0% found this document useful (0 votes)

62 views2 pagesHighway Construction Activity Guide

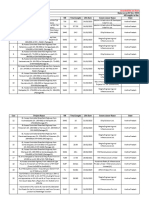

The document provides measurements and observations of a local highway. It notes the length, width, and thickness of the highway and compares it to barangay roads. National highways connect between provinces and have a minimum speed limit of 60 km/h, while barangay roads connect villages within a town and have a speed limit of 20 km/h. The document then outlines the 5-step process for constructing a road: 1) clearing and excavation, 2) mounting, 3) fine grading, 4) adding an aggregate base, and 5) asphalt paving.

Uploaded by

Meralie CapangpanganCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

62 views2 pagesHighway Construction Activity Guide

The document provides measurements and observations of a local highway. It notes the length, width, and thickness of the highway and compares it to barangay roads. National highways connect between provinces and have a minimum speed limit of 60 km/h, while barangay roads connect villages within a town and have a speed limit of 20 km/h. The document then outlines the 5-step process for constructing a road: 1) clearing and excavation, 2) mounting, 3) fine grading, 4) adding an aggregate base, and 5) asphalt paving.

Uploaded by

Meralie CapangpanganCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd