Professional Documents

Culture Documents

Betriebs-Anleitung: Design and Functions

Betriebs-Anleitung: Design and Functions

Uploaded by

Szaby KalmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Betriebs-Anleitung: Design and Functions

Betriebs-Anleitung: Design and Functions

Uploaded by

Szaby KalmanCopyright:

Available Formats

BETRIEBS-

ANLEITUNG

Operating Instructions · Manuel d’opération

Design and Functions

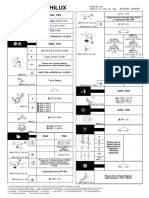

Chucking Stroke-End Monitoring

For hydraulically operated hollow- and solid chucking cylinders

INDEX ABC

INDEX G 200, G 300

INDEX V 200, V 200T

INDEX V 250, V 300

Control INDEX C 200 - 4

LL13 02.1 051 1 - 07.01

0701/KR

Note on applicability

Some illustrations in this publication may deviate slightly from the product supplied, but this will not detract

from their instructional value.

The right of alteration by reason of technical progress is reserved by INDEX.

A word on copyright

This publication is protected by the law of copyright. The rights thereby established, particularly those of

translation, reprinting, extraction of illustrations, reproduction by photo-mechanical or similar means, and

storage in data processing installations, are strictly reserved, even for use as extracts.

Photo-copies for personal and other use of one’s own may only be made of individual sections or parts thereof

as single copies.

© Copyright by INDEX-Werke GmbH & Co. KG Esslingen 2001

Contents

General ............................................................................................................................................................... 4

Where is the chucking stroke end monitoring system situated? ................................................................... 5

Hollow chucking cylinder................................................................................................................................ 7

Inductive proximity switches ............................................................................................................................. 7

Adjusting the chucking stroke end monitoring on the main spindle .............................................................. 8

Checking the adjustment for draw type chucking ...................................................................................... 9

Checking the adjustment for thrust type chucking .................................................................................... 9

Adjusting the chucking stroke end monitoring on the counter spindle ......................................................... 10

Checking the adjustment for draw type chucking ...................................................................................... 11

Checking the adjustment for thrust type chucking .................................................................................... 12

Solid chucking cylinder ................................................................................................................................... 13

Tripping Cam ...................................................................................................................................................... 14

Adjustment of the chucking stroke-end monitoring ........................................................................................ 14

Checking the adjustment for draw type chucking ...................................................................................... 16

Checking the adjustment for thrust type chucking .................................................................................... 16

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 3 –

General

For safety reasons it is absolutely necessary, to use the chucking stroke-end monitoring

with chucking cylinders, which are fitted with a chucking stroke-end monitoring,.

According to the design of the chucking cylinder, this is achieved by various methods.

In the following is described the position of the chucking stroke-end monitoring, its

functions and how it is adjusted.

Enabling is done with machine functions (MAFU).

MAFU 01/03 chucking stroke-end monitoring (main spindle)

(left spindle at V200T)

or

MAFU 03/03 chucking stroke-end monitoring (counter spindle)

(right spindle at V200T)

On delivery of the machine this function is enabled.

Danger of accident

When working with power chucks the MAFU ”chucking stroke-end

monitoring” must not be disabled under any circumstances.

Operation without a workpiece

At operation without a workpiece, the MAFU, "13/02 test run without material”

must be enabled. By this the chucking stroke-end monitoring will be blanked out

apart from other functions.

For operation refer to operating instructions ”Setting up and

Operation C200-4. Enabling and disabling of machine functions are

explained there.

The chucking stroke-end monitoring is adjusted on machines which

are equipped with power chucks by INDEX.

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 4 –

General

Where is the chucking stroke end monitoring

system situated?

INDEX G200, G300 - hollow chucking cylinder

Main spindle Counter spindle

Switch S8.0 and S8.1 S12.0 and S12.1

L1301.10511_1

INDEX ABC - hollow chucking cylinder

Switch S8.0 and S8.1

L1301.10511_6

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 5 –

General

INDEX V200 - solid chucking cylinder

Switch S8.0

L1301.10511_2

NDEX V250, V300 - solid chucking cylinder

L1301.10511_4

L1301.10511_3

Switch S8.0

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 6 –

Hollow chucking cylinder

On the hollow chucking cylinder the monitoring is achieved with a triggering ring and

two longitudinally adjustable inductive proximity switches.

