 32 Roof Curb - Apron DetailDocument1 page32 Roof Curb - Apron DetailAhmed Saber NassarNo ratings yet

- New Hampshire Department of Transportation: Concrete Wall JointDocument4 pagesNew Hampshire Department of Transportation: Concrete Wall Jointجميل عبد الله الحماطيNo ratings yet

- Especificación de Sistema de Anclaje en EstructuraDocument1 pageEspecificación de Sistema de Anclaje en EstructuraEnmanuel BrachoNo ratings yet

- Cooler Design Pressures/Temperatures: P T 880 PSIG A/C 60.67 BARGDocument4 pagesCooler Design Pressures/Temperatures: P T 880 PSIG A/C 60.67 BARGRio WijayantoNo ratings yet

- Inside Drop ManholeDocument1 pageInside Drop ManholeAtef MohamedenNo ratings yet

- ELXC SpecSheetDocument2 pagesELXC SpecSheetkskadryNo ratings yet

- Cable Route MarkerDocument2 pagesCable Route Markersundareee96No ratings yet

- إنشاء غرف أمن جدة (2) -ModelDocument1 pageإنشاء غرف أمن جدة (2) -ModelTariq KhanNo ratings yet

- PDW-TZ-1133 Tubular Lighting Pole DesignDocument1 pagePDW-TZ-1133 Tubular Lighting Pole Designihsan ul haqNo ratings yet

- TCX 1100 AbvDocument1 pageTCX 1100 AbvMarcoNo ratings yet

- Notes:: Plan End ViewDocument1 pageNotes:: Plan End Viewsowman tungNo ratings yet

- Moisture Monitor Digital Indicator Model M-607Document2 pagesMoisture Monitor Digital Indicator Model M-607Mansoor KhanaliNo ratings yet

- Box Girder - NotesDocument1 pageBox Girder - NotesTriChandra MaharjanNo ratings yet

- Structural - 20X40 Redtail Cabin - 01-26-24Document8 pagesStructural - 20X40 Redtail Cabin - 01-26-24ma.shaheNo ratings yet

- General Notes-Layout1Document1 pageGeneral Notes-Layout1Akmal KhanNo ratings yet

- Single Story HouseDocument19 pagesSingle Story HouseD4designNo ratings yet

- Ebs1-Fsfa11-Sapn-Dwpr-1002-D01-Typical Details Road Excavation CrossingDocument3 pagesEbs1-Fsfa11-Sapn-Dwpr-1002-D01-Typical Details Road Excavation CrossingAsaad AdnanNo ratings yet

- Wa0000.Document4 pagesWa0000.سلطان السواعيرNo ratings yet

- Balili-Tambak CMGP 2020Document33 pagesBalili-Tambak CMGP 2020BlessedNo ratings yet

- M-0.1 - Mechanical SpecificationsDocument1 pageM-0.1 - Mechanical SpecificationsAbdellatif AlhNo ratings yet

- Cornell-Engineers-Sample-Drawings PAGE1Document1 pageCornell-Engineers-Sample-Drawings PAGE1mohanumaNo ratings yet

- Genral NotesDocument1 pageGenral NotesArjay AletaNo ratings yet

- 31 Roof Curb - Sidepan DetailsDocument1 page31 Roof Curb - Sidepan DetailsAhmed Saber NassarNo ratings yet

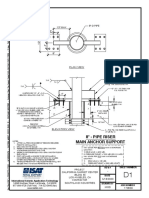

- 8" - Pipe Riser Main Anchor SupportDocument1 page8" - Pipe Riser Main Anchor SupportMD MDDNo ratings yet

- 33 Roof Curb - Backpan DetailDocument1 page33 Roof Curb - Backpan DetailAhmed Saber NassarNo ratings yet

- Ebs1-Fsfa11-Sapn-Dwpr-1003-D01-Typical Details River Excavation CrossingDocument3 pagesEbs1-Fsfa11-Sapn-Dwpr-1003-D01-Typical Details River Excavation CrossingAsaad AdnanNo ratings yet

- 24 Ridge (Fixed) DetailDocument1 page24 Ridge (Fixed) DetailAhmed Saber NassarNo ratings yet

