Professional Documents

Culture Documents

JHA Explosives Use - ROMO

Uploaded by

amar alfehailOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JHA Explosives Use - ROMO

Uploaded by

amar alfehailCopyright:

Available Formats

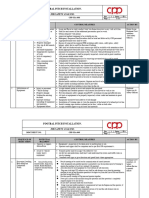

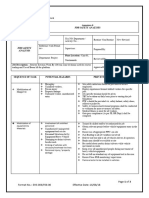

JOB HAZARD ANALYSIS (JHA)

JOB TITLE: DATE: x NEW

Explosives Use and Safety REVISED

LOCATION OF JOB: DIVISION: BRANCH:

Rocky Mountain National Park all ROMO Areas

TITLE OF EMPLOYEE(S) INVOLVED IN ANALYSIS: SUPERVISOR: DIVISION CHIEF:

Maintenance Worker Leader, Maintenance Workers, Laborers, Eng Facility Management

Equip. Operators, Maint Mechanics.

REQUIRED AND/OR RECOMMENDED Hard hat, ear & eye protection, non-synthetic clothing (as much as possible…) blasters vest w/

PERSONAL PROTECTIVE EQUIPMENT: applicable tools, radio, blasting cheat sheets, plans, and required documents, spare batteries

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE

Blasting work: preparing for work. Injuries or property damage -Our most important achievement is for every employee to conclude each and every day

resulting from lack of knowledge, without personal injury or damage to property.

communication, equipment, or -Employees are provided adequate orientation, equipment and training as per their duties and

training. responsibilities.

-Employees participate in and support an environment where all valid safety concerns can be

raised and addressed, without judgement or reprisal.

-BLASTER-IN-CHARGE HAS ABSOLUTE RESPONSIBILITY!

-Only authorized and/or certified employees will engage in blasting operations, under the

approval and direction of BIC & supervisors.

-Explosives are a vital and indispensable tool and need to be treated with extreme caution and

respect, and in full compliance with all applicable rules, regulations and policies.

Injuries or property damage -Employees trained and/or certified to use, handle, store and transport explosives must maintain

resulting from lack of training. their relevant endorsements, licenses, training and field requirements, or inform supervisor of

problems or concerns.

Injuries or property damage -Crew leaders and supervisors are responsible for providing crewmembers with adequate PPE and

resulting from lack of PPE and/or related training. Refer to Required personal equipment

training.

Injuries or property damage -Crew leaders and supervisors will conduct and document weekly safety meetings to discuss

resulting from lack of knowledge, safety issues, projects, and other work-related topics.

communication, equipment, or -BIC, Crew leaders and supervisors will also conduct a pre-blast briefing with personnel to

training. provide project orientation, assign duties and responsibilities, review blasting procedures, and

avoid miscommunication.

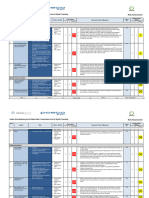

Blasting work: communication, planning, and Injuries or property damage -Good communication between guards and blaster-in-charge is essential and should reinforce

logistics. resulting from lack of individual awareness of real and potential hazards.

communication. -Radios, frequencies, and standard operating procedures (SOP’s) should be reviewed and clearly

understood by all participants before beginning work.

-Instructions will come from blaster-in-charge, or a designated radio contact.

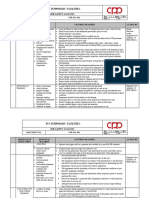

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE

-Positive radio communication is absolutely critical, and radios should be thoroughly

inspected and tested prior to leaving the shop.

Injuries or property damage -Each crew will be provided at least one first-aid kit and water-filter.

resulting from lack of -Crewmembers should be familiar with its location and contents at all times.

communication, equipment, or -Basic first aid/CPR training will be available for all crewmembers.

training.

General hazards, all hazards. -Safety is everyone’s primary responsibility, and all employees should take an active role

in hazard identification, analysis, and mitigation.

-If at any point, a job is deemed unsafe, guards and/or blasters should feel entitled to

stop until the appropriate PPE, engineering control’s, equipment or conditions are

available or exist to make the job safe.

Injuries or property damage -Each guard should receive training on basic radio procedures, emergency response plans,

resulting from lack of knowledge, and individual duties and responsibilities.

communication, equipment, or -Workers need to stay alert and focused on their surroundings and duties, the location of

training. other guards, and any/all hazards while performing blasting operations.

-Crewmembers should report any concerns or breaches of security to the blaster-in-charge

immediately.

