Professional Documents

Culture Documents

Ect Al Electrocolour 444

Uploaded by

Jitendra Kumar Singh0 ratings0% found this document useful (0 votes)

42 views1 pageElectro colour

Original Title

ECT AL ELECTROCOLOUR 444

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentElectro colour

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

42 views1 pageEct Al Electrocolour 444

Uploaded by

Jitendra Kumar SinghElectro colour

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

ElectroChem Technologies India Pvt. Ltd.

,

No. 4D / 1-A, 8th Street, 3rd Main Road,

Ambattur Industrial Estate,

Chennai 600 058,TamilNadu, India

Phone # + 91 44 26520024 / + 91 44 26520064

Fax # + 91 44 26520064

E Mail: lab@electrochemtechnologies.com

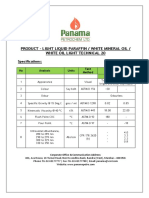

ECT AL ELECTROCOLOUR 444 PROCESS FLOW CHART

PROCESS No. PROCESS SEQUENCE PROCESS TIME PROCESS PARAMETER

10 INCOMING INSPECTION _ Shall be free from surface defects

ECT AL ETCH 303

20 ECT AL ETCH 303 2-3 MIN Conc : 60 ml/l

Temp: room

30 WATER RINSE 5-10 SEC. WATER

40 WATER RINSE 5-10 SEC. WATER

Depending upon the SULPHURIC ACID : 150 - 170 g/l

50 ANODIZING thickness - (2 min for 1 ECT ANODIZING ADDITIVE 445 : 20 g/l

0

Microns) Temperature : 18 -22 C

WATER RINSE

60 5-10 SEC. D.M WATER

70 WATER RINSE 5-10 SEC D.M WATER

ECT ELECTROCOLUR SALT 444 - 20 g/l

Sulphuric Acid : 25 g/l

ECT AL ELECTROCOLUR 444 ECT AL EC STABILIZER 443 S - 7 g/l

30 SEC - 15 MIN

80 OR

depending on colour

ECT AL EC STABILIZER 443 L - 25 g/l

Temperature : Room

Voltage : 15-20 V AC

WATER RINSE

90 5-10 SEC. D.M WATER

100 WATER RINSE 5-10 SEC D.M WATER

ECT COLD SEALING SALT : 10 g/l

0

110 30-90 Sec/Micron Temperature : 20-30 C

ECT COLD SEALING SALT 458

pH : 5.5-6.0

120 5-10 SEC D.M WATER

WATER RINSE - TWICE

130 1 MIN AIR

DRYING

Note : Do Black Dyeing after Stage 100 Do dye as per specification and wash twice with D.M water and go for Stage 110

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Tin Plating ProcessDocument3 pagesTin Plating Processkrishy76100% (1)

- Ashwani Metals PVT LTD: Process Flow Diagram For Nickel Plating On Brass-ScrewDocument2 pagesAshwani Metals PVT LTD: Process Flow Diagram For Nickel Plating On Brass-Screwpintu sinojiya100% (1)

- Now Purity, Coolness & Freshness Flow Into Your WorldDocument2 pagesNow Purity, Coolness & Freshness Flow Into Your Worldrijothomasv777No ratings yet

- Hahnshin Catalog NewDocument12 pagesHahnshin Catalog NewCESPI-PERUNo ratings yet

- Prius D: Data SheetDocument10 pagesPrius D: Data SheetbudivinolaNo ratings yet

- MAULIDocument5 pagesMAULIPulakPandeyNo ratings yet

- Water ChillerDocument74 pagesWater ChillerDimitri LyssiNo ratings yet

- Models K-40A K-40B K-42C K-42D: Ceramic Mixing Cartridges Conventional Single-Lever Type 40 & 42 MM SizesDocument2 pagesModels K-40A K-40B K-42C K-42D: Ceramic Mixing Cartridges Conventional Single-Lever Type 40 & 42 MM Sizesshenkee-1No ratings yet

- Seplite LSC750 PDFDocument6 pagesSeplite LSC750 PDFDiegoNo ratings yet

- Chemical ChartDocument1 pageChemical ChartSudhanshu DashNo ratings yet

- Centrifugal Pumps (2 HP To 10 HP) : Performance Range MotorDocument2 pagesCentrifugal Pumps (2 HP To 10 HP) : Performance Range MotorSherin PaulNo ratings yet

- WATER STILL Manesty - ManualDocument4 pagesWATER STILL Manesty - ManualPiyush A JoshiNo ratings yet

- Dosing Pump DocumentsDocument7 pagesDosing Pump Documentsbmanojkumar16No ratings yet

- Breakills Alien Lab 19 - EngDocument32 pagesBreakills Alien Lab 19 - Engdrestadyumna ChilspiderNo ratings yet

