Professional Documents

Culture Documents

Hanalei Re-Order Requirements v20210419

Uploaded by

annjelyn hazelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hanalei Re-Order Requirements v20210419

Uploaded by

annjelyn hazelCopyright:

Available Formats

Hanalei Re-Order Requirements

1. Shipping Instructions

2. Labeling Requirements

3. Packing Requirements

4. Document Requirements

5. Quality Control Standards

1) SHIPPING INSTRUCTIONS

I. Ship by Date: See PO (Delivery Instructions)

II. Pickup: Hanalei will arrange carrier pickup from warehouse once approved.

2) LABELING REQUIREMENTS

Use template provided by Hanalei.

Requirement: Check

I. Apply Inner/Master Carton labels on at least x1 side of each carton. Carton

count sequence must reset at #1 for each shipment. Refer to carton label

template provided by Hanalei.

II. Apply Pallet labels on at least x2 sides of each pallet. Pallet count sequence

must reset at 1 for each shipment. Refer to pallet label template provided by

Hanalei.

III. Attach Packing List copy to Pallet #1.

IV. Confirm TBD info highlighted in yellow on label templates provided by

Hanalei.

SLEE@HANALEICOMPANY.COM ⃒ 808.773.8320 ⃒ WWW.HANALEICOMPANY.COM REV. 4/19/21

Page 1 of 3

Hanalei Re-Order Requirements

3) PACKING REQUIREMENTS

Carton and Pallet Specifications

Dimension (in)

Master Carton Pallet

Length: See BOM 48”

Width: See BOM 40”

Height: See BOM Maximum 52”

Weight (lbs)

Maximum 30lbs Maximum 1,000lbs

Quantity (pcs)

See BOM N/A

Carton Packing Requirements: Check

Meets labeling requirements

Meets specifications above

No mixed cartons (only 1 SKU per carton)

No hazard symbol

No additional dunnage (i.e. no peanut foam, paper, bubble bags)

No more than 1” wide empty space inside packed carton.

No markings identifying manufacturer.

Pallet Packing Requirements: Check

Meets labeling requirements

Meets specifications above

Shrink-wrapped minimum of 5 times

Cartons do not extend beyond length and/or width of pallet.

No damaged pallets.

No markings identifying manufacturer

4) DOCUMENT REQUIREMENTS

Document Requirement: Check

I. Commercial Invoice

II. Packing List (incl. lot numbers)

III. Certificate of Analysis (inc. microbial testing and preservation testing results

IV. Safety Data Sheet

SLEE@HANALEICOMPANY.COM ⃒ 808.773.8320 ⃒ WWW.HANALEICOMPANY.COM REV. 4/19/21

Page 2 of 3

Hanalei Re-Order Requirements

5) QUALITY CONTROL STANDARDS

Add lot numbers on component and packing list

Acceptable Quality Limit (AQL) method for the QC inspection:

AQL General Inspection Level II with defect levels of Critical defects (0.65), Major defects (1.0)

and Minor defects (1.5) Our internal standards use the defect levels as:

AQL definitions for minor, major and critical:

o Minor: The defect doesn't affect the function or form of the item

e.g: Residue, Smudge, transit damage to unit carton

o Major: The defect could affect the function, performance or appearance

e.g: Overfilled product leaking on lid, discoloration

o Critical: The product cannot be sold

e.g: Foreign matter in the product, Open seams,

Broken/Shattered unit, Missing item in unit carton, Missing pump (if it

is spray), Damaged cap, melted or frozen

SLEE@HANALEICOMPANY.COM ⃒ 808.773.8320 ⃒ WWW.HANALEICOMPANY.COM REV. 4/19/21

Page 3 of 3

You might also like

- BearingsDocument52 pagesBearingsrahul singhNo ratings yet

- Master Formula Template UploadDocument3 pagesMaster Formula Template UploadCindy Barberes75% (4)

- Value Investors Club - Treasure ASA (TRE ASA)Document9 pagesValue Investors Club - Treasure ASA (TRE ASA)Lukas Savickas100% (1)

- Costco Packaging Specs AddendumsDocument16 pagesCostco Packaging Specs Addendumssaravanan_c1No ratings yet

- Abc Vendor ManualDocument29 pagesAbc Vendor Manualtripti keshanNo ratings yet

- Container Loading Procedure PDFDocument8 pagesContainer Loading Procedure PDFZAHID UMARNo ratings yet

- InspectionDocument32 pagesInspectionmaruf19900100% (1)

- F-02 Fabric Inspection ManualDocument13 pagesF-02 Fabric Inspection Manualzoomerfins22100% (1)

