Professional Documents

Culture Documents

Method Statement For Rebar, Formworks and Concrete Works

Uploaded by

wajid ZiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Rebar, Formworks and Concrete Works

Uploaded by

wajid ZiaCopyright:

Available Formats

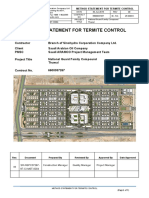

Branch of Sinohydro Corporation Company Ltd.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

METHOD STATEMENT FOR REBAR, FORMWOKRS AND

CONCRETE WORKS

Contractor Branch of Sinohydro Corporation Company Ltd.

Client Saudi Arabian Oil Company

PMSC Saudi ARAMCO Project Management Team

Project Title National Guard Family Compound

Thuwal

Contract No. 6600037267

Rev. DOCUMENT Prepared By Reviewed By Approved By Date Approved

SH-NGFC37267-87-CI- Construction Manager Quality Manager Project Manager

00 MST-0003

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 1 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

TABLE OF CONTENTS

FILE

PARAGRAPH

NO DESCRIPTION PAGE NO

NOS.

METHOD STATEMENT FOR REBAR, FORMWORKS

AND CONCRETE WORKS 1

TABLE OF CONTENTS 2

1 PROJECT UNDERSTANDING 3

2 SCOPE 3

3 PURPOSE 3

4 REFERENCES 3

5 DEFINITIONS 4

RESPONSIBILITIES 4

6

EQUIPMENTS 5

7

PROCEDURES

8 6

REBAR INSTALLATION

9 6

FORMWORKS INSTALLATION

10 6

CONCRETE WORKS

11 8

QUALITY INSPECTION

12 11

PRECAUTION AND SAFETY INSTRUCTION

13 12

1. PROJECT UNDERSTANDING

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 2 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

The National Guard Family Compound (NGFC) development is a National Guard

housing project along with supporting infrastructure and utilities with the total Built-up

area 37,608.48 m2. The Project will supply new kindergarten, Elementary &

Secondary schools, Mosque, Clinic, Retail, Police Station and Recreation Center in

addition to other supporting services. The site is located close to Thuwal, in the

western region of the Kingdom of Saudi Arabia. It is adjacent to the king Abdullah

University of Science and Technology (KAUST) at a Latitude (N) 22º19´15´´ and

Longitude (E) 39º08´22´´.

2. SCOPE :

This work includes the following;

2.1. Rebar installation, Formworks installation and concrete works for all type of structural

works mentioned in IFC drawings & Shop drawings.

3. PURPOSE :

This method statement defines the methodology for the rebar & formwork installation

and concrete works for all type of structure including Foundation, grade beams, grade

slab, Column, beams, Floor Slab, utilities foundation and all other similar structure

where applicable mentioned in IFC & Shop drawings.

4. REFERENCES :

4.1. Approved Issued for Construction (IFC) drawings and Shop Drawings.

4.2. Saudi Aramco Standards (Applicable as per Schedule B)

4.3. Project Specifications Division 3, Section 03100-Concrete Formwork

4.4. Project Specifications Division 3, Section 03200-Concrete Reinforcement

4.5. Project Specifications Division 3, Section 03300-Cast-in-Place Concrete

4.6. Project Specifications Section 01400-Quality Control Services

4.7. ACI-347 Recommended Practice for concrete Formwork

4.8. ACI-318 Building code Requirements for Reinforced concrete

4.9. ACI-117M-10 Specification for Tolerance for Concrete Construction & Materials.

4.10. SBC-Saudi Building Code

4.11. ACI-315 Details of concrete Reinforcement

4.12. ACI-301 Specifications for Structural Concrete

4.13. ASTM-615 Standards Specification for Deformed & Plain Bar.

4.14. IBC-2009 International Building Code

4.15. Contractor Site Safety Plan (CSSP)

5. DEFINITIONS :

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 3 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

5.1. IFC – Issued for Construciton.

5.2. SAES – Saudi Aramco Engineering Standards.

5.3. CQCI – Civil Quality Control Inspector.

5.4. CSSP – Contractor Site Safety Plan

6. RESPONSIBILITIES :

6.1. Site Surveyor: The Surveyor shall be fully responsible for formworks layout, rebar

installation layout, concrete pouring layout of the designated area as per IFC drawings and

Shop Drawings and will monitor all assigned works to complete the task. He will also be

responsible for the protection of bench mark and temporary bench mark.