Inductive proximity switches

Retaining Switch Switch Triggering ring

screws S8.0 S8.1

L1301.10511_5

Picture: main spindle - INDEX G200

Switch - S12.0

Switch - S12.1

L1301.10511_5

Picture: Counter spindle - INDEX G200

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 7 –

Hollow chucking cylinder

Adjusting the chucking stroke end monitoring on

the main spindle

S8.0 S8.1

0,4 0,4

Chucking cylinder

L1301.10511_11

Triggering ring when Permissible Triggering ring when

chucking cylinder is chucking range chucking cylinder is

in rear position in front position

Picture: Adjusting the switches S8.0 und S8.1

The power chuck must be fitted

Risk of accident!

Risk through inadvertent start of the spindle or of the machining

program!

The following actions must be performed before removing of covers:

- Select JOG mode.

- Open sliding guard and secure against inadvertent closing.

- Remove the covers from the left machine side.

- Move the chucking cylinder to the rear.

- Slacken the retaining screw for the switch S8.0 and slide the switch over the

triggering ring until both LEDs light up.

- After this, slide the switch S8.0 slowly foreward until the yellow LED goes off

plus further 0,4 mm (see picture "Setting the switches S8.0 und S8.1").

- Tighten the retaining screw.

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 8 –

Hollow chucking cylinder

- Move the chucking cylinder to the front.

- Slacken the retaining screw for the switch S8.1 and slide the switch over the

triggering ring until both LEDs light up.

- After this, slide the switch S8.1 slowly back until the yellow LED goes off plus

further 0,4 mm (see picture "Setting the switches S8.0 und S8.1").

- Tighten the retaining screw.

- Refit the covers on the left machine side.

Checking the adjustment for draw type chucking

MAFU 01/01 "Chucked, cylinder at front” =0

MAFU 01/03 "Chucking stroke-end monitoring" = 1

- Move the chucking cylinder to the front (open the material chucking system).

- Press key CLEAR ERROR MESSAGE.

S121.1

- Move the chucking cylinder to the rear (close the material chucking system)

At correct adjustment the alarm message: "81301/730 CHUCK PATH CONTROL -

Chuck path end when chucking" will be displayed in the alarm-line.

Checking the adjustment for thrust type chucking

MAFU 01/01 "Chucked, cylinder at front" =1

MAFU 01/03 "Chucking stroke-end monitoring" = 1

- Move the chucking cylinder to the rear (open the material chucking system).

- Press key CLEAR ERROR MESSAGE.

S121.1 - Move the chucking cylinder to the front (close the material chucking system)

At correct adjustment the alarm message: "81301/730 CHUCK PATH CONTROL -

Chuck path end when chucking" will be displayed in the alarm-line.

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 9 –

Hollow chucking cylinder

Adjusting the chucking stroke end monitoring on

the counter spindle

S12.1 S12.0

0,4 0,4

Chucking cylinder

L1301.10511_11

Permissible

Triggering ring when chucking range Triggering ring when

chucking cylinder is in chucking cylinder is in

front position rear position

Picture: Adjusting the switches S12.0 und S12.1

Counter spindle

cover

L1301.10511_7

Picture: Counter spindle cover

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 10 –

Hollow chucking cylinder

The power chuck must be fitted

Risk of accident!

Risk through inadvertent start of the spindle or of the machining

program!

The following actions must be performed before removing of covers:

- Select JOG mode.

- Open sliding guard and secure against inadvertent closing.

- Remove the covers from the right machine side and from the counter spindle.

- Move the chucking cylinder to the rear

- Slacken the retaining screw for the switch S12.0 and slide the switch over the

triggering ring until both LEDs light up.

- After this, slide the switch S12.0 slowly foreward until the yellow LED goes off

plus further 0,4 mm (see picture "Setting the switches S12.0 und S12.1").

- Tighten the retaining screw.

- Move the chucking cylinder to the front.

- Slacken the retaining screw for the switch S12.1 and slide the switch over the

triggering ring until both LEDs light up.

