Professional Documents

Culture Documents

Sg-c17wvz27s Ds en

Uploaded by

suan kwang TanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sg-c17wvz27s Ds en

Uploaded by

suan kwang TanCopyright:

Available Formats

VZ = 27 V (typ.

)

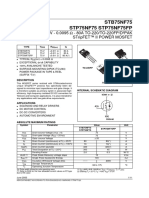

Automotive Alternator Diode

SG-C17xxZ27 Series Data Sheet

Description Package

Pressfit

The SG-C17xxZ27 series are the rectification diodes

designed for alternator circuit of automotives, and have

zener characteristics with high surge capability.

The package is the press-fit type that has high heat

release capability and high reliability for high

temperature and humidity environment. In addition, the

bridge circuit can be configured easily in small area by (2)

using suffix “S” type and suffix “R” type of reverse

polarity type.

(1)

Features

(1) (2)

● TJ = 235 °C Capability Suitable for High Reliability Suffix “S”

and Automotive Requirement

● Thermal Fatigue Capability: 5,000 cyc.

(1) (2)

● High Surge Capability

Suffix “R”

● RoHS Compliant

Not to scale

Applications

● Alternator Circuit for the 12 V Battery Automotive Pin No. Suffix “S” Suffix “R”

(1) Cathode Anode

(2) Anode Cathode

Typical Application

Voltage

Selection Guide

SG-C17xxZ27S

Rotor Regulator

TJ VZ

Part Number IF(AV)

(Max.) Min. Max.

SG-C17LXZ27S

35 A

Battery SG-C17LXZ27R

Stator SG-C17VLZ27S

50 A

SG-C17VLZ27R

SG-C17xxZ27R 235 °C 24 V 30 V

SG-C17VVZ27S

60 A

SG-C17VVZ27R

SG-C17WVZ27S

80 A

SG-C17WVZ27R

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 1

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

Contents

Description ------------------------------------------------------------------------------------------------------ 1

Contents --------------------------------------------------------------------------------------------------------- 2

Absolute Maximum Ratings --------------------------------------------------------------------------------- 3

Electrical Characteristics ------------------------------------------------------------------------------------ 4

SG-C17LXZ27S, SG-C17LXZ27R Rating and Characteristic Curves ----------------------------- 5

SG-C17VLZ27S, SG-C17VLZ27R Rating and Characteristic Curves ----------------------------- 6

SG-C17VVZ27S, SG-C17VVZ27R Rating and Characteristic Curves ----------------------------- 8

SG-C17VWZ27S, SG-C17VWZ27R Rating and Characteristic Curves --------------------------- 9

Physical Dimensions ----------------------------------------------------------------------------------------- 11

Marking Diagram-------------------------------------------------------------------------------------------- 13

Important Notes ---------------------------------------------------------------------------------------------- 14

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 2

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

Absolute Maximum Ratings

Unless otherwise specified, TA = 25 °C

Parameter Symbol Conditions Rating Unit Remarks

Peak Reverse Voltage VRM 20 V

35 SG-C17LXZ27S/R

50 SG-C17VLZ27S/R

Average Forward Current IF(AV) A

60 SG-C17VVZ27S/R

80 SG-C17WVZ27S/R

350 SG-C17LXZ27S/R

Half cycle sine-wave,

SG-C17VLZ27S/R

Surge Forward Current IFSM positive side, 10ms, 500 A

SG-C17VVZ27S/R

one shot.

600 SG-C17WVZ27S/R

50 SG-C17LXZ27S/R

One shot, 65 SG-C17VLZ27S/R

Surge Reverse Voltage VRSM V

See Figure 2. 75 SG-C17VVZ27S/R

95 SG-C17WVZ27S/R

Junction Temperature TJ −40 to 235 °C

Case Temperature TC See Figure 1. −40 to 215 °C

Storage Temperature TSTG −40 to 215 °C

Case temperature, TC

Heat sink Heat sink

Figure 1. Lead Temperature Measurement Conditions

0.8 Ω

VRSM 110 mF

2Ω

Device

Figure 2. Surge Reverse Voltage Measurement Circuit (JASO A-1)

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 3

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

Electrical Characteristics

Unless otherwise specified, TA = 25 °C

Parameter Symbol Conditions Min. Typ. Max. Unit Remarks

— — 1.25 SG-C17LXZ27S/R

IF = 100 A, — — 1.20 SG-C17VLZ27S/R

Forward Voltage Drop VF V

t = 5 ms — — 1.15 SG-C17VVZ27S/R

— — 1.10 SG-C17WVZ27S/R

Reverse Leakage Current IR VR = VRM — — 1 µA

Breakdown Voltage VZ IZ = 10 mA 24 27 30 V

Breakdown Voltage

rZ IZ = 10 mA — 22 — mV/°C

Temperature Coefficient

— — 0.6 SG-C17LXZ27S/R

Thermal Resistance Rth(j-C) (1) — — 0.5 °C/W SG-C17VLZ27S/R

SG-C17VVZ27S/R

— — 0.4

SG-C17WVZ27S/R

(1)

Rth(j-c) is thermal resistance between junction and case. Case temperature is measured as shown in Figure 1.

