Professional Documents

Culture Documents

Fire Fighting Report - HSPL - 13.03.2017

Uploaded by

Vaibhav SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Fighting Report - HSPL - 13.03.2017

Uploaded by

Vaibhav SharmaCopyright:

Available Formats

REPORT ON FIRE FIGHTING SYSTEM

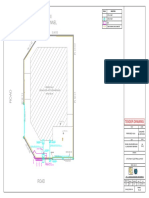

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

RE-CONSTRUCTION OF FACTORY BUILDING FOR

M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

REPORT ON FIRE FIGHTING SYSTEM

: SUBMITTED BY

M/s HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

: CONSULTANTS

PANGASA CHETANA DESIGNS PVT. LTD.

340, SULTANPUR, M.G. ROAD, NEW DELHI-110030

PANGASA CHETANA DESIGNS PVT. LTD 1|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

ARCHITECTURE

PANGASA CHETANA DESIGNS PVT. LTD 2|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

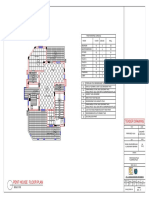

The following points have been incorporated for Fire Protection of the above plant for Haldiram

snacks at sector-68, Noida.

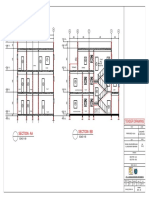

1) The proposed production hall (3 nos.) has been separated by open courts between the

blocks. There are also no interconnections between the production block to avoid any

fire egress. The eave height of the Production block has been considered as 8m.

2) Solid concrete block wall of 300mm thickness has been provided between the

Production hall and Packing hall as well as Production hall and Raw material area with a

fire rating of min 2hrs.

3) Fire rated windows in the openings of these separating walls has been provided for fire

protection.

4) The roof and the cladding of the Shed is been constructed with Rockwool panels of

necessary fire rating.

5) The segregation between the Packing hall(8m height) and Finished goods(G+2, with a

total ht. of 17m) with a corridor 4.5m wide and 6m height having concrete block work

on both sides of the corridor.

6) Necessary fire exits and fire doors have been provided as per NBC norms in the

production hall, Packing area and Raw material storage.

7) The staircases proposed in the factory sheds has been enclosed with concrete block

walls to protect against fire.

8) There are fire exits from all the staircases directly opening outside the building sheds.

9) No openings and windows have been proposed along the external wall where the

equipment’s are placed outside the shed.

PANGASA CHETANA DESIGNS PVT. LTD 3|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

FIRE FIGHTING SYSTEM

PANGASA CHETANA DESIGNS PVT. LTD 4|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

1. DESIGN CRITERIA

1.1 GENERAL:

The firefighting system has been designed and provided in the proposed Industrial complex at

Noida, in accordance with National Fire Protection Association, National Building Code 2016 and

relevant standards.

The existing Fire write up on the Industrial occupancy describes, design criteria and provisions to

be adopted in this building from fire protection point of view.

1.2 CODES & STANDARDS:

The following standard, bye-law, manual have been followed in the designing the Fire Fighting

System.

a) NFPA (National Fire Protection Association) standard and local guide lines together form the

basis for fire protection design of entire complex.

b) The Fire Protection system shall be designed and installed as per NFPA standards and UL /

FM approved.

c) National Building Code 2016 (Part-4 Fire & Life Safety).

d) Local bye-law and consultation with chief fire officer.

e) NFPA 14 – 2010 Installation of standpipe, private hydrant and house hydrant, NFPA 20 –

2010 Installation of stationary pumps for fire protection, NFPA 13 Installation of sprinkler

system and NFPA 24 – 2010 for installation of private service main.

As per NFPA the building classified as Ordinary Hazard (NFPA13 ANX-A .Pno15, Group 2)

(Clause A.5.3.2), building height more than 15 m.

OR

The building falls under the category of industrial building moderate hazard as per NBC 2016

part IV table, area more than 1000 sqm.

The requirements of fire fighting system as per NFPA & NBC 2016 are given below.

PANGASA CHETANA DESIGNS PVT. LTD 5|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

FIRE FIGHTING INSTALLATION

PROVISION AS PER NFPA or NBC 2016

Description AS Per NBC 2016 As Per NFPA

Type of Building Occupancy : Industrial Building (Group G Ordinary Hazard, Group 2

—2,v)

Classification of Fire Hazard : Moderate Hazard Ordinary Hazard

Occupancy.

Height of Building (Max.) : Area more than 1000 sqm.

Sl. No. Particular As per NBC 2016 As per NFPA Consider High

Group-G-2, (V) Class

1 FIRE EXTINGUISHERS REQUIRED REQUIRED Proposed

2 HOSE REEL REQUIRED REQUIRED Proposed

3 WET RISER REQUIRED REQUIRED Proposed

4 DOWN COMER NOT REQUIRED Proposed

5 YARD HYDRANT REQUIRED REQUIRED Proposed

6 AUTOMATIC SPRINKLER REQUIRED IN ENTIRE REQUIRED IN ENTIRE Proposed

SYSTEM BLDG. BLDG.

