Professional Documents

Culture Documents

Type of CNC

Uploaded by

Ariff Shastera0 ratings0% found this document useful (0 votes)

24 views2 pagesCNC machines use computer controls to precisely cut and shape various materials. The main types are CNC milling machines, which translate programs to move spindles and cut materials like metal; CNC lathes, which make precise cuts by rotating work pieces; and CNC plasma cutters, which use high-temperature gas plasma to cut heavy materials like steel. Other CNC machines include electric discharge machines, which remove material using electrical sparks; laser cutters, which precisely cut various materials using intense laser beams; drilling machines for making holes; and grinders for shaping materials through abrasion.

Original Description:

Original Title

TYPE OF CNC

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCNC machines use computer controls to precisely cut and shape various materials. The main types are CNC milling machines, which translate programs to move spindles and cut materials like metal; CNC lathes, which make precise cuts by rotating work pieces; and CNC plasma cutters, which use high-temperature gas plasma to cut heavy materials like steel. Other CNC machines include electric discharge machines, which remove material using electrical sparks; laser cutters, which precisely cut various materials using intense laser beams; drilling machines for making holes; and grinders for shaping materials through abrasion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views2 pagesType of CNC

Uploaded by

Ariff ShasteraCNC machines use computer controls to precisely cut and shape various materials. The main types are CNC milling machines, which translate programs to move spindles and cut materials like metal; CNC lathes, which make precise cuts by rotating work pieces; and CNC plasma cutters, which use high-temperature gas plasma to cut heavy materials like steel. Other CNC machines include electric discharge machines, which remove material using electrical sparks; laser cutters, which precisely cut various materials using intense laser beams; drilling machines for making holes; and grinders for shaping materials through abrasion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

TYPE OF CNC

CNC MILING MACHINE

One of the most common types of CNC machines, a CNC mill utilizes computer controls

to cut various materials. Mills can translate specific programs of numbers and letter in

order to move the spindle in various ways. Many mills use what is known as G-code,

which as mentioned, is a standardized programming language recognized by most CNC

machines. A CNC mill can have a wide array of functions, such as face milling, shoulder

milling, tapping, drilling and turning. Most CNC mills come in three to six-axis

configurations. A CNC mill is very large compared to other tools and can be quite costly.

Some CNC milling machine manufacturers include Okuma, HAAS and DMG Mori.

CNC LATHE

A lathe is a CNC machine that functions to cut work pieces as they are rotated. CNC

lathes can make precise cuts quickly by using various tools. These CNC machines are

quite effective in the precision they offer compared to manual lathes. They often have

fewer axes than CNC milling machines and are therefore smaller in size and more

compact. CNC lathes come with similar controls to those of CNC mills and can read both

G-code and other proprietary programming languages. Some of the most common of

CNC lathe machine manufacturers include HAAS, Mori Seiki and Okuma. The

framework of CNC lathes is similar to manual lathes.

CNC PLASMA CUTTER

The process of plasma cutting involves the cutting of a material using a plasma torch.

This method is most commonly used to cut heavy materials, such as steel and other forms

of metal. With a CNC plasma cutter, gas is blown at a very high speed from a nozzle.

While this is being done, an electrical arcs forms through the gas coming out of the

nozzle to the surface that is being cut. This converts some of the gas into plasma, and

these plasma temperatures range from 10,000 – 50,000 Degrees. The plasma is hot

enough to melt whatever material is being cut, and it blows away any molten metal from

the site of the cut. In terms of shape and size, CNC plasma cutters are very similar to

CNC routers. These machines only work with two-dimensional shapes.

CNC ELECTRIC DISCHARGE MACHINE

Electric discharge machining, or EDM for short, involves creating a specific shape within

a certain material by using electrical discharges, or sparks. In this process, the material is

removed from a specific work piece by a series of recurring electrical discharges between

two electrodes. These electrodes are separated by a dielectric fluid, which often receives

an electric voltage. In this machine, the material is placed in between two electrodes and

the machine then calculates to see the amount of electrical discharge each electrode need

to produce.

CNC LASER CUTTER

These types of machines are similar to CNC plasma machines, the only difference is that

lasers are mostly used for cutting and are great when it comes to cutting metals, plastic or

hardwood. Depending on the density and strength of the material, the intensity of the laser

can be adjusted.

CNC DRILLING MACHINE

Used to drill hole in the workpiece, the tool can locate the position for drilling quickly

and accurately, sophisticated drilling machines can also perform reaming, counterboring

and tapping holes.

CNC GRINDERS

A machine uses a rotary wheel to abrade the material by grinding or grating it into the

desired shape, it’s easier to program than milling machines and lathes.

