Professional Documents

Culture Documents

Daily PC1250 Form

Uploaded by

lilik0 ratings0% found this document useful (0 votes)

118 views1 pageCopyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

118 views1 pageDaily PC1250 Form

Uploaded by

lilikCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

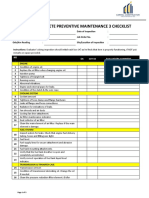

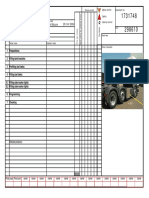

PT.

KALIMANTAN LESTARI RAHARJA

SITE SEMBOJA

DAILY MAINTENANCE CHECK SHEET

PC1250/SP8

DATE : SMR : TIME DOWN :

UNIT CODE : LOCATION : TIME UP :

"IMPORTANT BE SAFETY"

BEFORE DAILY MAINTENANCE, MACHINE MUST PARKED ON LEVEL GROUND,PARKING BRAKE TO BE

APPLIED. STOP ENGINE, AND PLACE PERSONAL DANGER TAGS.

Result : : Good Condition : Bad Condition/Backlog : Correction made / Emergency Repair

No COMPONENT AND ITEM CHECK/SERVICE Result No COMPONENT AND ITEM CHECK/SERVICE Result

Bottom Around Check: 27 Check grease level, fungtion of Auto lube.

1 Check lock-out switch 28 Check battery electrolit level, pool terminal & cable.

2 Check tension of track shoe LH/RH side 29 Check condition & function of :

3 Check tighten bolt & nut of T/shoe LH/RH side a. Rotary lamp

4 Check track link, sprocket, idler, rollers, & guard b. Work lamp

from wear, or loose bolt. c. Rear lamp

5 Check condition of Under Guard, covers & d. Optional lamp

counterweigh mounting. e. Travel alarm

6 Check oil leak from F/Drive & travel motor, f. Horn

line hoses. Inside Cabin Check:

7 Check upper/lower frame connection, T/Frame 30 Check condition & function of :

connection for bolt loose/ missing, crack a. Monitor panel

8 Check oil leakage from bucket, arm, boom b. Switches

cylinder & lines. c. Gauges

9 Check condition bucket, link, boom & arm stick d. Control dial

from wear, loose bolt lock pin, play, & crack. e. Hydraulik lever & Lock

10 Drain water & sediment from fuel tank, water f. Radio 2 ways/Communication

separator & air tank. g. Radio FM

11 Check oil level hydraulik, add if necessary h. Dispatch

Floor, Fender & Engine Around Check: 31 Check fuse box in cabin & Air Conditioner

12 Check condition of step ladder,floor & hand rail. 32 Check condition of Afff activator & controller

13 Ckeck PTO oil level & oil leak. 33 Check condition/function of emergency stop

14 Check oil leakage from around pump, OLSS. 34 Check condition/function wiper & spray, locks glass/

15 Check engine oil level, add if necessary door.

16 Check for leakage oil,water & fuel around engine 35 Check condition of seals cabin,glass & wipper

17 Check condition from crack, loose bolt, air/gas leak: 36 Check condition operator seat & safety belt

a. Turbo Charger Test performance :

b. Intake & Exhaust manipold a. Swing brake

c. A/C Compressor, hoses & pipe b. Operation of Hydraulik control & Lock

18 Check tension fan belt/alternator belt/AC belt c. Hydraulik drift.

19 Check condition of dust indicator gauge.

20 Check coolant level, add if necessary ADDITIONAL OIL , GREASE & WATER

21 Check condition of radiator fin/guard & win brake Water coolant radiator 140 Ltr

22 Check oil level swing machinery, add if necess. Engine ( SAE 30 ) Refill : 55.3 Ltr

23 Check oil leakage hyd tank, hoses & Control V. PTO ( SAE 30 ) Refill : 13.5 Ltr

24 Check oil leakage from swivel joint & hoses Hydraulik ( SAE 10 W ) Refill : 670 Ltr

25 Check nitrogen pressure fire estinguisher 50 kg Swing Machinery ( SAE 30 ) Refill : 48.6 Ltr(F&R)

dan fire estinguisher 6 kg Final Drive ( SAE 30 ) Refill : 44 Ltr(L&R)