Injuries or property damage -Blasters need to be continually aware of, and prepared for, dynamic and extreme weather.

resulting from work site hazards -Immediately vacate and guard site if lightning approaches.

such as weather. -Be aware of potential desensitizing of product from exposure to elements.

-Preferable to use non-electric initiation system.

Blasting work: preparing site/ signage. Injuries caused by inadequate -Post appropriate signs and guards around the perimeter of each shot.

guarding. -Maintain communications with all guards, “positive-response”, using radios if needed.

Blasting work: on site. Injuries caused by improper -Handle explosives with extreme care, observing all instructions included in each box of

handling. explosives and caps.

-Follow the “Always and never” instructions contained in each box of explosives and caps.

-Be aware of the possibility and hazard of stray Radio Frequency Energy.

-Never handle or prepare explosives, load holes, or tie bore-holes together with a radio chest

harness on.

-Keep radios at least 25’ away from explosives and related equipment.

-Place hands on ground for 5 seconds before handling electric detonators.

-No smoking within 50’ and use only non-sparking tools.

Injuries or property damage -Obtain and reference the following publication; National Park Service Guide for the

resulting from improper Storage, Transportation, Training of Explosives Use, and Handling of Explosives.

transportation of explosives. -Have all required documents readily available when transporting explosives (by vehicle,

person, or pack mule).

-Explosives should be secured inside backpacks in such a way as to not pose a safety hazard

to the person carrying the load or anyone else on the trail.

-Never carry caps in the same container as detonation cord or explosive product.

-When needed, explosives and supplies will be securely packed on NPS stock, under the

direction of a blaster and animal packer.

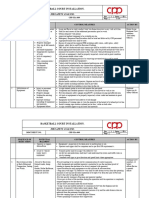

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE

Injuries or property damage -Double check that all holes are tied into shot.

resulting from improper initiation -Have spare batteries and/or spare initiators at the job site.

-Make sure the initiation site is a safe location.

-Give loud verbal warning prior to shot.

-Report to guards, “all clear,” and call them in or keep at posts for next shot.

Injuries caused by drilling -Operators need to find the safest, most effective position for themselves and the machine.

operations. -If possible, consider moving materials so that drills can be operated from such a position to

allow the driller to maintain good footing and posture.

-Drill operators should maintain a relaxed grip on the handles, reducing the conduction of

vibrations and impacts to hands, wrists, arms and elbows.

-Allow the weight of the drill to drive the bit, while guiding the shank in the middle of the

hole, with minimal pressure from the drill operator.

-If necessary, a spotter, or an additional operator can help support the machine or guide the

bit.

-Poinjar operators should take frequent breaks of appropriate length, and stretch often.

Machinery is not to be operated within 50’ of explosives.

-NEVER DRILL IN AN EXISTING BOREHOLE WHICH MAY CONTAIN

EXPLOSIVES!

-NEVER DRILL INTO A BOOTLEG!

Frozen bit, sudden stop, or -When all else fails, take a step back and a big, deep breath, maybe stretch a little, and try

fatigue/frustration. again or try something different.

-Drillers need to be attentive to the behavior of the drill and conscious of the type of rock

they are drilling.

-Micro-fractures and unforeseen seeps can jamb a bit, causing a sudden reaction with the

drill.

-Drillers should monitor the following: Changing tones-often signal a bit is about to break

completely through a rock. Fast and slow drilling-often indicates different layers and

hardness of rock. Color of the drill fines-a good indicator of the type of rock below.

Injuries caused by -Frame packs and backboards are available for transporting drills by foot.

transporting/packing drills. -Anyone carrying a drill should be extra careful of rough or loose footing and get assistance

while loading and unloading.

-Packers or other trained staff must lash drills tight and secure to pack stock.

-Poinjars should be purged whenever being transported or not in use.

Blasting work: Initiation. Misfire, Accidental detonation, -Handle explosives with extreme care, observing all instructions included in each box of

Exposure to Elements. explosives and caps.

-Don’t make up primers next to truck containing explosives. Place hands on ground for 5

seconds before handling electric detonators.

-No smoking within 50’ and no sparking tools allowed.

-Be aware of potential desensitizing of product from exposure to elements.

-Do not tamp primer!

-Follow the “Always and never” instructions contained in each box of explosives and caps.

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE

-Follow manufacturer’s instructions.

-Double check that all holes are tied into shot.

-Use only approved explosives (no nytroglycerin based

products).

-Allow no smoking or mechanized equipment within 50 feet

of holes.

