Professional Documents

Culture Documents

GE8261 Engineering Lab Lesson Plan

Uploaded by

jvanandh0 ratings0% found this document useful (0 votes)

41 views2 pagesOriginal Title

GE8261 EPL Lesson Plan

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views2 pagesGE8261 Engineering Lab Lesson Plan

Uploaded by

jvanandhCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

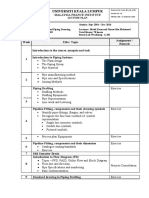

GE8261 Engineering Practices Laboratory

Lesson Plan

Plan

Time Exercise

Session Name of the Exercise / Activity Remark

Number

Safety precautions to be followed in workshop

1

Study of plumbing (Tools, valves, taps, pipe fittings)

Study of centrifugal pump

2

Suction pipe assembly

April

Various pipe assembly as per the requirements

3 Delivery pipe Assembly

Assembly of non-return vale

Study of Welding

4 Types of welding: Shielded Metal Arc, Gas welding

Types of joints

5 Preparation of butt joints, T-joints, lap joint

6 Demonstration of Sheet metal work and its applications

May

Study of sheet metal work

7 Tools used in sheet metal work

Preparation of tray and funnel

Demonstration on foundry, casting process for making

8

gear, step cone pulley

Study of Carpentry

9 Tools and power tools used in carpentry

Types of wooden joints and its applications

Preparation of middle lap joint

10

June

Preparation of Dove-tail joint

Study of Drilling practice and its applications

11

Preparation of Drill and tapping

Demonstration on Fitting, with steps to perform square and

12

V-fitting models

Study of Lathe

13

Various operations performed in lathe

Preparation of workpiece with turning and facing

14

July

workpiece with taper turning

15 Study of Air Conditioner

16 One Mark questions practice / Model Exam

GE8261 ENGINEERING PRACTICES LABORATORY LTPC

0 0 42

OBJECTIVES:

To provide exposure to the students with hands on experience on various basic engineering practices in Civil,

Mechanical, Electrical and Electronics Engineering.

GROUP A (CIVIL & MECHANICAL)

I CIVIL ENGINEERING PRACTICE 13

Buildings:

(a) Study of plumbing and carpentry components of residential and industrial buildings. Safety aspects.

Plumbing Works:

(a) Study of pipeline joints, its location and functions: valves, taps, couplings, unions, reducers, and elbows

in household fittings.

(b) Study of pipe connections requirements for pumps and turbines.

(c) Preparation of plumbing line sketches for water supply and sewage works.

(d) Hands-on-exercise: Basic pipe connections – Mixed pipe material connection – Pipe

Connections with different joining components.

(e) Demonstration of plumbing requirements of high-rise buildings.

Carpentry using Power Tools only:

(a) Study of the joints in roofs, doors, windows and furniture.

(b) Hands-on-exercise:

Wood work, joints by sawing, planing and cutting.

II MECHANICAL ENGINEERING PRACTICE 18

Welding:

(a) Preparation of butt joints, lap joints and T- joints by Shielded metal arc welding.

(b) Gas welding practice

Basic Machining:

(a) Simple Turning and Taper turning

(b) Drilling Practice

Sheet Metal Work:

(a) Forming & Bending:

(b) Model making – Trays and funnels.

(c) Different type of joints.

Machine assembly practice:

(a) Study of centrifugal pump

(b) Study of air conditioner

Demonstration on:

(a) Smithy operations, upsetting, swaging, setting down and bending. Example – Exercise –

Production of hexagonal headed bolt.

(b) Foundry operations like mould preparation for gear and step cone pulley.

(c) Fitting – Exercises – Preparation of square fitting and V – fitting models.

OUTCOMES:

On successful completion of this course, the student will be able to

• Fabricate carpentry components and pipe connections including plumbing works.

• Use welding equipment to join the structures.

• Carry out the basic machining operations

• Make the models using sheet metal works

• Illustrate on centrifugal pump, Air conditioner, operations of smithy, foundary and fittings

• Carry out basic home electrical works and appliances

• Measure the electrical quantities

• Elaborate on the components, gates, soldering practices.