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 4

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

SG-C17LXZ27S, SG-C17LXZ27R Rating and Characteristic Curves

40 100

35

10 TJ = 150 °C

Average Forward Current, IF (AV) (A)

30 TJ = 200 °C

Forward Current, IF (A)

TJ = 235 °C

25

1

20

0.1

15

TJ = 25 °C

10

0.01 TJ = 60 °C

5 TJ = 100 °C

0 0.001

190

0 195 200 205 210 215 220 0.0 0.2 0.4 0.6 0.8 1.0 1.2

Case Temperature, TC (°C) Forward Voltage, VF (V)

Figure 3. Power Dissipation Curves(2) Figure 4. IF vs. VF Typical Characteristics

100

1.E-03 TJ = 235 °C

TJ = 200 °C

1.E-04

10

Reverse Current, IZ (A)

TJ = 150 °C

Reverse Current, IR (A)

1.E-05

1.E-06 TJ = 100 °C 1

1.E-07 TJ = 60 °C

1.E-08 0.1

TJ = 25 °C t = 80 µs

1.E-09

0.01

1.E-10 26 28 30 32 34

0 5 10 15 20 25

Reverse Voltage, VZ (V)

Reverse Voltage, VR (V)

Figure 5. IR vs. VR Typical Characteristics Figure 6. IZ vs. VZ Typical Characteristics

(2)

See Figure 1 for the measurement conditions of lead temperature.

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 5

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

Thermal Resistance (°C/W) 10

0.1

0.01

Between Junction and Cace

Heat sink: ADC12 (30 × 30 × 4 mm)

0.001

0.001 0.01 0.1 1 10 100

Pulse Width (s)

Figure 7. Typical Transient Thermal Resistance (3)

SG-C17VLZ27S, SG-C17VLZ27R Rating and Characteristic Curves

60 100

TJ = 150 °C

50

10 TJ = 200 °C

Average Forward Current, IF (AV) (A)

Forward Current, IF (A)

TJ = 235 °C

40

1

30

0.1

20 TJ = 25 °C

TJ = 60 °C

0.01

10 TJ = 100 °C

0 0.001

0

190 195 200 205 210 215 220 0.0 0.2 0.4 0.6 0.8 1.0 1.2

Case Temperature, TC (°C) Forward Voltage, VF (V)

Figure 8. Power Dissipation Curves (4) Figure 9. VF vs. IF Typical Characteristics

(3)

See Figure 1 for measurement conditions of lead temperature.

(4)

See Figure 1 for measurement conditions of lead temperature.

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 6

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

1.E-03 100

TJ = 235 °C

TJ = 200 °C

1.E-04

TJ = 150 °C 10

Reverse Current, IZ (A)

Reverse Current, IR (A)

1.E-05

1.E-06 TJ = 100 °C

1

TJ = 60 °C

1.E-07

1.E-08

0.1

TJ = 25 °C

1.E-09 t = 80 µs

1.E-10 0.01

0 5 10 15 20 25 26 27 28 29 30 31

Reverse Voltage, VR (V) Reverse Voltage, VZ (V)

Figure 10. VR vs. IR Typical Characteristics Figure 11. IZ vs. VZ Typical Characteristics

10

Thermal Resistance (°C/W)

0.1

0.01

Between Junction and Cace

Heat sink: ADC12 (30 × 30 × 4 mm)

0.001

0.001 0.01 0.1 1 10 100

Pulse Width (s)

Figure 12. Typical Transient Thermal Resistance (5)

(5)

See Figure 1 for the measurement conditions of lead temperature.

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 7

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

SG-C17VVZ27S, SG-C17VVZ27R Rating and Characteristic Curves

70 100

TJ = 150 °C

60

TJ = 200 °C

10

Average Forward Current, IF (AV) (A)

TJ = 235 °C

Forward Current, IF (A)

50

1

40

30

0.1

TJ = 25 °C

20 TJ = 60 °C

0.01 TJ = 100 °C

10

0 0.001

190

0 195 200 205 210 215 220 0.0 0.2 0.4 0.6 0.8 1.0 1.2

Case Temperature, TC (°C) Forward Voltage, VF (V)

Figure 13. Power Dissipation Curves (6) Figure 14. VF vs. IF Typical Characteristics

1.E-03 TJ = 235 °C 100

TJ = 200 °C

1.E-04

TJ = 150 °C 10

Reverse Current, IR (A)

Reverse Current, IZ (A)

1.E-05

1.E-06 TJ = 100 °C

1

TJ = 60 °C

1.E-07

1.E-08

0.1

TJ = 25 °C

1.E-09 t = 80 µs

1.E-10 0.01

0 5 10 15 20 25 26 27 28 29 30

Reverse Voltage, VR (V) Reverse Voltage, VZ (V)

Figure 15. VR vs. IR Typical Characteristics Figure 16. IZ vs. VZ Typical Characteristics

(6)

See Figure 1 for the measurement conditions of lead temperature.

