Professional Documents

Culture Documents

Cum-04-E (Cyw-Duo User Manual) (Rev

Uploaded by

bashar mohammedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cum-04-E (Cyw-Duo User Manual) (Rev

Uploaded by

bashar mohammedCopyright:

Available Formats

CYW-DUO

Endoscope Washer & Disinfectors

Operator’s Manual

5Fl., Joongil Eines Platz III, 519, Dunchon-daero, Jungwon-gu, Seongnam-si, Gyeonggi-do 462-807, Korea

Tel: +82 31 747 9900, Fax: +82 31 747 9901 http://www.choyangmed.com

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 1 / 73

© 2014, Endoscope Washer & Disinfectors

Choyang Medical Industry Ltd.

All rights reserved. This publication is protected by copyright. Copying, disclosure to

others or the use of this publication is prohibited without the express written consent of

Choyang.

Choyang reserves the right to make changes in the specifications shown herein without

notice or obligation. Contact your Choyang representative or Choyang customer service

for more information.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 2 / 73

Contents

- Contents 3

Chapter 1 Device information 5

1.1 Overview 5

1.2 Principle of operation 5

1.3 Regulatory information 6

1.4 Disinfectants information 6

1.5 Resistance of corrosion 6

Chapter 2 Labeling information 7

2.1 General Labeling 7

2.2 Rating Label 8

Chapter 3 Intended Purpose 9

3.1 Intended Purpose 9

3.2 Product Features 9

Chapter 4 Device Description 10

4.1 The body 10

4.2 Accessories 11

4.3 Configuration 12

4.4 LCD Panel 14

Chapter 5 Technical Specifications 15

5.1 Product Specifications 15

5.2 Wiring Diagram 16

5.3 List of critical component parts 17

Chapter 6 Installation 19

6.1 Unpacking and Inspection 19

6.2 Space Requirements 19

6.3 Environmental requirements 19

6.4 Packaging List 20

6.5 Line Power Considerations 20

6.6 Water & Drain Connection 20

Chapter 7 How to use 21

7.1 General 21

7.2 Preparing the Unit for Operation 21

7.3 Power Supply 22

7.4 Water supply 22

7.5 Detergent Supply 22

7.6 Alcohol Supply 23

7.7 Disinfectant Supply 24

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 3 / 73

7.8 Endoscope Pre-cleaning 25

7.9 Available items for Endoscope washer & 26

disinfector

7.10 Time setting 26

7.11 Pre-start inspection 27

7.12 Load in the basin 28

7.13 Leakage Test 30

7.14 Automatic 33

7.15 Manual 36

7.16 Configuration 44

7.17 Printing system 55

7.18 Preparing the Unit for Transportation/Storage 55

Chapter 8 Maintenance 56

8.1 Introduction 56

8.2 After Service Information 56

8.3 Components Replacement 57

8.4 Disinfectant and Detergent lists 58

8.5 Cleaning/Disinfection 58

8.6 Self Disinfection System 59

8.8 Product lifetime 60

Chapter 9 Troubleshooting 61

9.1 General 61

9.2 Error message 62

9.3 Troubleshooting Guide 67

Chapter 10 Danger, Warning, Caution 69

10.1 Danger 69

10.2 Warning 69

10.3 Caution 70

Chapter 11 Condition for use and transfer 72

11.1 Condition for use 72

11.2 Condition for transfer / storage 72

Chapter 12 Product Approval and Quality Assurance 73

This product is certified as a medical device in the European Union under the Medical

Device Directive 93/42/EEC by SGS CE0120, exclusively for the intended purpose of

disinfects and washes medical flexible endoscope with chemical disinfectant.

Other non-medical uses ascribed to this device are not within the scope of CE certification,

and users should be aware product performance and/or safety has not been evaluated by

SGS for those purposes

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 4 / 73

CHAPTER

1

Device information

1.1 Overview

This is a medical device which automatically washes and disinfects the internal

channels and external surface of used Flexible endoscope with disinfecting fluid,

detergent, water (general water) and alcohol by nozzle. This product is composed

of main body, Grid, Accessory basket, Channel tube, Residual drain tube, Suction

tube, Leakage tester’s red tube, Leakage tester’s connector cap (OPTION), Channel

connector adapter (OPTION), Water supply & Drain Adapter.

1.2 Principle of operation

- After filling device with detergent, water and disinfectant, put endoscope in Basin.

- After power switch is on, select washing conditions according to requirements.

- detergent, disinfectant and water are supplied by motor’s power according to setting

condition and air is supplied in order to improve efficiency of washing and then

washing is implemented. Drain pump and lines are prepared to be able to drain

waste water which are made at this time.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 5 / 73

1.3 Regulatory information

Name, postal address, conformity assessment route of:

Product Name Endoscope Washer & Disinfector

Models CYW-DUO

Places of CHOYANG MEDICAL INDUSTRY LTD.

*Production 5Fl., Joongil Eines Platz III, 519, Dunchon-

*Final tests for above mentioned daero, Jungwon-gu, Seongnam-si, Gyeonggi-

products do 462-807, Korea

Tel: +82 31 747 9900,

http://www.choyangmed.com

Conformity Assessment Route 93/42/EEC Annex II

Class Endoscope Washer & IIb

Disinfector

Rule 15

1.4 Disinfectants information

The disinfectant used in this product should be the product that is developed as a

endoscope disinfectant. The following series disinfectant are used.

- OPA (Ortho-Phthalaldehyde)

- GA (Glutaraldehyde)

- PA (Peracetic Acid)

- CD (chlorine dioxide).

1.5 Resistance of corrosion

This product is made with sufficient materials to prevent the corrosion by disinfectant.

- Chamber; ABS material

- Pipe; PE material

- Nipple; STS 316

- Pump part; Rubber

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 6 / 73

CHAPTER

2

Labeling information

2.1 General Labeling

Symbol Descriptions Symbol Descriptions

CE Mark Serial Number

Model Type B Applied Part

Manufacturer Temperature limitation

EU Authorized

Humidity limitation

Representative

Refer to user’s Atmospheric pressure

manual limitation

User’s(Instruction)

Caution

Manual

Warning Electric shock

Danger Earth (ground)

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 7 / 73

Date of Waste Electrical and

Manufacturer Electronic Equipment

Fragile, handle with

UP/DOWN Position

care

Keep dry

2.2 Rating Label

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 8 / 73

CHAPTER

3

Intended Purpose

3.1 Intended Purpose

It disinfects and washes medical flexible endoscope with chemical disinfectant.

3.2 Product Features

This device is composed of Basin that endoscope can be put in, tank that disinfectant,

alcohol and detergent are stored in and pump and distributor to supply and distribute

these materials. This device’s disinfection type is the deposition disinfecting type by

deposition of endoscope and the recycling type that disinfectant is recycled.

Side effect

- Unpleasant irritating odor

- Bacteria which does not contain spore was moved.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 9 / 73

CHAPTER

4

Device Description

4.1 The body

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 10 / 73

4.2 Accessories

Water supply & Drain Adapter Grid Accessory basket

Channel tube Residual drain tube Suction tube

Channel Connector 6EA

Leakage tester’s Channel connector adapter

Leakage tester’s red tube

connector cap (OPTION) (OPTION)

Olympus Pentax Fujinon Olympus Pentax Fujinon

Depending on the endoscope you Depending on the endoscope

can choose one cap. you can choose one adapter.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 11 / 73

4.3 Configuration

No. Title Explanation

1) Top cover Automatic open/close system.

2) LCD panel It is a part to control operations.

3) Power switch It is a switch to apply the power to device.

4) Foot switch Open/Close the Top cover.

5) Spray arm Spray water on the surface of endoscope

6) Printer It prints operating time and its completion after product

operation

7) Caster Wheel for a move.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 12 / 73

No. Title Explanation

1) Top cover lifting It is a module to operate Top cover.

module

2) RS-232 Serial port Connect printer and scanner

3) Back cover It is a part that can be opened when repairing internals.

4) Overflow port Connect hose for drain of overflow water & disinfectant

5) Drain-R It is a connecting part that connects drain hose on the right

Chamber.

6) Drain-L It is a connecting part that connects drain hose on the left

Chamber.