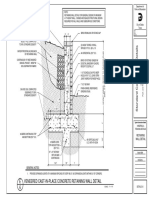

- E-6 Veneered Cast in Place Concrete Retaining Wall Detail - 201407301802202656Document1 pageE-6 Veneered Cast in Place Concrete Retaining Wall Detail - 201407301802202656Quoc Quynh MaiNo ratings yet

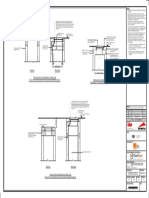

- Description REV Date Construction Drawing 0 JUNE'22Document1 pageDescription REV Date Construction Drawing 0 JUNE'22rajavelNo ratings yet

- 26 - RT609 - U - TYP - 014 - A MH Cover AdjustingDocument1 page26 - RT609 - U - TYP - 014 - A MH Cover AdjustinganooppattazhyNo ratings yet

- Revised Structural PlansDocument46 pagesRevised Structural Plansangelandlucifergabriel009No ratings yet

- Emitido Para: Detail Detail Rigid Steel Conduit GroundingDocument1 pageEmitido Para: Detail Detail Rigid Steel Conduit GroundingKevin GarcíaNo ratings yet

- Non-Entry Chamber Tegra 600: Installation GuideDocument7 pagesNon-Entry Chamber Tegra 600: Installation GuideXAVIER RUBIONo ratings yet

- Structurals 2Document1 pageStructurals 2seulipark2629No ratings yet

- Plumbing DWGDocument3 pagesPlumbing DWGJamillette NovesterasNo ratings yet

- Saudi Arabian Oil Company: DA-728550 005 P 0A3 K11 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-728550 005 P 0A3 K11 RestrictedWaqarNo ratings yet

- General Notes: D.P.W.HDocument1 pageGeneral Notes: D.P.W.HJemil Rose SamosNo ratings yet

- Surface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1Document1 pageSurface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1அம்ரு சாந்திவேலுNo ratings yet

- GCM Installation 4547Document15 pagesGCM Installation 4547AlaaNo ratings yet

- Rapid Initiator - 102806970 - 102806970Document3 pagesRapid Initiator - 102806970 - 102806970Syed HumzaNo ratings yet

- Dwg. Number Connector P/N Customer P/N P400-S08-037 C10-749671-Z2S APPC, 474283A, 101Document1 pageDwg. Number Connector P/N Customer P/N P400-S08-037 C10-749671-Z2S APPC, 474283A, 101akoe ajaNo ratings yet

- Designing Mep For A RoomDocument2 pagesDesigning Mep For A RoomdeddyNo ratings yet

- BBQ Chicken M-01Document1 pageBBQ Chicken M-01agflamesengineering.salesNo ratings yet

- 39 Roof Panel Penetration DetailDocument1 page39 Roof Panel Penetration DetailAhmed Saber NassarNo ratings yet

- 3.5xRC 21.5'X46.5' - Structural Drawing - R00Document31 pages3.5xRC 21.5'X46.5' - Structural Drawing - R00Moe Oo HtunNo ratings yet

- Lap Lengths System of Units: Steel Grade Bar SizeDocument1 pageLap Lengths System of Units: Steel Grade Bar SizeKanz Ur RehmanNo ratings yet

- 8" - Pipe Riser Main Anchor SupportDocument1 page8" - Pipe Riser Main Anchor SupportMD MDDNo ratings yet

- Concrete Equipment Pads (2 of 2) : I0330-056b.dgn 1/24/2009 I0330-056b.dgn 1/24/2009Document1 pageConcrete Equipment Pads (2 of 2) : I0330-056b.dgn 1/24/2009 I0330-056b.dgn 1/24/2009hakim2020No ratings yet

- Column SheduleDocument1 pageColumn SheduleAK DESIGN DESTINYNo ratings yet

- Column Schedule:: 1.center Lines As Per Arch Drgs 2.columns C1 and C2 Are 6"X18"Document1 pageColumn Schedule:: 1.center Lines As Per Arch Drgs 2.columns C1 and C2 Are 6"X18"mdtaher2001No ratings yet

- 6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria TableDocument1 page6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria Tablenishan_ravinNo ratings yet