7 MANUALLY OPERATED REQUIRED REQUIRED Proposed

ELECTRIC FIRE ALARM SYSTEM

8 AUTOMATIC DETECTION AND REQUIRED REQUIRED Proposed

ALARM SYSTEM

9 U/G STATIC WATER REQUIRED REQUIRED Proposed

STORAGE TANKS

10 OVERHEAD FIRE STATIC 20 20 Proposed

TANK (KL)

11 FIRE PUMPS NEAR U/G REQUIRED REQUIRED Proposed

WATER TANKS

12 Pumping Arrangement Diesel = 1 nos. cap of 2850 Diesel = 2 nos. cap of Proposed as

LPM 4550 LPM per NFPA

Hydrant = 1 nos. cap of Hydrant = 1 nos. cap of

2850 LPM 4550 LPM

Sprinkler = 1 nos. cap of Sprinkler = 1 nos. cap of

2850 LPM 4550 LPM

Jockey = 2 nos. cap of 180 Jockey = 2 nos. cap of

LPM 180 LPM

13 Water Curtain Pump * AS / CFO AS / CFO Not Proposed

14 U/G STATIC WATER 150 KL 500 KL (200 KL Proposed as

STORAGE TANKS additional water avail. per NFPA

from treated tank in

case of Emergency)

PANGASA CHETANA DESIGNS PVT. LTD 6|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

15 Pumping capacity duration 60 Minute (As Per IS 90 Minute Proposed as

15105: 2002) Table-2 per NFPA

16 FIRE PUMPS NEAR O/H WATER NOT REQUIRED Proposed

TANK

17 Down Comer pump near OH Tank NOT REQUIRED 900 LPM

Capacity

2. WATER SUPPLY AND STORAGE TANK (PROPOSED)

S.No.

Description Provision as per

(Overhead & Underground Storage) NFPA / NBC 2016 Provision Made

Underground Fire Water Tanks Fire Water Tank = 2 nos. of

100 KL, 2 nos. of 150 KL &

(As per 90 Minute working of fire pumps as per

1. 5,00,000 Treated Water Tank = 1

NFPA) nos. of 200 KL (In case of

emergency)

2. Overhead Water Tank (As Per NBC) 20,000 20,000

PANGASA CHETANA DESIGNS PVT. LTD 7|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

3. BRIEF SYSTEM DESCRIPTION

The static fire water storage water tanks for Fire Protection System have been provided

underground capacity of 500 cum capacity in compartments of 2 numbers 150 KL, 2 numbers

100 KL and supplementary treated water tank capacity of 200KL shall also be used in case of

emergency. Overflow to the fresh water tank to avoid stagnation in fire tank is proposed at the

location where direct access possible.

Fire department connection shall also be provided on the external wall of the property near the

main entrance. These shall comprise of 4 No. 63 mm dia male outlets capable of directly feeding

the ring mains through non return valves or directly filling the static fire storage tanks. These shall

be mounted in specially identified boxes.

The delivery line from the Overhead tank shall be connected to main fire riser at terrace level

with non-return valve; in additional down-comer (900LPM) pump shall be also proposed at terrace

to its risers.

3.1 EXTERNAL FIRE HYDRANT SYSTEM

3.1.1 External Fire Hydrants shall be provided from main Fire Hydrant line (common for external &

internal hydrants) running at site, with a spacing of maximum 45 meters between any two

hydrants. The external hydrants shall be positioned strategically to be easily accessed by the fire

brigade personnel.

3.1.2 Each External Fire Hydrant shall be provided with an external Fire Hose Cabinet (Size as per

TAC / LPA norms) along with the equipment (UL / Fm approved) as per the following

specifications:

i. 2 nos., 63mm diameter and 15m long rubberized fabric lined hose pipe with coupling on

either end.

ii. Gunmetal branch pipe with Gunmetal nozzle 20mm nominal bore.

3.2 INTERNAL FIRE HYDRANT SYSTEM

3.2.1 Single headed landing valves shall be provided in complex.

3.2.2 150mm dia Wet riser pipe with a Single headed landing valve shall be provided.

3.2.3 The internal diameter of inlet connection shall be at least 80 mm. The outlet shall be of instant

spring lock type gunmetal ferrule coupling of 63 mm dia for connecting to hose pipe.

3.3 Every FHC of wet riser will be provided with the following accessories (UL / FM approved).

i. 1 No. first aid hose reel with 19mm bore x 36.5 m long hose fittings with 6.35 mm shut off

nozzle.

ii. 1 No. Single outlet landing valve.

iii. 2 Nos. RRL hose pipe with hose of 63mm dia 15m long with male & female couplings at

both ends.

iv. 1 No. branch pipe 63mm dia with 20mm (nominal diameter) nozzle and suitable for

instantaneous connection.

v. 1 No. fireman’s axe.