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 8

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

Thermal Resistance (°C/W) 10

0.1

0.01

Between Junction and Cace

Heat sink: ADC12 (30 × 30 × 4 mm)

0.001

0.001 0.01 0.1 1 10 100

Pulse Width (s)

Figure 17. Typical Transient Thermal Resistance( 7)

SG-C17VWZ27S, SG-C17VWZ27R Rating and Characteristic Curves

90 100

TJ = 150 °C

80

TJ = 200 °C

10

70 TJ = 235 °C

Average Forward Current, IF (AV) (A)

Forward Current, IF (A)

60

1

50

40

0.1 TJ = 25 °C

30

TJ = 60 °C

20

0.01 TJ = 100 °C

10

0 0.001

0

190 195 200 205 210 215 220 0.0 0.2 0.4 0.6 0.8 1.0 1.2

Case Temperature, TC (°C) Forward Voltage, VF (V)

Figure 18. Power Dissipation Curves (8) Figure 19. VF vs. IF Typical Characteristics

(7)

See Figure 1 for the measurement conditions of lead temperature.

(8)

See Figure 1 for the measurement conditions of lead temperature.

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 9

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

1.E-03 TJ = 235 °C 100

TJ = 200 °C

1.E-04

TJ = 150 °C

10

Reverse Current, IZ (A)

Reverse Current, IR (A)

1.E-05

TJ = 100 °C

1.E-06 1

TJ = 60 °C

1.E-07

0.1

1.E-08 TJ = 25 °C

t = 80 µs

1.E-09 0.01

0 5 10 15 20 25 26 27 28 29

Reverse Voltage, VR (V) Reverse Voltage, VZ (V)

Figure 20. VR vs. IR Typical Characteristics Figure 21. IZ vs. VZ Typical Characteristics

10

Thermal Resistance (°C/W)

0.1

0.01

Between Junction and Cace

Heat sink: ADC12 (30 × 30 × 4 mm)

0.001

0.001 0.01 0.1 1 10 100

Pulse Width (s)

Figure 22. Typical Transient Thermal Resistance (9)

(9)

See Figure 1 for the measurement conditions of lead temperature.

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 10

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

Physical Dimensions

● Pressfit

φ12.80 +0.04

-0.03

φ11.4

φ1.26 ± 0.1

28.5 ± 0.5

Knurling 80°

Bottom

7.1

4.7

3.4

0.2±0.1

φ8

NOTES:

- Dimensions in millimeters

- Knurling number: 78

- Lead treatment: Pb-free (RoHS compliant)

- Must be pressfit into the heatsink when used.

- Dimensions without tolerances have a tolerance of ±0.2.

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 11

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

● Heatsink

- Recommended hole size and interference: See Figure 23

- Recommended heatsink material: ADC12 or the aluminum die-casting that has same characteristics as ADC12

- Recommended heatsink material strength: 140 to 160 Hv

● How to Pressfit

Note followings when the product is pressed into the heatsink.

- Press pin contact area: See Figure 24 (The press pin must not be pressed to “No press area”)

- Recommended press pin form: See Figure 25

- Contact area between the press pin and the product: ≥30 mm2 (If the contact area is too small, the product package

is deformed and the product damage may be caused.)

- Maximum press load: ≤10,000 N (See Figure 26)

ϕ8mm

Press pin

contact area

Heat sink Heat sink

No press area

ϕ12.64

ϕ12.69 0.04

0.10

Unit: mm

Figure 23 Recommended Hole Size and Interference Figure 24 Press Pin Contact Area

Press pin 10,000 N (max.)

Press load (N)

Distance

Figure 25 Recommended Press Pin Form Figure 26 Maximum Press Load

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 12

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

Marking Diagram

Specific Device Code (See Table 1)

YMDDX

Lot Number:

Y is the last digit of the year of manufacture (0 to 9)

M is the month of the year (1 to 9, O, N, or D)

DD is the day of the month (01 to 31)

X is control number

Table 1. Specific Device Code

Specific Device Code Part Number

AC27S SG-C17LXZ27S

AC27R SG-C17LXZ27R

BC27S SG-C17VLZ27S

BC27R SG-C17VLZ27R

DC27S SG-C17VVZ27S

DC27R SG-C17VVZ27R

HC27S SG-C17WVZ27S

HC27R SG-C17WVZ27R

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 13

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

SG-C17xxZ27

Important Notes

● All data, illustrations, graphs, tables and any other information included in this document (the “Information”) as to Sanken’s

products listed herein (the “Sanken Products”) are current as of the date this document is issued. The Information is subject to any

change without notice due to improvement of the Sanken Products, etc. Please make sure to confirm with a Sanken sales

representative that the contents set forth in this document reflect the latest revisions before use.