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- General Requirements:: Quality Requirements For Wooden Pallet SpecificationsDocument8 pagesGeneral Requirements:: Quality Requirements For Wooden Pallet Specificationsirtaza324197100% (1)

- Global URBN Fabric and Apparel Testing Manual 2.25.2019Document81 pagesGlobal URBN Fabric and Apparel Testing Manual 2.25.2019THYAGUNo ratings yet

- Cover Letter For Japan Visa ApplicationDocument1 pageCover Letter For Japan Visa Applicationannjelyn hazelNo ratings yet

- TCR22-2 Operating Manual - SkutevikenDocument266 pagesTCR22-2 Operating Manual - SkutevikenFlo Marine100% (2)

- Klipen Packing and Palletizing Standard 2022Document35 pagesKlipen Packing and Palletizing Standard 2022Roger Manrrique NinaNo ratings yet

- WFP 0000140775Document8 pagesWFP 0000140775teddynigusu5No ratings yet

- YETI - Product Manual (00000002)Document35 pagesYETI - Product Manual (00000002)vesalocalbusNo ratings yet

- Specification For BMW POLYBAGSDocument3 pagesSpecification For BMW POLYBAGSDarpan BhattNo ratings yet

- Labeling SOP - WRBU - UPDATED - 2017Document4 pagesLabeling SOP - WRBU - UPDATED - 2017Jorge Silva DiazNo ratings yet

- Packaging ManualDocument127 pagesPackaging ManualShruti JainNo ratings yet

- Annex A Technical Specification RevisedDocument6 pagesAnnex A Technical Specification Reviseddaniel.kNo ratings yet

- Alphabroder - Carton Specification-Version 7.0. 2019Document2 pagesAlphabroder - Carton Specification-Version 7.0. 2019DebashishDolonNo ratings yet

- QMS 2Document89 pagesQMS 2Oki SyahrialNo ratings yet

- Packing and Polybag Requirements and Guidelines 2-19-2019Document5 pagesPacking and Polybag Requirements and Guidelines 2-19-2019DebashishDolonNo ratings yet

- StandardizationDocument3 pagesStandardizationHoney de la TorreNo ratings yet

- Packaging and Label Raw MaterialDocument8 pagesPackaging and Label Raw MaterialRockyLagishettyNo ratings yet

- Product Zones: Zoning Defects and AppearanceDocument24 pagesProduct Zones: Zoning Defects and AppearanceP. LakshmanakanthNo ratings yet

- Dispensing Procedure, JewelDocument24 pagesDispensing Procedure, JewelMd. JewelNo ratings yet

- Fabric InspectionDocument7 pagesFabric InspectionAbhijeet Kumar100% (1)

- Printed Packaging Controls - Global Requirement - Version 4 - October 2015 PDFDocument7 pagesPrinted Packaging Controls - Global Requirement - Version 4 - October 2015 PDFMorales OctavioNo ratings yet

- Ejemplo de Reporte de InspecciónDocument42 pagesEjemplo de Reporte de InspecciónMaria BardalesNo ratings yet

- Complete Popcorn ExerciseDocument26 pagesComplete Popcorn ExerciseNur HidayatiNo ratings yet

- TSP2-5 Mandatory Quality Test - V8Document14 pagesTSP2-5 Mandatory Quality Test - V8Sazzad Hossain HossainNo ratings yet

- Renner Samples - Instruction Manual - ENGDocument19 pagesRenner Samples - Instruction Manual - ENGMuhammad Sabeeh ul hassanNo ratings yet

- Shipping and Routing Requirements: Box Content InformationDocument7 pagesShipping and Routing Requirements: Box Content InformationĐinh Đức ThiNo ratings yet

- Guyana TFO PKG W'SHP Session 2 - Laws, RegsDocument29 pagesGuyana TFO PKG W'SHP Session 2 - Laws, RegsClara VeranitaNo ratings yet

- Packaging and StorageDocument3 pagesPackaging and StorageIvana HalingkarNo ratings yet

- Commodity Requirements Bags and TwineDocument24 pagesCommodity Requirements Bags and TwineEnrique EnnyNo ratings yet

- Oregon State Public Health Laboratory: Courier System HandbookDocument22 pagesOregon State Public Health Laboratory: Courier System HandbookRohit KumarNo ratings yet

- DOT Test Report FormatDocument1 pageDOT Test Report FormatAmita PillaiNo ratings yet

- Dropship Packaging Guidelines 2.0Document6 pagesDropship Packaging Guidelines 2.0Samveg MehtaNo ratings yet

- Perry Ellis - Vendor Manual-Carton Specifications - V1 - 1 - 8Document22 pagesPerry Ellis - Vendor Manual-Carton Specifications - V1 - 1 - 8DebashishDolonNo ratings yet