You might also like

- Rajalakshmi Institute of Technology Engineering Practices Lab ManualDocument115 pagesRajalakshmi Institute of Technology Engineering Practices Lab ManualPavithraNo ratings yet

- GE8261 EP Lab ManualDocument82 pagesGE8261 EP Lab Manualsirajudeen I100% (1)

- CP For Ep LabDocument5 pagesCP For Ep LabKalai ArasanNo ratings yet

- Mechanical Workshop SyllabusDocument2 pagesMechanical Workshop SyllabusDr. Sudesh Singh (SET Assistant Professor)No ratings yet

- 5 6280779123619004524 PDFDocument143 pages5 6280779123619004524 PDFÀràvìñd CháñNo ratings yet

- BWS151 Workshop Syllabus & LPDocument4 pagesBWS151 Workshop Syllabus & LPᴀᴍᴀɴNo ratings yet

- Engineering Practices Lab ManualDocument180 pagesEngineering Practices Lab ManualLohit MNo ratings yet

- Ju Mech Ws New FormatDocument1 pageJu Mech Ws New FormatmanishjecrNo ratings yet

- 1st Year Lab Manual For Students Rev 2021Document142 pages1st Year Lab Manual For Students Rev 2021Shyam 4No ratings yet

- U19GE111 - EPL Syllabus Ver 6.0Document2 pagesU19GE111 - EPL Syllabus Ver 6.0jubairrubyNo ratings yet

- FFD 25303 Lecture Plan Sept 2016Document2 pagesFFD 25303 Lecture Plan Sept 2016knizam1971No ratings yet

- GE2115 Computer Practice Laboratory - I L T P C 0 0 3 2 List of Exercises A) Word Processing 15Document5 pagesGE2115 Computer Practice Laboratory - I L T P C 0 0 3 2 List of Exercises A) Word Processing 15Kingsly UshaNo ratings yet

- FFD 25303 Lecture Plan Jan 2016Document2 pagesFFD 25303 Lecture Plan Jan 2016knizam1971No ratings yet

- Engineering Workshop PracticeDocument3 pagesEngineering Workshop Practicemyatminmdy1516No ratings yet

- S1 Civil - & - Mechanical - WorkshopDocument5 pagesS1 Civil - & - Mechanical - WorkshopMathew JohnNo ratings yet

- Ge1101 - Engineering Practices Laboratory L T P C 0 0 3 2Document3 pagesGe1101 - Engineering Practices Laboratory L T P C 0 0 3 2eswar110582No ratings yet

- Gujarat Technological University: Course Name: Work-ShopDocument5 pagesGujarat Technological University: Course Name: Work-ShopadeliaNo ratings yet

- Workshop ManualDocument85 pagesWorkshop Manualpavithrapappu88No ratings yet

- WPDocument4 pagesWPSDMNo ratings yet

- List of PracticalsDocument5 pagesList of PracticalsSakil K SNo ratings yet

- Workshop ManualDocument60 pagesWorkshop ManualRishu pandey100% (1)

- Workshop Practice Lab ReportDocument111 pagesWorkshop Practice Lab Reportkaleem zargarNo ratings yet

- Title Page 1Document16 pagesTitle Page 1harimadhavareddyNo ratings yet

- Untitled 1Document3 pagesUntitled 1AmanNo ratings yet

- Manufacturing Processes & Production TechniquesDocument3 pagesManufacturing Processes & Production TechniquesQwer QwerNo ratings yet

- 02 Epl Lab Manual - 2017-18Document93 pages02 Epl Lab Manual - 2017-18jvanandhNo ratings yet

- Manufacturing Practices FinalDocument65 pagesManufacturing Practices FinalRoman ReignNo ratings yet

- 1 Manufacturing TechnologyDocument2 pages1 Manufacturing TechnologyNarasimha Murthy InampudiNo ratings yet

- Certificate of Originality of WorkDocument34 pagesCertificate of Originality of WorkKalyan HalderNo ratings yet

- Acknowledgement: Gawade S.R. Class Coordinator Prof. Shirke Sir, Principal Dr. Narve N.G. and All The StaffDocument16 pagesAcknowledgement: Gawade S.R. Class Coordinator Prof. Shirke Sir, Principal Dr. Narve N.G. and All The StaffShubham PhadtareNo ratings yet

- Aero Fluid Dynamics Laboratory Lab ManualDocument40 pagesAero Fluid Dynamics Laboratory Lab ManualSri E.Maheswar Reddy Assistant ProfessorNo ratings yet

- SOM Lab manualDocument41 pagesSOM Lab manualThiru KannanNo ratings yet

- Laboratory Manual: Department of Mechanical EngineeringDocument9 pagesLaboratory Manual: Department of Mechanical Engineeringrajamanickam sNo ratings yet