7) Electric circuit It is a device that shuts off the power when Over-current is

breaker made.

8) Fuse It is a device that shuts off the power when Over-current is

made.

9) Power cable It is a fixing cable that supplies the power AC 220-230V.

10) Water inlet It is a part to connecting with supplying hose.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 13 / 73

4.4 LCD Panel

No. Title Explanation

1 TIME and DATA Set the current time and date.

2 AUTOMATIC All procedures will be finished according to memorized

cycle program.

3 MANUAL If you want to perform an additional or individual cycle, you

can choose each cycle parameter.

- Time set: Leakage, Wash, Detergent, Disinfectant,

Alcohol and Air dry.

- Temp. set : Disinfectant

- Drain, Retank and Discharge function.

4 Config You can set all the parameters in this menu

5 7/50 Cycle counting

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 14 / 73

CHAPTER

5

Technical Specifications

5.1 Product Specifications

Design Specifications Title Specifications

Electrical voltage and

220-230VAC, 50/60Hz, 670VA

frequency

Leakage – Wash 1 – Air blow 1 – Detergent - Wash 2 – Air

Automatic Process blow 2 – Disinfectant – Wash 3 – Immersion drain – Air

blow 3 – Alcohol purge – Air dry

- Water : 10sec ~ 250sec (unit : 1sec)

- Detergent : 5sec ~ 250sec (unit : 1sec)

- Disinfectant : 1min ~ 120min (unit : 1min)

Time

- Air : 10sec ~ 250sec (unit : 1sec)

- Immersion drain : ON/ON, ON/OFF, OFF/ON, OFF/OFF

- Alcohol purge : 10sec ~ 250sec (unit : 1sec)

- Disinfectant : 20 liters X 2ea (Right, Left)

- Detergent : 1.5 liters

Tank capacity

- Alcohol : 1.5 liters

- Water : 25 liters

Chamber capacity 13 liters (Dual Basin)

- Air pressure : 0.3㎏f/㎠

Leakage Test

- Check time : about 4mins

Tank heat 0 ~ 55℃

Fuse (EN 60127-2) 250VAC, 10A

Type of protection against

Class 1, B Type

electric shock

Dimensions(mm) 790 x 960 x 1036 ( W x Lx H )

Weight 140 kg

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 15 / 73

5.2 Wiring Diagram

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 16 / 73

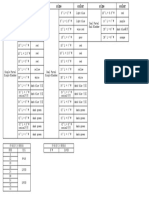

5.3 List of critical component parts

Part name Manufacturer Type/Model Technical Standards Mark(s) of

/Trademark Data Conformity

Power supply DONGYANG DYP-G15B 250 V, 16A KS C 60227-5 KTC (HH04028-

cords 12026A)

Fuse LITTELFUSE 0312010HX 250V, 10A IEC 60127-2 KTL (SU05001-

6008)

Noise Filter TDK-LAMBDA MB-1210 250 V, 10 A IEC 60939-2 UL

CORP (E141509)

ELB SATURN SIB-30 220 V, 30 A K60947-2 ERI

(JA05004-7001)

Enclosure LG CHEMICAL TR300 Overall UL 94 UL

LTD 55.0cm by (67171)

45.0cm by

4cm, 4 mm

thick, Rated

minimum FV-

0 flame

rating.

Main switch EVEREL SX82178B1 250V, 16A UL 61058-1 UL

GROUP SPA E210000 (E67171)

(SIGNAL LUX)

SMPS(12Vdc) MEAN WELL RPS-60-12 12Vdc, 10 A UL 60601-1 UL

(E98133)

SMPS(24Vdc) MEAN WELL MPS-120-24 24Vdc, 10 A UL 60601-1 UL

(E227340)

Sol-valve SNV Co. SNV2W 220V, AC 7W EN 60730-1 CE

/ DC 8W EN60730-2-8

Booster pump CSE CO., LTD. BSP-2500A 220V, 60Hz, Tested in

MAX.Pressur appliance

e: 2.5kgf/㎠,

Flow:

2000ml/min

Disinfectant PAN WORLD NH-40PX 220V, 60Hz, EN 60034 CE

Pump CO., LTD. 50W

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 17 / 73

Water/Drain PAN WORLD NH-100PX- 220V, 60Hz, EN 60034 CE

Pump CO., LTD. ZZ 200W

Air Pump G&M Tech Inc. 12RNS 220V, 2.5bar EN 60204-1 TUV

EN 60034-1

Photo coupler LITE-ON MOC3041 Viso UL 1577 UL(E113898)

in PCB TECHNOLOGY 7.5kVpeak

CORP

Terminal DEGSON 2EDGV-TR- 300V UL 1059 UL

5.0

Floating DAHAN DLF-103 150m𝞨 IEC 61010-1 CE

contact

Sensor SENSOR CO resistance.

LTD 10M𝞨

insulation

resistance

Connector YEON HO YH396NNV, 250V 7.5A, UL 1977 UL

V-0

ELECTRONICS YH396-NNIR UL 94 (E108706)

CO LTD UL

(E67171)

Electric ball VALCON AT12-3T 12 Vdc, 850 EN61000-6-1 CE

valve COMPANY mA EN61000-6-3

LIMITED

Terminal DEGSON 2EDGV- 300 V, 15 A UL 1059 UL

block in PCB ELECTRONICS THR-5.0 Min. FV-0 UL60947-7-1 (E228872)

CO LTD flame rating. UL 94

PCB KINGBOARD KR-6150C Min. FV-0 UL 94 UL

LAMINATES KB-6155 flame rating. (E123995)

HOLDINGS

LTD

Wire Ming- MJ-09 10A / 250V EN 60799 CE

Jun electric

wire factory

Leakage TECHNO CD-5S 220V, 38mA IEC 61010-1 Tested in

pump TAKATSUKI appliance

CO., LTD.

Thermal cut WOO SUNG MS-1 250V, 7.5A EN 60730-1 TUV

out ELECS CO., EN 60730-2-9 (N810117560100

LTD. 1)

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 18 / 73

CHAPTER

6

Installation

6.1 Unpacking and Inspection

The CYW-DUO automatic endoscope washer &

disinfector system has passed full quality assurance

testing before shipment. Thus, the unit should be

operated upon delivery. The unit should be unpacked,

installed and tested only by an authorized Choyang

Medical representative.

6.2 Space Requirements

The working area for CYW-DUO should be prepared

according to the dimensions shown in figure on the right.

6.3 Environmental requirements

Do not install the device in the following

places

- Unstable or inclined surfaces.

- Outdoors or places that exposed the gases (ex.

Sulfurous acid gas, chlorine etc.) or high humidity.

Environmental conditions

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 19 / 73

- See the chapter 11

6.4 Packaging List

The CYW-DUO packaging list includes the following:

1. CYW-DUO unit

2. Grid 2EA

3. Accessory basket 2EA

4. Channel tube Channel Connector 6EA

5. Residual drain tube 2EA

6. Suction tube

7. Leakage tester’s red tube 2EA

8. Leakage tester’s connector cap (OPTION)

9. Channel connector adapter (OPTION)

10. Water supply & Drain Adapter

11. Operator’s manual

6.5 Line Power Considerations

The unit is delivered factory-set for the proper ac line voltage rating of the country to which

it is shipped. The ac line voltage appears on the label affixed to the rear panel.

The unit is equipped with a power cable – one end for connection at the rear panel of the

unit, the other end with a 2-pin plug for connection to a single-phase ac receptacle, suited

to the labeled power rating.

Electric power cable 3m long (supplied) with plug for local power source

6.6 Water & Drain Connection

The device is gravity-drained it is essential that the distant drain is lower than the water at

the rear part of device.

The best drainage conditions are achieved by installing the distant drain connection less

than 20cm from ground level and not more than 1m distant.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 20 / 73

CHAPTER

7

How to use

7.1 General

This chapter contains detailed operating instructions for the CYW-DUO unit. For easy

reference, a checklist-type summary of procedures for the entire operation is also included.

7.2 Preparing the Unit for Operation

1. Remove the box covering from the unit.

2. Water supply pressure ( more than 3kgf/cm2) is checked.

3. Connect the Accessoriest on the unit.

4. Required amount of the chemical liquid tank is filled.

5. Plug the appropriate end of the power cable into the 230V~ connection point on

rear panel of the unit, and the other end into a suitable AC outlet.