● The Sanken Products are intended for use as components of electronic equipment or apparatus (transportation equipment and its

control systems, home appliances, office equipment, telecommunication equipment, measuring equipment, etc.). Prior to use of the

Sanken Products, please put your signature, or affix your name and seal, on the specification documents of the Sanken Products

and return them to Sanken. If considering use of the Sanken Products for any applications that require higher reliability (traffic

signal control systems or equipment, disaster/crime alarm systems, etc.), you must contact a Sanken sales representative to discuss

the suitability of such use and put your signature, or affix your name and seal, on the specification documents of the Sanken

Products and return them to Sanken, prior to the use of the Sanken Products. The Sanken Products are not intended for use in any

applications that require extremely high reliability such as: aerospace equipment; nuclear power control systems; and medical

equipment or systems, whose failure or malfunction may result in death or serious injury to people, i.e., medical devices in Class

III or a higher class as defined by relevant laws of Japan (collectively, the “Specific Applications”). Sanken assumes no liability or

responsibility whatsoever for any and all damages and losses that may be suffered by you, users or any third party, resulting from

the use of the Sanken Products in the Specific Applications or in manner not in compliance with the instructions set forth herein.

● In the event of using the Sanken Products by either (i) combining other products or materials or both therewith or (ii) physically,

chemically or otherwise processing or treating or both the same, you must duly consider all possible risks that may result from all

such uses in advance and proceed therewith at your own responsibility.

● Although Sanken is making efforts to enhance the quality and reliability of its products, it is impossible to completely avoid the

occurrence of any failure or defect or both in semiconductor products at a certain rate. You must take, at your own responsibility,

preventative measures including using a sufficient safety design and confirming safety of any equipment or systems in/for which

the Sanken Products are used, upon due consideration of a failure occurrence rate and derating, etc., in order not to cause any

human injury or death, fire accident or social harm which may result from any failure or malfunction of the Sanken Products.

Please refer to the relevant specification documents and Sanken’s official website in relation to derating.

● No anti-radioactive ray design has been adopted for the Sanken Products.

● The circuit constant, operation examples, circuit examples, pattern layout examples, design examples, recommended examples, all

information and evaluation results based thereon, etc., described in this document are presented for the sole purpose of reference of

use of the Sanken Products.

● Sanken assumes no responsibility whatsoever for any and all damages and losses that may be suffered by you, users or any third

party, or any possible infringement of any and all property rights including intellectual property rights and any other rights of you,

users or any third party, resulting from the Information.

● No information in this document can be transcribed or copied or both without Sanken’s prior written consent.

● Regarding the Information, no license, express, implied or otherwise, is granted hereby under any intellectual property rights and

any other rights of Sanken.

● Unless otherwise agreed in writing between Sanken and you, Sanken makes no warranty of any kind, whether express or implied,

including, without limitation, any warranty (i) as to the quality or performance of the Sanken Products (such as implied warranty

of merchantability, and implied warranty of fitness for a particular purpose or special environment), (ii) that any Sanken Product is

delivered free of claims of third parties by way of infringement or the like, (iii) that may arise from course of performance, course

of dealing or usage of trade, and (iv) as to the Information (including its accuracy, usefulness, and reliability).

● In the event of using the Sanken Products, you must use the same after carefully examining all applicable environmental laws and

regulations that regulate the inclusion or use or both of any particular controlled substances, including, but not limited to, the EU

RoHS Directive, so as to be in strict compliance with such applicable laws and regulations.

● You must not use the Sanken Products or the Information for the purpose of any military applications or use, including but not

limited to the development of weapons of mass destruction. In the event of exporting the Sanken Products or the Information, or

providing them for non-residents, you must comply with all applicable export control laws and regulations in each country

including the U.S. Export Administration Regulations (EAR) and the Foreign Exchange and Foreign Trade Act of Japan, and

follow the procedures required by such applicable laws and regulations.

● Sanken assumes no responsibility for any troubles, which may occur during the transportation of the Sanken Products including

the falling thereof, out of Sanken’s distribution network.

● Although Sanken has prepared this document with its due care to pursue the accuracy thereof, Sanken does not warrant that it is

error free and Sanken assumes no liability whatsoever for any and all damages and losses which may be suffered by you resulting

from any possible errors or omissions in connection with the Information.

● Please refer to our official website in relation to general instructions and directions for using the Sanken Products, and refer to the

relevant specification documents in relation to particular precautions when using the Sanken Products.

● All rights and title in and to any specific trademark or tradename belong to Sanken and such original right holder(s).