26 Check water at washer wiper tank. Grease ( NLGI-G2-L1 )

NO BACKLOG DESCRIPTION FIGURE INDEX PART NUMBER DESCRIPTION Qty

CHECKED BY, APPROVED BY,

(...............................) (...............................)

pc1250

You might also like

- 00 Truck Crane Inspection FormDocument10 pages00 Truck Crane Inspection FormRiza DSNo ratings yet

- Servis WT 103 Hino PM 1000 Hour 15 Maret 2023Document4 pagesServis WT 103 Hino PM 1000 Hour 15 Maret 2023Damsixboy 999No ratings yet

- New Form Daily Check WADocument3 pagesNew Form Daily Check WAAzura ZameNo ratings yet

- VMC Preventive Master Check ListDocument33 pagesVMC Preventive Master Check Listmugunthaa6686% (14)

- Inspection Unit PC 200Lc - 8moDocument28 pagesInspection Unit PC 200Lc - 8moBima AditamaNo ratings yet

- NAF-001-FP-CHECKLISTDocument6 pagesNAF-001-FP-CHECKLISTdesign sseNo ratings yet

- Form Comissioning EXCAVATORDocument1 pageForm Comissioning EXCAVATORAysenNo ratings yet

- (HSE-ForM-A.05) Form Inspection Rough Terrain CraneDocument6 pages(HSE-ForM-A.05) Form Inspection Rough Terrain CraneIvansyah SastrowardoyoNo ratings yet

- Documentation Check List For Equipment Supplier (2 No's File With Complete Documents)Document5 pagesDocumentation Check List For Equipment Supplier (2 No's File With Complete Documents)Baldev SinghNo ratings yet

- Caterpillar: Cat - D6RDocument8 pagesCaterpillar: Cat - D6Rkkmech100% (1)

- NO Spare Parts Service 10000 Hrs 20000 Hrs 30000 HrsDocument3 pagesNO Spare Parts Service 10000 Hrs 20000 Hrs 30000 HrsrandyNo ratings yet

- ENGINE AND COMPONENT INSPECTIONDocument9 pagesENGINE AND COMPONENT INSPECTIONekoimampNo ratings yet

- Preventive Maintenance Check ListDocument23 pagesPreventive Maintenance Check Listindrabhansingh22443No ratings yet

- PC 1250 Initial 100 HR Service SheetDocument4 pagesPC 1250 Initial 100 HR Service SheetJamyansuren TseveendorjNo ratings yet

- 132kv Grid Station FNF, SheikhupuraDocument18 pages132kv Grid Station FNF, Sheikhupurasyed waheedNo ratings yet

- Unit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikDocument13 pagesUnit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikkkmechNo ratings yet

- 5 SM 2200 MaintenanceDocument48 pages5 SM 2200 MaintenancePlr. Baswapur100% (1)

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- Jadwal Weekly MaintanaceDocument8 pagesJadwal Weekly Maintanaceardy ansyahNo ratings yet

- Trent XWB Under Cowl GuideDocument67 pagesTrent XWB Under Cowl Guidehakoj29142100% (1)

- Pre - Flight Inspection Appendix - A8: Aircraft Reg. PK-Total Hours: Total Cycles: DateDocument7 pagesPre - Flight Inspection Appendix - A8: Aircraft Reg. PK-Total Hours: Total Cycles: DateAdhi Gusrifqi Amali100% (1)

- WO Number: - Date: - Op. CodeDocument2 pagesWO Number: - Date: - Op. CoderudiNo ratings yet

- Unit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikDocument15 pagesUnit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikkkmechNo ratings yet

- Aircraft preflight checklist inspectionDocument29 pagesAircraft preflight checklist inspectionKushal MankaniNo ratings yet

- Inspection For Hiab Cranes: APC 11/2012 Rev. 0Document2 pagesInspection For Hiab Cranes: APC 11/2012 Rev. 0Muhammad Ahmed Abd ElmonemNo ratings yet