Disinfectant expiration: The specification of disinfectant

manufacturer. Refer to 8.4

Do not reuse Detergent & Alcohol

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 21 / 73

7.3 Power Supply

1. Plug in the power cable to the power supply.

2. Turn on the circuit breaker on the back and on/off switch on the front of the device.

* The LED indicators on the LCD display show that the power is switched on.

Checking the Power Line voltage. Use AC Voltage

Measurement Mode in the tester to measure the power voltage.

Make sure that the power voltage is in the range of 230V~,

50Hz

7.4 Water supply

1. Turn on the water supply valve.

2. Turn off the water supply valve when the device is not in

use.

* Water can be supplied by pressing on/off switch. Level

sensor that prevents liquid in basin from overflowing is

installed.

* It is required to use under 3kgf/cm2 water pressure.

* Potable water is the minimum standard. Incoming water

must be pre-filtered to minimum of 0.45 microns. The water filter is included with

the device. The routine maintenance schedule recommends every 6 months or

sooner, depending on the pre-filtration system and the quality of the incoming

water.

Water supply pressure (more than 3kgf/cm2) is checked

7.5 Detergent Supply

Open the center front door and open the detergent tank cap and pour detergent.

You can easily check the level of detergent with level sensing electrode.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 22 / 73

* Select a detergent solution that has bacteriostatic properties to inhibit bacterial

growth in the detergent reservoir and detergent line. The dual enzymes in the

detergent rapidly attack soils and the low foam properties aid effective recirculation.

Follow the manufacturer’s dilution and temperature recommendations.

* If you do not choose the detergent which is needed to use at room temperature,

please first consult with the manufacturer of this device.

Never use household detergent in the device.

Do not reuse Detergent

7.6 Alcohol Supply

Open the alcohol tank cap and pour alcohol. You can easily check the level of

alcohol with level sensing electrode.

* Choyang medical recommends use of Isoprophylene alcohol(IPA).

Above the 70% IPA can use the disinfection purpose.

Do not reuse Alcohol

Alcohol Detergent

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 23 / 73

7.7 Disinfectant Supply

1. You can pour it into basin and press re-tank button on the LCD panel after going

through manual mode.

2. Disinfectant is filled up into the tank. You can check the level of disinfectant with

disinfectant level gauge. Make sure disinfectant tank is empty before you pour

disinfectant to the tank.

3. You can see the above message after the retank process is completed.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 24 / 73

* Select a low-foaming, high level disinfectant specifically manufactured for high-level

medical instrument disinfection. The product must be capable of destroying M.

tuberculosis.

* Consult the product label for appropriate contact time and temperature when

programming the disinfection cycle.

Do not mix with detergents or other chemicals

* Disinfectants must be monitored for potency on a daily basis. Consult the

disinfectant manufacturer recommendations for monitoring guidelines.

* Use the manufacturer’s test strips to test the potency of the solution on a daily basis.

If the potency of the solution is below its minimum recommended concentration

discard and replace it with fresh solution.

* Never use disinfectant beyond the manufacturer’s recommended reuse life, even if

the potency levels are acceptable.

* Never use disinfectant with unacceptable potency levels, even if the reuse date is

unexpired.

7.8 Endoscope Pre-cleaning

All endoscopes must be pre-cleaned prior to disinfection.

Before connection the channels of the endoscopes to adaptors on the device,

manual pre-cleaning is required to minimize contamination.

Follow the endoscope manufacturer instructions and established professional

guidelines to properly pre-clean the endoscope.

The following are the usual method.

1. Washing a secretion or blood on the surface of endoscope right after examination.

2. Brushing inside of biopsy channel (use a brush supplied by endoscope

manufacturer)

3. All channels allow the free passage of water without any blockage.

Refer to the endoscopes manufacturer’s instructions to verify that all channels are

free from obstructions.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 25 / 73

7.9 Available items for Endoscope washer & disinfector

1. It is recommended that only stainless-steel instruments to avoid corrosion.

2. Only clean and disinfect thermolabile instruments using a chemical process.

Heat-stable endoscopic accessories should be thermally disinfected and

sterilized.

3. Generally this device is for four types of flexible endoscopes as below.

4. CHOYANG MEDICAL INDUSTRY LTD. provides specification about the

endoscope information to be used, as established during disinfection testing.

- Type : GASTROINTESTINAL VIDEOSCOPE

- Insertion tube Outer Diameter : Ø 9.8mm

- Channel Size : Ø 2.8mm

- Working Length : 1030mm

- Total Length : 1350mm

7.10 Time Setting

You can set time for every cycle parameter and save it and choose it in normal

operation.

Select service mode by pressing ‘Config’ ‘Service’ button.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 26 / 73

In this mode, you can change every parameter time setting by pressing up-down

button after select each parameter. The color of selected parameter value will be

turned to red.

After finishing time setting, press ‘ENTER’ button in order to save the parameters

into the buffer memory.

In auto or manual, if any failures of operation even after

pressing start/stop button, press drain button in manual mode

for all water out then start/stop again.

7.11 Pre-start Inspection

Use the following procedure to inspect the device before startup.

1. Check the incoming water quality. Replace any dirty pre-filtered.

2. Add the detergent and alcohol, if “tank low” alert is appeared on the LCD display.

3. Check the disinfectant reuse life expiration date for both tanks. Replace expired

disinfectant.

4. Test the disinfectant in both tanks for potency. Replace any disinfectant that has

less than acceptable potency levels.

5. Make sure there is no leak.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 27 / 73

7.12 Load in the basin

7.12.1 How to place endoscope

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 28 / 73

7.12.2 Channel Connection Guide

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 29 / 73

7.12.3 Connect & Disconnect Method of Channel tube

1. Assemble the channel tubes and the channel connector adapter as the below picture.

2. Connect the endoscope’s channel and device’s

channel.

(Refer to each endoscope manufacture’s manual for

connecting.)

3. Put all of accessories in the accessory basket.

4. Push the channel button in the basin to

disconnect the

channel tube.

7.13 Leakage Test

After you finish preparation process, you are ready to operate CYW-DUO. This is the

main screen.

We have two different types of leakage test, Manual or Real-time.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 30 / 73

It is essential to carry out a manual leakage test.

Follow the manufacturer’s instructions when performing a

manual leakage test prior to disinfection procedures.

Connect water-resistant cap and leakage tester’s connector cap. Then, place endoscope

into the basin.

Water-resistant cap on the endoscope should be covered.

Pentax Olympus

Before

connecting

the water-

resistant

cap

After

connecting

the water-

resistant

cap

1. Real-time leakage test

A. You can check leakage of endoscope during reprocessing cycle. Automatic

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 31 / 73

leakage test is performed before washing 1 cycle just after pressing automatic

button in main screen or leakage button in manual mode. Then, CYW-DUO

checks the leakage air pressure between cycle and cycle. If there is any

problem on leakage air pressure.

B. Temperature range of real-time leakage test : 15℃ ~ 60℃

2. Manual leakage test

A. If you select manual leakage test, leakage check will be passed during

automatic cycle. In this case, you should check leakage before the cycle in

CYW-DUO manual mode or during pre-cleaning cycle.

B. Manual leakage test in Manual mode

i. Place the endoscope into basin. Connect water-resistant cap and leakage

test adapter.

ii. Press leakage button.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 32 / 73

iii. Water supplied into basin 5 seconds after supplying air inside of endoscope.

After filling up the basin up to basin level sensor, top cover will be opened

automatically.

You can check air bubbles from endoscope. Move insertion tube up and

down, right and left because bending section is very sensitive area. If any

bubble found, first of all, the endoscope must be taken out immediately and

repaired.

iv. If you press complete button, top cover is closed and water is drained out

and leakage test air will be released automatically. Detach leakage tester

adapter for next procedure.

7.14 Automatic

7.14.1 Automatic process

You can choose automatic or manual in this main screen. If you choose automatic,

you can see the following screen. You can stop by ‘ESC’ button or pause by ‘PAUSE’

button.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 33 / 73

After finishing the whole cycle, you can see the following message.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 34 / 73

7.14.2 User checklist

In order to ensure the process fluids flow, please check these lists.