- After this, slide the switch S12.1 slowly back until the yellow LED goes off plus

further 0,4 mm (see picture "Setting the switches S12.0 und S12.1").

- Tighten the retaining screw.

- Refit the covers.

Checking the adjustment for draw type chucking

MAFU 03/01 ""Chucked, cylinder at front” =0

MAFU 03/03 "Chucking stroke-end monitoring" = 1

- Move the chucking cylinder to the front (open the material chucking system).

- Press key CLEAR ERROR MESSAGE.

S121.1

- Move the chucking cylinder to the rear (close the material chucking system)

At correct adjustment the alarm message: "81301/730 CHUCK PATH CONTROL -

Chuck path end when chucking" will be displayed in the alarm-line.

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 11 –

Hollow chucking cylinder

Checking the adjustment for thrust type chucking

MAFU 03/01 "Chucked, cylinder at front" =1

MAFU 03/03 ""Chucking stroke-end monitoring" = 1

- Move the chucking cylinder to the rear (open the material chucking system).

- Press key CLEAR ERROR MESSAGE.

S121.1 - Move the chucking cylinder to the front (close the material chucking system)

At correct adjustment the alarm message: "81301/730 CHUCK PATH CONTROL -

Chuck path end when chucking" will be displayed in the alarm-line.

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 12 –

Solid chucking cylinder

On the solid chucking cylinder the monitoring is accomplished by means of a switch

and a longitudinally adjustable tripping cam.

The size of the tripping cam, and the from it resulting chucking range, depend on the

power chuck (refer to section: ”Tripping cam”).

The adjustment of the chucking stroke-end monitoring for the solid

chucking cylinder is described by the example of the INDEX V-

machines.

Switch S8.0

Tripping cam

INDEX V200 L1301.10511_8

Switch S8.0

Tripping cam

INDEX V250, V300 L1301.10511_9

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 13 –

Solid chucking cylinder

Tripping Cam

Various tripping cams are available according to the chucking stroke.

Tripping cam

T60341.10 (Ø30)

T60341 (Ø20)

T-slot nut

T60341.20 (Ø40)

fixing screw

L1301.10511_10

Adjustment of the chucking stroke-end monitoring

The power chuck must be fitted

Risk of accident!

Risk through inadvertent start of the spindle or of the machining

program!

The following actions must be performed before removing of covers:

- Select JOG mode.

- Open sliding guard and secure against inadvertent closing.

- Remove the cover.

- Select the appropriate tripping cam and fit it.

The switch and the tripping cam must be adjusted in such a way

that the switchS8.0 is triggered in the front and in the rear chucking

cylinder position.

- Slacken the tripping cam fixing-screw.

- Then move the tripping cam until the switch S8.0 is triggered.

- By moving the switch horizontally (after slackening the mounting bracket) the

respective chucking stroke ”Y” of the chuck can be adjusted (refer also to Picture:

”Mounting brackets for the switch S8.0).

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 14 –

Solid chucking cylinder

Y

Tripping cam

Switch S8.0

L1301.10511_15

Picture: Adjusting to the chucking stroke ”Y” by shifting the switch.

Mounting bracket Switch Mounting bracket

INDEX V250,V300 S8.0 INDEX V200

L1301.10511_14 L1301.10511_13

Picture: Mounting brackets for the switch S8.0

- Tighten the retaining screws of the bracket and the cam.

;yy; ;yy;

- Now move the chucking cylinder forwards and backwards, in order to check if the

switch S8.0 is triggered in both positions.

;;

yy

y;yy ;;

yy

;;

y;

S8.0

y;yy

;; S8.0

Chucking cylinder at rear y;

Chucking cylinder at the front

L1301.10511_12

- Refit the cover

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 15 –

Solid chucking cylinder

Checking the adjustment for draw type chucking

MAFU 01/01 "Chucked, cylinder at front” =0 1)

MAFU 01/03 "Chucking stroke-end monitoring" = 1 1)

MAFU 03/01 "Chucked, cylinder at front” =0 2)

MAFU 03/03 "Chucking stroke-end monitoring" = 1 2)

- Move the chucking cylinder to the front (open the material chucking system).

- Press key CLEAR ERROR MESSAGE.