PANGASA CHETANA DESIGNS PVT. LTD 8|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

3.4 FIRE WATER SOURCE

Water storage for the complex shall be met through municipal / Bore-well supply and any short

fall shall be compensated tanker water. Total water storage of 5, 00,000 liters in underground

tanks for Fire Fighting tanks and supplementary treated water tank capacity of 200KL shall also

be used in case of emergency.

3.5 FIRE BRIGADE INLET CONNECTIONS

UL / FM approved Fire brigade inlet connections to the system shall comprise of 4 instantaneous

pattern 63 mm dia. male inlet shall be with cap an chains complete with a 6" dia. sluice valve, non

return valve housed in a MS cabinet with glass fronted door. The cabinet shall be suitable for

outdoor mounting.

Fire service inlet with gate and non-return valve to charge the hydrant system in the event of

failure of the static pump directly from the mobile pump of the fire services shall be provided.

3.6 PORTABLE FIRE EXTINGUSHER (UL / FM approved)

i. Portable fire extinguisher shall be provided accordance with NFPA 10 & IS 2190:1992 in

all parts of building.

ii. It is proposed to provide fire extinguishers with ISI marked.

iii. These shall be placed or hanged on wall in a group on several suitable places.

Classification of extinguishers shall be as per the following table:

Class of Fire Description Suitable Type of Appliances

a. Fire in ordinary combustibles (wood, fibers, Gas Expelled Water Type, HFC

rubber plastics, paper and the like) 236

b. Fires in flammable liquids, paints, grease, Chemical extinguishers of

solvents and the like carbon dioxide, HFC 236, dry

powder type and buckets.

c. Fire in gaseous substances under Chemical extinguishers of

pressure including liquefied gases (Class carbon dioxide, HFC 236 and

C fire-Not Gases but Electrical Equipment) dry powder type.

HFC 236 Clean agent Fire Extinguishers 4.0 Kg. Capacity suitable for all classes of

fire, easy snap safety seal, state of the art magnetic pressure gauge, Instalert,

controllable discharge mechanism, EPDM rubber hosepipe.

ABC powder based MAP Fire Extinguishers 10.0 Kg. Capacity suitable for A,B&C

classes of fire, easy snap safety seal ,state -of -the- art magnetic pressure gauge,

Instalert, controllable discharge mechanism, EPDM rubber hosepipe.

PANGASA CHETANA DESIGNS PVT. LTD 9|Page

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

Monnex powder Fire Extinguishers 4.0 Kg. Capacity suitable for B&C classes of fire,

easy snap safety seal, state -of -the- art magnetic pressure gauge, Instalert, controllable

discharge mechanism, EPDM rubber hosepipe.

3.7 SPRINKLER SYSTEM

The automatic sprinkler system shall be provided in the entire area as per NFPA (National Fire

Protection Association) and NBC 2016. The material of construction supports, spacing, between

sprinklers, arrangement of sprinklers, cover page of sprinklers etc. shall be as per NFPA 13,

NFPA 13a etc. An electrical sensor flow switch shall be provided and connected to fire control

panel so that it would be possible to identify the location and the affected floor immediately.

4. SYSTEM DESCRIPTION FOR HYDRANT & SPRINKLER SYSTEM

4.1 HYDRANT SYSTEM DESCRIPTION:

4.1.1 The main fire pumps near underground tank shall be consist of two nos. of main electric pumps

(4550 lpm each for fire hydrant and sprinkler), two nos. of Jockey pump (180 LPM), Down comer

pump (900 LPM) and two nos. of main diesel operated pumps (4550 LPM) in plant room located

at site near RO plant.

4.1.2 The pump head shall be sufficient to ensure 4.5 Kg / cm 2 (As / NFPA) minimum pressure at

farthest point.

4.1.3 The delivery line from the fire pump shall be connected to a common delivery header through

isolating valves, NRVs and pressure gauge connections.

4.1.4 The hydrant and sprinkler wet riser shall be provided with air release valve at the highest points to

release the trapped air in the pipe work.

4.1.5 Four way Fire Brigade Inlet Connections shall be provided for external hydrant line & U.G tank.

4.1.6 Hydrant stations and cabinet shall be provided at all designated location inside hydrants. The

hydrant stations shall be located in fire hose cabinet as per drawing.

4.1.7 Water monitoring units shall be placed at site at various location for covering

5. SPRINKLER SYSTEM DESCRIPTION:

5.1 The automatic sprinkler system shall be installed to protect the entire factory (production hall,

packing area, raw material storage dispatch area, canteen, admin block, pump room etc.).