- P2006T Tua Quick Checkli̇stDocument19 pagesP2006T Tua Quick Checkli̇staskinfirataskinNo ratings yet

- Moduspec ChecklistDocument64 pagesModuspec Checklistbehnam197100% (8)

- Hitachi ZX870 Service ReportDocument5 pagesHitachi ZX870 Service ReportpojokbioNo ratings yet

- Power Steering System: Section 6ADocument13 pagesPower Steering System: Section 6AJarry PotterNo ratings yet

- Hyundai 180-250D - Cutoff - AdjustmentDocument3 pagesHyundai 180-250D - Cutoff - AdjustmentAaronNo ratings yet

- Rolls-Royce': Record of Temporary RevisionsDocument5 pagesRolls-Royce': Record of Temporary RevisionsAnonymous 298xlo3uUNo ratings yet

- Mobile Pumpcrete Preventive Maintenance 3 Checklist: Carwill Construction IncDocument5 pagesMobile Pumpcrete Preventive Maintenance 3 Checklist: Carwill Construction IncCarwill TesdaNo ratings yet

- Void SubstationDocument46 pagesVoid SubstationPrabhat HambireNo ratings yet

- S1 Maintenance DetailsDocument6 pagesS1 Maintenance DetailsHemanthNo ratings yet

- Generator PM ChecklistDocument2 pagesGenerator PM ChecklistYan's Senora Bescoro100% (3)

- Fortnightly - Checklist - Kobelco CranesDocument3 pagesFortnightly - Checklist - Kobelco Cranesdevansh ranaNo ratings yet

- Calavar Condor 446q8 Operators Maintenance and Part ManualDocument20 pagesCalavar Condor 446q8 Operators Maintenance and Part ManualMichelle100% (55)

- Linde ChecklistDocument47 pagesLinde ChecklistVicente TanNo ratings yet

- Fire PUMPS T&C ChecklistDocument6 pagesFire PUMPS T&C ChecklistUmair BaBerNo ratings yet

- IAE V2500 Under Cowl GuideDocument61 pagesIAE V2500 Under Cowl GuideWalter Radzewicz100% (1)

- Power Transformer Pre Commisioning ChecklistDocument26 pagesPower Transformer Pre Commisioning ChecklistRajesh TK100% (2)

- Transformer Check ListDocument2 pagesTransformer Check ListKanhiya Prasad100% (2)

- Ishaq Instruction To Bidders - Rev0Document38 pagesIshaq Instruction To Bidders - Rev0ishaq ahmedNo ratings yet

- Light Repair and WashingDocument29 pagesLight Repair and Washingfrenz2kiranNo ratings yet

- Checklist RigDocument104 pagesChecklist RigKiryaki Francis100% (2)

- Maintenance Check ListDocument6 pagesMaintenance Check ListGunadevan ChandrasekaranNo ratings yet

- Guias de Inspeccion Cheyenne IIDocument23 pagesGuias de Inspeccion Cheyenne IIesedgar100% (1)

- 303-03 Engine Cooling 2.3L EcoBoost - Diagnosis and Testing - Engine CoolingDocument21 pages303-03 Engine Cooling 2.3L EcoBoost - Diagnosis and Testing - Engine CoolingCARLOS LIMADANo ratings yet

- Oildyne Trim Pump Testing and Repair GuideDocument52 pagesOildyne Trim Pump Testing and Repair GuideJerry MooreNo ratings yet

- PT Mandiangin Batu Bara Periodic Service Check SheetDocument12 pagesPT Mandiangin Batu Bara Periodic Service Check SheetkkmechNo ratings yet

- National Transmission and Despatch Company Mechanicalchecks, Visualinspections and ElectricaltestsDocument22 pagesNational Transmission and Despatch Company Mechanicalchecks, Visualinspections and Electricaltestsmirmunum100% (1)