You might also like

- Machine Mall - All PagesDocument6 pagesMachine Mall - All PagesGM Business DevelopmentNo ratings yet

- 12 Types of CNC MachinesDocument8 pages12 Types of CNC MachinesVirnic FarmNo ratings yet

- Manual TB6560Document16 pagesManual TB6560erickmoraesNo ratings yet

- Plasma Cutting MachineDocument7 pagesPlasma Cutting MachineEng-Ahmed SalamaNo ratings yet

- CNCDocument1 pageCNCAimeeael Khristya SanchezNo ratings yet

- Maurya Motors AssignmentDocument21 pagesMaurya Motors Assignmentshubham kumar mehtaNo ratings yet

- 12 Different Types of CNC Machine (Complete Guide) & PDFDocument16 pages12 Different Types of CNC Machine (Complete Guide) & PDFAK KHANNo ratings yet

- Plasma CuttingDocument4 pagesPlasma CuttingJasmeet Singh LoyalNo ratings yet

- CNC Lab ManualDocument40 pagesCNC Lab ManualPavaniNo ratings yet

- Types of Machining ToolsDocument3 pagesTypes of Machining ToolsPassmore DubeNo ratings yet

- CNC ManualDocument53 pagesCNC ManualPavaniNo ratings yet

- New DOCX DocumentDocument39 pagesNew DOCX DocumentPavaniNo ratings yet

- CNC Lab ManualDocument40 pagesCNC Lab ManualPavaniNo ratings yet

- Lec.05 Programming of Manufacturing CellsDocument13 pagesLec.05 Programming of Manufacturing CellsAmer Abd EL-hkimNo ratings yet

- Automated Machine ToolsDocument29 pagesAutomated Machine ToolsSyafawati OsmanNo ratings yet

- Internship ReportDocument12 pagesInternship ReportNirav100% (1)

- What Is A CNC Machine and How Does It Aid ManufacturingDocument7 pagesWhat Is A CNC Machine and How Does It Aid ManufacturingjackNo ratings yet

- Major CNC Machine Tool TypesDocument4 pagesMajor CNC Machine Tool Typesirinuca12No ratings yet

- The Main Difference Between CNC Lathe and CNC Milling?: Differences in CNC MethodsDocument2 pagesThe Main Difference Between CNC Lathe and CNC Milling?: Differences in CNC MethodsSyafi NafisNo ratings yet

- Machine Cutting Is A Manufacturing Process That Involves The Controlled Removal of Material From A Larger Piece To Achieve A Desired Shape or PartDocument1 pageMachine Cutting Is A Manufacturing Process That Involves The Controlled Removal of Material From A Larger Piece To Achieve A Desired Shape or PartArfan KhanNo ratings yet

- Types of CNC and EDNDocument3 pagesTypes of CNC and EDNkarla cancheNo ratings yet

- Fact Sheet: METAL REMOVAL/CUTTINGDocument4 pagesFact Sheet: METAL REMOVAL/CUTTINGAl EnggNo ratings yet

- What Is CNCDocument9 pagesWhat Is CNCHayyanNo ratings yet

- Numerical Control: Jump To Navigation Jump To SearchDocument13 pagesNumerical Control: Jump To Navigation Jump To SearchPunitNo ratings yet

- Grinding, Lapping, Polishing, EDM, Laser Cut, Water Jest, EtcDocument32 pagesGrinding, Lapping, Polishing, EDM, Laser Cut, Water Jest, EtceliiiiiiNo ratings yet

- MR22524125344Document3 pagesMR22524125344Aye Chan AungNo ratings yet

- Numerical Control - Wikipedia, The Free EncyclopediaDocument4 pagesNumerical Control - Wikipedia, The Free EncyclopediazidaaanNo ratings yet

- Uses of CNC Lathe MachineDocument3 pagesUses of CNC Lathe MachineKhairul IkhwanNo ratings yet

- Plasma Cutting With ROBOTSDocument8 pagesPlasma Cutting With ROBOTSpal_malayNo ratings yet

- College of Industrial Technology: Chaptr Ii Review of Related LiteratureDocument18 pagesCollege of Industrial Technology: Chaptr Ii Review of Related LiteratureJerick HernandezNo ratings yet

- CNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqDocument51 pagesCNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqEngr.shamiNo ratings yet

- Micro MachiningDocument25 pagesMicro MachiningVishalNaranjeNo ratings yet

- InternshipDocument17 pagesInternshipsoumyaNo ratings yet

- CNC Cutting Tool Live Monitoring and Cost ReductionDocument10 pagesCNC Cutting Tool Live Monitoring and Cost ReductionKodali Rithvik0% (2)

- EN ComboDocument12 pagesEN ComboKiran Gowda KNo ratings yet

- Career Episode 3: Preparation of Individual Parts Before AssemblyDocument8 pagesCareer Episode 3: Preparation of Individual Parts Before AssemblyHarmeetNo ratings yet