The sprinkler requirement as per NFPA is given below:

A. Production hall & packing area = K 200, 79°C, ESFR type

B. Raw material storage = K 115, 70°C, ESFR type

C. Finished good material storage = K 160, 70°C, ESFR type

D. Admin, canteen, utility, pump room = K 80, 68°C, QR type

E. Corridor, lab and other area = K 80, 68°C, QR type

PANGASA CHETANA DESIGNS PVT. LTD 10 | P a g e

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

5.2 The Sprinkler System shall be fed from underground tank by means of pumps.

5.3 For the sprinkler system the building shall have divided into zones as for effective protection from

fire.

5.4 The sprinkler heads shall be UL listed fixed temperature type with a quartzoid bulb containing

liquid having high vapor pressure held in position by a forged GM yoke and deflector. The rated

temperature of quartzoid bulb shall be 68 to 79 deg. C for production /packing area /admin/

storage area. A water motor gong and an inspection test connection shall be provided on the

down streamside of the system.

5.5 Sprinkler system consist followings, sprinkler alarm valves with trims, Sprinkler main, branch and

internal piping complete with valves, alarms and supporting arrangements. Sprinkler heads with

spare sprinklers, Flow switches, Connections to risers etc.

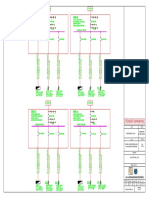

6. SCHEDULE OF FIRE FIGHTING PUMPS

Sl. Description of Pump Flow Rate Pumping Qty. Motor Total

No. Head KW Motor KW

A) PUMPING SYSTEM

1 Electrical Driven 4550 LPM 125 M 1 No. 135 135

Pump (Hydrant

System)

2 Electrical Driven 4550 LPM 125 M 1 No. 135 135

Pump (Sprinkler

System)

3 Diesel Engine Driven 4550 LPM 125 M 2 No. 24 volt 24 volt

Pump (Backup)

4 Electrical Driven 180 LPM 125 M 2 No. 5.5 11

Pump (Jockey)

5 Electrical Driven 900 LPM 35 M 1 No. 7.5 7.5

Pump (Down comer)

6.1 SETTING OF PRESSURE SWITCHES HYDRANT / SPRINKLER SYSTEM DESCRIPTION:

The fire pump shall operate on drop of pressure in the mains as given clause:-

The pump operating sequence shall be arranged in such a manner to start the pump

automatically but should be capable of being stopped manually by stop push buttons only.

PANGASA CHETANA DESIGNS PVT. LTD 11 | P a g e

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

FIRE ALARM SYSTEM

Packaging

Here in this area we have installed multi detectors and ADW.

PANGASA CHETANA DESIGNS PVT. LTD 12 | P a g e

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

Multi detectors – They are a combination of smoke and heat detectors. They get activated when they

sense smoke or when they sense a rise in temperature beyond a preset temperature level.

ADW – It’s a heat detector which works on the principle of Rat of Rise. When the air at normal pressure

inside the tubes expands and exerts pressure on the pressure sensor then it gives a trigger to the

controller which interprets the same change in pressure into the rate of change of temperature. This

rate of change when goes beyond the normal rate of rise then the system gives an alarm. This kind of

system is very effective in all kinds of temperature levels because it works by detecting the rate of rise of

temperature rather than triggering on exceeding a particular temperature level.

Production Hall

Here we have the multi detectors and the dLISt controller

Multi detectors – same as explained in packaging setup.

dLIST – This is a system which is actually a heat sensing system. In this there is a sensor cable laid along

the roof, which contains heat sensors at a distance of 5m each. This also works on the same principle of

Rate of Rise of temperature as the ADW, though it does not have any tubes or air pressure. This system

is better than ADW in terms of just one thing that this system gives the location of the sensor at which

the abnormal change in temperature or fire is detected. This information is available on the dLIST

PANGASA CHETANA DESIGNS PVT. LTD 13 | P a g e

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

controller which is the basic control and display unit of this system. This system can be connected with

our main Fire Alarm Panel to display the alarm condition on same.

MCP – We also have MCPs that are connected in the loop. The MCPs are Manual Call Points which have

a switch which operates when the front glass of the MCP is broken. These devices are used in cases

where the fire is visible to a person and he/she wants to raise an alarm for same manually.

Fire Alarm Panel

Securiton fire alarm panel model No. SCP 3000 is being installed on this site. This system is capable of

handling 14 loops with upto 250 (depending on current consumption of all devices connected) devices

per loop. So here one single panel is capable of handling all the fire devices (viz. smoke detectors, heat

detectors, ADW and dLIST) installed at the site.

