Professional Documents

Culture Documents

Lab 2 PSOC

Uploaded by

Awais KhalidCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab 2 PSOC

Uploaded by

Awais KhalidCopyright:

Available Formats

Power System Operation and Control Lab 02

STUDY OF DIFFERENT TYPES OF FAULTS ON GENERATOR

PARAMETERS

Submitted by

Abdul Ahad

Abdul Wahab Nasir

Mian Sajawal Shah

Submitted to

Sir Naeem Iqbal

Course Title

Power System Operation and Control

Date of Submission: June 13, 2020.

Department of Electrical Engineering

PAKISTAN INSTITUTE OF ENGINEERING AND APPLIED SCIENCES,

ISLAMABAD

STUDY OF DIFFERENT TYPES OF FAULTS ON

GENERATOR PARAMETERS

2.1. Abstract

Synchronous Generator is an important element of power systems and their protection is

essential. The trend toward a deregulated global electricity market has put the electric utilities

under severe stress to keep the machines continuously in service to give uninterrupted power

supply to the customers. Hence the synchronous generator is the most critical equipment of the

power industry and fault detection is important to prevent outages and black outs. The faults in

the synchronous generator are classified as an internal faults and external faults. The internal

faults are phase to phase and phase to earth faults in stator winding, whereas external faults are

the faults those occur outside the generator which are due to short circuit, over loading and

unbalanced loading.

2.2. Objective

In this Experiment we shall observe;

How to develop a standalone generator system to supply power to a specific load.

Effect of different faults on rotor angle, speed and output power of synchronous

generator.

2.3. Background

Generator faults can be considered under the following heads:

2.3.1. Stator Winding Faults

Such faults occur mainly due to the insulation failure of the stator coils. The main types of

stator winding faults are:

Phase-to-earth faults

Phase-to-phase faults and

Inter-turn faults involving turns of the same phase winding.

The stator winding faults are the most dangerous and are likely to cause considerable

damage to the expensive machinery. So, automatic protection is absolutely necessary to

clear such faults in the shortest possible time in order to minimize the extent of damage.

2.3.2. Field Winding or Rotor Circuit Faults

Faults in the rotor circuit may be either earth faults (conductor-to-earth faults) or inter-turn

faults, which are caused by severe mechanical and thermal stresses. The field system is

normally not grounded (i.e., remains isolated from the earth) and, therefore, a single fault

between field winding and rotor body due to insulation breakdown does not give rise to any

fault current.

However, a second earth fault will short circuit some part of the rotor winding and may thereby

develop an unsymmetrical field system, giving unbalanced force on the rotor. This can cause

severe vibration of the rotor with possible damage to the bearings. Thus a single earth fault can

be tolerated for a while but it should not be allowed to continue. Rotor earth fault protection is

provided in case of large generators.

2.3.3. Abnormal Operating Conditions

The abnormal operating conditions that are likely to occur in a generator are:

Failure of prime mover (turbine) resulting in operation of the generator as a synchronous

motor

Failure of field

Unbalanced loading and subsequent heating of generator

Overloading

Over-voltage at generator terminals

Over-speed

Ventilation failure

Current leakage in the body of the generator.

2.4. Circuit Diagram

Figure 01: Simulink Circuit Diagram

2.4.1. Task 01: Line to Ground Fault at Phase A

Scope Output

Figure 02: Scope Output L-G Fault

Voltage Output

Figure 03: Voltage Output L-G Fault

Conclusions

The above figure show impact on Voltage, Rotor Angle, Speed and Power of a system

when a line to ground fault acts at phase A from time t=1sec to 1.1 sec. The Figures clearly

show that when fault occurs the voltage supplied to the load drops. This drop in Voltage is

compensated by increase in voltage of other phases that are not at fault.

2.4.2. Task 02: Line to Line Fault b/w Phase A & B

Scope Output

Figure 04: Scope Output L-L Fault

Voltage Output

Figure 05: Voltage Output L-L Fault

Conclusions

In this task we observe impact of line to line fault on the system and now as the fault

is a phase fault the drop in voltage does not reaches zero as in previous case. From the Scope

output it can be observed that the electrical power during fault increases to a much higher

value than in case of L-G Fault. The Rotor Angle of the two phases are affected by fault but

the magnitude is less than that of task 1. The speed is unaffected by the fault.

2.4.3 Task 03: Double Line to Ground Fault

Scope Output

Figure 06: Scope Output LL-G Fault

Voltage Output

Figure 07: Voltage Output LL-G Fault

Conclusion

The above figure show impact on Voltage, Rotor Angle, Speed and Power of a system

when a double line to ground fault acts at phase A & B from time t=1sec to 1.1 sec. The Fault’s

impact is much similar to that of line to line fault. Here also the speed is unaffected.

2.4.4. Task 04: Three Phase to Ground Fault

Scope Output

Figure 8: Scope Output Three Phase to Ground Fault

Voltage Output

Figure 09: Voltage Output Three Phase to Ground Fault

Conclusion

On observation we see that the three phase to ground fault (LLL-G) was more severe

than three phase fault and now the fault effects rotor angle of all three phase simultaneously.

We also observe that there is power surge just before removal of fault.

2.4.5. Task 05: Comparison of Previous Tasks

Conclusion

Upon Comparison of the above tasks it was found that:

Rotor angle is most affected in case of single line to ground fault. In case of three phase

fault the all three phases effect rotor angle.

The Speed of Synchronous Generator is unaffected by induced fault.