- WP Sem 2Document4 pagesWP Sem 2Ansh DhankharNo ratings yet

- Workshop Manual 15wsl24 PDFDocument94 pagesWorkshop Manual 15wsl24 PDFZiyauddin SeikhNo ratings yet

- Co Po MappingDocument129 pagesCo Po Mappingarup100% (1)

- L TH T P Full Marks. External Exam Marks Internal Exam Marks External Pas Marks Total Pass Marks Duration of External Exams 4 50 30 20 - 25Document4 pagesL TH T P Full Marks. External Exam Marks Internal Exam Marks External Pas Marks Total Pass Marks Duration of External Exams 4 50 30 20 - 25Pʀʌĸʌsʜ Kʋɱʌʀ AʛʌʀwʌɭNo ratings yet

- Workshop Lab ManualDocument92 pagesWorkshop Lab ManualRajuNo ratings yet

- MT 1 Lab Manual PDFDocument40 pagesMT 1 Lab Manual PDFrajamanickam sNo ratings yet

- Laboratory Manual: Department of Mechanical EngineeringDocument7 pagesLaboratory Manual: Department of Mechanical Engineeringrajamanickam s0% (1)

- TT Electrician 2017 Pages 129 39Document12 pagesTT Electrician 2017 Pages 129 39Ghodke ParmeshwarNo ratings yet

- Engineering Workshop Lab ManualDocument74 pagesEngineering Workshop Lab ManualMD Al-AminNo ratings yet

- Engineering Workshop Lab ManualDocument74 pagesEngineering Workshop Lab Manual39 Mohit KumarNo ratings yet

- List of Workshop Basic Training CourseDocument7 pagesList of Workshop Basic Training CourseCerose SakilNo ratings yet

- 4me4 23 Production Practice LabDocument103 pages4me4 23 Production Practice Labsamuel mechNo ratings yet

- Justification 3Document129 pagesJustification 3Naveen SSNo ratings yet

- Automobile Engineering Diploma Third Semester Workshop PracticeDocument2 pagesAutomobile Engineering Diploma Third Semester Workshop PracticeSachi MensiNo ratings yet

- Piping: Design & ArrangementDocument2 pagesPiping: Design & ArrangementMrShaz ZainalNo ratings yet

- CHE106 FM Lab Manual 18feb22 1Document98 pagesCHE106 FM Lab Manual 18feb22 1ARUN K CHOCKALINGAMNo ratings yet

- CBLM Smaw NC Ii PipeDocument40 pagesCBLM Smaw NC Ii PipeRyanM.PradelNo ratings yet

- ProgrammeDocument5 pagesProgrammeFIONA CHATOLANo ratings yet

- Structral Design Laboratory: Lab ManualDocument72 pagesStructral Design Laboratory: Lab ManualSolomon AhimbisibweNo ratings yet

- Ep LabDocument89 pagesEp LabkanagavelNo ratings yet

- Raghu Engineering CollegeDocument30 pagesRaghu Engineering CollegeKalisetti AnilNo ratings yet

- Synopsis Pnumatic Hammer 1Document14 pagesSynopsis Pnumatic Hammer 1jsushil379No ratings yet

- EE101 Electrical Workshop Lab ManualDocument49 pagesEE101 Electrical Workshop Lab ManualIhsaan Gulzar100% (1)

- RMK Group A4 PPT MT-I (UNIT-I)Document82 pagesRMK Group A4 PPT MT-I (UNIT-I)Rajmchz100% (1)

- 2160503Document3 pages2160503Yash MadlaniNo ratings yet

- WorkshopDocument5 pagesWorkshopr55088299No ratings yet

- Failure Analysis in Engineering ApplicationsFrom EverandFailure Analysis in Engineering ApplicationsRating: 1 out of 5 stars1/5 (1)

- Multi-Criteria Decision Making Using TOPSIS Method PDFDocument8 pagesMulti-Criteria Decision Making Using TOPSIS Method PDFRajaa KodadNo ratings yet

- 02 Epl Lab Manual - 2017-18Document93 pages02 Epl Lab Manual - 2017-18jvanandhNo ratings yet

- Anna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/16Document16 pagesAnna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/16jvanandhNo ratings yet

- 1 s2.0 S2211812814008955 MainDocument10 pages1 s2.0 S2211812814008955 MainjvanandhNo ratings yet

- Anna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/16Document16 pagesAnna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/16jvanandhNo ratings yet