6.2. Civil/Site Engineer: The Civil/Site Engineer shall responsible for the execution of all

rebar, formworks installation and concrete works as per IFC drawings, and project

specification under safe conditions and following the contractor site safety plan.

6.3. QC Inspector: The QC Inspector shall be responsible for all quality inspection

activities are carrying out as per latest revision of IFC drawings and to ensure compliance

with all requirements of relevant contract documents.

6.4. Construction Manager: The Construction Manager shall be responsible for executing

all constriction activities as per relevant project specification, in accordance with quality,

safety and schedule requirements.

6.5. Quality Control Manager: The Quality Control Manager (QCM) shall be responsible

for organizing and allocating inspection work to CQCI.

6.6. Laboratory Technician: Laboratory technician shall be testing independently as a

representative of third party Aramco approved testing laboratory and shall be responsible

for inspection and field testing, materials sampling and related laboratory works as required

by the specifications.

6.7. Safety Inspector: Safety inspector would be responsible for the following:

a) He will make sure all construction activities would be carried out under approved

CCSP.

b) He will make sure all site workers are following proper PPEs.

c) He will make sure all equipment have proper valid certificate before starting the site

works.

d) He will make sure the provision of flagman to assist the equipment operator and

warn people for any movement of equipment.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 4 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

e) He will make sure the presence of work permit and list involved personnel at site

and work permit should have the clearance from electrical, Mechanical, instrument

department and also permits for succeeding work.

f) He will make sure that signals, signs and barricades will not be removed from site

until work finished.

6.8. Document Controller: Document Controller shall keep records of all documents to be

controlled in systematic order so that they can be accessed easily. Maintains clear

communication with all departments and ensures proper and effective flow of information.

7. EQUIPMENTS: Main Equipment shall be below but not limited to;

i. Bar Bending and Cutting Machine

ii. Hacksaw Blade and other hand tools

iii. JCB Fork Lift

iv. Rigging tools and accessories

v. Electric Circular Saw

vi. Miscellaneous hand tools

vii. Face Shields and hand gloves

viii. Meter Tape

ix. Claw bar

x. Concrete Pump

xi. Truck Mixer

xii. Concrete Vibrator

xiii. Hand shovel

xiv. Slump Cone

xv. Slump Tray

xvi. Test Cylinder

xvii. Trowel

xviii. Wheel Borrow

8. PROCEDURES :

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 5 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

8.1. REBAR INSTALLATION:

8.1.1. Delivery and Identification

i. Material and Equipment shall be delivered and identified under provision of the

contract documents.

ii. Ship reinforcement steel in bundles limited to one size and length.

iii. Identification-Tag each bundle at mill with waterproof tag showing name of mill,

heat number, grade and size of bars and identifying number and shop drawings.

Tags shall not remove till reinforcement in place.

iv. Uncoated Black steel/ Re-Bar will be used for building works if otherwise not

mentioned in IFC drawings and shop drawings.

8.1.2. Methodology

Materials unloading should be in a proper way to avoid any scratching or

damaging and placing rebar with cover.

Reinforcing bars shall be hot rolled deformed in accordance with dimension

specified in the Bar Bending Schedule as mentioned in the IFC & Shop drawings.

Contractor will review all rebar bending details prior to fabrication to verify that

concrete cover and anchor bolt clearance can be maintained.

Bar cutting length shall be grouped with respect to their mark numbers by putting

tag identification.

Rebar should be keep by supporting timber dunnage rack.

Rebar shall be free from dirt, mill scale, rust scale, oil, grease and other foreign

matter.

Rebar should be placed as per spacing marked in IFC drawings.

Rebar should be binding properly with binding wire.

Chair shall be provided at regular inerval to support the rebar network.

Rebar spacer of approved material shall be placed at the bottom and to the sideds

where necessary to maintain the clear cover. For concrete clear cover of

reinforcement IFC drawings VA-ESGQ01-001-A shall be followed for minimum

cover requirements.

8.2. FORMWORKS INSTALLATION

a) Preparation

i. Formworks panels facing to concrete surfaces shall be clean or free from

foreign materials prior to installation. Tape,gasket,plug, and/or caulk joints, gas

and apertures in forms so that the joint will remain watertight and withstand

placing pressure without bulging outward or creating surface irregularities.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 6 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

ii. Application of form oil should be made upon completion of formworks

installation and in accordance with the specification.

b) Methodology

Formworks lines, levels, and centers should be according to approved Issued for

Construction (IFC) drawings and Shop Drawings.