- Material Control ProcedureDocument4 pagesMaterial Control ProcedurePrime CapNo ratings yet

- QC Group Act. 3Document6 pagesQC Group Act. 3Abigael PescasioNo ratings yet

- Halobutyl Tire Inner Liners Problem Solving GuideDocument2 pagesHalobutyl Tire Inner Liners Problem Solving GuideN.B.P100% (1)

- LogisticsDocument6 pagesLogisticssudheer_scdcNo ratings yet

- Sr. No. Subject Queries From SAR Warehousing & DistributionDocument4 pagesSr. No. Subject Queries From SAR Warehousing & DistributionAbhimanyu ArjunNo ratings yet

- Packing and Polybag Requirements and GuidelinesDocument4 pagesPacking and Polybag Requirements and GuidelinesHuongly QuachNo ratings yet

- BRD Orkla Group Logistics 1.0 SuppliersDocument13 pagesBRD Orkla Group Logistics 1.0 SuppliersSiew Ming SooNo ratings yet

- Incoming Quality Assurance (IQA) : Completed Learning ObjectivesDocument8 pagesIncoming Quality Assurance (IQA) : Completed Learning ObjectivestharakadesilvaNo ratings yet

- Shipping Platform Standards 2019 PDFDocument32 pagesShipping Platform Standards 2019 PDFPaula CordobaNo ratings yet

- Annex 4 - Product - Specifications - Technical Requirements - GHSC-PSM-TO1-2017-MCO-LUB-IDIQ - FINALDocument18 pagesAnnex 4 - Product - Specifications - Technical Requirements - GHSC-PSM-TO1-2017-MCO-LUB-IDIQ - FINALGahininathJagannathGadeNo ratings yet

- PackagingDocument35 pagesPackagingGurnoor KaurNo ratings yet

- Paint Receiving ProcedureDocument4 pagesPaint Receiving ProcedureHaytham Elsayed100% (1)

- General Labeling Requirements, Applicable To All Merchandise ItemsDocument10 pagesGeneral Labeling Requirements, Applicable To All Merchandise ItemsJorge Alberto Legaria MartinezNo ratings yet

- 80080-GT-017-E - SIGNED - 2-Packing RequirementsDocument14 pages80080-GT-017-E - SIGNED - 2-Packing RequirementsPaul NieNo ratings yet

- 7.3.3.1 Commodity Stacking GuidelinesDocument2 pages7.3.3.1 Commodity Stacking Guidelines9567592146No ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- OIML R87-2004Contenido Neto PDFDocument16 pagesOIML R87-2004Contenido Neto PDFanamrg2434No ratings yet

- Quantity of Product in Prepackages OIML R 87Document16 pagesQuantity of Product in Prepackages OIML R 87olivertello80No ratings yet

- ECI Instructions Letter - Textile PDFDocument7 pagesECI Instructions Letter - Textile PDFRajan KamachiNo ratings yet

- ECI Instructions Letter - TextileDocument7 pagesECI Instructions Letter - TextileRajan KamachiNo ratings yet

- Efibca Q A Eng Final ADocument20 pagesEfibca Q A Eng Final ASunny GhadgeNo ratings yet

- 17tre-137 Pi ReportDocument4 pages17tre-137 Pi ReportjuanaaalejandrasalcedosamperNo ratings yet

- Technical Specifications - Urea and NPKDocument3 pagesTechnical Specifications - Urea and NPKAgro LinkNo ratings yet

- New Product Launch Lab Testing GuidelinesDocument4 pagesNew Product Launch Lab Testing Guidelinesannjelyn hazelNo ratings yet

- Lab and APC Testing, Product Registration Complete GuidelinesDocument4 pagesLab and APC Testing, Product Registration Complete Guidelinesannjelyn hazelNo ratings yet

- C-PCERGO2LEC - Group Activity 3.1 - Finals Topics Research and PresentationDocument1 pageC-PCERGO2LEC - Group Activity 3.1 - Finals Topics Research and Presentationannjelyn hazelNo ratings yet

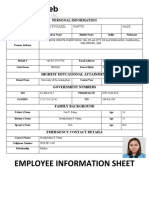

- Employee Information Sheetv1Document1 pageEmployee Information Sheetv1annjelyn hazelNo ratings yet

- Lean Office AssessmentDocument8 pagesLean Office Assessmentannjelyn hazelNo ratings yet

- Running of Vehicle Report ProcessDocument3 pagesRunning of Vehicle Report Processannjelyn hazelNo ratings yet

