Professional Documents

Culture Documents

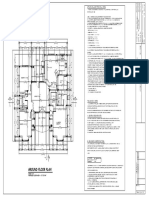

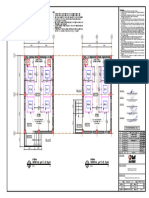

إنشاء غرف أمن جدة (2) -Model

Uploaded by

Tariq KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

إنشاء غرف أمن جدة (2) -Model

Uploaded by

Tariq KhanCopyright:

Available Formats

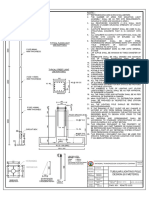

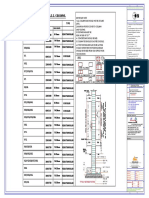

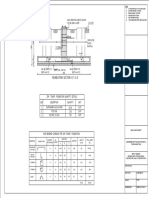

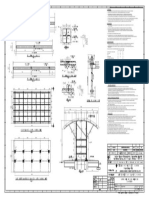

ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE NOTED .

-CONCRETE

PRECAST CONCRETE, CLASS C35.

(28 DAYS COMPRESSIVE CYLINDER STRENGTH fc'=35MPa)

MAX. SIZE AGGREGATE = 20mm

-STEEL REINFORCEMENT

STEEL REINFORCEMENT TO BE TYPE 2 HIGH YIELD DEFORMED BARS GRADE

420 (fy=420 MPa)

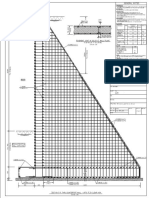

-SELECTED ENGINEERING BACKFILL CHARACTERISTICS

∅=36° MINIMUM

MAX. SIZE AGGREGATE = 60mm.

MAXIMUM PASSING @ 75microns=15%

Cu >= 4

COMPACTION TO BE 95% OF MDD.

max. = 19.00 KN/m3

-GENERAL BACKFILL

∅=32° MINIMUM ; max. = 19.00 KN/m3

1. LEVELING PAD VERTICAL TOLERANCE ±3mm.

2. ALL CHAMFERS TO BE 10mm x 10 mm.

3. ERECTION TOLERANCE 25mm ALONG 3m STRAIGHT EDGE.

VERTICAL TOLERANCE ± 25mm PER EVERY 3m OF WALL HEIGHT, OR ±50mm

OVERALL.

4. NO CRACKS SHALL BE VISIBLE TO NAKED EYE WHEN PANELS ARE DELIVERED

TO SITE.

5. kN VALUES ARE FOR GEOSTRAP GRADE.

6. PANEL COLUMN NUMBERS ABOVE THE WALL ARE GIVEN AT CENTER LINE OF

PANEL.

7. ALL LOOSE MATERIAL BELOW RE WALL TO BE REPLACED BY COMPACTED

GATE GATE SELECTED ENGINEERING FILL.

8. ELEVATION IS SHOWN IN FACE VIEW.

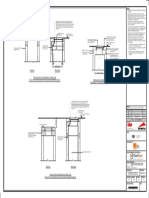

9. ALL CONCRETE SURFACES EXPOSED TO SOIL TO BE COATED WITH MINIMUM

2 LAYERS OF BITUMINOUS PAINT. BITUMINOUS PAINT SHALL NOT BE PUT ON

LAND SCAPE BARRIER THE FILTER STRIP AT THE JOINT LOCATION.

10. EACH UNIT SHOULD BE DATED AND CODE MARKED ON BACK AND SIDE FACE

FOR EASY IDENTIFICATION.

11. PANEL CASTING TOLERANCE TO BE ±5mm.

12. PANEL STRUCTURAL THICKNESS = 140mm.

13. GEOCORE CONNECTOR: PATENT PROTECTED.

14. MINIMUM PANEL EMBEDMENT DEPTH IS 800mm.

15. CONTRACTOR SHALL VERIFY ON SITE THERE ARE NO UTILITIES 40cm BELOW

THE GROUND LEVEL ON THE FULL EXTENT OF THE REINFORCED SOIL MASS

BARRIER (STRIP LENGTH). IN CASE UTILITIES ARE ENCOUNTERED, THEIR POSITION

SHALL BE CLEARLY MARKED ON SITE PRIOR TO INSTALLATION OF MSE WALL.

16. * - DIMENSION TO BE MEASURED AT SITE PRIOR TO INSTALATION.

17. THIS DRAWING TO BE READ IN CONJUNCTION WITH ALL DRAWINGS ISSUED

BY FREYSSINET.