Formworks faces should be true flat and free from any corrugation/undulation that

may affect the concrete finish surface.

Formworks end should be braced perfectly so support all forms are maintained in

their desired position during and after concrete placing also build sufficiently tight

to prevent mortar leakage.

Formworks shall be tighten with sufficient braced in whole area in order to

resulting concrete surface conform to specified tolerence.

Brace forms adequately to retain forms in position during concrete placement and

curing.

Provide morter-tight forms which conform to shapes, lines and dimension shown in

IFC drawings and produce smooth surface without fins and projections.

Foam tape should be fixed all joints in formworks and edges in order to prevent

the loss of cement slury.

Formworks faces to concrete shall be provide oil agent to easy removal of forms

after concrete and should not stuck in concrete while removing.

Formworks alignment should be straight and its maximum tolerence should not be

exceed as specified in ACI-117 forms and formed surfaces.

Coats forms with form release agent prior to placement of reinforcing steel. Form

release agent shall not apply where concrete surfaces require special finishes.

Conduit and pipes shall be embedded in accordance with project specification and

Block-outs, inserts, sleeves, anchors, and other embedded items should be

properly identified, positioned and secured.

Ensuring items to be embedded in concrete are free from oil and foreign

matterials. Ensure anchor bolts do not come in contact with reinforcing steel.

Pipes and other embedded items should be checking before concrete placement.

Constraction, expansion and construction joint shall be provided as specified in

IFC drawings and shop drawings.

Formworks external edges exposed to concrete shall be chamfered by inserting

25mm angles strips in the form, this case will not apply under ground concrete

portion.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 7 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

Formworks shall not be removed until concrete has attained sufficient strength to

support its own weight and the imposed loads. Forms shall be removed when

safety and serviceability are not impaired.

Formworks removal should be conducted carefully as per project specification and

take extra attention that it should not disturnb the concrete surface smoothness.

Form sheets should not be thrown down to the ground directly. Extreme care shall

be taken so as not to damage the formworks.

After the carefull removal of formworks foreign materials should be clean carefully

such as sticks, boards, loose rocks, snad, debris, etc within forms.

Form sheets shall be properly segregated accroding to the size and stored under

the shelter for re-use.

Cut Back rods and ties in a manner preventing swelling.

Damaged formworks shall not be re-use for further activities and it should be

segregated separately.

8.3. CONCRETE WORKS:

a) Pre-Pouring:

i. Provide delivery tickets for ready-mix concrete as per ASTM C94 including

weights of cement and each size aggregates and amount of water to be

added at plant.

ii. Water Quality shall be provide results for tests on mixing water meets

standards.

iii. Pouring plan schedule shall be informed Saudi Aramco prior to 48 hrs of any

concrete activity. The confirmation shall be obtained by mail or other

convenient process recommended by Aramco.

b) Contractor shall employ an independent approved testing laboratory to test

conformity of materials to specifications. Concrete testing shall be performed by

a concrete field technician. Allow free acces to obtain test samples.

c) Method of Sampling and Testing:

Fresh Concrete Sampling: ASTM C72

Specimen Preparation: ASTM C31

Compressive Strength: ASTM C39

Temperature: ASTM C1064, ACI 301

d) Acceptance of completed concrete work requires conforemance with

dimensional, tolerences, appearance and strength as indicated or specified.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 8 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

e) Reject concrete delivered to job site that exceeds the time limit 90 mins or failed

field inspection test.

f) Workability shall comply with ACI or Aramco Standards.

g) Mixing and transportation concrete shall confirm to concreting procedure set in

ASTM C94, ACI 304R.

h) Concrete acceptance shall be sign delivery batch tickets to indicate concrete

acceptance and reject truck without have any batch tickets.

i) For concrete pouring the quality control inspector (Civil) shall check and make

sure that the activities have been fulfilled prior to placement of concrete.

j) Inspection of Embedded Items:

i. The Project Engineer shall check the placement and position of all embedded

items against the controlled IFC drawings. The Site Engineer also responsible

for checking the posiiton of the embedded items before the concrete

placement to ensure that no displacement happened.