- 50-0RG2N-DD-021 Data Sheet For Ad-306001 (Bit)Document3 pages50-0RG2N-DD-021 Data Sheet For Ad-306001 (Bit)RajaramNo ratings yet

- Schedule of Loads and Design Computation:: LegendDocument1 pageSchedule of Loads and Design Computation:: LegendTraci ReyNo ratings yet

- 1.Rc Details Industrial Building Details-Rev-1Document7 pages1.Rc Details Industrial Building Details-Rev-1Civil StructureNo ratings yet

- Ac 2Document20 pagesAc 2sandaliNo ratings yet

- Closing Pipes CatalogueDocument43 pagesClosing Pipes CatalogueAdn AdinaNo ratings yet

- Do 400 000Document6 pagesDo 400 000utkuNo ratings yet

- Vacuum Forming Homework SheetDocument8 pagesVacuum Forming Homework Sheetafnaaocndutihe100% (1)

- Technical Specification of Cable Trays 1564375363Document21 pagesTechnical Specification of Cable Trays 1564375363Alla Naveen KumarNo ratings yet

- Chapter 6Document9 pagesChapter 6Christeena HenryNo ratings yet

- ATS - Catalogo Compañia AirmaticDocument24 pagesATS - Catalogo Compañia AirmaticJORGE VELAZQUEZNo ratings yet

- Complex GreasesDocument2 pagesComplex Greasestsrinvas thadaboinaNo ratings yet

- Pharmaglass PPG - GlassDocument3 pagesPharmaglass PPG - GlassRafique AjmeriNo ratings yet

- ICNF2023 PosterSessionDocument2 pagesICNF2023 PosterSessionVijay BahetiNo ratings yet

- Bs130 CSPG Guidelines 24062021 PDFDocument38 pagesBs130 CSPG Guidelines 24062021 PDFRamesh GuptaNo ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityDocument8 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilitymmlingNo ratings yet

- Anchor Bolt MTCDocument6 pagesAnchor Bolt MTCshamshadkadavath1998No ratings yet

- Design For Assembly: DR Richard FarrDocument65 pagesDesign For Assembly: DR Richard FarrXCVBNMNo ratings yet

- Project Activities With Start-Up MaterialDocument6 pagesProject Activities With Start-Up MaterialJOSHUA MASHETI WENDONo ratings yet

- Mineral Fillers: What? Purpose? How?Document8 pagesMineral Fillers: What? Purpose? How?Pajarillaga Franz Erick QuintoNo ratings yet

- Urethane Belt Program CatalogDocument52 pagesUrethane Belt Program CatalogricardoNo ratings yet

- Datasheets LOR DatasheetDocument6 pagesDatasheets LOR DatasheetRaJesh PandianNo ratings yet

- Polymers 13 03480 v2Document13 pagesPolymers 13 03480 v2SEBASDAZACNo ratings yet

- Production InfoDocument4 pagesProduction InfoHamza MalikNo ratings yet

- FULLpractical Research PDFDocument87 pagesFULLpractical Research PDFRubygen R CañeteNo ratings yet

- Unit-1 3 PDFDocument35 pagesUnit-1 3 PDFSathish ChanNo ratings yet

- Minimum Wages in TelanganaDocument5 pagesMinimum Wages in TelanganafinserinhrNo ratings yet

- Design Igienic Imbinari Demontabile Filetate (DOC 13©EHEDG)Document3 pagesDesign Igienic Imbinari Demontabile Filetate (DOC 13©EHEDG)George GhirasimescuNo ratings yet

- 9 LarsLap-FLHDocument5 pages9 LarsLap-FLHHai NguyenNo ratings yet

- Mold Design Check ListDocument6 pagesMold Design Check ListRbai praveenNo ratings yet

- Durability of Sustainable Construction MaterialsDocument11 pagesDurability of Sustainable Construction MaterialsAbir DuttaNo ratings yet

- Me 473 - Unit 4 - 1Document70 pagesMe 473 - Unit 4 - 1Ama Serwaa YeboahNo ratings yet

- Aluminum Alloy Nomenclature and Temper DesignationsDocument23 pagesAluminum Alloy Nomenclature and Temper DesignationsAmin AminiNo ratings yet