1. All channels of endoscopes should be free passage of water before loading in the

basin.

2. All connections were made before, and were still in place after finishing the whole

cycle.

If the LEAK TEST connectors were not connected to the

ENDOSCOPES, It can result in serious DAMAGE to

ENDOSCOPES.

7.14.3 Description of each process

1. LEAKAGE

- Test intended to confirm that the surface covering the endoscope is intact.

- Control the supplied pressure 290mbar by regulator.

- Leakage air pump specification :

medical compressed air (oil/fat free)

Maximum air pressure : 320mbar

2. WASH 1

- Wash the dust off endoscope’s inside and surface

- Channel cleaning and washing spray

3. DETERGENT

- Remove soil and bio-film on endoscopes using diluted detergent

4. WASH 2 :

- Rinse the detergent

5. DISINFECT :

- Disinfect endoscopes by filling up basin with disinfectant

- Re-tank the disinfectant after this process.

6. WASH 3 :

- Final rinsing of the endoscopes

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 35 / 73

7. ALCOHOL

- Alcohol blowing through the channels

8. AIR DRY

- Air purging rinse water from the channels of the endoscopes

- Air pump specification :

Applications : Medical, Dental & E.N.T. Equipments

As an oil-less air compressor and vacuum

Free Flow : 20 LPM / Max. Vacuum : 650mmHg / Max. Pressure : 6 bar

* All solutions except disinfectant are discharged after each process.

* The endoscope and the channels of the endoscope should be dried prior to storage

in accordance with the manufacturer’s instructions.

7.15 Manual

If you choose manual, you can see the following screen.

You can select each cycle operation, leakage, washing, detergent, disinfection,

alcohol purging and air drying. Also, you can operate drain, retank and discharge.

You can go to main screen by pressing ESC button.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 36 / 73

7.15.1 Leakage

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 37 / 73

7.15.2 Washing

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 38 / 73

7.15.3 Disinfection

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 39 / 73

7.15.4 Air Drying

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 40 / 73

7.15.5 Drain

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 41 / 73

7.15.6 Retank

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 42 / 73

7.15.7 Discharge

After disinfectant’s reusable life or beyond acceptable potency level, you should change

the disinfectant according to the instruction. Then, go to ‘manual’ ‘discharge’. After

discharge process is finished, the cycle counting will be changed into ‘0’. Refer to the

factory setting section for cycle counting parameter setting.

If you press ‘discharge’ button, you may see the above screen. Press ‘start’ button for

discharging disinfectant down to the drainage.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 43 / 73

Please remove all remain disinfectant through disinfectant outlet which is located under

the disinfectant tank after finishing automatic discharging process. Refer to 3.4

Preparation section.

7.16 Configuration

Press ‘config’ button in order to enter configuration mode.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 44 / 73

You can see three sub-menus in configuration mode. Service, Memory and Barcode.

If you want to go to main screen, press ESC.

7.16.1 Service

1. Leakage

A. Choose real-time leakage test or manual leakage test.

2. Wash 1

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 45 / 73

A. Set washing 1 cycle time with up-down button.

B. Set range of wash : off, 10sec ~ 250sec(every 1sec)

C. If you set the time “off”, it will be skipped.

3. Air blow 1

A. This is between Wash 1 and Detergent.

B. Set range of air : off, 5sec ~ 250sec(every 1sec)

4. Detergent

A. Set detergent cycle time with up-down button.

B. Set range of detergent : off, 5sec ~ 250sec(every 1sec)

C. If you set the time “off”, it will be skipped.

D. We recommend using medical grade detergent, such as enzymatic detergent.

Do not use household detergent in the device.

5. Wash 2

A. Set washing 2 cycle time with up-down button.

B. Set range of wash : off, 10sec ~ 250sec(every 1sec)

C. If you set it as 0 sec, it will be skipped.

6. Air blow 1

A. This is between Wash 2 and Disinfectant.

B. Set range of air : off, 5sec ~ 250sec(every 1sec)

7. Disinfectant

A. Set Disinfection cycle time with up-down button.

B. Set range of disinfectant : off, 5sec ~ 250sec(every 1sec)

C. If you set the time “off”, it will be skipped.

D. Please follow the manufacturer’s instruction of high level disinfectant.

8. Wash 3

A. Set washing 3 cycle time with up-down button.

B. Set range of wash : off, 10sec ~ 250sec(every 1sec)

C. If you set the time “off”, it will be skipped.

9. Immersion Drain

A. Immersion drain means filling up basin with water and drain it out. You can

choose immersion drain function in order to reduce the chance of dilution

between disinfectant and water.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 46 / 73

B. There are 4 options in this function.

i. ON/ON, ON/OFF, OFF/ON, OFF/OFF

10. Air blow 3

A. This is between Wash 3 and Alcohol Purge.

B. Set range of air : off, 5sec ~ 250sec(every 1sec)

C. If you set the time “off”, it will be skipped.

11. Alcohol Purge

A. Set alcohol purging cycle time with up-down button.

B. Set range of alcohol : off, 5sec ~ 250sec(every 1sec)

C. If you set the time “off”, it will be skipped.

D. This function is upon user’s choice. If you want to use alcohol to help drying

channel inside, we recommend using 70% hospital grade alcohol solution.

12. Air Dry

A. Set air drying cycle time with up-down button.

B. Set range of air : off, 5sec ~ 250sec(every 1sec)

C. If you set the time “off”, it will be skipped.

13. Refill Date

A. This is related with reuse life of disinfectant. If you set 14 days according to the

disinfectant instruction, alarm will be appeared after 14 days from the date you

discharge and retank disinfectant.

B. Set reuse life with up-down button. If you don’t want it, set it as maximum.

* Please press enter to save all the parameter value. If you press esc button, you can

go back to configuration screen without saving.

7.16.2 Memory

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 47 / 73

You can save 10 specific parameters to memory field or load it from memory field. If you

want to change default parameter, go to service mode, section 4.4. Refer to figure as

above.

1. Memory field

A. You can choose any memory field and set parameters.

B. When you use this Memory screen, it is highly recommended to use stylus pen

for touch screen.

7.16.3 Barcode

You can build your own database management system in CYW-DUO. The input method

is key board in touch screen and barcode reader.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 48 / 73

Click the blank box in red box.

You can type it with keyboard above or scan barcode with scanner reader. Then, press

OK to save or ESC to go back.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 49 / 73

You can add, modify or delete titles in red box. Press ADMIN for title change. Then, you

will see the following screen.

When you press ADD or MODIFY button, you will see the screen above. You can type

the title or scan barcode.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 50 / 73

Also, you can delete titles.

If you select barcode function on both screens at the same time, you will see the

following error screen because there is only one barcode reader.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 51 / 73

7.16.4 Factory

There is factory setting mode in order to set technical parameters. Press SERVICE

button for 5 seconds.

1. Self-disinfection

A. You can adjust time for self-disinfection. This time setting is for circulation of

disinfectant through water line.

B. When you press the ‘SELF DISINFECTION’ button for 5 seconds, self disinfection

process operates. (Refer to chapter 6.3 Maintenance _ self-disinfection)

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 52 / 73

2. Detergent

You can adjust the amount of detergent for detergent cycle. And you can also

calibrate the detergent pump.

3. Disinfectant

A. This is for setting temperature of high level disinfectant. Sometimes, we should

heat up disinfectant according to instruction from manufacturer in order to get the

best result.

B. The maximum temperature is up to 55 degrees 53terili.

4. Alcohol

A. You can adjust the amount of alcohol for alcohol purging cycle.

5. Disinfectant date/transfer

A. This is for optional disinfectant transfer function. Contact Choyang representative

for more information.

6. ETC

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 53 / 73

A. Printer: ON/OFF toggle

B. Complete Bell: Number of complete bell when process is completed. ‘0’ means no

bell.

C. Language: You are able to change language by language editor. Contact Choyang

representative for more information.

D. Barcode: ON/OFF toggle

E. Detergent Immersion: Default status of detergent cycle is spraying type. If you

want to fill the basin with water during detergent cycle, toggle the parameter ON.