PANGASA CHETANA DESIGNS PVT. LTD 14 | P a g e

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

Fire exit signage

An exit sign is a device in a public facility (such as a building, aircraft or boat) denoting the location

of the closest emergency exit in case of fire or other emergency. Most relevant codes (fire , building ,

health or safety) require exit signs to be permanently lit

Hooter

Hooters / Sounders are very important part of the Fire Detection & Alarm system. It will alert the people

and help to take necessary steps to stop the Fire.

PANGASA CHETANA DESIGNS PVT. LTD 15 | P a g e

REPORT ON FIRE FIGHTING SYSTEM

RE-CONSTRUCTION OF FACTORY BUILDING FOR M/S HALDIRAM SNACKS PVT. LTD.

PLOT NO. A-11, SEC.-68, NOIDA

PANGASA CHETANA DESIGNS PVT. LTD 16 | P a g e

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995From EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Rating: 5 out of 5 stars5/5 (1)

- Jockey PumpDocument44 pagesJockey Pumpahmad safiriNo ratings yet

- Project ReportDocument42 pagesProject Reportkamlesh patel100% (1)

- LPCB Approved: Dry Pillar Fire HydrantsDocument6 pagesLPCB Approved: Dry Pillar Fire HydrantsZahir KhiraNo ratings yet

- Viking SR, Pendent K 5.6Document10 pagesViking SR, Pendent K 5.6dzikri nur hNo ratings yet

- LPCB Approved Dry Pillar Fire HydrantsDocument6 pagesLPCB Approved Dry Pillar Fire HydrantsAdil MominNo ratings yet

- Section 15375 - Fire-Suppression StandpipesDocument17 pagesSection 15375 - Fire-Suppression StandpipesAhmed AliNo ratings yet

- 201123-1609-HMR Fire Scheme ReportDocument4 pages201123-1609-HMR Fire Scheme ReportMine FollowerNo ratings yet

- DBR - Fire Fighting - HPMC ParalaDocument16 pagesDBR - Fire Fighting - HPMC ParalaKiran LokhandeNo ratings yet

- OSP054-PR-REP-14606-Rev.7 - WASCO Firefighting System Hydraulic Calculation ReportDocument131 pagesOSP054-PR-REP-14606-Rev.7 - WASCO Firefighting System Hydraulic Calculation ReportEslam Shibl100% (1)

- Fire protection system philosophy for Collie Urea PlantDocument60 pagesFire protection system philosophy for Collie Urea PlantLorena Dávila100% (1)

- Scope of Work 0Document87 pagesScope of Work 0Emamoke100% (2)

- Final Design: Design Criteria Report - Fire ProtectionDocument7 pagesFinal Design: Design Criteria Report - Fire Protectionozelwill5388No ratings yet

- Technical Data: 1. DescriptionDocument8 pagesTechnical Data: 1. DescriptionWael Abdel HakimNo ratings yet

- Projet Topping de Condensat - Skikda SC Instrument Specification For Tank Gauging SystemDocument19 pagesProjet Topping de Condensat - Skikda SC Instrument Specification For Tank Gauging SystemKARIMNo ratings yet

- Schedule of Guaranteed Technical Particular For L.V. Heat Shrinkable Outdoor Termination & Straight Th. Joints For Xlpe/Pvc CableDocument5 pagesSchedule of Guaranteed Technical Particular For L.V. Heat Shrinkable Outdoor Termination & Straight Th. Joints For Xlpe/Pvc CableShiv ChauhanNo ratings yet

- Corrosion Inhibitor Injection System Data Sheet Surface Facility EPC Services Phase-4 Development ProjectDocument11 pagesCorrosion Inhibitor Injection System Data Sheet Surface Facility EPC Services Phase-4 Development ProjectNesrine MhedhbiNo ratings yet

- Sitecna Tailored Solutions For Crytical Service ApplicationsDocument4 pagesSitecna Tailored Solutions For Crytical Service Applicationstoto.gmbhNo ratings yet

- TFP490 01 2006Document20 pagesTFP490 01 2006Kai Shen GohNo ratings yet

- Model AG168 Standard Response Upright Sprinkler (SIN AG1124)Document4 pagesModel AG168 Standard Response Upright Sprinkler (SIN AG1124)arieNo ratings yet

- TFP151 11 2021Document10 pagesTFP151 11 2021INGENIERIA8 FYSNo ratings yet

- Compliance Report - Rev 01Document2 pagesCompliance Report - Rev 01wael hassanNo ratings yet

- UL 698 1 Industrial Control Equipment For Use in Hazardous (Classified) LocationsDocument10 pagesUL 698 1 Industrial Control Equipment For Use in Hazardous (Classified) LocationsreeawsNo ratings yet

- Traveling Grate Boiler 50 TPH 95 KGCM 450CDocument52 pagesTraveling Grate Boiler 50 TPH 95 KGCM 450CMajid KhanNo ratings yet

- Fire Hydrant System PhilosophyDocument26 pagesFire Hydrant System PhilosophyJhajjar100% (1)