Fluctuation in power during fault occurrence is most for three phase fault followed by

double line to ground fault and then least for single phase fault.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Lab 3 PSOCDocument7 pagesLab 3 PSOCAwais KhalidNo ratings yet

- Lab 1 PSOCDocument10 pagesLab 1 PSOCAwais KhalidNo ratings yet

- Abdul Ahad Abdul Wahab Nasir Mian Sajawal ShahDocument6 pagesAbdul Ahad Abdul Wahab Nasir Mian Sajawal ShahAwais KhalidNo ratings yet

- Experiment 10 Study of Different Excitation Schemes For Emergency Diesel GeneratorDocument13 pagesExperiment 10 Study of Different Excitation Schemes For Emergency Diesel GeneratorAwais KhalidNo ratings yet

- Table 8.1 - Pin Out of 741C Operational AmplifierDocument9 pagesTable 8.1 - Pin Out of 741C Operational AmplifierAwais KhalidNo ratings yet

- Experiment 12:: BSEE 2017-2021 Semester 8 InstructorDocument5 pagesExperiment 12:: BSEE 2017-2021 Semester 8 InstructorAwais KhalidNo ratings yet

- MATPOWER ManualDocument249 pagesMATPOWER ManualAwais KhalidNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Clap SwitchDocument10 pagesThe Clap SwitchCM-A-12-Aditya BhopalbadeNo ratings yet

- Gu301a User ManualDocument3 pagesGu301a User ManualnandomataNo ratings yet

- Ground Fault On Autrosafe SystemsDocument1 pageGround Fault On Autrosafe SystemsPadam SinghNo ratings yet

- Thyristor ValveDocument5 pagesThyristor ValveRisi SinghNo ratings yet

- Is-Iec 60309-2 (2002)Document74 pagesIs-Iec 60309-2 (2002)Lean_Heredia100% (1)

- EXO2 Electric Circuits CrosswordDocument2 pagesEXO2 Electric Circuits Crosswordjeankabore2005No ratings yet

- Ducati 400-M (16J12L21AN336)Document4 pagesDucati 400-M (16J12L21AN336)band summersNo ratings yet

- APFC Troubleshooting ManualDocument28 pagesAPFC Troubleshooting ManualMaintenance Circle100% (1)

- Activity 6.1.5 DC Motor ConstructionDocument3 pagesActivity 6.1.5 DC Motor Constructionapi-254136507No ratings yet

- 196 HD1 1SZ DC12VDocument3 pages196 HD1 1SZ DC12VAbreham aberaNo ratings yet

- Investigation of Ferroresonance Causing Sustained High Voltage at A De-Energized 138 KV Bus: A Case StudyDocument12 pagesInvestigation of Ferroresonance Causing Sustained High Voltage at A De-Energized 138 KV Bus: A Case StudyMoba AddictNo ratings yet

- Liebert Gxt3 Ups Quick Start Guide 6kva Rt630Document4 pagesLiebert Gxt3 Ups Quick Start Guide 6kva Rt630asssasasNo ratings yet

- Module 4 Sesion 1 Temperature and Displacement SensorsDocument39 pagesModule 4 Sesion 1 Temperature and Displacement SensorsManav Jain100% (3)

- WI-NG-6460-002-057 Work Instruction For - Protection Relays General Electrical Tests Rev00Document6 pagesWI-NG-6460-002-057 Work Instruction For - Protection Relays General Electrical Tests Rev00Mohamed NasrNo ratings yet

- EmiiDocument49 pagesEmiiŠãüřãbh PãthãkNo ratings yet

- 20 KV SupremeDocument1 page20 KV SupremeHeru SudionoNo ratings yet

- Diagrama Electrico C18 IndustrialDocument2 pagesDiagrama Electrico C18 IndustrialJoséNo ratings yet

- Electronics 1 SlidesDocument27 pagesElectronics 1 SlidesAwais MuhammadNo ratings yet

- p10 Series Light Manual EnglishDocument2 pagesp10 Series Light Manual EnglishRosmiNo ratings yet

- VT022Document14 pagesVT022Toni RenedoNo ratings yet

- Cat 14h MotorgraderDocument2 pagesCat 14h MotorgraderAshraf m aliNo ratings yet

- Mitigation of The Transient Recovery Voltage On Generator Circuit Breaker During Generator Fed FaultsDocument4 pagesMitigation of The Transient Recovery Voltage On Generator Circuit Breaker During Generator Fed FaultsryreddyNo ratings yet

- Qcs 2014 - Sec21 p18 - Uninterruptible Power SupplyDocument6 pagesQcs 2014 - Sec21 p18 - Uninterruptible Power Supplychandra100% (1)

- Design and Implementation of A Solar Charge Controller With Variable OutputDocument12 pagesDesign and Implementation of A Solar Charge Controller With Variable OutputEmmanuel SundayNo ratings yet

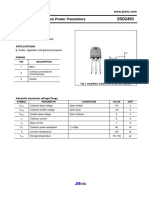

- Silicon NPN Darlington Power Transistors: DescriptionDocument3 pagesSilicon NPN Darlington Power Transistors: DescriptionVictor HemzNo ratings yet

- Schneider Interpact INS 63Document91 pagesSchneider Interpact INS 63Brain Alexis Bastias HernandezNo ratings yet

- Stepper Motor ManualDocument15 pagesStepper Motor ManualZine eddine Hadj mokhnachrNo ratings yet

- Ma-Dm - rsis-III-16-003 - Non Twisted FRC N2xy 2x1.5mm2 Cable - KmiDocument1 pageMa-Dm - rsis-III-16-003 - Non Twisted FRC N2xy 2x1.5mm2 Cable - Kmiafie pio pioNo ratings yet

- Ot Iii 962-0512Document142 pagesOt Iii 962-0512Kien TranNo ratings yet

- Multi Kabel CatalogueDocument33 pagesMulti Kabel CatalogueHendri AskoroNo ratings yet