DSGN-AEZ-16003

SG-C17xxZ27-DSE Rev.1.3 SANKEN ELECTRIC CO., LTD. 14

Oct. 15, 2018 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2016

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- S07B VishaySiliconixDocument6 pagesS07B VishaySiliconixLatthawitSanNo ratings yet

- RFG70N06, RFP70N06, RF1S70N06, RF1S70N06SM: 70A, 60V, 0.014 Ohm, N-Channel Power Mosfets FeaturesDocument9 pagesRFG70N06, RFP70N06, RF1S70N06, RF1S70N06SM: 70A, 60V, 0.014 Ohm, N-Channel Power Mosfets FeaturesAnca SterianNo ratings yet

- RFG70N06, RFP70N06, RF1S70N06Document8 pagesRFG70N06, RFP70N06, RF1S70N06Juan Carlos GarcíaNo ratings yet

- High-Capacity Switch Capable of Handling 20 A Loads With Large Inrush CurrentsDocument6 pagesHigh-Capacity Switch Capable of Handling 20 A Loads With Large Inrush CurrentsMuhammad Purbo SantosoNo ratings yet

- OMRON G7Ldatasheet J055-E3-04Document14 pagesOMRON G7Ldatasheet J055-E3-04Charith PereraNo ratings yet

- 364 23768 0 BLF278Document23 pages364 23768 0 BLF278MelLda UdjuNo ratings yet

- SQJ992EP: Vishay SiliconixDocument11 pagesSQJ992EP: Vishay SiliconixcqlNo ratings yet

- Hgtd7N60B3S, Hgt1S7N60B3S, Hgtp7N60B3: 14A, 600V, Ufs Series N-Channel Igbts FeaturesDocument7 pagesHgtd7N60B3S, Hgt1S7N60B3S, Hgtp7N60B3: 14A, 600V, Ufs Series N-Channel Igbts FeaturesnudufoqiNo ratings yet

- DatasheetDocument11 pagesDatasheetWILLIAMNo ratings yet

- Subminiature Basic Switch SSGDocument8 pagesSubminiature Basic Switch SSGMuhamad PriyatnaNo ratings yet

- LM108 PDFDocument10 pagesLM108 PDFMartín SayagoNo ratings yet

- Alfa OmegaDocument9 pagesAlfa Omegapratik gautamNo ratings yet

- SKN 71, SKR 71: Rectifier DiodeDocument3 pagesSKN 71, SKR 71: Rectifier DiodeRafael GarciaNo ratings yet

- Motocone - 6380V1.0 DatasheetDocument13 pagesMotocone - 6380V1.0 DatasheetAchsanul KhabibNo ratings yet

- IRF 3805-IRF 3805S-IRF 3805L - MosfetDocument12 pagesIRF 3805-IRF 3805S-IRF 3805L - MosfetTiago LeonhardtNo ratings yet

- Relevo G3RV OmronDocument18 pagesRelevo G3RV Omronelkin mezaNo ratings yet

- SQ4435EY: Vishay SiliconixDocument9 pagesSQ4435EY: Vishay SiliconixCesar RementizoNo ratings yet

- 7915Document13 pages7915ysfhkNo ratings yet

- PA-2 Unit (Lot. 62 ) : Circuit DiagramDocument8 pagesPA-2 Unit (Lot. 62 ) : Circuit Diagramfazenda sao gabrielNo ratings yet

- sst200, Sst200a VishayDocument5 pagessst200, Sst200a Vishayrolan444No ratings yet

- STB13NK60Z - STB13NK60Z-1 STP13NK60Z/FP - STW13NK60ZDocument17 pagesSTB13NK60Z - STB13NK60Z-1 STP13NK60Z/FP - STW13NK60ZGaston GottardiNo ratings yet

- Irf3205Zpbf Irf3205Zspbf Irf3205Zlpbf: Automotive MosfetDocument13 pagesIrf3205Zpbf Irf3205Zspbf Irf3205Zlpbf: Automotive MosfetAurelian IordacheNo ratings yet

- Irf3805Pbf Irf3805Spbf Irf3805Lpbf: FeaturesDocument14 pagesIrf3805Pbf Irf3805Spbf Irf3805Lpbf: Featurescarmel asentistaNo ratings yet

- FDPA Programing1231Document10 pagesFDPA Programing1231Engr. Syed Ghulam Mustafa ShahNo ratings yet

- LM1577/LM2577 Series Simple Switcher Step-Up Voltage RegulatorDocument26 pagesLM1577/LM2577 Series Simple Switcher Step-Up Voltage Regulatorсоня соняNo ratings yet

- Ceiling & Floor (60Hz, R22)Document92 pagesCeiling & Floor (60Hz, R22)jose antonioNo ratings yet