- LennRO LBW S 1 ENDocument3 pagesLennRO LBW S 1 ENdaveNo ratings yet

- F (C) D Magnetic Float Level Switch - B0Document24 pagesF (C) D Magnetic Float Level Switch - B0Albertus KaryadiNo ratings yet

- Boiler Water Test Bulan MARET 2022Document4 pagesBoiler Water Test Bulan MARET 2022Anto AriNo ratings yet

- Plate Damage As A Result of Delayed Boiling: K. Hallenberger, M. VetterDocument11 pagesPlate Damage As A Result of Delayed Boiling: K. Hallenberger, M. VetterdoufethiNo ratings yet

- Ea-R-19202 Eco Tanning Sheep With Sertan WTDocument1 pageEa-R-19202 Eco Tanning Sheep With Sertan WTsamiNo ratings yet

- Chiller Tripping Points (AutoRecovered)Document34 pagesChiller Tripping Points (AutoRecovered)Saurabh RuhellaNo ratings yet

- Válvula de Presión CheckDocument2 pagesVálvula de Presión CheckronaldNo ratings yet

- Lampiran D.3 Data Spesifikasi Teknis PompaDocument21 pagesLampiran D.3 Data Spesifikasi Teknis PompaEddy ArryNo ratings yet

- Proposal Plant 1Document3 pagesProposal Plant 1shivakumar ctNo ratings yet

- FDX Magnetic Float Level Switch - NewDocument29 pagesFDX Magnetic Float Level Switch - NewWidhi ImranovichNo ratings yet

- Omv rEQUESTDocument1 pageOmv rEQUESTSamir AjiNo ratings yet

- Anodizing Eloxal Guidelines 19.07.2013.2013Document5 pagesAnodizing Eloxal Guidelines 19.07.2013.2013Rade RadićNo ratings yet

- Hot Water-High Pressure Cleaners: Operating ManualDocument56 pagesHot Water-High Pressure Cleaners: Operating ManualOwen BarnesNo ratings yet

- TamPur 130 TDS ASIA 20180403Document2 pagesTamPur 130 TDS ASIA 20180403Ismail Ali AhamedNo ratings yet

- GS02 33 35Document2 pagesGS02 33 35Adal VeraNo ratings yet

- Marine Fuel Stability and CompatibilityDocument1 pageMarine Fuel Stability and CompatibilityAbdul RaheemNo ratings yet

- ABRIVATIONDocument15 pagesABRIVATIONbhag singhNo ratings yet

- FS3Document2 pagesFS3Trần Thanh TiếnNo ratings yet

- Technical Data Sheet Bright Acid Tin Process: Solution Composition: Optimum RangeDocument4 pagesTechnical Data Sheet Bright Acid Tin Process: Solution Composition: Optimum Rangeshanmukha MechanicalNo ratings yet

- R080Z - R180Z Watercooled, 50 HZ TIRZ80/11 SM 6.1 Technical Information Sheet 01/04Document1 pageR080Z - R180Z Watercooled, 50 HZ TIRZ80/11 SM 6.1 Technical Information Sheet 01/04MAZENNo ratings yet

- Honda ProjectDocument40 pagesHonda ProjectUsmanTyagiNo ratings yet

- SF20-22 Poppet, 2-Way, N.C., High Pressure: Solenoid ValvesDocument2 pagesSF20-22 Poppet, 2-Way, N.C., High Pressure: Solenoid ValvesMarcos RodrigoNo ratings yet

- VAMAJA - Audco Valves OfferDocument16 pagesVAMAJA - Audco Valves OfferJKKNo ratings yet

- Industrial Gearbox Oils: Parthan EpDocument20 pagesIndustrial Gearbox Oils: Parthan EpChetan PrajapatiNo ratings yet

- Control Valve DatasheetDocument1 pageControl Valve DatasheetretrogradesNo ratings yet

- HydropompeDocument4 pagesHydropompeReggie TopsNo ratings yet

- Applicable Raw Water Quality (Supplied by Owner) : Well No. 238 Is Not TestedDocument2 pagesApplicable Raw Water Quality (Supplied by Owner) : Well No. 238 Is Not TestedMyungkwan HaNo ratings yet

- Gas Over Oil Actuators PDFDocument12 pagesGas Over Oil Actuators PDFShakeel AhmedNo ratings yet

- TCX TTDSeriesDocument2 pagesTCX TTDSeriespaachangaNo ratings yet

- Fresh Water Generator SONDEX SFD 13 PDFDocument70 pagesFresh Water Generator SONDEX SFD 13 PDFa.amangazinov1995No ratings yet

- Water Meter Data Sheet PDFDocument2 pagesWater Meter Data Sheet PDFKamel MahdiNo ratings yet