F. Transfer Set Count: You can limit the numbers of reuse according to the regulation

from disinfectant manufacturer or Infection control department in your hospital.

G. Transfer Set Date: You can set start and end date of current disinfectant manually.

This is used in special occasion. Default value is as below.

H. Leakage Alarm : ON/OFF toggle

I. Channel Alarm : ON/OFF toggle

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 54 / 73

7.17 Printing system

You will get a printed reprocessing cycle result whether it is completed successfully or

failed.

Date : Date

Time : Time

Scope No. : Making out manually Scope

No. after printing

Basin : Left basin or Right basin

Total working : Operating time for each mode

Leakage :

Washing (sec) :

Rinsing (sec) :

Disinfecting (min) :

Disinfection temperature : The specification of disinfectant

manufacturer. Refer to 8.4

7.18 Preparing the Unit for Transportation/Storage

When the unit is to be transported to another location or stored, the following must be

performed

1. Disconnect the power cable.

2. Disconnect the water supply and drain hose.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 55 / 73

CHAPTER

8

Maintenance

8.1 Introduction

This chapter contains the CYW-DUO Endoscope Washer-Disinfectors systems routine

inspection and maintenance instructions. Only those procedures designated herein may

be carried out by clinic/hospital staff. All other procedures designated herein may be

performed only by CHO YANG MEDICAL-authorized technical personnel.

8.2 After Service Information

The CYW-DUO Endoscope Washer-Disinfectors system generates high voltages within the

main cabinet. Therefore, the interior of the unit should be checked by CHOYANG

MEDICAL authorized technical personnel only.

All correspondence with your CHOYANG representative, regarding the unit, should include

the model and serial numbers appearing on the identification label.

Policy

When the problem occurs due to the problem of the manufacturer, the A/S shall be

provided for 2 year at no cost. Other than that, if the problems occur due to the

delivery of the hospital, treatment and the wrong use etc, separate cost will be

requested. For the A/S that occurs in foreign countries such as in EU etc, it shall

be processed through the regional agency and our producer will take responsibility

for the provision of components etc.

When medical accidents or recall etc happens and they are due to the

inappropriateness of the device, the producer will take the whole responsibility.

Other than that, free A/S can be decided depending on the contract with the

customer.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 56 / 73

8.3 Components Replacement

1. Fuse

To check and/or replace the fuses on the auxiliary panel, turn off the unit and

disconnect

Before removing a fuse turn off the key switch, remove the power

cable from the power receptacle and wait approximately two

minutes to allow for high voltage discharge.

For continuous protection against fire hazard, replace fuses only

with the same type and rating of fuse. Fuse type is slow-blow

10A/250V or equivalent.

For exact fuse rating, refer to the fuse listing on the rear panel.

2. Printer paper

① Pull the small cover to open it and remove the used paper roll.

② Install the new paper roll. At this point, unroll several inches of the paper from

the new roll.

③ Put the printer cover back.

④ Press “Print button” to adjust the tension.

3. UV lamp

- HOUR METER equipped on the device means working time of the device.

- Replace the UV lamp in the water tank when hour meter display more than

8,000hours or after 11months

- Replace the UV lamp in the water tank when the lights of UV detector on the

device turns off.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 57 / 73

8.4 Disinfectant and Detergent lists

Disinfectant Detergent

- MATRIX (Whiteley Medical)

8.5 Cleaning / Disinfection

Keeping the device clean improves its performance, reduces unnecessary repairs,

and lengthens its life.

You should keep basin dry after use.

It’s best to clean spills on the outside of device as they occur. Use a soft damp cloth

to gently wipe away spills and dust. Do not use benzene and thinner. It can be

cleaned with a neutral detergent or alcohol using a clean, soft cloth.

If you decide to dispose of this device, please observe local waste disposal

regulations.

Remove the power cable from the ac outlet before cleaning /

Disinfecting with liquids.

1. Basin cleaning

- Open the lid after using the device to keep dry in the basin. (Except when long

term disused.)

- Periodically wipe the inside of the lid and the basin with a dry soft cloth to

remove any dirt or liquid.

- Level sensor in the basin : Open the cap of the level sensor and softly clean

the sensor with a endoscope brush. Carefully screw on the cap again.

- Channel connection(PMCD) in the basin : Clean the inside of channel

connection(PMCD) with a endoscope brush.

2. Disinfectant filter cleaning

- The cleaning procedure is needed when debris is in the disinfectant filter.

- Open the disinfectant filter cap to the right which is located in front of the frame.

- After taking out the filter net and removing the debris, start to wash with water.

- The cleaned filter net is in place and screwed the disinfectant filter cap.

Unless the disinfectant filter cap is not properly closed, the leak

might occur during disinfectant procedure.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 58 / 73

8.6 Self Disinfection System

- Required to be disinfected for water lines.

- This action should be performed every 3 months at least.

- This action should be operated without endoscopes or accessories in the basin.

1. Select self disinfection mode by pressing

‘Config’ → ’SERVICE’ (for 5seconds) → ‘SELF DISINFECTION’ (for 5 seconds.)

You can see the message as below. Press the ‘START’ button.

2. Water tank will be empty automatically.

There is a possibility that there is still some small amount of water bottom of water tank.

Open the water faucet (water discharging hole) located bottom inside of front door and

take all this water out as well. Then close the water faucet again.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 59 / 73

3. Pour new fresh disinfectant chemical or alcohol over basin about 8~15 liters following

the message. Then, press the ‘CONTINUE’ button.

4. Disinfectant chemical or alcohol flows into water tank as much time as you set.

When finished, buzzer will sound and the complete message will appear as below.

Press the ‘EXIT’ button.

8.7 Product lifetime

5 years

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 60 / 73

CHAPTER

9

Troubleshooting

9.1 General

Should the Cho Yang MEDICAL Endoscope Washer-Disinfectors unit malfunction, consult

the Troubleshooting Guide in this chapter to identify the possible cause.

Hospital staff may perform the troubleshooting procedures in this chapter, except where

specifically stated that troubleshooting must be carried out by Choyang MEDICAL –

authorized technical personnel only.

Improper use or adjustment of this device may invalidate the

Choyang MEDICAL Service Warranty Agreement. Contact your

Choyang MEDICAL representative before any attempt to

troubleshoot this unit in any manner other than as specified in this

manual.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 61 / 73

9.2 Error message

9.2.1 Basin is not empty

1. Press stop button when the basin is not empty. Go to manual mode and drain out

remains.

2. Otherwise, press continue button to proceed selected cycle or check drain sensor.

9.2.2 Black out

1. If the system was black out, you can proceed remain cycle by pressing continue

button.

2. Otherwise, you can select another cycle in order to reprocess it again

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 62 / 73

9.2.3 Channel blocking

1. Follow regional instruction for channel blockage.

2. We recommend continuing remain cycle because you have to disinfect and clean

endoscope before checking channel blockage of endoscope. After finish the whole

cycle, you can get a failure report. Separate the endoscope from the completed

endoscopes. Go to manual mode and press AIR DRY button in order to check

channel blockage of the device.

3. Otherwise, check the channel blockage of endoscope by its manufacturer or

representatives.

9.2.4 Communication error

1. Communication failure when the connection line between main board and display

board has problem.

2. Check its tightness of connection or contact your service representative.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 63 / 73

9.2.5 Leakage error

1. Normal leakage test air pressure is 290mbar. If the pressure of leakage test air is

below 240mbar checking at 1 minute intervals, leakage error sign is displayed in

the screen. And then the device keeps trying to maintain leakage test air level by

working air pump continuously.

2. We recommend continuing remain cycle because we have to disinfect and clean

endoscope before checking leakage of endoscope. After finish the whole cycle, go

to manual mode and press LEAKAGE button or connect manual leakage tester in

order to check leakage of endoscope manually.

3. Otherwise, check the leakage of endoscope by its manufacturer or representatives.

9.2.6 Door is open

1. Close the door before you do any operation.

2. If you see this warning sign when it is closed, contact your service representative

to check door sensor.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 64 / 73

9.2.7 High temperature

1. The maximum temperature of disinfectant is 55℃. If it exceeds this value, you will

see the following screen.

2. Choose continue or stop the cycle. We recommend checking temperature sensor

or contact your service representative.