- A Methodology For Effective Implementation of Lean Strategies and Its Performance Evaluation in Manufacturing OrganizationsDocument29 pagesA Methodology For Effective Implementation of Lean Strategies and Its Performance Evaluation in Manufacturing OrganizationsMohammed SirelkhatimNo ratings yet

- VIKOR Technique: A Systematic Review of The State of The Art Literature On Methodologies and ApplicationsDocument38 pagesVIKOR Technique: A Systematic Review of The State of The Art Literature On Methodologies and ApplicationsDynieke CaesarNo ratings yet

- Anna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/4Document4 pagesAnna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/4jvanandhNo ratings yet

- Multiattribute Evaluation of Organic and InorganicDocument16 pagesMultiattribute Evaluation of Organic and InorganicjvanandhNo ratings yet

- Template For Syllabus - LaboratoryDocument1 pageTemplate For Syllabus - LaboratoryjvanandhNo ratings yet

- Lean Six SigmaDocument3 pagesLean Six SigmajvanandhNo ratings yet

- Applied Sciences: Hesitant Fuzzy Linguistic Term and TOPSIS To Assess Lean PerformanceDocument13 pagesApplied Sciences: Hesitant Fuzzy Linguistic Term and TOPSIS To Assess Lean PerformancejvanandhNo ratings yet

- Application of A Modified VIKOR Method For Decision-Making Problems in Lean Tool SelectionDocument14 pagesApplication of A Modified VIKOR Method For Decision-Making Problems in Lean Tool SelectionjvanandhNo ratings yet

- Omega: Majid Mohammadi, Jafar RezaeiDocument12 pagesOmega: Majid Mohammadi, Jafar RezaeijvanandhNo ratings yet

- CO and PO, PSO Mapping With CO - C406K - OEC1711 - Leansixsigma - R2021Document1 pageCO and PO, PSO Mapping With CO - C406K - OEC1711 - Leansixsigma - R2021jvanandhNo ratings yet

- Applied Mathematical Modelling: Mohammad Kazem Sayadi, Majeed Heydari, Kamran ShahanaghiDocument6 pagesApplied Mathematical Modelling: Mohammad Kazem Sayadi, Majeed Heydari, Kamran ShahanaghijvanandhNo ratings yet

- Template For Syllabus - Lean ManufacturingDocument2 pagesTemplate For Syllabus - Lean ManufacturingjvanandhNo ratings yet

- CPM PERT project network crashing activities expected time varianceDocument2 pagesCPM PERT project network crashing activities expected time variancejvanandhNo ratings yet

- Syllabus - Laboratory - C207 - ME1307 - MT LAB I R2021Document1 pageSyllabus - Laboratory - C207 - ME1307 - MT LAB I R2021jvanandhNo ratings yet

- Syllabus - Operations ManagementDocument2 pagesSyllabus - Operations ManagementjvanandhNo ratings yet

- Syllabus - ENTREPRENEURSHIP DEVELOPMENTDocument2 pagesSyllabus - ENTREPRENEURSHIP DEVELOPMENTjvanandhNo ratings yet

- Syllabus - Laboratory - C207 - ME1307 - MT LAB I R2021Document1 pageSyllabus - Laboratory - C207 - ME1307 - MT LAB I R2021jvanandhNo ratings yet

- Syllabus - Lean and Agile ManufacturingDocument2 pagesSyllabus - Lean and Agile ManufacturingjvanandhNo ratings yet

- TQM Principles and Tools for Quality ImprovementDocument2 pagesTQM Principles and Tools for Quality ImprovementjvanandhNo ratings yet

- CPM PERT project network crashing activities expected time varianceDocument2 pagesCPM PERT project network crashing activities expected time variancejvanandhNo ratings yet

- Syllabus - Lean SixsigmaDocument2 pagesSyllabus - Lean SixsigmajvanandhNo ratings yet

- Solution - Assignment 8Document2 pagesSolution - Assignment 8jvanandhNo ratings yet

- Solution - Assignment 8Document2 pagesSolution - Assignment 8jvanandhNo ratings yet

- Solution - Assignment 7Document2 pagesSolution - Assignment 7jvanandhNo ratings yet

- Chemistry One Liner Questions PDFDocument10 pagesChemistry One Liner Questions PDFHacker Mudu0% (1)

- Soldering Techniques Lecture Note NowDocument12 pagesSoldering Techniques Lecture Note NowOluwakayode JohnNo ratings yet

- 1 PB PDFDocument6 pages1 PB PDFSantoshNo ratings yet

- NIC Recovery List SakshiDocument728 pagesNIC Recovery List SakshiMuneer LoneNo ratings yet