- Form Mekanik AndrewDocument19 pagesForm Mekanik AndrewDoedoey ChNo ratings yet

- Halliburton: Power Pack Hydraulic Quick Disconnect Skid S12A Suggested Interval: 120 DAYSDocument4 pagesHalliburton: Power Pack Hydraulic Quick Disconnect Skid S12A Suggested Interval: 120 DAYSKhalfan Al HabsiNo ratings yet

- Starting and Testing ZCU 20/30 LocomotivesDocument5 pagesStarting and Testing ZCU 20/30 LocomotivesUsman GhaniNo ratings yet

- General InformationDocument111 pagesGeneral Informationkhaledserag23No ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- Truck and Trailer Report DocumentDocument1 pageTruck and Trailer Report DocumentZeckNo ratings yet

- Form Commisioning SANY - SKT 90S 2 LBRDocument1 pageForm Commisioning SANY - SKT 90S 2 LBRj.andry. dprNo ratings yet

- Transit CheckDocument2 pagesTransit Checka.teamwork2016No ratings yet

- MCR Machine Condition Report SummaryDocument8 pagesMCR Machine Condition Report SummarylilikNo ratings yet

- PC 200-7 Ex 01 KEDDocument8 pagesPC 200-7 Ex 01 KEDlilikNo ratings yet

- Ffu 0000090 01Document9 pagesFfu 0000090 01lilikNo ratings yet

- PC 200-7 Ex 02 KEDDocument8 pagesPC 200-7 Ex 02 KEDlilikNo ratings yet

- PC 200-7 Ex 04 KEDDocument8 pagesPC 200-7 Ex 04 KEDlilikNo ratings yet

- Valve c4Document5 pagesValve c4lilikNo ratings yet

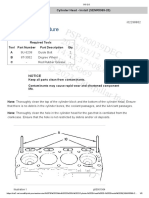

- Cyl Head c4Document5 pagesCyl Head c4lilikNo ratings yet

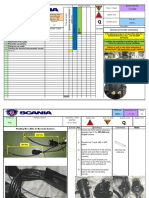

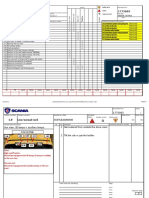

- Chassis variant Document with Safety Risks and InstructionsDocument9 pagesChassis variant Document with Safety Risks and InstructionslilikNo ratings yet

- Ffu 0000068 01Document9 pagesFfu 0000068 01lilikNo ratings yet

- Ffu 0000036 01Document12 pagesFfu 0000036 01lilikNo ratings yet

- Ffu 0000007 01Document12 pagesFfu 0000007 01lilikNo ratings yet

- Ffu 0000026 01Document12 pagesFfu 0000026 01lilikNo ratings yet

- Cylinder Blok c4Document7 pagesCylinder Blok c4lilikNo ratings yet

- Ffu 0000089 01Document15 pagesFfu 0000089 01lilikNo ratings yet

- Ffu 0000029 01Document4 pagesFfu 0000029 01lilikNo ratings yet

- Relocating Air ReservoirsDocument7 pagesRelocating Air ReservoirslilikNo ratings yet

- Ffu 0000038 01Document6 pagesFfu 0000038 01lilikNo ratings yet

- Ffu 0000028 01Document5 pagesFfu 0000028 01lilikNo ratings yet

- Ffu 0000015 01Document10 pagesFfu 0000015 01lilikNo ratings yet

- Ffu 0000130 01Document22 pagesFfu 0000130 01lilikNo ratings yet

- Ffu 0000017 01Document10 pagesFfu 0000017 01lilikNo ratings yet

- C7.1 Mech Engine SpecsDocument5 pagesC7.1 Mech Engine SpecslilikNo ratings yet

- Recommended Engine Overhaul PartsDocument28 pagesRecommended Engine Overhaul PartslilikNo ratings yet

- PT Karunia Tunggal Lestari Form Kanibal Spare Part RemanDocument2 pagesPT Karunia Tunggal Lestari Form Kanibal Spare Part RemanlilikNo ratings yet

- Lay Out Workshop TeritibDocument1 pageLay Out Workshop TeritiblilikNo ratings yet