3. When disinfectant tank reaches up to 70℃, thermostat(non-self return type) will be

operate to prevent overheating.

9.2.8 High or Low level alerts

1. There are 3 kinds of tank, Detergent, Alcohol and Disinfectant.

2. If the Alcohol or Detergent tank is almost empty, you can see the following

message.

3. Fill up the tanks with proper solutions.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 65 / 73

4. In case of Disinfectant, there are 2 sensors, level high and level low. Check tank

level.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 66 / 73

9.2.9 Cycle counting

1. You should set the maximum number of cycle depending on the hospital regulation

or disinfectant you use.

2. You can see the following message after the fixed maximum number of disinfectant

cycle.

3. The disinfectant must be replaced normally.

9.2 Troubleshooting Guide

PROBLEM POSSIBLE CAUSE SOLUTION

Does not supply the * The power is not connected. * Connect the power cable.

power. * Power switch is turned off. * Turn on the power switch “ON”.

* The fuse is broken or the circuit * Replace the fuse or repair the

breaker is out of order. Circuit breaker.

The water supply does * Water supply valve is not open. * Check that the water supply

not work. * Water supply pump error. valve is open.

* Change or repair water supply

pump.

Disinfectant is not * The shortage of disinfectant. * Supply disinfectant.

supplied. * Disinfectant supply valve or pump * Change or repair disinfectant

error. supply valve or pump.

Disinfectant is supplied, * Drain electric valve error. * Change or repair drain electric

but do not stay in the * Water level sensor is out of order. valve.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 67 / 73

basin * Check, repair or change water

level sensor.

Disinfectant is supplied, * Main board error. * Check or repair main board.

but overflow in the basin * Water level sensor in the basin is out * Check, repair or change water

of order. level sensor.

Drainage is not flow out * Drain pipe is closed. * Check the drain pipe and

* Drain valve is out of order. remove dust.

* Check, repair or change water

level sensor.

During the leakage test, * Air pump error. * Check or repair air pump.

the air is not supplied

When the water increase * Check the water supply valve or * Replace new part.

in water tank sensor of 2 step, high and middle in

water tank.

“Water low” sign appear * Check water supply opening valve. *Check sensor of bottom in

on screen during * Check sensor of bottom in water water tank.

machine is working tank.

“Disinfectant low” sign * Check disinfectant in tank. * Check sensor.

appear on screen during * Check sensor of bottom in

machine is working disinfectant tank.

Drain or re-drain motor * Try to change motor valves each. * Replace new motor valve

valve is not working * Together check bad one. (MV1/MV2).

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 68 / 73

CHAPTER

10

Danger, Warning, Caution

10.1 Danger

- Disinfectant expiration: the specification of disinfectant manufacturer. Refer

to 8.4

10.2 Warning

- No modification of this equipment is allowed. Do not modify this equipment

without authorization of the manufacturer.

- Please do not use not-grounded power outlet. It may be a cause of electric

shock.

- Attempted servicing of this device with the help of persons not authorized by

Choyang medical may have lethal consequences and will immediately void

any warranty.

- Do not reuse Detergent & Alcohol

- Never use household detergent in the device.

- Disinfection time : The specification of disinfectant manufacturer. Refer to 8.4

- Disinfectant expiration : The specification of disinfectant manufacturer. Refer

to 8.4

- Disinfection temperature : The specification of disinfectant manufacturer.

Refer to 8.4

- Before removing a fuse turn off the key switch, remove the power cable from

the power receptacle and wait approximately two minutes to allow for high

voltage discharge.

- Remove the power cable from the ac outlet before cleaning / Disinfecting

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 69 / 73

with liquids

- Unless the disinfectant filter cap is not properly closed, the leak might occur

during disinfectant procedure.

- If the LEAK TEST connectors were not connected to the ENDOSCOPES, It

can result in serious DAMAGE to ENDOSCOPES.

10.3 Caution

- The user should use the device according to this operator’s manual.

- Checking the Power Line voltage. Use AC Voltage Measurement Mode in

the tester to measure the power voltage. Make sure that the power voltage is

in the range of 230V~, 50Hz.

- Do not install the device in the following places

1) Unstable or inclined surfaces.

2) Outdoors or places that exposed the gases (ex. Sulfurous acid gas,

chlorine etc.) or high humidity.

- Do not use it with the medical device with big occurrence of electromagnetic

waves in the surroundings. It can cause the failure of the device.

- Serviceman shall be careful not to damage internal wiring. Operator or

patient may have electric shock by internal wiring damage.

- Water supply pressure (more than 3kgf/cm2) is checked.

- Do not mix with detergents or other chemicals.

- In auto or manual, if any failures of operation even after pressing start/stop

button, press drain button in manual mode for all water out then start/stop

again.

- It is essential to carry out a manual leakage test.

Follow the manufacturer’s instructions when performing a manual leakage

test prior to disinfection procedures.

- Water-resistant cap on the endoscope should be covered

- For continuous protection against fire hazard, replace fuses only with the

same type and rating of fuse. Fuse type is slow-blow 10A/250V or

equivalent.

- Environmental conditions. Refer to chapter 11.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 70 / 73

- Improper use or adjustment of this device may invalidate the Choyang

MEDICAL Service Warranty Agreement. Contact your Choyang MEDICAL

representative before any attempt to troubleshoot this unit in any manner

other than as specified in this manual.

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 71 / 73

CHAPTER

11

Condition for use and transfer

11.1 Condition for use

Hospital Room

Physical Ambient temperature(Device); 15℃ ~ 40℃

Conditions Relative Humidity; 30 ~ 80%

Atmospheric pressure; 80kPa-106kPa

11.2 Condition for transfer / storage

Ambient temperature; -20℃~70℃

Physical

Relative Humidity; 10 ~ 90%

Conditions

Atmospheric pressure; 50kPa-106kPa

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 72 / 73

CHAPTER

12

Product Approval and Quality Assurance

Our Endoscope Washer & Disinfector (model: CYW-DUO) is

approved CE mark in accordance with Medical device directive

93/42/EEC of Europe.

The standards of our quality system and product are as follows ;

- ISO 9001: 2008

- ISO 13485: 2003

- KGMP(Korean Good Manufacturing Practices)

CHOYANG MEDICAL INDUSTRY LTD.

5Fl., Joongil Eines Platz III, 519, Dunchon-daero, Jungwon-gu,

Seongnam-si, Gyeonggi-do 462-807, Korea

Tel: +82 31 747 9900 Fax : +82 31 747 9901

MEDISERV TECHNOLOGIES ITALIA

Piazza A. Graf, 132-10126

Tel.; +39 011 6670443

(Dec. 09, 2014, Rev.4) CHOYANG MEDICAL INDUSTRY LTD. 73 / 73

You might also like

- Alcon Centurion Operators Manual ScannedDocument197 pagesAlcon Centurion Operators Manual ScannedhernandezzNo ratings yet

- Constellation AlconDocument10 pagesConstellation Alconnelson hurtado lNo ratings yet

- (MRK-3100P) Service ManualDocument92 pages(MRK-3100P) Service ManualAnderson Caires AbdallaNo ratings yet

- Foco - Berchtold Chromophare D-300,530,650 - User ManualDocument40 pagesFoco - Berchtold Chromophare D-300,530,650 - User ManualRafael AlbuquerqueNo ratings yet

- 453564282181-G60g70g80-Lp-Sg-Eng 2.0Document114 pages453564282181-G60g70g80-Lp-Sg-Eng 2.0Guille MaierNo ratings yet

- Whitestar Signature Pro Operator Manual PDFDocument218 pagesWhitestar Signature Pro Operator Manual PDFLuis EsparzaNo ratings yet

- OPMI-Lumera-i EN 32 010 0106IDocument8 pagesOPMI-Lumera-i EN 32 010 0106IEdward Valderrama0% (1)

- Instructions For Use Tau Clave 3000 Fractionated Vacuum: Tau Steril S.N.C Via Gorizia, 6/a Fino Mornasco (CO)Document14 pagesInstructions For Use Tau Clave 3000 Fractionated Vacuum: Tau Steril S.N.C Via Gorizia, 6/a Fino Mornasco (CO)7777777777777-733005No ratings yet