- Move the chucking cylinder to the rear (close the material chucking system)

y;y;yy y;y;yy y;y;yy

S121.1

At correct adjustment the alarm message: "81301/730 CHUCK PATH CONTROL -

Chuck path end when chucking" will be displayed in the alarm-line.

;;

;; ;; ;;

y;yy ;;

y;yy ;;

y;yy

chucking range

Permissible

y;

Within the

clamping range

y;

Chucking cylinder

at the front

y; L1301.10511_12

Chucking cylinder

at the rear

Overtravel!

Checking the adjustment for thrust type chucking

MAFU 01/01 "Chucked, cylinder at front" =1 1)

MAFU 01/03 "Chucking stroke-end monitoring" = 1 1)

MAFU 03/01 "Chucked, cylinder at front" =1 2)

MAFU 03/03 "Chucking stroke-end monitoring" = 1 2)

- Move the chucking cylinder to the rear (open the material chucking system).

- Press key CLEAR ERROR MESSAGE.

- Move the chucking cylinder to the front (close the material chucking system)

;yy;yy ;yy;yy ;yy;yy

S121.1

At correct adjustment the alarm message: "81301/730 CHUCK PATH CONTROL -

Chuck path end when chucking" will be displayed in the alarm-line.

;; ;; ;;

;;

y;yy ;;

y;yy ;;

y;yy

chucking range

Permissible

y;

Within the

clamping range

y;

Chucking cylinder

at the front

Overtravel!

y;

Chucking cylinder

at the rear

L1301.10511_12

1) INDEX V200 and V200T left machine - 2) INDEX V200T right machine

Chucking Stroke-End Monitoring - INDEX G200, G300, ABC, V200…V300

– 16 –

INDEX-Werke GmbH & Co. KG

Hahn & Tessky

Postfach 10 03 54

D-73726 Esslingen

Fax (0711) 3191 - 587

E-Mail TED@INDEX-Werke.de

You might also like

- LL1302 - 10186-Indexare SpindelDocument11 pagesLL1302 - 10186-Indexare SpindelSzaby Kalman100% (1)

- Betriebs-Anleitung: Option For The ControlDocument40 pagesBetriebs-Anleitung: Option For The ControlAmir Hodzic100% (1)

- LL1602 10184Document18 pagesLL1602 10184Amir Hodzic100% (1)

- Ly1302 10332Document2 pagesLy1302 10332Amir Hodzic100% (1)

- Betriebs-Anleitung: Option For The ControlDocument54 pagesBetriebs-Anleitung: Option For The ControlAmir Hodzic100% (1)

- LH1402 - 10013 MBLDocument48 pagesLH1402 - 10013 MBLSzaby Kalman100% (2)

- Betriebs-Anleitung: Option To The MachineDocument8 pagesBetriebs-Anleitung: Option To The MachineAmir HodzicNo ratings yet

- Betriebs-Anleitung: Option For The MachineDocument13 pagesBetriebs-Anleitung: Option For The MachineAmir HodzicNo ratings yet

- LL1302 - 10332-Functiile MasiniDocument16 pagesLL1302 - 10332-Functiile MasiniSzaby Kalman100% (1)

- LL1302 40011-ProgramareDocument60 pagesLL1302 40011-ProgramareSzaby Kalman100% (1)

- TM Functional Safety 07 2011 enDocument229 pagesTM Functional Safety 07 2011 enWaldemarNo ratings yet

- Betriebs Anleitung: Attachment Bar Loading MagazineDocument48 pagesBetriebs Anleitung: Attachment Bar Loading MagazineAmir Hodzic100% (1)

- Betriebs-Anleitung: Programming HintsDocument44 pagesBetriebs-Anleitung: Programming HintsAmir Hodzic100% (1)

- Gv-500&780 Operation Manual 04 VerDocument395 pagesGv-500&780 Operation Manual 04 VersunhuynhNo ratings yet

- Dat A Interfaces F or Heidenhain Controls of The Series: Service ManualDocument98 pagesDat A Interfaces F or Heidenhain Controls of The Series: Service ManualMariusz DubasNo ratings yet

- AC Servopack CACR-SRxxBE Operation ManualDocument28 pagesAC Servopack CACR-SRxxBE Operation ManualcoronaqcNo ratings yet