- Technical Data: 1. DescriptionDocument6 pagesTechnical Data: 1. DescriptionDanie CastilloNo ratings yet

- Supply Chemical Injection SkidsDocument4 pagesSupply Chemical Injection Skidsbmanojkumar16No ratings yet

- 12 2018.12.05 - LETRAN - Fire Protection SpecificationsDocument12 pages12 2018.12.05 - LETRAN - Fire Protection Specificationsjoey100% (1)

- 500 Kva DGDocument17 pages500 Kva DGRahul Gupta100% (1)

- ES0153-75440100-DBR-0003 Dust ExtractionDocument19 pagesES0153-75440100-DBR-0003 Dust Extractionraaj bharathNo ratings yet

- GAS Oil System, Steam & Condense Return & Steam Trace Insulation SpecificationDocument29 pagesGAS Oil System, Steam & Condense Return & Steam Trace Insulation SpecificationepbamdadNo ratings yet

- Side Wall SprinklersDocument6 pagesSide Wall SprinklersRamesh arumugamNo ratings yet

- Designing and Drafting Specification for Fire AppliancesDocument16 pagesDesigning and Drafting Specification for Fire AppliancesSuriya DasNo ratings yet

- FF ThornDocument1 pageFF ThornmostafaelbalashonyNo ratings yet

- Standard Codes Followed in LPG IndustriesDocument41 pagesStandard Codes Followed in LPG IndustriesSanjay PatelNo ratings yet

- Ibc Case StudyDocument4 pagesIbc Case StudyzubairkkhanNo ratings yet

- FF Design Report - Ovid Kling - Agri-Products Market Center Project at Tafo (Ayat Site) - Rev-00Document6 pagesFF Design Report - Ovid Kling - Agri-Products Market Center Project at Tafo (Ayat Site) - Rev-00Nuhamin ZablonNo ratings yet

- Capacity Building Programme On " New Techniques and Strategies in Prevention and Management of Industrial DisastersDocument41 pagesCapacity Building Programme On " New Techniques and Strategies in Prevention and Management of Industrial DisastersgrasimlookNo ratings yet

- Water Mist Spec Mdts 46352Document4 pagesWater Mist Spec Mdts 46352Abhey DograNo ratings yet

- Desalination Plant - DBRDocument3 pagesDesalination Plant - DBRtribhu100% (1)

- Konishi Vietnam Factory Electrical EstimationDocument8 pagesKonishi Vietnam Factory Electrical EstimationMinh Hải ChuNo ratings yet

- Chap 12 FirefightingDocument10 pagesChap 12 Firefightingadilmomin45No ratings yet

- Standard Codes Followed in LPG IndustriesDocument41 pagesStandard Codes Followed in LPG Industriesaarunsnair100% (2)

- Fire Fighting System DesignDocument12 pagesFire Fighting System DesignPrashant Bahirgonde100% (5)

- Sp-47-27 (Fire Fighting Equipment and Facilities)Document17 pagesSp-47-27 (Fire Fighting Equipment and Facilities)khorzooNo ratings yet

- Dust Supression SystemDocument5 pagesDust Supression SystemSUBHONo ratings yet

- My Refence BoqDocument6 pagesMy Refence BoqJaveedMdJaveedNo ratings yet

- Design Basis Dtd.3.12.2013Document10 pagesDesign Basis Dtd.3.12.2013Adil MominNo ratings yet

- Fire Alarm System DBRDocument19 pagesFire Alarm System DBRKirty VardhanNo ratings yet

- Model N25 ESFR Pendent Sprinkler: Note: Victaulic® and IGS™ Are Trademarks of VictaulicDocument4 pagesModel N25 ESFR Pendent Sprinkler: Note: Victaulic® and IGS™ Are Trademarks of VictaulicpippoNo ratings yet

- A Study On Rail Spring Workshop, Gwalior (M.P)Document43 pagesA Study On Rail Spring Workshop, Gwalior (M.P)Rachna Marcus100% (4)

- RC2 1004 PDFDocument28 pagesRC2 1004 PDFstrumx7No ratings yet

- Se 001 Se11 001Document18 pagesSe 001 Se11 001Faizan AhmedNo ratings yet

- C-1) Fir Fighting Technical SpecificationDocument32 pagesC-1) Fir Fighting Technical Specificationahmed foxNo ratings yet

- Basis of Design - Sacrificial Anodes CathDocument5 pagesBasis of Design - Sacrificial Anodes CathAndreas Schlager100% (2)

- EQU - For Ex - ProtectaDocument2 pagesEQU - For Ex - ProtectaAkhilesh KumarNo ratings yet

- New Co-generation plant fire protection measuresDocument6 pagesNew Co-generation plant fire protection measuresOrlando Gamboa HuertasNo ratings yet