ii. The Civil Quality Control Inspector and the Saudi Aramco representatives

shall inspect the pre-pour inspection all reinforcement and other embedded

items to ensure that the approved type and numbers are installed within the

specified tolerences and records accordance their approval by initiating on

Quality Records to signify final inspection for the structure to be poured. The

Civil Quality Control Inspector shall coordinate with the ME/Elec. Quality

Control Inspector to ensure that all required tests and inspection on any

embedded pipes, electrical conduits are completed and in compliance with

conctrolled IFC & Shop drawings, standards and codes.

k) Sampling and testing shall comply with;

i. No concrete shall be ordered until field installation works have been released

by the Quality Control Department and the site Engineer notified.

ii. The Civil QC Inspector shall check the truck delivery note to stablish that the

correct delivery has been made such as mix type, location and time of

batching.

iii. The 3rd Party independent testing laboratory technician shall monitor concrete

receiving and conduct necessary field tests and sampling of fresh concrete

and record the results.

iv. Any Field test that indiactes the concrete deficiency, field technician shall

report Civil Quality Control Inspector immediately and should reject such

concrete delivery.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 9 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

v. The Field Technician shall obtain samples from the 1 st truck mixer during

discharge unless otherwise instructed by the CQCI. Slump and Cylinder test

samples shall be taken from the end of the mixture truck chute or at the

discharge point of the concrete pump hose.

vi. The Field Test of Slump, Concrete Temperature shall be record by Field

technician .

vii. Concrete cylinder sample set of 04 Nos. cylinders shall be marked with the

number, the casting date and designated letter for each cylinder sample of

the set.

viii. All structural concrete shall have a minimum cylinder compressive strength

should be following below unless otherwise noted;

f’c = 28 MPa for Footings, Grade Beams, Slab on Grade, Column &

Walls.

f’c= 35 MPa for Hollow core Slab, Topping, Concrete Slab and Beams.

ix. Lean Concrete beneath foundation, where specified on IFC Drawings, shall

have a minimum compressive strength of 14 MPa @ 28 days.

i. Deformed Bars: Reinforcing Bars - 420 Mpa, Yield grade 60, Black steel. Use

deformed bars complying with the requirements of ASTM A-615.

ii. Additional testing shall be carried out as and when instructed by the CQCI.

Such samples and test shall be additional to the routine samples and tests.

iii. After Sampling and initial set on-site curing, the cylinders shall be tested for

compressive strength in the laboratory at the age of 7 days (2 Samples) and 28

days (2 Samples) in accordance with Contracts.(Ref.: VE-000A03-B-Vol.004

Section 03300, under Sub-sec 3.07.) unless otherwise directed by the Saudi

Aramco Representatives.

iv. Sampling shall comply with ASTM C172 and perform tests specified for each

40 cubic meters of fresh concrete or fraction thereof, but not less than one set

of four to six cylinders for each day’s concreting.

l) Concrete Placement shall comply with Specfication 03300 (3.03)

i. All concrete shall be deposited as close to its final position and shall be brought

up in layers approximately parallel to the construction joint panel.

ii. Readymix concrete shall be provided from batching plant as per approved

design mix.

iii. Concrete pumps will be available on site and replacement pump shall be

requested if there is any problem with the pump on site.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 10 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

iv. All concrete shall be throughly consolidated by vibrators, working concrete

around reinforcement and embedded fixtures and into corners of the forms.

Vibrators shall be adequately sized as per ACI-309, Table 5.1

v. Vibrator shall not be used to move concrete laterally. Vibrators should be

inserted and withdrawn vertically at intervals of five to twenty seconds duration

and at points 460mm to 750mm apart, penetrating previously placed fresh

concrete.

vi. Construction joint will not be permitted other than in the locations indicated on

the IFC draings.

vii. On slopping surfaces, concrete placement shall start at the lower portion of the

slope and progress upward in the forms.

viii. At construction joint, roughen concrete surface and in accordance with ACI 318

and ACI 301.

ix. Concrete shall not be dropped freely from a height of more than 1m and shall

be distributed in uniform layers not to exceed 600mm in height, avoiding

inclined layers and cold joints.

x. Concreting once started shall be continious until a section is completed. When

stoppage occurs, construction joints shall be placed horizontally or vertically.