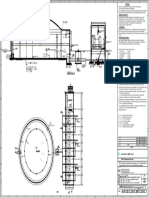

COVERED CAR PARKING

VIP 10 NOS.

1: ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE NOTED.

2: THE SIZE,THICKNESS & ARRANGEMENTS OF FRAMING SHALL BE DESIGN TO WITHSTAND

WIND LOAD AT THE LOCALITY OF THE CAR PARKING SHADE. DESIGN CALCULATION BY

CONCEDERING ALL THE FORCES ON THE PARKING SHADE SHALL SUBMIT FOR REVIEW

AND APPROVAL. CONTRACTOR SHALL BE RESPONSIBLE TO STRENGHTEN THE FRAMING

AS PER THE LOAD CALCULATIONS.

2: THE DRAWING IS FOR THE INDICATION OF CAR PARKINGSHADE SIZE, HEIGHT, SHAPE

AS BUILT BY _____________________ DATED ___________________

REV.

NO. DATE BY DESCRIPTION CHKD. CERT. APPD.

DRAWING COMPLETION CERTIFICATE (DCC) :

ء

CAR PARKING SHED 01

Saudi Electricity Company

DRAWN BY ___________ CHECKED BY ___________ AS SHOWN

SCALE : ___________

DATE STARTED _____________________ DATE COMPLETED ____________________

OPR'G DEPT. _______________________ ENG DEPT. _____________________

THIS DRAWING IS NOT TO BE USED FOR CERTIFIED

CONSTRUCTION OR FOR ORDERING MATERIAL

UNTIL CERTIFIED AND DATED BY ___________ DATED ___________

STANDARD PARKING SHED DETAIL

SECURITY ROOM ء

STANDARD SAUDI ARABIA

CONTRACT NO. JOB ORDER NO. INDEX PLANT NO. DRAWING NO. SHEET NO. REV. NO.

You might also like

- Cover - Jrc12 & Jrc14Document1 pageCover - Jrc12 & Jrc14raghebomNo ratings yet

- Cover - Jrc12 & Jrc14Document1 pageCover - Jrc12 & Jrc14hatem hamaidiNo ratings yet

- PDW-TZ-1133 Tubular Lighting Pole DesignDocument1 pagePDW-TZ-1133 Tubular Lighting Pole Designihsan ul haqNo ratings yet

- RW 2-03Document1 pageRW 2-03kigonyaNo ratings yet

- General Notes-1: Table 1: Lap Splices For RebarsDocument1 pageGeneral Notes-1: Table 1: Lap Splices For RebarsTanvir IslamNo ratings yet

- Ilovepdf Merged 1Document3 pagesIlovepdf Merged 1Kartheek ChepuriNo ratings yet

- 1.CWRPH-00 - Gad-R0-1550 KL Gad-1Document1 page1.CWRPH-00 - Gad-R0-1550 KL Gad-1sNo ratings yet

- Midlanding: +2100 LVL 181716151413121110 R 150mm. T 300mmDocument1 pageMidlanding: +2100 LVL 181716151413121110 R 150mm. T 300mmyash ayreNo ratings yet

- 1.CWRPH-00 - Gad-R0-1400 KL Gad-1Document1 page1.CWRPH-00 - Gad-R0-1400 KL Gad-1sNo ratings yet

- S-1 RevisedDocument1 pageS-1 Revisedbernard1agoncillioNo ratings yet

- 2100 KL Correction - 220211 - 015003Document3 pages2100 KL Correction - 220211 - 015003sNo ratings yet

- Cemex Solid K4 - Raw Meal SiloDocument3 pagesCemex Solid K4 - Raw Meal Silojoselito navarroNo ratings yet

- 1.CWRPH-00 - Gad-R0-2100 KL Gad-1Document1 page1.CWRPH-00 - Gad-R0-2100 KL Gad-1sNo ratings yet

- 2100 KL GAD Correction - 220211 - 015654Document1 page2100 KL GAD Correction - 220211 - 015654sNo ratings yet

- Nfef 60 44 Ci DR TD 001 - d2 - 000Document1 pageNfef 60 44 Ci DR TD 001 - d2 - 000Abid AyubNo ratings yet

- Bat-Dwg-Dd-Me-00-Eg-6101 - R0 - Grounding, Earthing and Lightning Protection System Shematic DiagramDocument1 pageBat-Dwg-Dd-Me-00-Eg-6101 - R0 - Grounding, Earthing and Lightning Protection System Shematic DiagramCosphiiiNo ratings yet