- Brahmos Aerospace Thiruvananthapuram LimitedDocument23 pagesBrahmos Aerospace Thiruvananthapuram LimitedRohan Baby-MathewsNo ratings yet

- Micro MachiningDocument25 pagesMicro MachiningYour ChoiceNo ratings yet

- Procesos Secundarios de Manufactura: Router CNCDocument2 pagesProcesos Secundarios de Manufactura: Router CNCEunice Macias RealNo ratings yet

- Sheet Metal FormingDocument5 pagesSheet Metal FormingScribdd3r100% (2)

- What Is Hole Punching? What Is Drilling?Document6 pagesWhat Is Hole Punching? What Is Drilling?Krisha Ann RosalesNo ratings yet

- CIM, Unit - 1Document21 pagesCIM, Unit - 1Nitin KotnalaNo ratings yet

- EDM Wirecut Working PrincipleDocument22 pagesEDM Wirecut Working Principlemunjivramana_6611003No ratings yet

- EDM Wire Cut ReportDocument12 pagesEDM Wire Cut ReportAidilNo ratings yet

- Minor Project Report Contents 1Document9 pagesMinor Project Report Contents 1Muhd Shabeeb ANo ratings yet

- Chapter 3 Computerised Numerical Control (CNC)Document37 pagesChapter 3 Computerised Numerical Control (CNC)farizanNo ratings yet

- Industrial VisitDocument7 pagesIndustrial VisitKandula KrishnarjunNo ratings yet

- Chapter 5 - CNC ToolingDocument50 pagesChapter 5 - CNC ToolingDani AbHalimNo ratings yet

- Project Report ON "Resistance Spot Welding": Department of Mechanical Engineering Gitam University VisakhapatnamDocument32 pagesProject Report ON "Resistance Spot Welding": Department of Mechanical Engineering Gitam University VisakhapatnamAbhinashNo ratings yet

- Chapter3 - Cutting Tools For CNC MachinesDocument46 pagesChapter3 - Cutting Tools For CNC MachinesTharun Kumar Chõwdâry100% (1)

- What Is Die SinkingDocument5 pagesWhat Is Die SinkingRavendran KrishnanNo ratings yet

- Lathe Machine.Document12 pagesLathe Machine.PUBLIC USERNo ratings yet

- What Is CNC Rapid Prototype Machining and How Does It WorkDocument13 pagesWhat Is CNC Rapid Prototype Machining and How Does It WorkjackNo ratings yet

- Introduction To CNC MachiningDocument36 pagesIntroduction To CNC MachiningNavya VelagaNo ratings yet

- Cam RepotrtDocument12 pagesCam RepotrtAntony NjorogeNo ratings yet

- Examples of CNC Machines: Punched Tape Servomechanisms MachiningDocument5 pagesExamples of CNC Machines: Punched Tape Servomechanisms MachiningTushar KhorateNo ratings yet

- Desktop Manufacturing Use Machine Above This To Make ProductsFrom EverandDesktop Manufacturing Use Machine Above This To Make ProductsNo ratings yet

- Paper-Cutting Machines: A Primer of Information about Paper and Card Trimmers, Hand-Lever Cutters, Power Cutters and Other Automatic Machines for Cutting PaperFrom EverandPaper-Cutting Machines: A Primer of Information about Paper and Card Trimmers, Hand-Lever Cutters, Power Cutters and Other Automatic Machines for Cutting PaperNo ratings yet

- Structural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkFrom EverandStructural Drafting - A Practical Presentation of Drafting and Detailed Methods used in Drawing up Specifications for Structural Steel WorkRating: 3 out of 5 stars3/5 (1)

- Meeting Situations Set ADocument1 pageMeeting Situations Set AAriff ShasteraNo ratings yet

- Temperature Measurement: Information of The ExperimentDocument1 pageTemperature Measurement: Information of The ExperimentAriff ShasteraNo ratings yet

- Engineering Design DAM 21503: Prepared By: Noraniah Binti KassimDocument31 pagesEngineering Design DAM 21503: Prepared By: Noraniah Binti KassimAriff ShasteraNo ratings yet

- Health Hazards: Lectured By: Mohd Hadri Mohamed NorDocument63 pagesHealth Hazards: Lectured By: Mohd Hadri Mohamed NorAriff ShasteraNo ratings yet

- Lab 2 ElektropneumatikDocument6 pagesLab 2 ElektropneumatikAriff ShasteraNo ratings yet

- Template Short Report - SafetyDocument1 pageTemplate Short Report - SafetyAriff ShasteraNo ratings yet

- Front Page - Foundry DAM11502Document1 pageFront Page - Foundry DAM11502Ariff ShasteraNo ratings yet