- MeasuringDocument4 pagesMeasuringlilikNo ratings yet

- Scania Vehicle Accessories Online HomepageDocument2 pagesScania Vehicle Accessories Online HomepagelilikNo ratings yet

- Gambar Instalasi Listrik WorkshopDocument1 pageGambar Instalasi Listrik WorkshoplilikNo ratings yet

- 0 - 1 - CV TarnoDocument2 pages0 - 1 - CV TarnolilikNo ratings yet

- CV RramlanDocument16 pagesCV RramlanlilikNo ratings yet

- Binzel - Katalog MAGDocument64 pagesBinzel - Katalog MAGAdrian KustraNo ratings yet

- Cell Structure ActivityDocument4 pagesCell Structure ActivitysharksiedNo ratings yet

- NOISE ANALYSISDocument16 pagesNOISE ANALYSISDiana Rose TapelNo ratings yet

- Sponge BobDocument4 pagesSponge BobchabriesNo ratings yet

- Textiles and Clothing SustaninabilityDocument134 pagesTextiles and Clothing Sustaninabilitydike100% (1)

- Catalogus 2010 ENGELSDocument52 pagesCatalogus 2010 ENGELShacikadiNo ratings yet

- Erasmus Rotterdam University MCDocument24 pagesErasmus Rotterdam University MCAndreea CroitoruNo ratings yet

- Encore 700 Diaphragm Pump 1Document12 pagesEncore 700 Diaphragm Pump 1bagurtoNo ratings yet

- Radiological Investigations: UltrasonographyDocument42 pagesRadiological Investigations: UltrasonographyDeeptanu GhoshNo ratings yet

- Sampling and Field Testing at Wastewater Treatment FacilitiesDocument11 pagesSampling and Field Testing at Wastewater Treatment FacilitiesSundarapandiyan SundaramoorthyNo ratings yet

- Philips HF C-Arm BrochureDocument2 pagesPhilips HF C-Arm Brochuregarysov50% (2)

- Jigoku Shoujo Eikyuu No SonzaiDocument166 pagesJigoku Shoujo Eikyuu No Sonzaiapi-224188021No ratings yet

- 9701 w09 QP 41Document20 pages9701 w09 QP 41Hubbak KhanNo ratings yet

- Essotherm 500 PDFDocument8 pagesEssotherm 500 PDFdonyaNo ratings yet

- Mitsubishi Motors: Service ManualDocument29 pagesMitsubishi Motors: Service ManualCristobalNo ratings yet

- Gen Ed Answer Key (A)Document7 pagesGen Ed Answer Key (A)Antonette Escarpe TorcinoNo ratings yet

- Demonstration POSTNATAL EXAMINATION Easy WayDocument9 pagesDemonstration POSTNATAL EXAMINATION Easy Wayjyoti singhNo ratings yet

- Iot PresentationDocument9 pagesIot PresentationAbdul Majid ShaikhNo ratings yet

- Engineering StudiesDocument4 pagesEngineering StudiesSamuel PhegelloNo ratings yet

- The Nature of Substance - Rudolf Hauschka PDFDocument250 pagesThe Nature of Substance - Rudolf Hauschka PDFBruno Morin100% (5)

- Sabp X 002Document18 pagesSabp X 002Hassan MokhtarNo ratings yet

- Hero LetterDocument3 pagesHero LetterArunachalam Muthiah0% (1)

- Pip Venix LRDocument2 pagesPip Venix LRThanh VoNo ratings yet

- Legend of Nueva VizcayaDocument10 pagesLegend of Nueva VizcayaAndreanna Maria100% (1)

- Rajagiri Public School Unit Test PhysicsDocument3 pagesRajagiri Public School Unit Test PhysicsNITHINKJOSEPHNo ratings yet

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet

- Yanmar Mechnical PumpDocument16 pagesYanmar Mechnical Pump송성훈100% (9)

- My Version of Meatlaof Project DraftDocument3 pagesMy Version of Meatlaof Project DraftCloue Faye I. BasalloNo ratings yet

- Circuits Review P2Document44 pagesCircuits Review P2José CastilloNo ratings yet