As needed, provided keys and dowels.

xi. In no case temperature of concrete shall exceed 32 0C when pouring concrete

accordance with ACI 301 Section 4.2.2.8.

xii. Curing and protection shall confirm to the specificatio 03300-(3.06). The Civil

Quality Control Inspector shall perform surveilance inspection to the curing

application. Curing and protection shall be as per specification.

m) Concrete Finishing shall comply with Specification 03300-(3.05)

i. Verify that floor surfaces are acceptable to receive the work.

ii. Exposed concrete surfaces shall be uniform in appearance, without defects

and finished to a smooth finish.

iii. The QC Department shall maintain records of laboratory testing, surveilance

and inspection activities to verify conformance to approved construction

drawings and specification requirements.

9. Quality Inspection

Inspection test Plan (ITP) specific to project requirements shall be made and

inspection activites are recorded either on the forms as given under related

docuemtns.

Ensure that approved 60 grade of black steel is used at site.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 11 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

Rebar shall be free from loose mill scale and any surface rust prior to placement in

position.

Binding wire shall be free from rust and conform to the project specification.

Lap length shall be provide as per IFC & Shop drawings.

Verify site activities to conform the approved IFC & Shop drawings plan.

All activities would be carried out under approved inspection test plan (ITP) to

meet the project quality pan.

QC inspector shall assure that accepted material to be used at site and documents

can be produced upon Saudi Aramco request.

All Formworks materials to be used in the works shall be in accordance with the

project specification.

Embedded parts (if any) should be checked carefully prior to fixing of formworks.

Both horizontal & vertical formworks reference layout and elevation should be

reflected as the reference control line during starting works and inspection.

Vertical and horizontal bracing of formworks shall be standard inerval and equal

distance.

Approved Controlled IFC drawings and Shop drawings shall be used.

Approved inspection checklist shall be followed during inspection.

Inspection of erected formwork, shoring, bracing to ensure work is in accordance

with formwork design and supports, fastenings, wedges, ties, and items prior to

concrete placement.

10. Precaution and safety Instruction

Cuts, punctures and abrasions are the typical hazards of rebar and tie wires.

Foot, hand, head & eye protection are required during bending of rebar.

Not allowing cutting of rebar by using heating of oxyzen acetylene procedure.

Never get in a position between, under or against loads during rigging and loading

of materials.

Always wear gloves for handling rebar and take care of people working around.

Any move for loading or unloading of using equipment should have a watchman to

inform others.

Operator of bar-bending machine should be trained if any requirement at site.

The working area on elevated surfaces must have a good access as per CSSP

and barricade with hard barrier with safety signboard and inspected by the

competent person prior to start working.

Vertical & horizontal bracing of formwork must be at standard interval and equal

distance.

Formwork removal shall be done by wearing complete PPE’s to prevent accidnets.

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 12 of 13)

Branch of Sinohydro Corporation Company Ltd. METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE

WORKS

Al-Takhasussi Road, Building No.6517, Riyadh12311

Tel. No. +966 1 8030338 Fax +966 1 4622565 DATE 27 Jun-2016 REV 00

http://www.sinohydro.com CONTRACTNO 6600037267 B.I. NO. 25-00034

METHOD STATEMENT National Guard Family Compound

PROJECT TITLE

SH-NGFC37267-87-CI-MST-0003 Thuwal

Always wear gloves for handling shuttering of formworks and other tools and must

be aware other people working around.

Trained concrete pump operator and banks man shall be engaged to control or

operate readymix truck and pump.

Experienced labour shall be engaged to hold the pump hose and equally

distributed the concrete by layer.

END

METHOD STATEMENT FOR REBAR, FORMWORKS AND CONCRETE WORKS

(Page 13 of 13)

You might also like

- Method Statement For Structural Excavation and BackfillDocument14 pagesMethod Statement For Structural Excavation and Backfillwajid ZiaNo ratings yet

- Method Statement For Underground Utilities Excavation and BackfillingDocument12 pagesMethod Statement For Underground Utilities Excavation and Backfillingwajid ZiaNo ratings yet

- Pile Head Treatment Method StatementDocument12 pagesPile Head Treatment Method StatementĐặng Quang Huy100% (1)

- Method Statement For Formworks, Rebars, Cast-In-Situ ConcreteDocument28 pagesMethod Statement For Formworks, Rebars, Cast-In-Situ ConcreteAzhar Ali87% (15)

- Method Statement For Construction of Substructure Elements)Document8 pagesMethod Statement For Construction of Substructure Elements)Akash Yadav100% (2)

- METHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Document7 pagesMETHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Osama MZ100% (1)

- 3) Method Statement For Formwork Steel & Concrete WorkDocument9 pages3) Method Statement For Formwork Steel & Concrete WorkMukesh PrajapatNo ratings yet