- STB 75 NF 75Document11 pagesSTB 75 NF 75costas1182No ratings yet

- Unisonic Technologies Co., LTD: P-Channel Enhancement ModeDocument5 pagesUnisonic Technologies Co., LTD: P-Channel Enhancement ModeMaz RofulNo ratings yet

- HGTG7N60A4D, HGTP7N60A4D, HGT1S7N60A4DS: 600V, SMPS Series N-Channel IGBT With Anti-Parallel Hyperfast Diode FeaturesDocument9 pagesHGTG7N60A4D, HGTP7N60A4D, HGT1S7N60A4DS: 600V, SMPS Series N-Channel IGBT With Anti-Parallel Hyperfast Diode FeaturesJarden VegaNo ratings yet

- 7912CT EtcDocument13 pages7912CT EtcCuong TranNo ratings yet

- IRF3205Z IRF3205ZS IRF3205ZL: Automotive MosfetDocument12 pagesIRF3205Z IRF3205ZS IRF3205ZL: Automotive MosfetJose M PeresNo ratings yet

- 78L05M UnisonicTechnologiesDocument8 pages78L05M UnisonicTechnologiesasepNo ratings yet

- 4953 IC DatasheetDocument10 pages4953 IC DatasheetAmit BhatiaNo ratings yet

- Semikron Datasheet SKN 70 02236900Document3 pagesSemikron Datasheet SKN 70 02236900Israel AlvesNo ratings yet

- SKN 240, SKR 240: Rectifier DiodeDocument3 pagesSKN 240, SKR 240: Rectifier DiodeSidnei de Souza MartinsNo ratings yet

- Irf740As, Sihf740As, Irf740Al, Sihf740Al: Vishay SiliconixDocument8 pagesIrf740As, Sihf740As, Irf740Al, Sihf740Al: Vishay SiliconixbillyNo ratings yet

- N-Fet Sub85n03Document6 pagesN-Fet Sub85n03efbdu.comNo ratings yet

- Datasheet LD1117AGDocument15 pagesDatasheet LD1117AGAnand MugaleNo ratings yet

- Annex Getting Started With ATV312: Short-Circuit Current Ratings (SCCR) and Branch Circuit ProtectionDocument4 pagesAnnex Getting Started With ATV312: Short-Circuit Current Ratings (SCCR) and Branch Circuit ProtectionTommy KhNo ratings yet

- AE Bolted CB EnclosuresDocument6 pagesAE Bolted CB EnclosuresMuhamad PriyatnaNo ratings yet

- Stp9Nk70Z - Stp9Nk70Zfp STB9NK70Z - STB9NK70Z-1 - STW9NK70ZDocument14 pagesStp9Nk70Z - Stp9Nk70Zfp STB9NK70Z - STB9NK70Z-1 - STW9NK70ZDarinell Marrugo GarridoNo ratings yet

- 8693Document15 pages8693jose03No ratings yet

- LCDSPLN-S-18-CDL - LCDSPLN-R-18-CDL - 16072019Document2 pagesLCDSPLN-S-18-CDL - LCDSPLN-R-18-CDL - 16072019Anilkumar KolpuruNo ratings yet

- AC FusesDocument16 pagesAC Fusesankitkumawat622No ratings yet

- Diodo Semikron 1639760083Document3 pagesDiodo Semikron 1639760083boubakeur atouiNo ratings yet

- 300w PA Using A MRF300AN Transistor by Sergey EX8MLE The Four Metres Website - 1625828700391Document6 pages300w PA Using A MRF300AN Transistor by Sergey EX8MLE The Four Metres Website - 1625828700391Jeannot BopendaNo ratings yet

- STF3NK80ZDocument18 pagesSTF3NK80ZGheorghe DavidNo ratings yet

- Schema BertDocument4 pagesSchema BertArda AkberkNo ratings yet

- Miniature Basic Switch KDocument5 pagesMiniature Basic Switch KMuhamad PriyatnaNo ratings yet

- SQJ960EP: Vishay SiliconixDocument11 pagesSQJ960EP: Vishay SiliconixgilamadaNo ratings yet

- Sharp Sn80a Chassis 21sl41 TV SMDocument12 pagesSharp Sn80a Chassis 21sl41 TV SMpozarica3030No ratings yet

- 6N60 PDFDocument7 pages6N60 PDFRey TiburonNo ratings yet

- DS Semiconductor Protection Square Body Fuses Protistor Size 000 00 1 2 3 GS 690VAC FRDocument24 pagesDS Semiconductor Protection Square Body Fuses Protistor Size 000 00 1 2 3 GS 690VAC FREmitech SARLNo ratings yet

- Xraytube DG-073BDocument6 pagesXraytube DG-073BMAX GNo ratings yet

- N-Channel 600 V, 0.255 Ω Typ., 13 A Mdmesh M2 Power Mosfets In D Pak, I Pak, To-220 And To-247 PackagesDocument27 pagesN-Channel 600 V, 0.255 Ω Typ., 13 A Mdmesh M2 Power Mosfets In D Pak, I Pak, To-220 And To-247 PackagesTablet7 HomeNo ratings yet