- 26 - RT609 - U - TYP - 014 - A MH Cover AdjustingDocument1 page26 - RT609 - U - TYP - 014 - A MH Cover AdjustinganooppattazhyNo ratings yet

- 6312 e Civ DTR DC V I 002 Burnt Oil Pit Signed 23-09-2020Document1 page6312 e Civ DTR DC V I 002 Burnt Oil Pit Signed 23-09-2020manikandanNo ratings yet

- COMP WALL WITH RETAINING WALL ModelDocument1 pageCOMP WALL WITH RETAINING WALL ModelAmarjit KulkarniNo ratings yet

- Genral NotesDocument1 pageGenral NotesArjay AletaNo ratings yet

- 265 HcsDocument3 pages265 HcsNaveen NunnaNo ratings yet

- General Notes & Specifications PDFDocument2 pagesGeneral Notes & Specifications PDFPriodeep ChowdhuryNo ratings yet

- Notes PDFDocument1 pageNotes PDFVemajala GaneshNo ratings yet

- Simple Vertical Engine 1Document4 pagesSimple Vertical Engine 1Orlando Rojas PintoNo ratings yet

- SLAB REINF-ModelDocument1 pageSLAB REINF-Modelankita saxenaNo ratings yet

- General Notes Concrete Works and Reinforcing Bars: Project TitleDocument5 pagesGeneral Notes Concrete Works and Reinforcing Bars: Project TitleCamille Ariel100% (1)

- Cable Route MarkerDocument2 pagesCable Route Markersundareee96No ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFMr. SinghNo ratings yet

- Hollow Core Slab DesignDocument3 pagesHollow Core Slab DesignNaveen Nunna0% (1)

- Gen NotesDocument1 pageGen NotesGian OrillosaNo ratings yet

- RCC Drawing of Open Drain 11-10-2022Document16 pagesRCC Drawing of Open Drain 11-10-2022AKB CONSULTANTSNo ratings yet

- Ns2-Vk02-P0ucb-171652 - CHS Electrical & Control Building - Beam & Girder Re-Bar Schedule - Fi-2Document3 pagesNs2-Vk02-P0ucb-171652 - CHS Electrical & Control Building - Beam & Girder Re-Bar Schedule - Fi-2Doan Ngoc DucNo ratings yet

- 33 70 00-7 Generator Pad Detail PDFDocument1 page33 70 00-7 Generator Pad Detail PDFNadom MutlibNo ratings yet

- AS05Document1 pageAS05Vic NairaNo ratings yet

- Proposed Three Bedroom-P2Document1 pageProposed Three Bedroom-P2MatthewNo ratings yet

- Details of RCC ColumnDocument1 pageDetails of RCC ColumnRavi Kumar RaiNo ratings yet

- 25M Tower FDN - 2Document1 page25M Tower FDN - 2Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- 20171003-Beam & Slab Schedule-01Document1 page20171003-Beam & Slab Schedule-01Atul ShrivastavaNo ratings yet

- 6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria TableDocument1 page6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria Tablenishan_ravinNo ratings yet

- Garage Door HeadDocument1 pageGarage Door Headmansoormasud6No ratings yet

- Roof Framing PlanDocument1 pageRoof Framing PlanZandie GarciaNo ratings yet

- Column LayoutDocument1 pageColumn Layoutlagnajit dasNo ratings yet

- Column LayoutDocument1 pageColumn Layoutlagnajit dasNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- General NotesDocument1 pageGeneral NotesDesign explorer olomizanaNo ratings yet

- Notes: - : Dimension Details Reinforcement DetailsDocument1 pageNotes: - : Dimension Details Reinforcement DetailsRajkumar SagarNo ratings yet

- Roof Framing Plan: Construction NotesDocument1 pageRoof Framing Plan: Construction NotesNefritiri BlanceNo ratings yet

- PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1Document1 pagePARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1irshad khanNo ratings yet

- Anthony Wanjiku Revised StructuralDocument1 pageAnthony Wanjiku Revised Structuralpatrickmore09No ratings yet

- Crash Barrier With Friction SlabDocument1 pageCrash Barrier With Friction SlabSachin Dalal100% (1)

- 60020-00sit-Al-Eng-Arc-Spd-0009 - Excavation PlanDocument1 page60020-00sit-Al-Eng-Arc-Spd-0009 - Excavation PlanniyasNo ratings yet

- Cadd Designer'S: Thadgolu VillageDocument1 pageCadd Designer'S: Thadgolu VillageDileep K MahadevaiahNo ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- Solar System For 60m WellDocument3 pagesSolar System For 60m WellM.zahirNo ratings yet