- MS For Formwork, Rebars, & Cast-In-Situ Concrete Rev. DDocument18 pagesMS For Formwork, Rebars, & Cast-In-Situ Concrete Rev. DIbrahim NaguibNo ratings yet

- Method Statement For Conventional Formwork BlogDocument9 pagesMethod Statement For Conventional Formwork BlogMohasin KhanNo ratings yet

- Method Statement For Substructural Waterproofing Works REV 00Document40 pagesMethod Statement For Substructural Waterproofing Works REV 00Bleep News100% (1)

- Method Statement For Columns2Document5 pagesMethod Statement For Columns2Jasmine TsoNo ratings yet

- Method of Statement For Concrete WorksDocument15 pagesMethod of Statement For Concrete WorksAhmed Ibrahim100% (1)

- Road and Parking Area Method StatementDocument22 pagesRoad and Parking Area Method StatementAmin KhanNo ratings yet

- Method Statement For Concrete Repairing WorksDocument42 pagesMethod Statement For Concrete Repairing WorksKAKA100% (1)

- Method Statement For PS Concrete WorksDocument12 pagesMethod Statement For PS Concrete WorksMuhammad Sami ParvezNo ratings yet

- MS - Gypsum Dry Wall Partition WorkDocument14 pagesMS - Gypsum Dry Wall Partition Worklinga2014100% (1)

- Method Statement FOR Raft Concrete: 1.0 Scope of Works 2.0 References 3.0 ResponsibilitiesDocument12 pagesMethod Statement FOR Raft Concrete: 1.0 Scope of Works 2.0 References 3.0 ResponsibilitiesJHONALIZANo ratings yet

- Method Statement For Excavation and Backfilling WorksDocument15 pagesMethod Statement For Excavation and Backfilling WorksĐặng Quang Huy100% (6)

- Method Statement For Formwork Falsework PDFDocument34 pagesMethod Statement For Formwork Falsework PDFbryanNo ratings yet

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Document9 pagesMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- RCC Method StatementDocument10 pagesRCC Method StatementSagar AliasjackeyNo ratings yet

- Concrete Method Statement PDF FreeDocument14 pagesConcrete Method Statement PDF FreeAli Kaya100% (2)

- Method Statement for Ceramic Tile InstallationDocument4 pagesMethod Statement for Ceramic Tile InstallationAli SaifNo ratings yet

- Masonry Construction MethodsDocument65 pagesMasonry Construction Methodssenthil67% (3)

- IASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksDocument8 pagesIASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksJoe PsNo ratings yet

- Roof Waterproofing-Method StatementDocument5 pagesRoof Waterproofing-Method StatementTATATAHERNo ratings yet

- Method Statement For Anti Termite TreatmentDocument5 pagesMethod Statement For Anti Termite TreatmentrayNo ratings yet

- Method of Statement For BlockworksDocument2 pagesMethod of Statement For BlockworksMohammad SaadehNo ratings yet

- Method Statement For PLASTERINGDocument6 pagesMethod Statement For PLASTERINGVinodh Palanichamy100% (1)

- Method Statement: For Internal & External Plastering Works: Rev. Date Prepared by Checked & Approved byDocument9 pagesMethod Statement: For Internal & External Plastering Works: Rev. Date Prepared by Checked & Approved byEyutt Hghgh100% (1)

- Method Statement For Casting of Cement Based ScreedDocument8 pagesMethod Statement For Casting of Cement Based Screedmd_rehan_2100% (1)

- Excavation Backfilling Compaction MethodDocument5 pagesExcavation Backfilling Compaction MethodAnonymous a3K3Wg100% (1)

- Method Statement For Concrete WorkDocument6 pagesMethod Statement For Concrete WorktotA ahmedNo ratings yet

- 20 0650 Demolition Method StatementDocument23 pages20 0650 Demolition Method StatementFazrin inasNo ratings yet

- Prefabricated Building Method Statement for COODO 64 VW Showroom ProjectDocument15 pagesPrefabricated Building Method Statement for COODO 64 VW Showroom ProjectarunNo ratings yet

- Method Statement for Aluminium Window InstallationDocument13 pagesMethod Statement for Aluminium Window Installationpp100% (2)

- WMS (Method Statement For Formwork, Reinforcement and Concrete Works)Document9 pagesWMS (Method Statement For Formwork, Reinforcement and Concrete Works)PUI CHEE KHIAN100% (1)