- Created Status PO Number Internal SKU: Open Open Open Open Open Open Open Open Open Open Open Open Open Open Open OpenDocument4 pagesCreated Status PO Number Internal SKU: Open Open Open Open Open Open Open Open Open Open Open Open Open Open Open Openannjelyn hazelNo ratings yet

- Dvx-Sop/Yyyy-Xxx Dvx-Sop/Yyyy-Xxx/Xx Dvx-Jd/Yyyy-Xxx Dvx-Jd/Yyyy-Xxx/XxDocument7 pagesDvx-Sop/Yyyy-Xxx Dvx-Sop/Yyyy-Xxx/Xx Dvx-Jd/Yyyy-Xxx Dvx-Jd/Yyyy-Xxx/Xxannjelyn hazelNo ratings yet

- Vibration Control Technology Industry (Freudenberg Schwab)Document111 pagesVibration Control Technology Industry (Freudenberg Schwab)ismailNo ratings yet

- Understanding: Sexual HarassmentDocument8 pagesUnderstanding: Sexual HarassmentAlex TwahirwaNo ratings yet

- Week 1Document15 pagesWeek 1Jamaica AlejoNo ratings yet

- Pointy Hat - The Cowboy - Ranger ConclaveDocument5 pagesPointy Hat - The Cowboy - Ranger Conclave678ojyhiopNo ratings yet

- Rabe 1 Reviewer 2022 2023Document174 pagesRabe 1 Reviewer 2022 2023Dencel BarramedaNo ratings yet

- 5990200Document551 pages5990200Basit Ahmad bhat0% (1)

- Culture and CraftDocument27 pagesCulture and CraftFreya UmelNo ratings yet

- Drugs: Samkox Productions 0774852021Document2 pagesDrugs: Samkox Productions 0774852021MichaelNo ratings yet

- Holy Is The Lord-GDocument1 pageHoly Is The Lord-Gmolina.t4613No ratings yet

- Causes and Effects of The Cold WarDocument2 pagesCauses and Effects of The Cold WarkhanrrrajaNo ratings yet

- Ebf Rehearsal RubricDocument1 pageEbf Rehearsal Rubricapi-518770643No ratings yet

- Antacyd PDFDocument5 pagesAntacyd PDFIra YunrarzNo ratings yet

- The Greatest Trump Raffle Ever - A Tommy Zegan OriginalDocument2 pagesThe Greatest Trump Raffle Ever - A Tommy Zegan OriginalPR.comNo ratings yet

- Assignment Marks: 30: InstructionsDocument2 pagesAssignment Marks: 30: InstructionsbishtamitdipNo ratings yet

- Communityhealth 141122094330 Conversion Gate02Document22 pagesCommunityhealth 141122094330 Conversion Gate02Titser JoNo ratings yet

- Global Forecasts DiscussionDocument10 pagesGlobal Forecasts DiscussionkareemarfaNo ratings yet

- SaviorKitty - (Seven Deadly Sins Series 4) PrideDocument48 pagesSaviorKitty - (Seven Deadly Sins Series 4) PrideMarife LuzonNo ratings yet

- The Aim of This Essay Is To Critically Analyse IronmanDocument4 pagesThe Aim of This Essay Is To Critically Analyse IronmanAura IonescuNo ratings yet

- Faculty of Education: Dr. Ghanshyam Singh P.G. College, Soyepur, Lalpur, VaranasiDocument4 pagesFaculty of Education: Dr. Ghanshyam Singh P.G. College, Soyepur, Lalpur, VaranasiRajeshKumarJainNo ratings yet

- The Need For Culturally Relevant Dance EducationDocument7 pagesThe Need For Culturally Relevant Dance Educationajohnny1No ratings yet

- CDBFRDDocument88 pagesCDBFRDmarcol99No ratings yet

- GoKReport1819Final 23091uDocument28 pagesGoKReport1819Final 23091uGurukrupa DasNo ratings yet

- General Rules ICT Lab Rules PE & Gym RulesDocument1 pageGeneral Rules ICT Lab Rules PE & Gym Rulestyler_froome554No ratings yet

- The Role of Customer Knowledge Management (CKM) in Improving Organization-Customer RelationshipDocument7 pagesThe Role of Customer Knowledge Management (CKM) in Improving Organization-Customer RelationshipAbdul LathifNo ratings yet

- Data Coding SchemesDocument26 pagesData Coding SchemesJovanie CadungogNo ratings yet

- Dead Poets SocietyDocument1 pageDead Poets SocietyNagy ZenteNo ratings yet

- LY Adverbs Combined ListDocument1 pageLY Adverbs Combined ListcarmencrisanNo ratings yet