Premature firing, misfires, and partial -The “Blaster-in-Charge” controls the blast initiation device.

detonation. -Check for proper resistance in EBC series.

-Use EBW’s or Non-EL blast system when electromagnetic

radiation or extraneous electricity is present. (Radio transmitters,

radar, high voltage electric lines, blowing dust or snow, etc.)

-Immediately vacate and guard site if lightning approaches.

-Follow misfire procedures in the event of a misfire or partial

detonation

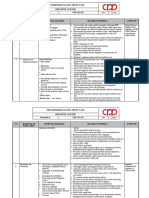

ROMO Blasting Guidelines for Guards ROMO General Blasting Procedures: -MISFIRE Instructions:

Pre-blast briefing: Get your assignment; make sure you -Contact ROMO before beginning project

understand all specifics of blast plan. If you have any questions -Brief guards, send out and establish 1. Retry standard initiation procedure—double check connections

at any time, ask them. security: 2. Inform guards of situation, continue to securely guard area

Radio Check: Set radios to channel 11 (or other channel as -positive response system 3. Remove non-el or lead wires from blasting machine

assigned by Blaster-in-Charge). We use a "positive response" -Prepare explosives, load holes/place 4. Check unit, replace batteries or entire unit

system. Go to your designated spot and report to Blaster-in- charges, tie together, lay-out lead wire, Snip 6 to 12” off non-el and retry or try different initiator

Charge (BIC) when on site. If at any time there is a problem, double check system 5. Reshoot starting with, “Blasting Two”

contact BIC and yell "STOP!" - “BLASTING ONE”; Guards respond 6. If nothing, disconnect wires, check continuity, shunt wires

"BLASTING ONE"- (Blaster has checked set-up, wired in cap -Test Cap (Optional) 7. Continue to guard scene, wait 30 minutes

and is ready to leave site.) Guards respond in order "Guard # -Un-shunt and test lead line 8. Cautiously return to blast site, inspect all wires, cap(s), delay(s),

__, clear" if area secure. A vocal perimeter should be -Tie/connect cap to non-el or D-cord d-cord, non-el cord, connections, ‘T’ joints, and any exposed part

established. -Un-shunt cap-tie into lead line or non-el of set-up

"BLASTING TWO"- (Blaster is at initiation site, doing final -Inspect set-up 9. If burning, do not enter site for 12 hours or 1 hour after last

checks.) All guards respond to BIC in order. - “BLASTING TWO”; Guards respond smoke

"BLASTING NOW"-All guards respond to BIC. Blaster and -Return to Initiation site 10.Re-assess entire setup. Back-up cap? Options?

all guards yell out “Blasting!" (Shot initiated right after all -Check continuity of circuit

guards have checked in.) After shot, all guards maintain secure -Connect lead wire/non-el to initiator

area until notified that blast site is clear. - “BLASTING NOW”; Guards respond

"ALL CLEAR"-Guards respond. Return to blast site. and all yell. “blasting now.”

REMEMBER! -Initiate shot; “BOOM” --if misfire,

YOU are responsible for security of the blast area. No follow misfire procedures

unauthorized persons are allowed in the area! If anything is -Disconnect & Shunt lead wire

other than what the blast plan calls for, contact the Blaster-In- -Inspect blast site, if not all clear, follow -MISFIRES probably most often occur due to old/weak batteries in

Charge IMMEDIATELY! misfire procedures. initiators.

- “ALL CLEAR”; Guards respond

-Proceed to next shot or clean up.

JSA Instructions Emergency Evacuation Instructions

The JSA shall identify the location of the work project or activity, the name of Work supervisors and crew members are responsible for developing and discussing

employee(s) writing the JSA, the date(s) of development, and the name of the field emergency evacuation procedures (EEP) and alternatives in the event a person(s)

appropriate line officer approving it. The supervisor acknowledges that employees becomes seriously ill or injured at the work site.

have read and understand the contents, have received the required training, and are

qualified to perform the work project or activity. Be prepared to provide the following information:

a. Nature of the accident or injury (avoid using victim’s name).

Blocks 1, 2, 3, 4, 5, and 6: Self-explanatory b. Type of assistance needed, if any (ground, air or water evacuation).

c. Location of accident or injury, best access route into the work site (road

Block 7: Identify all tasks and procedures associated with the work project or activity name/number), identifiable ground/air landmarks.

that have potential to cause injury or illness to personnel and damage to property or d. Radio frequency(s).

material. Include emergency evacuation procedures (EEP). e. Contact person.

f. Local hazards to ground vehicles or aviation.

g. Weather conditions (wind speed & direction, visibility, temp).