- 06b AppendixB2 (1000HPRig) 1582535891879Document103 pages06b AppendixB2 (1000HPRig) 1582535891879Harsh TiwariNo ratings yet

- 3.TYPICAL DETAILS-TYP DETAILSDocument1 page3.TYPICAL DETAILS-TYP DETAILSNaqqash SajidNo ratings yet

- Wadi Channel: Tender DrawingDocument1 pageWadi Channel: Tender DrawingVaibhav SharmaNo ratings yet

- General Arrangement and Foundation Drawing of " DB" Pump Coupled With Totally Enclosed Fan Cooled Motor (With Lovejoy Coupling L110/25)Document1 pageGeneral Arrangement and Foundation Drawing of " DB" Pump Coupled With Totally Enclosed Fan Cooled Motor (With Lovejoy Coupling L110/25)Vaibhav SharmaNo ratings yet

- Tender Drawing: LPDB1/R4Document1 pageTender Drawing: LPDB1/R4Vaibhav SharmaNo ratings yet

- Green Area Vsat-Antenna: Existing RoadDocument1 pageGreen Area Vsat-Antenna: Existing RoadVaibhav SharmaNo ratings yet

- Tender Drawing: Bausher Al Watayah Proposed VillaDocument1 pageTender Drawing: Bausher Al Watayah Proposed VillaVaibhav SharmaNo ratings yet

- AmStd Basin Price ListDocument7 pagesAmStd Basin Price ListSrinivass AmirishettyNo ratings yet

- Tender Drawing: Symbol DescriptionDocument1 pageTender Drawing: Symbol DescriptionVaibhav SharmaNo ratings yet

- Tender Drawing: Bausher Al Watayah Proposed VillaDocument1 pageTender Drawing: Bausher Al Watayah Proposed VillaVaibhav SharmaNo ratings yet

- Tender Drawing: Symbol DescriptionDocument1 pageTender Drawing: Symbol DescriptionVaibhav SharmaNo ratings yet

- Annexure - Ix: Design Basis For Storm Water Drainage SystemDocument3 pagesAnnexure - Ix: Design Basis For Storm Water Drainage SystemVaibhav SharmaNo ratings yet

- AmStd Pro & Commercial Price ListDocument5 pagesAmStd Pro & Commercial Price ListVaibhav SharmaNo ratings yet

- Amazon Sort Center Jaid-Jaipur Plumbing & Rain Water DBR 18-06-2020 Rev.-01Document37 pagesAmazon Sort Center Jaid-Jaipur Plumbing & Rain Water DBR 18-06-2020 Rev.-01Vaibhav SharmaNo ratings yet

- Annexure - Ix: Design Basis For Storm Water Drainage SystemDocument3 pagesAnnexure - Ix: Design Basis For Storm Water Drainage SystemVaibhav SharmaNo ratings yet

- Sliding Gate: Tender DrawingDocument1 pageSliding Gate: Tender DrawingVaibhav SharmaNo ratings yet

- Pent House Floor Plan: Tender DrawingDocument1 pagePent House Floor Plan: Tender DrawingVaibhav SharmaNo ratings yet

- Section-Aa Section - BB: Tender DrawingDocument1 pageSection-Aa Section - BB: Tender DrawingVaibhav SharmaNo ratings yet

- Section-Aa Section - BB: Tender DrawingDocument1 pageSection-Aa Section - BB: Tender DrawingVaibhav SharmaNo ratings yet

- Haldiram Factory MEP Design Report ObservationsDocument6 pagesHaldiram Factory MEP Design Report ObservationsVaibhav SharmaNo ratings yet

- AmStd Pro & Commercial Price ListDocument5 pagesAmStd Pro & Commercial Price ListVaibhav SharmaNo ratings yet

- AmStd Pro & Commercial Price ListDocument5 pagesAmStd Pro & Commercial Price ListVaibhav SharmaNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument4 pagesPump Performance Datasheet: Operating Conditions LiquidVaibhav SharmaNo ratings yet

- Site PlanDocument1 pageSite PlanVaibhav SharmaNo ratings yet

- HSPL Sector 68 - Technical FAS Write UpDocument4 pagesHSPL Sector 68 - Technical FAS Write UpVaibhav SharmaNo ratings yet

- 2021.04.21 MAPEI Comments To PCD DrawingsDocument4 pages2021.04.21 MAPEI Comments To PCD DrawingsVaibhav SharmaNo ratings yet

- Design Basis Report - PL & FFDocument17 pagesDesign Basis Report - PL & FFVaibhav SharmaNo ratings yet

- PANDAS - Series DataframesDocument118 pagesPANDAS - Series DataframesVaibhav SharmaNo ratings yet

- Haldiram Snacks Private Limited, Sector-68, NoidaDocument1 pageHaldiram Snacks Private Limited, Sector-68, NoidaVaibhav SharmaNo ratings yet