- Ransport and Installation Instructions CTX 510 EcoDocument32 pagesRansport and Installation Instructions CTX 510 EcoMiliano FilhoNo ratings yet

- Site Preparation Guide: Systemdocumentation Cellcube FB 200Document32 pagesSite Preparation Guide: Systemdocumentation Cellcube FB 200pr3m4nNo ratings yet

- 17 HK63Document39 pages17 HK63faqall0% (1)

- YCM500AW Operatin Manual - InglésDocument107 pagesYCM500AW Operatin Manual - InglésConociendoANuestraGenteNo ratings yet

- L150 - 210 Series SAFETY (E) Rev.11084859872753034548980Document111 pagesL150 - 210 Series SAFETY (E) Rev.11084859872753034548980АндрейNo ratings yet

- Betriebs-Anleitung: Option For The MachineDocument60 pagesBetriebs-Anleitung: Option For The MachineSzaby Kalman100% (2)

- EP3 Use ManualDocument321 pagesEP3 Use Manualalejandro becerraNo ratings yet

- CAK36 ElectricalDocument33 pagesCAK36 Electricals_barriosNo ratings yet

- Beginner's ManualDocument47 pagesBeginner's ManualBenny Firdaus100% (2)

- Hyundai WIA SKT15 21 Series Technical DataDocument20 pagesHyundai WIA SKT15 21 Series Technical Datasunhuynh100% (1)

- MVP 8040 Operators Manual Mveqth00 (Awea)Document224 pagesMVP 8040 Operators Manual Mveqth00 (Awea)Anonymous regHjENo ratings yet

- Service Manual: July 2010Document264 pagesService Manual: July 2010Luis Manuel Batlle AguileraNo ratings yet

- VM1 PLWD r02x2-304Document241 pagesVM1 PLWD r02x2-304ag cnc & wedm machining shopNo ratings yet

- 01 - FB200 User Manual, 003396, EN, 2013-11-20, V2.01 PDFDocument53 pages01 - FB200 User Manual, 003396, EN, 2013-11-20, V2.01 PDFpr3m4n0% (1)

- CNC Centurion 7 Programming Manual 179Document441 pagesCNC Centurion 7 Programming Manual 179Алексей ДоронинNo ratings yet

- Seicos 21l IntrustionDocument61 pagesSeicos 21l IntrustionkhoaNo ratings yet

- Mechanical Technical CTX Beta 1250 TCDocument296 pagesMechanical Technical CTX Beta 1250 TCsetmeinNo ratings yet

- CNC Emco Turn 365 PDFDocument362 pagesCNC Emco Turn 365 PDFDiego Fernando Cadena ArangoNo ratings yet

- Yaskawa CACR-HR Series ManualDocument122 pagesYaskawa CACR-HR Series ManualsunhuynhNo ratings yet

- Manual FanucDocument6 pagesManual FanucWermeson SousaNo ratings yet

- B-62114en 03 050120Document183 pagesB-62114en 03 050120CONG TRAN NGOCNo ratings yet

- Qp2040-l Fanuc 0imdDocument267 pagesQp2040-l Fanuc 0imdAlbertoQuezadaNo ratings yet

- Siemense CNC 48SP2Document19 pagesSiemense CNC 48SP2Xaoc KabataNo ratings yet

- Recomendaciones HDD Sinumerik 840c CHD - Empf - 76Document7 pagesRecomendaciones HDD Sinumerik 840c CHD - Empf - 76Antonio de la TorreNo ratings yet

- Pulse Generator A860-0201-T001 Fanuc DatasheetDocument7 pagesPulse Generator A860-0201-T001 Fanuc DatasheetDany HernandezNo ratings yet

- HurcoLathe Max Start r0115-101Document108 pagesHurcoLathe Max Start r0115-101rastaeggNo ratings yet

- M300 M300-V Programming ManualDocument361 pagesM300 M300-V Programming ManualAndey RibalkoNo ratings yet

- FZ08 Fanuc Bed12 20Wz BA10 2000 ENDocument40 pagesFZ08 Fanuc Bed12 20Wz BA10 2000 ENCristian Gasca PatiñoNo ratings yet