- PathCentre Service Manual PDFDocument210 pagesPathCentre Service Manual PDFTom Barnston0% (1)

- User List SurajDocument241 pagesUser List SurajAbiNo ratings yet

- Statim 5.1 Field Troubleshooting Guide PDFDocument59 pagesStatim 5.1 Field Troubleshooting Guide PDFLeandro Neves de Oliveira100% (1)

- Atom Incu I Service Manual & Parts List P5Document42 pagesAtom Incu I Service Manual & Parts List P5Diego DiazNo ratings yet

- Voluson E6 PDFDocument362 pagesVoluson E6 PDFCristiano Bolla Fernandes100% (1)

- Highjump OverviewDocument30 pagesHighjump OverviewVenkatasubramanian SivagnanasundaramNo ratings yet

- Stryker 1488Document10 pagesStryker 1488Victor Hugo Lazarte Gonzalez100% (1)

- ElectroFusion Installation Manual (European Version)Document44 pagesElectroFusion Installation Manual (European Version)Jorge BaronNo ratings yet

- Manual de Usuario Autorefractometro Viewlight RK-11 EnglishDocument50 pagesManual de Usuario Autorefractometro Viewlight RK-11 EnglishCarol Sanchez50% (2)

- CSEC English B Paper 02 May 2019Document28 pagesCSEC English B Paper 02 May 2019Kelly LightbourneNo ratings yet

- Zeiss OPMI Vario User ManualDocument264 pagesZeiss OPMI Vario User Manualguaji159100% (3)

- Service ManualDocument168 pagesService ManualiyadNo ratings yet

- Quantel Medical Optimis II Service ManualDocument68 pagesQuantel Medical Optimis II Service ManualAbi50% (2)

- SM - 30 - 4043 - A2 - en - Image Recovery - PartitionRecovery PDFDocument13 pagesSM - 30 - 4043 - A2 - en - Image Recovery - PartitionRecovery PDFGerald Florian VasquezNo ratings yet

- CLM 3100 Service ManualDocument69 pagesCLM 3100 Service ManualAnderson Caires AbdallaNo ratings yet

- SM - 30 - 4043 - A1 - en - Service Instructions VISUCAM Lite PDFDocument39 pagesSM - 30 - 4043 - A1 - en - Service Instructions VISUCAM Lite PDFGerald Florian Vasquez100% (5)

- Service ManualDocument84 pagesService ManualRonald GabrielNo ratings yet

- Ophthalmometer: Instruction ManualDocument38 pagesOphthalmometer: Instruction ManualSergio SuarezNo ratings yet

- Best Practice Warehouse Labeling & Bin-LocationsDocument20 pagesBest Practice Warehouse Labeling & Bin-LocationsNathan WeiserNo ratings yet

- EG600WRDocument80 pagesEG600WRbacbaphi88100% (4)

- ARK 1a ARK 1 - OME - 30712 P902 B PDFDocument104 pagesARK 1a ARK 1 - OME - 30712 P902 B PDFAzzam SaputroNo ratings yet

- Nickel Cadmium Battery MsdsDocument2 pagesNickel Cadmium Battery MsdsSuns Wahjoedhi100% (2)

- 1188 Vs 1288 SystemDocument2 pages1188 Vs 1288 SystemNacho Andrade B100% (1)

- FI FF450 Downloads BrochureDocument4 pagesFI FF450 Downloads BrochureBlancaGuzmanGranados50% (2)

- Whitestar Signature Service Manual ActualizadoDocument274 pagesWhitestar Signature Service Manual Actualizadoisrael garza100% (1)

- GALILEI G6 Operator ManualDocument40 pagesGALILEI G6 Operator Manualjuana100% (3)

- Erbe ICC-200 - Instruction ManualDocument8 pagesErbe ICC-200 - Instruction ManualFrancisco AvilaNo ratings yet

- Manual Cavitron Bob Cat ProDocument76 pagesManual Cavitron Bob Cat ProAndres FelipeNo ratings yet

- VISUCAM Lite (From October 2003) Service Manual: Version 10/2003 Order No. 1263-690 MS-TDDocument50 pagesVISUCAM Lite (From October 2003) Service Manual: Version 10/2003 Order No. 1263-690 MS-TDGerald Florian Vasquez0% (2)

- Visucam 200 Si 500 PDFDocument96 pagesVisucam 200 Si 500 PDFMirela Marinescu100% (4)

- Alcon Phaco Machine Series 20000 Legacy - Service Manual PDFDocument400 pagesAlcon Phaco Machine Series 20000 Legacy - Service Manual PDFJean Marr100% (2)

- 1088HDCameraOperatingManual PDFDocument46 pages1088HDCameraOperatingManual PDFHelpmedica IDINo ratings yet

- OTV-S200: Visera Elite Ii Video System CenterDocument2 pagesOTV-S200: Visera Elite Ii Video System CenterMarcos RojasNo ratings yet

- HumaLyte Plus User PDFDocument52 pagesHumaLyte Plus User PDFAyaovi Jorlau75% (8)

- Medical Batteries CatalogueDocument32 pagesMedical Batteries CatalogueSerdar KartalcıNo ratings yet

- Bexen Reanibex 700 Defibrillator - User Manual PDFDocument197 pagesBexen Reanibex 700 Defibrillator - User Manual PDFEnrique CasfiNo ratings yet

- SATO Barcode Programming Language PDFDocument286 pagesSATO Barcode Programming Language PDFWiranto SihimNo ratings yet

- HyBase 1000 Service Manual 2013-05 (EN)Document36 pagesHyBase 1000 Service Manual 2013-05 (EN)waldirNo ratings yet

- Medi Pump PDFDocument8 pagesMedi Pump PDFwiroarNo ratings yet

- Equipo de Organos Welch Allyn PocketDocument3 pagesEquipo de Organos Welch Allyn PocketpaolaNo ratings yet

- CUM-02-E (CYW-201 User Manual) (Rev.2)Document30 pagesCUM-02-E (CYW-201 User Manual) (Rev.2)Miguel DiazNo ratings yet

- Bci-Cat-9200 Advisor Vital Signs MonitorDocument2 pagesBci-Cat-9200 Advisor Vital Signs MonitorAbraham AlmirudisNo ratings yet

- Vitron 2020 User ManualDocument18 pagesVitron 2020 User ManualMas Adi Wijaya KusumaNo ratings yet

- Cataract Surgery Catalog: The Exclusive 1.8 MM Solution From Bausch & LombDocument6 pagesCataract Surgery Catalog: The Exclusive 1.8 MM Solution From Bausch & LombcwsalesproNo ratings yet

- 1926-User Manual PDFDocument25 pages1926-User Manual PDFBashar MohammadNo ratings yet

- S9 Series Service ManualDocument122 pagesS9 Series Service ManualRadovan JakovljevicNo ratings yet

- Emed ES300 Operation ManualDocument30 pagesEmed ES300 Operation Manualhany madcorNo ratings yet

- Focus On: Anterior & Posterior ExcellenceDocument12 pagesFocus On: Anterior & Posterior Excellenceophtho india incNo ratings yet

- Nidek Al ScanDocument6 pagesNidek Al ScanBanukumar RajendranNo ratings yet

- PaceDocument1 pagePacePrabhat SagarNo ratings yet

- NK Accessories Cardiology GR PDFDocument101 pagesNK Accessories Cardiology GR PDFWamala Benjamin Julius100% (1)

- Service Manual Noa IIIDocument65 pagesService Manual Noa IIICristian Andres Valencia100% (1)

- Equator MANTA TERMICA PDFDocument68 pagesEquator MANTA TERMICA PDFAnonymous MnaMZQWwCNo ratings yet

- Jenway 6400, 6405 Spectrophotometer - Service Manual PDFDocument96 pagesJenway 6400, 6405 Spectrophotometer - Service Manual PDFLuther QuispeNo ratings yet

- Schematic Diagram Colussi SA Inglese PDFDocument4 pagesSchematic Diagram Colussi SA Inglese PDFfpanci50% (2)