Block 8: Identify all known or suspect hazards associated with each respective

h. Topography.

task/procedure listed in block 7. For example:

i. Number of person(s) to be transported

a. Research past accidents/incidents. j. Estimated weight of passengers for air/water evacuation.

b. Research the Health and Safety Code or other appropriate literature.

c. Discuss the work project/activity with participants The items listed above serve only as guidelines for the development of emergency

d. Observe the work project/activity evacuation procedures.

e. A combination of the above

JSA and Emergency Evacuation Procedures Acknowledgement

Block 9: Identify appropriate actions to reduce or eliminate the hazards identified in

block 8. Abatement measures listed below are in the order of the preferred As supervisor I acknowledge that the following employees have participated in the

abatement method: development of this JSA, accompanying evacuation procedures and have also been

a. Engineering Controls (the most desirable method of abatement). For example, briefed on the provisions thereof:

ergonomically designed tools, equipment and furniture.

b. Substitution. For example, switching to high flash point, non-toxic solvents.

c. Administrative Controls. For example, limiting exposure by reducing the work Supervisor’s Signature:

schedule.

d. PPE (least desirable method of abatement). For example, using hearing

protection when working with or close to portable machines (chain saws, rock

drills, portable water pumps)

e. A combination of the above.

Block 10: The JSA must be reviewed and approved by a supervisor.

Block 11: List all recommended and required PPE relevant for job/activity

You might also like

- Jha Bridge Work - RomoDocument8 pagesJha Bridge Work - Romoalexander pimentel jrNo ratings yet

- JHA Signpost Construction - ROMODocument5 pagesJHA Signpost Construction - ROMOSagar SahareNo ratings yet

- JHA Signpost Construction - ROMODocument4 pagesJHA Signpost Construction - ROMOAlejandro AaronNo ratings yet

- JHA Rock Work - ROMODocument4 pagesJHA Rock Work - ROMOhoaihan.geo13No ratings yet

- Lorentz Pp150-Pp200 Ac Powerpack Manual enDocument3 pagesLorentz Pp150-Pp200 Ac Powerpack Manual enejboerioNo ratings yet

- JHA Handling Materials - ROMODocument4 pagesJHA Handling Materials - ROMOFebrizalNo ratings yet

- CM3 Reviewer - L3Document3 pagesCM3 Reviewer - L3A.GNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionDocument13 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo Oshin100% (1)

- JHA Crosscut Saw Use & Maintenance - ROMODocument5 pagesJHA Crosscut Saw Use & Maintenance - ROMORandy100% (1)

- Jsa For Electrical Installation.Document2 pagesJsa For Electrical Installation.Anna JisabaNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For RC Pipes InstallationDocument15 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For RC Pipes InstallationTaiwo Oshin100% (1)

- 2.3 Intended Use: Safety and ResponsibilityDocument2 pages2.3 Intended Use: Safety and Responsibilityalang_businessNo ratings yet

- RAM - Pile CroppingDocument14 pagesRAM - Pile CroppingDaniel Cryer0% (1)

- Construction MachineriesDocument3 pagesConstruction MachineriesJoyce MarananNo ratings yet

- Ninl JhaDocument21 pagesNinl JhaHari NairNo ratings yet

- Jsa For Football Pitch InstallationDocument4 pagesJsa For Football Pitch InstallationAnna JisabaNo ratings yet

- JHA Rock Drill Use and Maintenance - ROMODocument3 pagesJHA Rock Drill Use and Maintenance - ROMOAprilia Rizki ArdilaNo ratings yet

- Jsa For Temporary Facility Installations PS5Document9 pagesJsa For Temporary Facility Installations PS5Anna JisabaNo ratings yet

- RA Pump TemoraryDocument12 pagesRA Pump TemoraryCarlos ImmanuelNo ratings yet

- Attachment Example of Lone Working Risk AssessmentDocument8 pagesAttachment Example of Lone Working Risk AssessmentRodrigoNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- Fabrication Work Shop RADocument4 pagesFabrication Work Shop RASalah Abd Eldayem67% (3)

- UC RK 12 0188 PersonalProtectiveEquipmentDocument27 pagesUC RK 12 0188 PersonalProtectiveEquipmentLei Cassandra DespiNo ratings yet