- Test 1 Dam 21303 A Dae 23403Document3 pagesTest 1 Dam 21303 A Dae 23403Ariff ShasteraNo ratings yet

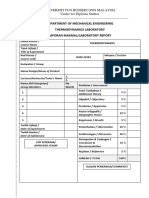

- Frontcover Thermodynamics BahagianyangmasihbelumdiisiDocument1 pageFrontcover Thermodynamics BahagianyangmasihbelumdiisiAriff ShasteraNo ratings yet

- Handout - Foundry (DAM 11502)Document6 pagesHandout - Foundry (DAM 11502)Ariff ShasteraNo ratings yet

- Lab Activity 5 Reynolds Experiment: Learning OutcomesDocument10 pagesLab Activity 5 Reynolds Experiment: Learning OutcomesAriff ShasteraNo ratings yet

- Flow Rate Through A Venturi MeterDocument12 pagesFlow Rate Through A Venturi MeterAriff ShasteraNo ratings yet

- Ch-6 Reaming, Boring, BroachingDocument47 pagesCh-6 Reaming, Boring, BroachingAnkush AhirraoNo ratings yet

- NoDocument1 pageNoPapi MudaNo ratings yet

- Assignment Feb 21-Ver 1Document8 pagesAssignment Feb 21-Ver 1ostaz onlineNo ratings yet

- 3 CNC ProgrammingDocument59 pages3 CNC ProgrammingbusterrrNo ratings yet

- Common G and M Codes For CNC MachinesDocument2 pagesCommon G and M Codes For CNC MachinesSiddhrajsinh ZalaNo ratings yet

- Index: Lathe MachineDocument33 pagesIndex: Lathe MachinedakshNo ratings yet

- CNC Milling Labsheet - DJJ40142Document8 pagesCNC Milling Labsheet - DJJ40142tonik 66No ratings yet

- Tool Design 2 MarksDocument85 pagesTool Design 2 MarksKesava PrasadNo ratings yet

- Turning ReportDocument24 pagesTurning Reportnenocool50% (2)

- Alat TukangDocument5 pagesAlat TukangMuhammad DahlanNo ratings yet

- Lathe Lab Report 2220259Document8 pagesLathe Lab Report 2220259Hiumi K.No ratings yet

- Machine Tools Lab ManualDocument51 pagesMachine Tools Lab ManualCharan KumarNo ratings yet

- Making G The Jim M Claar R Anvil Vise: Micha Ael Wollow WskiDocument2 pagesMaking G The Jim M Claar R Anvil Vise: Micha Ael Wollow WskiMike MoultonNo ratings yet

- Jigs & FixturesDocument124 pagesJigs & Fixturespaul chandra100% (1)

- Mastercam PDFDocument2 pagesMastercam PDFNguyên Trương0% (1)

- Contact PointsDocument2 pagesContact PointsEdwin MPNo ratings yet

- AMP Summer Question Paper (Msbte Study Resources)Document4 pagesAMP Summer Question Paper (Msbte Study Resources)Varad DateNo ratings yet

- Sachin Solanki CNC/IPC/13 Summary SupportDocument61 pagesSachin Solanki CNC/IPC/13 Summary Supportshivam modanwalNo ratings yet

- KSQ Rock Drilling Tools+E CatalogDocument120 pagesKSQ Rock Drilling Tools+E CatalogIvan SalasNo ratings yet

- Price List Updated TGL 08 Feb 21 SupermaketDocument11 pagesPrice List Updated TGL 08 Feb 21 SupermaketHeGun HokNo ratings yet

- Tool Description Make QuantityDocument3 pagesTool Description Make QuantityHughoNo ratings yet

- Catalogo Sensitiv TADocument12 pagesCatalogo Sensitiv TAFranGigaNo ratings yet

- Case Study Lathe.....Document16 pagesCase Study Lathe.....Zul AimanNo ratings yet

- Threads Unc, Unf, UnefDocument3 pagesThreads Unc, Unf, UnefIlya FuksmanNo ratings yet

- Catalog KnuthDocument252 pagesCatalog Knuthlorenzinho290No ratings yet

- CNC Process Planning and Machining - Getting Started (Is+dl)Document9 pagesCNC Process Planning and Machining - Getting Started (Is+dl)PAVAN KALYANNo ratings yet

- CNC G M KodlarıDocument2 pagesCNC G M KodlarıMürsel cncNo ratings yet

- Delivery Order: NO Item Description Issa/Pn QTY RemarksDocument3 pagesDelivery Order: NO Item Description Issa/Pn QTY RemarksTb Ahmad FaisalNo ratings yet

- Production of Chess PiecesDocument19 pagesProduction of Chess PieceshoanghuanNo ratings yet

- Lathe ReportDocument16 pagesLathe ReportMuhammad Aisamuddin88% (8)