- Service Manual: Washing Machine Frontloader AWM 5120Document17 pagesService Manual: Washing Machine Frontloader AWM 5120marian_iaminNo ratings yet

- Dar Breathing Filter Hme SellsheetDocument2 pagesDar Breathing Filter Hme SellsheetmangkunegaraNo ratings yet

- Draft System BalancingDocument5 pagesDraft System BalancinglisluciNo ratings yet

- Nibong-1 Pilot Test 14112015Document4 pagesNibong-1 Pilot Test 14112015Abdullah முகமது جواهرNo ratings yet

- Ultrasonic Couplant Comparison GuideDocument1 pageUltrasonic Couplant Comparison GuideRoyal AccessoriesNo ratings yet

- TDS 103Document5 pagesTDS 103MouResNo ratings yet

- Ferrolex D - 15: Technical DataDocument1 pageFerrolex D - 15: Technical DataukalNo ratings yet

- Extractor Eco BrochureDocument6 pagesExtractor Eco Brochureckyee88-1No ratings yet

- Service Manual: Washing Machine Frontloader AWM 8123Document17 pagesService Manual: Washing Machine Frontloader AWM 8123Gustavo ValdezNo ratings yet

- 165-14 - Instructions Retorta para CutingDocument17 pages165-14 - Instructions Retorta para CutingJuan SersopulosNo ratings yet

- Poroshell120 5991-7352ENDocument4 pagesPoroshell120 5991-7352ENKarinNo ratings yet

- Eletrochemicaldesalter 191231094907Document6 pagesEletrochemicaldesalter 191231094907ShakerMahmoodNo ratings yet

- Pre Firing Water Quality Control Unit 1, 29 Maret - 1 AprilDocument8 pagesPre Firing Water Quality Control Unit 1, 29 Maret - 1 AprilOkta RianaNo ratings yet

- Technical Service Data Sheet: Al Hotseal 460Document2 pagesTechnical Service Data Sheet: Al Hotseal 460Jitendra Kumar SinghNo ratings yet

- Optimisation of Brass Plating Condition in Plating of Patented Steel WireDocument7 pagesOptimisation of Brass Plating Condition in Plating of Patented Steel WireJitendra Kumar SinghNo ratings yet

- Argoshine Bright Silver: Salient FeaturesDocument3 pagesArgoshine Bright Silver: Salient FeaturesJitendra Kumar SinghNo ratings yet

- Technical Service Data Sheet: Ultraclean 130Document2 pagesTechnical Service Data Sheet: Ultraclean 130Jitendra Kumar SinghNo ratings yet

- Electrochem Technologies India Pvt. LTD.,: Analysis InstructionsDocument1 pageElectrochem Technologies India Pvt. LTD.,: Analysis InstructionsJitendra Kumar SinghNo ratings yet

- Analysis Procedure - Hydrochloric AcidDocument2 pagesAnalysis Procedure - Hydrochloric AcidJitendra Kumar SinghNo ratings yet

- Electrochem Technologies India Pvt. LTD.,: Analysis InstructionsDocument1 pageElectrochem Technologies India Pvt. LTD.,: Analysis InstructionsJitendra Kumar SinghNo ratings yet

- TeknosDocument76 pagesTeknosMartin LafonNo ratings yet

- Electrochem Technologies India Pvt. LTD.,: Analysis InstructionsDocument1 pageElectrochem Technologies India Pvt. LTD.,: Analysis InstructionsJitendra Kumar SinghNo ratings yet

- Paras Filter Industries - CatalogDocument4 pagesParas Filter Industries - CatalogJitendra Kumar SinghNo ratings yet

- CBEPL's Rental DG Offer - A S UDTOG - 26.07.21Document3 pagesCBEPL's Rental DG Offer - A S UDTOG - 26.07.21Jitendra Kumar SinghNo ratings yet

- Technical Service Data Sheet: Met Clean 289Document2 pagesTechnical Service Data Sheet: Met Clean 289Jitendra Kumar SinghNo ratings yet

- Technical Service Data Sheet: Acid Inhibitor 311Document1 pageTechnical Service Data Sheet: Acid Inhibitor 311Jitendra Kumar SinghNo ratings yet

- Technical Service Data Sheet: Cupratech Ac 382Document5 pagesTechnical Service Data Sheet: Cupratech Ac 382Jitendra Kumar SinghNo ratings yet

- Paras Filter Industries - CatalogDocument4 pagesParas Filter Industries - CatalogJitendra Kumar SinghNo ratings yet