- DSS - Layout.Without - TX AP-2023.07.06Document1 pageDSS - Layout.Without - TX AP-2023.07.06sundareee96No ratings yet

- Notes (General) : Steel CDocument1 pageNotes (General) : Steel CpastorgeeNo ratings yet

- 100 Bed Hospital Okpala StructuralDocument83 pages100 Bed Hospital Okpala StructuralEngr Josh ChisimdiNo ratings yet

- Ratio Analysis - SeminarDocument6 pagesRatio Analysis - SeminarTariq KhanNo ratings yet

- Lecture 7 - CVP Analysis - JJDocument33 pagesLecture 7 - CVP Analysis - JJTariq KhanNo ratings yet

- Morrison and Sainsburry RatioDocument5 pagesMorrison and Sainsburry RatioTariq KhanNo ratings yet

- Lecture 4 - Ratio Analysis - JJDocument43 pagesLecture 4 - Ratio Analysis - JJTariq KhanNo ratings yet

- Lecture 5 - Cash Flow Statements - JJDocument23 pagesLecture 5 - Cash Flow Statements - JJTariq KhanNo ratings yet

- Creating AoN Diagrams V2Document58 pagesCreating AoN Diagrams V2Tariq KhanNo ratings yet

- Introduction To Operations Management V8Document27 pagesIntroduction To Operations Management V8Tariq KhanNo ratings yet

- PDE4911 Lecture 4 Introduction To Planning V7Document39 pagesPDE4911 Lecture 4 Introduction To Planning V7Tariq KhanNo ratings yet

- PDE4911 Risk Management V2Document48 pagesPDE4911 Risk Management V2Tariq KhanNo ratings yet

- Lecture 9 - SolutionsDocument3 pagesLecture 9 - SolutionsTariq KhanNo ratings yet

- Lecture Week 4 - PDE4910 Strategic Fit V6Document56 pagesLecture Week 4 - PDE4910 Strategic Fit V6Tariq KhanNo ratings yet

- Lecture 2 - Introduction To PRINCE2 V8Document55 pagesLecture 2 - Introduction To PRINCE2 V8Tariq KhanNo ratings yet

- LG - Mock Drill - VSLDocument12 pagesLG - Mock Drill - VSLTariq KhanNo ratings yet

- QAS 9 - Project Quality Plan ContentDocument3 pagesQAS 9 - Project Quality Plan ContentTariq KhanNo ratings yet

- QAS 18 - Traceability and StorageDocument1 pageQAS 18 - Traceability and StorageTariq KhanNo ratings yet

- QAS 23 - Inspection and Test Plan PDFDocument1 pageQAS 23 - Inspection and Test Plan PDFTariq KhanNo ratings yet

- QAS 17 - Purchasing and ProcurementDocument1 pageQAS 17 - Purchasing and ProcurementTariq KhanNo ratings yet

- QAS 21 - Project Completion and Handover ProcedureDocument1 pageQAS 21 - Project Completion and Handover ProcedureTariq KhanNo ratings yet

- QAS 19 - Subcontractor and Supplier Performance PDFDocument1 pageQAS 19 - Subcontractor and Supplier Performance PDFTariq KhanNo ratings yet

- QAS 16 - Quality Control RecordsDocument2 pagesQAS 16 - Quality Control RecordsTariq KhanNo ratings yet

- QAS 3 - Quality Policy StatementDocument1 pageQAS 3 - Quality Policy StatementTariq Khan100% (1)

- QAS 1-Quality Management PlanDocument2 pagesQAS 1-Quality Management PlanTariq KhanNo ratings yet

- HEALTH, SAFETY AND ENVIRONMENTAL PLAN Al RAKHEESDocument151 pagesHEALTH, SAFETY AND ENVIRONMENTAL PLAN Al RAKHEESTariq KhanNo ratings yet

- Execution PlanDocument21 pagesExecution PlanTariq KhanNo ratings yet

- West Depot - Mock Drill - 14 May 2016Document5 pagesWest Depot - Mock Drill - 14 May 2016Tariq KhanNo ratings yet

- Method StatementDocument5 pagesMethod StatementTariq KhanNo ratings yet

- 3A2 Station - Mock Drill - 09 May 2016Document8 pages3A2 Station - Mock Drill - 09 May 2016Tariq KhanNo ratings yet

- Quality PlanDocument53 pagesQuality PlanTariq Khan100% (1)

- Maintenance and Control of Measuring DevicesDocument3 pagesMaintenance and Control of Measuring DevicesTariq KhanNo ratings yet