- Vt-1150 User ManualDocument22 pagesVt-1150 User ManualAnne RodriguesNo ratings yet

- 802Dsl AlarmesDocument438 pages802Dsl AlarmesWagner Rodolfo da SilvaNo ratings yet

- Cnctrain Fanuc0M: CNC Simulation Systems 1995 2010Document51 pagesCnctrain Fanuc0M: CNC Simulation Systems 1995 2010Siti Idah TawhidNo ratings yet

- 21 Series Mill Controller Operation Manual: Date: 2013/11/08Document138 pages21 Series Mill Controller Operation Manual: Date: 2013/11/08Saif Uddin Ahmed100% (1)

- B-65012E03 AC Spindle Motor Series (SPVH) Descriptions 1987Document322 pagesB-65012E03 AC Spindle Motor Series (SPVH) Descriptions 1987John BacsikNo ratings yet

- Operator Manual Num10xx SerieDocument393 pagesOperator Manual Num10xx SeriePius Studer100% (1)

- Manual Lista Parametros MDDocument1,264 pagesManual Lista Parametros MDLincoln AntonioNo ratings yet

- YCM NSV SeriesDocument26 pagesYCM NSV SeriesCNC SYSTEMSNo ratings yet

- P7ME In-Process Programming ManualDocument405 pagesP7ME In-Process Programming ManualConstantin DumitruNo ratings yet

- M&H Probing ManualDocument52 pagesM&H Probing ManualWietse van der Steen100% (1)

- Separate Detector Interface (B-63943EN - 02)Document18 pagesSeparate Detector Interface (B-63943EN - 02)Heriberto SalazarNo ratings yet

- Siemense SM 06 04 23 76Document17 pagesSiemense SM 06 04 23 76skidamdnevnoNo ratings yet

- Operators Manual: Victor 2 / Victor 2 Plus / Victor 2 SuperDocument55 pagesOperators Manual: Victor 2 / Victor 2 Plus / Victor 2 SuperToniNo ratings yet

- Mitsubishi Manuals 1351Document21 pagesMitsubishi Manuals 1351Roohollah TavassoliNo ratings yet

- ABB IRB 6400 Servo Change ManualDocument21 pagesABB IRB 6400 Servo Change ManualAntonio SanchezNo ratings yet

- Siemens Controls: Geared MotorsDocument30 pagesSiemens Controls: Geared MotorsDavid AguilarNo ratings yet

- Maintenance InstructionsDocument30 pagesMaintenance InstructionsAmir HodzicNo ratings yet

- Betriebs-Anleitung: Option For The MachineDocument13 pagesBetriebs-Anleitung: Option For The MachineAmir HodzicNo ratings yet

- Betriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Document28 pagesBetriebs-Anleitung: Bar Loading Magazine Index LM 3200 LM 3700 LM 4200Amir HodzicNo ratings yet

- Betriebs-Anleitung: Programming HintsDocument44 pagesBetriebs-Anleitung: Programming HintsAmir Hodzic100% (1)

- LL1602 10141Document100 pagesLL1602 10141Amir HodzicNo ratings yet

- Betriebs-Anleitung: Option To The MachineDocument8 pagesBetriebs-Anleitung: Option To The MachineAmir HodzicNo ratings yet

- Betriebs Anleitung: Attachment Bar Loading MagazineDocument48 pagesBetriebs Anleitung: Attachment Bar Loading MagazineAmir Hodzic100% (1)

- Notes On Operating Materials: General InformationDocument18 pagesNotes On Operating Materials: General InformationAmir HodzicNo ratings yet

- Ponedjeljak Utorak Srijeda Četvrtak PetakDocument1 pagePonedjeljak Utorak Srijeda Četvrtak PetakAmir HodzicNo ratings yet

- Arabiyyah Bayna Yadayk Book 1Document403 pagesArabiyyah Bayna Yadayk Book 1Al Huda75% (12)

- Engle SkiDocument1 pageEngle SkiAmir HodzicNo ratings yet

- Hydraulic TurbinesDocument45 pagesHydraulic TurbinesAshlin Augusty100% (1)

- Practice Workbook: Designing Steel StructuresDocument29 pagesPractice Workbook: Designing Steel StructuresdodogogdoNo ratings yet