- International Care SymbolsDocument12 pagesInternational Care SymbolsBincy AbrahamNo ratings yet

- Steelworks Products and Tinsmithing ToolsDocument39 pagesSteelworks Products and Tinsmithing ToolsEli SuarezNo ratings yet

- Separation and Purification of Organic Compounds-DistillationDocument17 pagesSeparation and Purification of Organic Compounds-DistillationMarie Maraniag100% (1)

- Ferrous: AlloysDocument18 pagesFerrous: AlloyssunsirNo ratings yet

- BS en 1708-1 (2010)Document76 pagesBS en 1708-1 (2010)Peter TvardzíkNo ratings yet

- Model: P830 Series (316L Type) : High Purity Pressure Gauge (BA Grade)Document6 pagesModel: P830 Series (316L Type) : High Purity Pressure Gauge (BA Grade)민성규No ratings yet

- Dyeing MachinesDocument12 pagesDyeing Machinestalha mehboobNo ratings yet

- Organic Reagents Used in Inorganic AnalysisDocument52 pagesOrganic Reagents Used in Inorganic AnalysisBns Bgs100% (1)

- SPINDO Catalogue New PDFDocument56 pagesSPINDO Catalogue New PDFTitus Deus PrizfelixNo ratings yet

- Polyamide Selection-NylonDocument24 pagesPolyamide Selection-NylonShivaranjani KuruparanNo ratings yet

- XCR Series - Brazed Plate Heat Exchangers: For Pleasant-Temperature MomentsDocument2 pagesXCR Series - Brazed Plate Heat Exchangers: For Pleasant-Temperature Momentsjcastell100No ratings yet

- Physical: MetallurgyDocument4 pagesPhysical: MetallurgySanjanaNo ratings yet

- 2020.12.29 CTW320-CGD-AIC-000659-E01-Subm.-MAR Steel Pipe Painting (Red Oxide Primer & Gloss Top Coat (let-AIC-002289)Document6 pages2020.12.29 CTW320-CGD-AIC-000659-E01-Subm.-MAR Steel Pipe Painting (Red Oxide Primer & Gloss Top Coat (let-AIC-002289)Jafffar MahasnehNo ratings yet

- Appropriate Building Technology Lecture 4Document19 pagesAppropriate Building Technology Lecture 4Nahum HabtamuNo ratings yet

- Polyshield: (Bituminous Damp Proof Membrane)Document31 pagesPolyshield: (Bituminous Damp Proof Membrane)Mathikumar Melur MelurNo ratings yet

- 53106-mt - Mechanics of Composite MaterialsDocument2 pages53106-mt - Mechanics of Composite MaterialsSRINIVASA RAO GANTANo ratings yet

- Functions and Applications of Geosynthetics in Roadways: SciencedirectDocument9 pagesFunctions and Applications of Geosynthetics in Roadways: SciencedirectMrutyunjaya BeheraNo ratings yet

- 693b Chockfast Orange Hardener Ratio Guide For Chocking Between Steel SteelDocument2 pages693b Chockfast Orange Hardener Ratio Guide For Chocking Between Steel SteelDiego PachecoNo ratings yet

- Portable Fire Extinguisher Types Classes SelectionDocument14 pagesPortable Fire Extinguisher Types Classes SelectionAdebayo O. Johnson100% (2)

- Admixtures by Portland CementDocument36 pagesAdmixtures by Portland CementVijayakrishna SingamsettiNo ratings yet

- JEE MAINS - Test 09 - Solution Notes (Chemistry) - JEE MAINS - Test 09 Solution Notes (Chemistry)Document32 pagesJEE MAINS - Test 09 - Solution Notes (Chemistry) - JEE MAINS - Test 09 Solution Notes (Chemistry)Mohit SuaradkarNo ratings yet

- ORI - Maxx AromourDocument4 pagesORI - Maxx Aromourjose castilloNo ratings yet

- Answer 1 Tablet Coating ValidationDocument9 pagesAnswer 1 Tablet Coating ValidationPankaj JaatNo ratings yet

- TDS For Epoxy SystemDocument4 pagesTDS For Epoxy SystemhemantrulzNo ratings yet

- Replacement of Aggregate With Plastic WasteDocument3 pagesReplacement of Aggregate With Plastic WasteDharma banothuNo ratings yet

- Billet Casting Principles and PracticeDocument11 pagesBillet Casting Principles and PracticeNaveen Gupta100% (2)