- Mobilization PlanDocument6 pagesMobilization PlanTariq Khan100% (1)

- Steel RebarDocument10 pagesSteel RebarStructureClassNo ratings yet

- RR KABEL Wires and Cables PDFDocument412 pagesRR KABEL Wires and Cables PDFsbjamdadeNo ratings yet

- STEICO Installation Instructions Facade Insulation en IDocument40 pagesSTEICO Installation Instructions Facade Insulation en IHeiki JürgensteinNo ratings yet

- Proconnect H05 - H07-BQ-FDocument1 pageProconnect H05 - H07-BQ-FPaul ScottNo ratings yet

- Published-Pdf-0289-6-Evaluation Some of Mechanical Properties of Mortar Containing Metakaolin and PolypropyleneDocument7 pagesPublished-Pdf-0289-6-Evaluation Some of Mechanical Properties of Mortar Containing Metakaolin and Polypropylenemohammad YFNo ratings yet

- Huntsman ChemicalDocument24 pagesHuntsman ChemicalChris SmithNo ratings yet

- Copper Weld BrochureDocument4 pagesCopper Weld Brochurefarfugliare100% (1)

- Technical Data Probes DatasheetDocument5 pagesTechnical Data Probes DatasheetasfsndNo ratings yet

- Al600 UNS N06600Document4 pagesAl600 UNS N06600kart_rlNo ratings yet

- Aluminium CatalogueDocument34 pagesAluminium CatalogueCitra Dwi KusumawardaniNo ratings yet

- SHS ELS Module 3Document23 pagesSHS ELS Module 3sei gosa0% (1)

- The Advantages of MyceliumDocument3 pagesThe Advantages of Myceliumdiyana a.fNo ratings yet

- Jis G3133-2009Document15 pagesJis G3133-2009Đình Sỹ TTPNo ratings yet

- 1986 Supplement To:: American Concrete InstituteDocument16 pages1986 Supplement To:: American Concrete InstituteAzmi BazazouNo ratings yet

- Concept of Logistics & Supply ChainDocument20 pagesConcept of Logistics & Supply ChainkeyarjpNo ratings yet

- Different Types of Electrical BushingsDocument14 pagesDifferent Types of Electrical BushingsRafael CarvalhoNo ratings yet

- Surface CoatingDocument29 pagesSurface CoatingAbdullah RamzanNo ratings yet

- Rencana Anggaran Biaya (Rab) : Pekerjaan Musholla, Kanopi Curah Dari Finish Bin, Paving Block Dan Sumur TradisionalDocument10 pagesRencana Anggaran Biaya (Rab) : Pekerjaan Musholla, Kanopi Curah Dari Finish Bin, Paving Block Dan Sumur TradisionalWillie SudhantaNo ratings yet

- MS 1380 1995Document25 pagesMS 1380 1995Joseph100% (5)

- Failed Reheater Showing Thin Lipped RuptureDocument4 pagesFailed Reheater Showing Thin Lipped Rupturefernandosimic96No ratings yet

- Design of Reinforced Concrete 9th Edition - Jack C. Mccormac 3Document2 pagesDesign of Reinforced Concrete 9th Edition - Jack C. Mccormac 3curiosity12No ratings yet

- Installation With Mortar - Umlauf 2015Document18 pagesInstallation With Mortar - Umlauf 2015Moud SaklyNo ratings yet

- Trace Therm Brochure F 1Document4 pagesTrace Therm Brochure F 1Amro Metwally El HendawyNo ratings yet

- Importance of Sidhee Portland Pozzolana Cement PDFDocument77 pagesImportance of Sidhee Portland Pozzolana Cement PDFNovember RainNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueSekar AyuNo ratings yet

- North American Glazing GuidelinesDocument10 pagesNorth American Glazing GuidelinesAyça Bayram OzcanlarNo ratings yet

- To (For Approval)Document1 pageTo (For Approval)Jeyvie Cabrera OdiameNo ratings yet

- ACI 351.1R-12 Grouting Between Foundations and Bases For SupportDocument25 pagesACI 351.1R-12 Grouting Between Foundations and Bases For SupportadngNo ratings yet

- Polymer Grafted Carbon Nanotubes - Synthesis, ProperitiesDocument23 pagesPolymer Grafted Carbon Nanotubes - Synthesis, Properitiesbrian barretusNo ratings yet

- MRPL Mechster 9000TA LSE 2Document1 pageMRPL Mechster 9000TA LSE 2reinpolyNo ratings yet