- C 12 S 20Document21 pagesC 12 S 20Varda ShahidNo ratings yet

- Product - Light Liquid Paraffin / White Mineral Oil / White Oil Light Technical 20Document1 pageProduct - Light Liquid Paraffin / White Mineral Oil / White Oil Light Technical 20Jitendra Kumar SinghNo ratings yet

- Canning Hand BookDocument72 pagesCanning Hand BookJitendra Kumar SinghNo ratings yet

- United States Patent (15) 3,671,408: Martini (45) June 20, 1972Document4 pagesUnited States Patent (15) 3,671,408: Martini (45) June 20, 1972Jitendra Kumar SinghNo ratings yet

- C 12 S 20Document21 pagesC 12 S 20Varda ShahidNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 PipingDocument15 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- WKM Dynaseal 310 Metal Seated Ball Valves 2Document2 pagesWKM Dynaseal 310 Metal Seated Ball Valves 2Khai HuynhNo ratings yet

- Experiment 3: Neutralization Capacity of Commercial Antacid AcidDocument10 pagesExperiment 3: Neutralization Capacity of Commercial Antacid AcidfizaNo ratings yet

- Amberlite™ Hpr2800 H Ion Exchange Resin: Product Data SheetDocument4 pagesAmberlite™ Hpr2800 H Ion Exchange Resin: Product Data SheetsamarthNo ratings yet

- Chem Exam 2 2012Document2 pagesChem Exam 2 2012Britanny NelsonNo ratings yet

- Example. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedDocument4 pagesExample. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedJames NeoNo ratings yet

- DS Barred Tee (Rev)Document2 pagesDS Barred Tee (Rev)Advis100% (2)

- Special Steel Structures - Courses - 2013Document253 pagesSpecial Steel Structures - Courses - 2013Largu George DanielNo ratings yet

- 568 RR Thulasi - CMS Agro Madurai BOQDocument30 pages568 RR Thulasi - CMS Agro Madurai BOQEr S Thirumarai NathanNo ratings yet

- Corrosion Project Presentation SlidesDocument20 pagesCorrosion Project Presentation SlidesIsmeth Amir Johari100% (1)

- PG Metric Threaded CABLE GLANDDocument1 pagePG Metric Threaded CABLE GLANDjigneshNo ratings yet

- Thin-Walled Pressure VesselsDocument18 pagesThin-Walled Pressure Vesselsjomarie apolinarioNo ratings yet

- CE Board Nov 2020 - RCD - Set 3 MonoDocument2 pagesCE Board Nov 2020 - RCD - Set 3 MonoDale MalazzabNo ratings yet

- HILTI Anchor FasteningDocument91 pagesHILTI Anchor FasteningkstayroskNo ratings yet

- Super Blonde ShellacDocument9 pagesSuper Blonde ShellacBudi Budaya BstNo ratings yet

- Edited MSDS TDM 02.05.2022Document1 pageEdited MSDS TDM 02.05.2022Sajjad MaqboolNo ratings yet

- #10 - Energy Balance - 01 (Rev01)Document48 pages#10 - Energy Balance - 01 (Rev01)Valentino LunardiNo ratings yet

- Demoulding of Concrete Cubes From Plastic MDocument4 pagesDemoulding of Concrete Cubes From Plastic MangelinemiuNo ratings yet

- Final Salt AnalysisDocument8 pagesFinal Salt AnalysisAnonymous SomeoneNo ratings yet

- Sculpting With LightDocument15 pagesSculpting With LightMizuho IeiriNo ratings yet

- (Re) Coating of Pylons With ZINGAENDocument5 pages(Re) Coating of Pylons With ZINGAENMarco Antonio MoncerrateNo ratings yet

- Chemical Reactions Test Yourself 3Document2 pagesChemical Reactions Test Yourself 3Nizar MTechNo ratings yet

- CTET Question BankDocument347 pagesCTET Question BankDMNo ratings yet

- SCS Filtration Water Separators - NPDocument1 pageSCS Filtration Water Separators - NPSebastian GanciNo ratings yet

- Science-SQP 2 Term2Document13 pagesScience-SQP 2 Term2Srivatsan BalajiNo ratings yet

- Frame MaterialsDocument29 pagesFrame MaterialsPluviophileNo ratings yet

- Nanoheterostructures For Efficient Hydrogen Evolution Reaction in Alkaline Water ElectrolyzersDocument13 pagesNanoheterostructures For Efficient Hydrogen Evolution Reaction in Alkaline Water ElectrolyzersSirigiri ThrineshNo ratings yet

- Corrosion Testing D Rossi CathodicDocument63 pagesCorrosion Testing D Rossi CathodicRahmat MohsinNo ratings yet

- Batangas State University College of Engineering, Architecture & Fine ArtsDocument4 pagesBatangas State University College of Engineering, Architecture & Fine ArtsJohn Kevin de CastroNo ratings yet