- TD WD440 V4.0Document141 pagesTD WD440 V4.0BCD94No ratings yet

- Owner, S Manual: Pentax Video ProcessorDocument44 pagesOwner, S Manual: Pentax Video ProcessorMaximiliano GonzálezNo ratings yet

- Manual Clv-U40Document4 pagesManual Clv-U40Ingrid SanchezNo ratings yet

- Um Sprint Xe Eng 2354920-1Document100 pagesUm Sprint Xe Eng 2354920-1Victor Montilva100% (1)

- 1 - Tourniquet Cuff BrochureDocument12 pages1 - Tourniquet Cuff Brochurebashar mohammedNo ratings yet

- 产品规格及纱布套 (3) (2024-04-13 09 - 39 - 34)Document1 page产品规格及纱布套 (3) (2024-04-13 09 - 39 - 34)bashar mohammedNo ratings yet

- 1SMA4737 - 1SMA200Z: Taiwan SemiconductorDocument8 pages1SMA4737 - 1SMA200Z: Taiwan SemiconductorRaphael Santos do NascimentoNo ratings yet

- 1 - CUFF LIST - 加水印 (2023-01-16 18 - 04 - 51)Document3 pages1 - CUFF LIST - 加水印 (2023-01-16 18 - 04 - 51)bashar mohammedNo ratings yet

- Plastic Quick Connectors (2023-11-14 13 - 40 - 17)Document15 pagesPlastic Quick Connectors (2023-11-14 13 - 40 - 17)bashar mohammedNo ratings yet

- Vsmis30352 1-2572788Document6 pagesVsmis30352 1-2572788bashar mohammedNo ratings yet

- Thyristor Module: Phase LegDocument6 pagesThyristor Module: Phase LegNabaz AliNo ratings yet

- Electric TransaxleDocument27 pagesElectric Transaxlebashar mohammedNo ratings yet

- SDS Nickel Cadmium PP ContainersDocument6 pagesSDS Nickel Cadmium PP ContainersharmlesdragonNo ratings yet

- Proforma Invoice C202401016Document4 pagesProforma Invoice C202401016bashar mohammedNo ratings yet

- TorqueDocument34 pagesTorquebashar mohammedNo ratings yet

- Stryker FlocontrolDocument1 pageStryker Flocontrolbashar mohammedNo ratings yet

- Z207A V1.22 EngDocument40 pagesZ207A V1.22 Engbashar mohammedNo ratings yet

- Endurun: Owner's ManualDocument20 pagesEndurun: Owner's Manualbashar mohammedNo ratings yet

- ION F18 1 3kVA Install ManualDocument54 pagesION F18 1 3kVA Install ManualBashar MohammadNo ratings yet

- Cranio13 HDocument56 pagesCranio13 Hbashar mohammedNo ratings yet

- Uninterruptible Power Systems: Operation ManualDocument21 pagesUninterruptible Power Systems: Operation Manualbashar mohammedNo ratings yet

- Urologie - HermannDocument60 pagesUrologie - Hermannbashar mohammedNo ratings yet

- Error Code E6+E7: 1.flow Chart of E6+E7 Check (For XT 2700/3200/3300/5600/5700/7600)Document9 pagesError Code E6+E7: 1.flow Chart of E6+E7 Check (For XT 2700/3200/3300/5600/5700/7600)bashar mohammedNo ratings yet

- Endoscopic UnitsDocument30 pagesEndoscopic Unitsbashar mohammedNo ratings yet

- Vfi3000t User ManualDocument36 pagesVfi3000t User Manualbashar mohammedNo ratings yet

- Makelsan Ups Powerack Se RT Series 1 10 Kva User Manual enDocument44 pagesMakelsan Ups Powerack Se RT Series 1 10 Kva User Manual enbashar mohammedNo ratings yet

- Ups SLC Twin Pro Series 0.7.. 3 kVA: User'S ManualDocument32 pagesUps SLC Twin Pro Series 0.7.. 3 kVA: User'S Manualbashar mohammedNo ratings yet

- Makelsan Ups KGK Powerpack Se 1 2 3 en User ManualDocument52 pagesMakelsan Ups KGK Powerpack Se 1 2 3 en User ManualAbdelwhab ElsaftyNo ratings yet

- ION F18 1 3kVA Install ManualDocument54 pagesION F18 1 3kVA Install ManualBashar MohammadNo ratings yet

- Sayed Khadum Albatat General Hospital: Basra - IraqDocument1 pageSayed Khadum Albatat General Hospital: Basra - Iraqbashar mohammedNo ratings yet

- Elx50 Automated Strip Washer: Operator'S GuideDocument182 pagesElx50 Automated Strip Washer: Operator'S Guidebashar mohammedNo ratings yet

- Item Price: MAX Bunos 10 PC 50 PC 100 PCDocument1 pageItem Price: MAX Bunos 10 PC 50 PC 100 PCbashar mohammedNo ratings yet

- Revised CH 5 Material Handling PDFDocument19 pagesRevised CH 5 Material Handling PDFTaha Bzizi100% (1)

- Lib FirmwareDocument32 pagesLib FirmwareAbhishek PubbisettyNo ratings yet

- 10 1109@icacccn 2018 8748820Document5 pages10 1109@icacccn 2018 8748820a4 auto motiveNo ratings yet

- Atlas Copco Tensor DS UK PDFDocument16 pagesAtlas Copco Tensor DS UK PDFAlessandroNo ratings yet

- MES For A Garment IndustryDocument17 pagesMES For A Garment Industrysivanesan rajamanickamNo ratings yet

- Tc52 Tc57 Specification Sheet en Us 5Document4 pagesTc52 Tc57 Specification Sheet en Us 5YassineNo ratings yet

- 2481 - VIDAS Family - External Barcode Readers PDFDocument3 pages2481 - VIDAS Family - External Barcode Readers PDFHadi AlbitarNo ratings yet

- AIN2601-22-S1 - Study Unit 1 - Data and The Computerised Information System ProcessDocument11 pagesAIN2601-22-S1 - Study Unit 1 - Data and The Computerised Information System ProcessShane GowerNo ratings yet

- Haramaya University: College of Computing and Informatics Department of Computer ScienceDocument54 pagesHaramaya University: College of Computing and Informatics Department of Computer SciencehamzaademNo ratings yet

- Domino F530i All Sectors BrochureDocument12 pagesDomino F530i All Sectors BrochureTenday Agus Setya WibawaNo ratings yet

- Z-3190 ProgrammingGuideDocument71 pagesZ-3190 ProgrammingGuideDaniel Glen-WilliamsonNo ratings yet

- MS7220 Argus Presentation Laser Scanner Installation and User's GuideDocument52 pagesMS7220 Argus Presentation Laser Scanner Installation and User's GuideMárcioNo ratings yet

- QR Code Attendance Using Web BrowserDocument3 pagesQR Code Attendance Using Web BrowserرمقالحياةNo ratings yet

- UrometerDocument29 pagesUrometersiva rajNo ratings yet

- Casio TK-3200Document2 pagesCasio TK-3200nemo_tikNo ratings yet

- Burna's ProjectDocument80 pagesBurna's ProjectFavour NwachukwuNo ratings yet

- Supplier - Logistics - Manual - EA SC XX M 001Document13 pagesSupplier - Logistics - Manual - EA SC XX M 001csabaNo ratings yet

- Lexmark Key Code ListDocument9 pagesLexmark Key Code Listoliste80No ratings yet

- Merck Life Science Branding - Other UpdatesDocument31 pagesMerck Life Science Branding - Other UpdatesjohnyNo ratings yet

- HDSD (Eng) Cs-t240Document212 pagesHDSD (Eng) Cs-t240vinhnguyen26993No ratings yet

- Manual BTS 600Document73 pagesManual BTS 600Julio MalerbaNo ratings yet

- CTLG MINI08engDocument48 pagesCTLG MINI08enggadacz111No ratings yet

- PR-11146 - Brochure TM Optix MTS Brochure PR-11146Document8 pagesPR-11146 - Brochure TM Optix MTS Brochure PR-11146lab RSUDPameungpeukNo ratings yet

- Humaclia 150: SpecificationsDocument8 pagesHumaclia 150: SpecificationsHussam DaradkahNo ratings yet

- Opticon M-10Document2 pagesOpticon M-10bobmohNo ratings yet