- lm741 NacionalDocument10 pageslm741 NacionalChristian PaulNo ratings yet

- 9600232dgdadgdb PDFDocument58 pages9600232dgdadgdb PDFJovanNo ratings yet

- Transistor IRFS3307Document13 pagesTransistor IRFS3307Titan Jaya AutomationNo ratings yet

- 111Document6 pages111suan kwang TanNo ratings yet

- 4 Adc/8 Dac With PLL, 192 KHZ, 24-Bit Codec Ad1939: Features General DescriptionDocument32 pages4 Adc/8 Dac With PLL, 192 KHZ, 24-Bit Codec Ad1939: Features General Descriptionsuan kwang TanNo ratings yet

- 3312 - 2 MM SMD Trimming Potentiometer: 4800P Series - Thick Film Surface Mount Medium BodyDocument4 pages3312 - 2 MM SMD Trimming Potentiometer: 4800P Series - Thick Film Surface Mount Medium Bodysuan kwang TanNo ratings yet

- KEMET Part Number: C1210C107M8PACTUDocument1 pageKEMET Part Number: C1210C107M8PACTUsuan kwang TanNo ratings yet

- MIP2K4 Panasonic PDFDocument2 pagesMIP2K4 Panasonic PDFRoberto Mendes0% (1)

- Important Notice: Kind RegardsDocument18 pagesImportant Notice: Kind Regardssuan kwang TanNo ratings yet

- STM 8 Af 5288Document125 pagesSTM 8 Af 5288Unik WadhwaniNo ratings yet

- High-Wattage General Purpose Relay: Small PCB Relay For Automobile UseDocument3 pagesHigh-Wattage General Purpose Relay: Small PCB Relay For Automobile Usesuan kwang TanNo ratings yet

- 4 Adc/8 Dac With PLL, 192 KHZ, 24-Bit Codec Ad1939: Features General DescriptionDocument32 pages4 Adc/8 Dac With PLL, 192 KHZ, 24-Bit Codec Ad1939: Features General Descriptionsuan kwang TanNo ratings yet

- Circuit Breaker: FeaturesDocument2 pagesCircuit Breaker: Featuressuan kwang TanNo ratings yet

- General: SpecificationsDocument10 pagesGeneral: Specificationssuan kwang TanNo ratings yet

- FSTD16861 20-Bit Bus Switch With Level Shifting: General Description FeaturesDocument6 pagesFSTD16861 20-Bit Bus Switch With Level Shifting: General Description FeaturesDurango BdgNo ratings yet

- Datasheet PDFDocument20 pagesDatasheet PDFEduRoiNo ratings yet

- Mitsumi Ic Products CatalogDocument76 pagesMitsumi Ic Products Catalogsuan kwang TanNo ratings yet

- LMC555 CMOS Timer: 1 Features 3 DescriptionDocument32 pagesLMC555 CMOS Timer: 1 Features 3 Descriptionsuan kwang TanNo ratings yet

- rt9715 RichtekDocument16 pagesrt9715 RichtekSergey VotinovNo ratings yet

- 1A Output 78 Series Regulators 500ma Output 78 Series RegulatorsDocument15 pages1A Output 78 Series Regulators 500ma Output 78 Series Regulatorssuan kwang TanNo ratings yet

- YPI7575C Amphenol Advanced Sensors Product DetailsDocument3 pagesYPI7575C Amphenol Advanced Sensors Product Detailssuan kwang Tan50% (2)

- 2A / - 30V Bipolar Transistor: TransistorsDocument4 pages2A / - 30V Bipolar Transistor: Transistorssuan kwang TanNo ratings yet

- General Description Features: Single 300ma LDO in 1.0mm × 1.0mm DFN PackageDocument15 pagesGeneral Description Features: Single 300ma LDO in 1.0mm × 1.0mm DFN PackageMaugrys CastilloNo ratings yet

- Description: 2 GBIT (256M × 8 Bit) Cmos Nand E PromDocument65 pagesDescription: 2 GBIT (256M × 8 Bit) Cmos Nand E Promsuan kwang Tan100% (1)

- AOD407 P-Channel Enhancement Mode Field Effect Transistor: Features General DescriptionDocument6 pagesAOD407 P-Channel Enhancement Mode Field Effect Transistor: Features General Descriptionsuan kwang TanNo ratings yet

- YPI7575C Amphenol Advanced Sensors Product DetailsDocument3 pagesYPI7575C Amphenol Advanced Sensors Product Detailssuan kwang Tan50% (2)

- Features: Elektronische Bauelemente - 1 A, - 80 V PNP Plastic Encapsulated TransistorDocument2 pagesFeatures: Elektronische Bauelemente - 1 A, - 80 V PNP Plastic Encapsulated Transistorsuan kwang TanNo ratings yet