- 41 2osopDocument6 pages41 2osopMiguel Angel RodriguezNo ratings yet

- Topic 4 - Implement and Monitor Procedures For Identifying Hazards, and AssessingDocument12 pagesTopic 4 - Implement and Monitor Procedures For Identifying Hazards, and AssessingFrancis Albert Samantila GimeNo ratings yet

- Jsa For Basket Ball C Ourt Installation.Document6 pagesJsa For Basket Ball C Ourt Installation.Anna JisabaNo ratings yet

- Accident Prevention Plan - Manglore Port TrustDocument19 pagesAccident Prevention Plan - Manglore Port TrustRahul ShandilyaNo ratings yet

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaNo ratings yet

- FBDocument16 pagesFBKomal DhamNo ratings yet

- Personal Protective Equipment Issuance and Monitoring GuidelinesDocument8 pagesPersonal Protective Equipment Issuance and Monitoring Guidelineswindell PatalinghugNo ratings yet

- 06 Scaffold Erection and Dismantling (JHA-JSA)Document4 pages06 Scaffold Erection and Dismantling (JHA-JSA)AmanNo ratings yet

- Fy11 sh-22300-11 OSHASummaryDocument4 pagesFy11 sh-22300-11 OSHASummaryAbdellatif CHADDADNo ratings yet

- Risk Assessment Guide Ref No. 69 Assessment For: LEAD BURNING/PLUMBING WORK - Lead Burning (Welding) of Lead Sheet or Pipe Significant RisksDocument6 pagesRisk Assessment Guide Ref No. 69 Assessment For: LEAD BURNING/PLUMBING WORK - Lead Burning (Welding) of Lead Sheet or Pipe Significant RisksemmyNo ratings yet

- Erection of Tanks JSADocument4 pagesErection of Tanks JSASalah Abd EldayemNo ratings yet

- 014 Eia 14 Jul 2014Document11 pages014 Eia 14 Jul 2014Mo AlfNo ratings yet

- Cosh Session 2Document42 pagesCosh Session 2Andrea A. IgupNo ratings yet

- Annexure 8 EHSS Actions Related SOPs - 1-17 2021Document53 pagesAnnexure 8 EHSS Actions Related SOPs - 1-17 2021sachin mathewNo ratings yet

- SWP-019 Work at HeightDocument7 pagesSWP-019 Work at Heightadrianlim13No ratings yet

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocument6 pagesJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekarNo ratings yet

- 03-F07 Job Safe Procedure Template - DAMMAM - NO. 01Document1 page03-F07 Job Safe Procedure Template - DAMMAM - NO. 01jawad khanNo ratings yet

- M1-Safety StandardsDocument9 pagesM1-Safety StandardscarlNo ratings yet

- Equipment/reactor Erection Work JsaDocument3 pagesEquipment/reactor Erection Work JsaAKBAR ALINo ratings yet

- Kaden Road Project Master Risk AssessmentDocument11 pagesKaden Road Project Master Risk Assessmentabdullah ashrafNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionDocument11 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo OshinNo ratings yet

- Personal Protective Equipment (Ppe) TrainingDocument38 pagesPersonal Protective Equipment (Ppe) TrainingHisham Bin Abdul HafeezNo ratings yet

- Download-Guide To Install PDFDocument40 pagesDownload-Guide To Install PDFTran Cong HauNo ratings yet

- Safety Code of ConductDocument17 pagesSafety Code of ConductSundaramoorthy SelvanathanNo ratings yet

- Method Statement & Risk Assessment PDFDocument5 pagesMethod Statement & Risk Assessment PDFAmit BhattNo ratings yet

- Notes 4Document12 pagesNotes 4moraine.hills3No ratings yet

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- Roles & Responsibilties of Salvage TeamDocument2 pagesRoles & Responsibilties of Salvage Teamsiva50% (2)

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- PT. PLI - ID CardDocument1 pagePT. PLI - ID CardAlam DooNo ratings yet

- Pier ExtensionDocument14 pagesPier ExtensionRahulNo ratings yet

- S3EMIA - 315 - PR1 - Working On and Near WaterDocument7 pagesS3EMIA - 315 - PR1 - Working On and Near WaterSiwaNo ratings yet

- 12 Life Saving RulesDocument15 pages12 Life Saving RulesVăn Trần ĐìnhNo ratings yet

- Oatings Nspector Afety: Module 9: Coatings Inspector SafetyDocument34 pagesOatings Nspector Afety: Module 9: Coatings Inspector SafetyFatimaNo ratings yet

- Laboratory ManagementDocument11 pagesLaboratory Managementfatin harrisNo ratings yet