- Old Papers of TNPSC VAO Solved 2010 With AnswersDocument4 pagesOld Papers of TNPSC VAO Solved 2010 With AnswersKarthik VijayNo ratings yet

- LPG For Heavy Duty Engines 2017Document116 pagesLPG For Heavy Duty Engines 2017Neagoie Sergiu100% (1)

- KDENDocument104 pagesKDENRobert BrownNo ratings yet

- Final Seminar Report GrapheneDocument24 pagesFinal Seminar Report GrapheneDinesh Chahal75% (4)

- Door DHR-2B Manual V1Document6 pagesDoor DHR-2B Manual V1angela1590No ratings yet

- QSI PartsDocument76 pagesQSI PartsAdrian CantaragiuNo ratings yet

- Hilux: GGN, TGNDocument26 pagesHilux: GGN, TGNbelkaidaNo ratings yet

- Security Services For E-Mail Attacks Possible Through E-Mail Establishing Keys Privacy Authentication of The Source Message Integrity Non-RepudiationDocument76 pagesSecurity Services For E-Mail Attacks Possible Through E-Mail Establishing Keys Privacy Authentication of The Source Message Integrity Non-RepudiationPapithaNo ratings yet

- Stress DistributionDocument25 pagesStress DistributionAbdul RehamanNo ratings yet

- Service Manual: Das Herz Der Heizung The Heart of HeatingDocument94 pagesService Manual: Das Herz Der Heizung The Heart of HeatingCedric ChatonNo ratings yet

- Sourcebook 4 - Tech Manual (v0.9)Document448 pagesSourcebook 4 - Tech Manual (v0.9)James Myers86% (7)

- CTC V40: Installation-And Maintenance InstructionsDocument52 pagesCTC V40: Installation-And Maintenance Instructionsvitalii pinteaNo ratings yet

- Lecture 13 Production DrawingDocument28 pagesLecture 13 Production DrawingLiaquat khanNo ratings yet

- Analysis of Bond Stress Distribution For Prestressing Strand by StandardDocument8 pagesAnalysis of Bond Stress Distribution For Prestressing Strand by StandardSameerKareeeemNo ratings yet

- Presentation1 1Document15 pagesPresentation1 1DARK STRANGERNo ratings yet

- HYSYSDocument390 pagesHYSYSEfosaUwaifoNo ratings yet

- Module1 IntroductionDocument13 pagesModule1 Introductionmarlo ignacioNo ratings yet

- Chap 9 Indices, Exponentials and Logarithms Part 1 PDFDocument44 pagesChap 9 Indices, Exponentials and Logarithms Part 1 PDFArahNo ratings yet

- Chapter 8 Slope and Deflection Strength of Materials Part 1 PDFDocument14 pagesChapter 8 Slope and Deflection Strength of Materials Part 1 PDFsivaNo ratings yet

- Capacitive and Inductive Proximity SensorsDocument16 pagesCapacitive and Inductive Proximity Sensorsislamooov100% (1)

- Example 11 Cast in Place Concrete Cantilever Retaining Wall - 20200101Document15 pagesExample 11 Cast in Place Concrete Cantilever Retaining Wall - 20200101Angela GonzálezNo ratings yet

- Service Conditions - SBI - As On June 2008Document73 pagesService Conditions - SBI - As On June 2008ashiquekumar100% (1)

- Manual 315 PDFDocument155 pagesManual 315 PDFNikitsoNo ratings yet

- Drilling and BlastingDocument5 pagesDrilling and BlastingPramodNo ratings yet

- 150 67-Eg1Document104 pages150 67-Eg1rikoNo ratings yet

- 303-07A+Engine+IgnitionDocument4 pages303-07A+Engine+IgnitionP HandokoNo ratings yet

- Controlled Blasting Techniques: National Institute of Technology Karnataka, SurathkalDocument17 pagesControlled Blasting Techniques: National Institute of Technology Karnataka, SurathkalNikhil Ranjan0% (1)

- FERRERO Extensometer Uncertainty Fullpaper IMEKO TC 8Document9 pagesFERRERO Extensometer Uncertainty Fullpaper IMEKO TC 8pawanNo ratings yet