- Wiring Diagram Index: Released ReleasedDocument161 pagesWiring Diagram Index: Released Releasedsuan kwang TanNo ratings yet

- Specifications:: EnglishDocument3 pagesSpecifications:: Englishsuan kwang TanNo ratings yet

- BD3500 - BD3506: 35A Bosch Type Press-Fit DiodeDocument2 pagesBD3500 - BD3506: 35A Bosch Type Press-Fit Diodeandreas adi KristiawanNo ratings yet

- BD3500 - BD3506: 35A Bosch Type Press-Fit DiodeDocument2 pagesBD3500 - BD3506: 35A Bosch Type Press-Fit Diodeandreas adi KristiawanNo ratings yet

- Radial Ceramic Case Resistors Wirewound / Metal OxideDocument3 pagesRadial Ceramic Case Resistors Wirewound / Metal Oxidesuan kwang TanNo ratings yet

- Wansview IP Camera ManualDocument54 pagesWansview IP Camera ManualMaria Jose PareaNo ratings yet

- XML Web ServicesDocument457 pagesXML Web ServicesSoner GönülNo ratings yet

- PLC Wiring Q&aDocument59 pagesPLC Wiring Q&apascal sitanggangNo ratings yet

- Maths Unit 1 and Unit 2Document36 pagesMaths Unit 1 and Unit 2saisastra3No ratings yet

- 21 InfotainmentDocument10 pages21 InfotainmentIqtidar ANo ratings yet

- Esim ProgrammerDocument198 pagesEsim ProgrammerWeslley MouraNo ratings yet

- MIT SW No. 5Document4 pagesMIT SW No. 5Airon BendañaNo ratings yet

- Subnetting ItexampracticeDocument12 pagesSubnetting ItexampracticeMohammad Tayyab KhusroNo ratings yet

- Traktor Signatures Set-Up DubfireDocument1 pageTraktor Signatures Set-Up DubfireAndres Fernando Rodriguez JaramilloNo ratings yet

- Thar MN04-20CE - ABPR-20 Operator Manual PDFDocument53 pagesThar MN04-20CE - ABPR-20 Operator Manual PDFSerge LapointeNo ratings yet

- MS Word FundamentalsDocument49 pagesMS Word Fundamentalsladsjovero6162100% (1)

- 03 T HVP PDFDocument6 pages03 T HVP PDFkimikien1No ratings yet

- ScanSoft OmniPage SE 4.0Document1 pageScanSoft OmniPage SE 4.0hadzilNo ratings yet

- DLL ICT Week 11.3Document9 pagesDLL ICT Week 11.3Jojo SamaniegoNo ratings yet

- Airo Part ManualDocument52 pagesAiro Part ManualCemYurtseverNo ratings yet

- Failure Rate Standar Data PredictionDocument298 pagesFailure Rate Standar Data Predictionratrihaningds100% (1)

- Demandware Load Test Plan - TemplateDocument4 pagesDemandware Load Test Plan - TemplateAshok JagtapNo ratings yet

- Ecological Modelling and Energy DSSDocument325 pagesEcological Modelling and Energy DSSNàpoles RaymundoNo ratings yet

- PMM PPT-1Document56 pagesPMM PPT-1Chandra BoddedaNo ratings yet

- DDO TipsDocument9 pagesDDO TipsRich Vincent100% (1)

- Resume - Nikhil SachanDocument2 pagesResume - Nikhil SachanAshish AggarwalNo ratings yet

- Part 2: Chapter 1-IntroductionDocument26 pagesPart 2: Chapter 1-IntroductionSeif AshrafNo ratings yet

- Applicationpedia - Snipping Tools To Take A Screenshot On WindowsDocument9 pagesApplicationpedia - Snipping Tools To Take A Screenshot On WindowsOecil KritingzNo ratings yet

- GJFJJDDSGGDDGDFSGFDSGDocument119 pagesGJFJJDDSGGDDGDFSGFDSGSanke AshokNo ratings yet

- Free PPT Templates: Insert The Sub Title of Your PresentationDocument48 pagesFree PPT Templates: Insert The Sub Title of Your PresentationMaria XaritidouNo ratings yet

- Goal Seek ExcelDocument21 pagesGoal Seek ExcelAsna Sicantik ManikNo ratings yet

- Vogue Color Book PDFDocument4 pagesVogue Color Book PDFhellomoscaNo ratings yet

- Kazrog True Iron User GuideDocument20 pagesKazrog True Iron User GuideParsa ShomaliNo ratings yet

- New ResumeDocument6 pagesNew ResumeMichael EaganNo ratings yet

- 8 Bit Parallel To Serial ConverterDocument7 pages8 Bit Parallel To Serial ConverterJackKulchNo ratings yet