- CommentsDocument1 pageCommentsVaibhav SharmaNo ratings yet

- My FM Globel SprinklerDocument119 pagesMy FM Globel SprinklerVaibhav SharmaNo ratings yet

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Lightweight Honda Powered Portable PumpDocument1 pageLightweight Honda Powered Portable PumpFiretex Protective Technologies Pvt Ltd FiretexNo ratings yet

- 1103A-33TG1 ElectropaK PN1781Document2 pages1103A-33TG1 ElectropaK PN1781GONZALONo ratings yet

- 21st Refinery Technology Meet - The CompendiumDocument474 pages21st Refinery Technology Meet - The CompendiumAnurag Ingle100% (5)

- Turbomolecular Pump: Vacuum Pump Turbopump Vacuum Momentum Fan Pump VacuumDocument4 pagesTurbomolecular Pump: Vacuum Pump Turbopump Vacuum Momentum Fan Pump VacuumEmil Florin TutaNo ratings yet

- CAA Type Certificate for Agusta A109 Helicopter SeriesDocument3 pagesCAA Type Certificate for Agusta A109 Helicopter Seriessebastian becerraNo ratings yet

- NB-983 CO ManualDocument2 pagesNB-983 CO ManualGabriel BanuNo ratings yet

- Metric and Inch (Sae) Fasteners: All ModelsDocument20 pagesMetric and Inch (Sae) Fasteners: All ModelsAndré TarginoNo ratings yet

- Energy Chain and Efficiency in Urban Traffic For ICE - EVDocument7 pagesEnergy Chain and Efficiency in Urban Traffic For ICE - EVAkshay ManiyarNo ratings yet

- 2008 Mondeo Owner ManualDocument286 pages2008 Mondeo Owner Manualusa_400486% (7)

- Property of American Airlines: Operating ManualDocument134 pagesProperty of American Airlines: Operating ManualThắng Xuân50% (2)

- List of Gujarat Gas CNG stations in Punjab and HaryanaDocument1 pageList of Gujarat Gas CNG stations in Punjab and HaryanaAbhinav AnandNo ratings yet

- Flow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Document1 pageFlow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Qayyum KhanNo ratings yet

- Crew ListDocument20 pagesCrew Listenciu georgeNo ratings yet

- Method of Fuel Injection in Small Diesel Engines: Procedia EngineeringDocument6 pagesMethod of Fuel Injection in Small Diesel Engines: Procedia EngineeringAbdulrahman Al HuribyNo ratings yet

- Flight Line MarshallerDocument24 pagesFlight Line MarshallerCap TainNo ratings yet

- Assessment-Task-1 BSBWHS605Document33 pagesAssessment-Task-1 BSBWHS605Tawan Prayord100% (1)

- En 12697 43 - 2005Document8 pagesEn 12697 43 - 2005Valentina CoroiNo ratings yet

- 7.environment: Dream of Clean India Maintaining A Culture of Swachhata Public Places Beyond Individual HousesDocument61 pages7.environment: Dream of Clean India Maintaining A Culture of Swachhata Public Places Beyond Individual HousesDarshan KanganeNo ratings yet

- Kitchen Tools and EquipmentDocument4 pagesKitchen Tools and EquipmentCorine Joy TapoNo ratings yet

- Commercial Service Letter: Noisy 250 Series Engine Fuel PumpsDocument1 pageCommercial Service Letter: Noisy 250 Series Engine Fuel Pumpsoscar horacio floresNo ratings yet

- K1492 (D) Published in The Official Gazette Issue No. 1412Document25 pagesK1492 (D) Published in The Official Gazette Issue No. 1412ICSILNo ratings yet

- SMPV RulesDocument48 pagesSMPV RulesAnonymous LFgO4WbID100% (1)

- Produced Water Treatment: Product DefinitionDocument4 pagesProduced Water Treatment: Product DefinitionThiruppathirajanNo ratings yet

- Pick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct AnswersDocument6 pagesPick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct Answersأحمد إبراهيم شواربNo ratings yet

- BREB-Bakhrabad Gas Vetting OpinionDocument2 pagesBREB-Bakhrabad Gas Vetting OpinionibiNo ratings yet

- Ethanol Production, Uses, Exporting Countries & Largest ProducersDocument23 pagesEthanol Production, Uses, Exporting Countries & Largest Producersanirudh89p67% (3)

- Terminologies in Petroleum IndustryDocument7 pagesTerminologies in Petroleum Industryarvind_dwivedi100% (1)

- Wolseley Merry Tiller ManualDocument10 pagesWolseley Merry Tiller ManualcancuniaNo ratings yet

- SM 35Document236 pagesSM 35BUKURU Juma100% (2)

- Colliery Engineering Vol 34 1914 PDFDocument828 pagesColliery Engineering Vol 34 1914 PDFjohn silverNo ratings yet