- Diagnostic Ultrasound System T3300 Operating Instructions en v1.894Document146 pagesDiagnostic Ultrasound System T3300 Operating Instructions en v1.894Harold James BoyrasNo ratings yet

- Coffee Table Book 140 Years 140 StoriesDocument156 pagesCoffee Table Book 140 Years 140 StoriesNikita Sara100% (1)

- Neuro Linguistic ProgrammingDocument10 pagesNeuro Linguistic Programminggimgi100% (2)

- MicrobesDocument8 pagesMicrobesNothing SpecialNo ratings yet

- Reaction Paper: Duterte's War On DrugsDocument2 pagesReaction Paper: Duterte's War On DrugsMat PaualNo ratings yet

- Anxiety Journal Daily Prompts For Coping With Anxious Thoughts and FeelingsDocument100 pagesAnxiety Journal Daily Prompts For Coping With Anxious Thoughts and FeelingsGabriela Ioana Ionita100% (2)

- Collado 2010Document20 pagesCollado 2010JoãoNo ratings yet

- Canadian GMP Draft Guidelines 2007Document123 pagesCanadian GMP Draft Guidelines 2007peruvdNo ratings yet

- Perry Senior Aims To Serve: HeroDocument3 pagesPerry Senior Aims To Serve: HeroWatertown Daily TimesNo ratings yet

- Solid & HWM Lecture No # 3Document37 pagesSolid & HWM Lecture No # 3Baz Mohammad MazaheriNo ratings yet

- Alcoholics QuizDocument54 pagesAlcoholics QuizChitra K LakshmanNo ratings yet

- Two-Minute Step Test of Exercise Capacity: Systematic Review of Procedures, Performance, and Clinimetric PropertiesDocument9 pagesTwo-Minute Step Test of Exercise Capacity: Systematic Review of Procedures, Performance, and Clinimetric PropertieslokoxfalsoNo ratings yet

- PRC FormsDocument5 pagesPRC FormsKevinJanCelestinoNo ratings yet

- Somanabolic+Muscle+Maximizer+PDF+ +eBook+Free+Download+Kyle+LeonDocument34 pagesSomanabolic+Muscle+Maximizer+PDF+ +eBook+Free+Download+Kyle+LeonAaron BarclayNo ratings yet

- FebuxostatDocument1 pageFebuxostatSandrine Barredo100% (4)

- Microwave As An Emerging Technology For The Treatment of Biohazardous Waste: A Mini-ReviewDocument9 pagesMicrowave As An Emerging Technology For The Treatment of Biohazardous Waste: A Mini-ReviewAyuni ZaiddinNo ratings yet

- Social Responsibility and Business 4Th Edition Ferrell - Thorne - FerrellDocument6 pagesSocial Responsibility and Business 4Th Edition Ferrell - Thorne - FerrellRachel Ann CruzNo ratings yet

- World Air Quality Report 2018 en PDFDocument22 pagesWorld Air Quality Report 2018 en PDFAsif KhanNo ratings yet

- UmatDocument5 pagesUmatAshmita KumarNo ratings yet

- IG 2,,,,00576880, Nwosu Anselem, Novelle Centre, 945Document29 pagesIG 2,,,,00576880, Nwosu Anselem, Novelle Centre, 945Anselem NwosuNo ratings yet

- Wellness Tourism Sector Strategy - National Export Strategy (2018-2022)Document55 pagesWellness Tourism Sector Strategy - National Export Strategy (2018-2022)Ministry of Development Strategies and International TradeNo ratings yet

- PUDV3134Document1 pagePUDV3134rakesh adamalaNo ratings yet

- Reiki Symbols PDFDocument8 pagesReiki Symbols PDFpatelpratik1972No ratings yet

- 2021 Fed School Code ListDocument114 pages2021 Fed School Code ListMarc FrankelNo ratings yet

- Pediatrics Professional PortfolioDocument2 pagesPediatrics Professional Portfolioapi-319246416No ratings yet

- Ethics - Nursing Test QuestionsDocument31 pagesEthics - Nursing Test QuestionsRNStudent1100% (5)

- UnicefDocument66 pagesUnicefRomaine smithNo ratings yet

- 1st Case Musculoskeletal - AuliaDocument25 pages1st Case Musculoskeletal - AuliaAULIA ANGRAININo ratings yet

- My C (1) .V Tiwari FinalDocument5 pagesMy C (1) .V Tiwari FinalSandip Prasad TiwariNo ratings yet