- Method Statement For Shoring WorkDocument24 pagesMethod Statement For Shoring WorkAzhar Ali78% (9)

- Method of Statement Structural SteelDocument45 pagesMethod of Statement Structural SteelMahmoud Moustafa Elnegihi100% (3)

- Concrete Works Method StatementDocument41 pagesConcrete Works Method StatementDomie Neil Bucag SalasNo ratings yet

- Method Statement Slab & Beam ConcretingDocument3 pagesMethod Statement Slab & Beam Concretingudithairesha100% (6)

- ITP Temporary HoardingDocument1 pageITP Temporary HoardingMohd Azrin100% (1)

- METHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesDocument10 pagesMETHOD STATEMENT Gypsum Board Ceiling Gypsum Partitions Ceiling TilesHARISH ROHANNo ratings yet

- Method Statement For PlasteringDocument14 pagesMethod Statement For Plasteringjameel100% (1)

- The Rise Resort Skim Coating ProjectDocument10 pagesThe Rise Resort Skim Coating ProjectMin Luo100% (1)

- Method of Statement - Drainage WorksDocument6 pagesMethod of Statement - Drainage Worksainamin77No ratings yet

- Method Statement Structural Excavation & BackfillingDocument16 pagesMethod Statement Structural Excavation & Backfillingcenkunal83% (12)

- 6.ITP For RebarDocument1 page6.ITP For RebarDaniel Sinaga100% (1)

- China Harbour Roof Waterproofing MethodDocument18 pagesChina Harbour Roof Waterproofing MethodYash Sharma100% (6)

- Method Statement For Finishing WorkspdfDocument7 pagesMethod Statement For Finishing Workspdfmohamed nabilNo ratings yet

- Method Statement For Establishment of Site FacilitiesDocument9 pagesMethod Statement For Establishment of Site FacilitiesNaveen GladsonNo ratings yet

- MOS For CMU Block WorkDocument10 pagesMOS For CMU Block WorkAlvene TagocNo ratings yet

- C1-10 Demolition and Site ClearanceDocument25 pagesC1-10 Demolition and Site ClearanceJacky TiongNo ratings yet

- Method Statement For Sign Board Excavation & Installation - Safe Work Method of StatementDocument2 pagesMethod Statement For Sign Board Excavation & Installation - Safe Work Method of StatementUmair AslamNo ratings yet

- Method Statement For Staircase HandrailDocument18 pagesMethod Statement For Staircase HandrailEnviron Support50% (2)

- 1701-Drainage Method StatementDocument3 pages1701-Drainage Method StatementMisz_10_ScorpioNo ratings yet

- Method Statement Suspended CeilingDocument20 pagesMethod Statement Suspended CeilingImelda Valiente100% (3)

- Termite Control Method StatementDocument7 pagesTermite Control Method Statementwajid ZiaNo ratings yet

- Mos 1047 04 21Document45 pagesMos 1047 04 21DSJNo ratings yet

- 2755-MCD-CON-CEP-0070 - Concrete Repair Works For Cold JointDocument19 pages2755-MCD-CON-CEP-0070 - Concrete Repair Works For Cold JointNURLINURLINDANo ratings yet

- Termite Control Method StatementDocument7 pagesTermite Control Method Statementwajid ZiaNo ratings yet

- Termite Control Method StatementDocument7 pagesTermite Control Method Statementwajid ZiaNo ratings yet

- RTA Waterproofing Works ApprovalDocument1 pageRTA Waterproofing Works Approvalwajid ZiaNo ratings yet

- METHOD STATEMENT FOR Grout WORKSDocument6 pagesMETHOD STATEMENT FOR Grout WORKSwajid ZiaNo ratings yet

- BCT593 ASSIGNMENT ESTIMATING March August 2023Document7 pagesBCT593 ASSIGNMENT ESTIMATING March August 2023MAXSWELL MANGGIE ZAMRYNo ratings yet

- Prefabricated Steel Bridge DesignDocument85 pagesPrefabricated Steel Bridge Designadityadh100% (1)

- TERA Joint-Floor Joint SystemDocument16 pagesTERA Joint-Floor Joint SystemAmir ZahirovicNo ratings yet

- Forward Constructing PDFDocument148 pagesForward Constructing PDFAnon19No ratings yet

- 20.09.2017 Rak-Addendum BoqDocument447 pages20.09.2017 Rak-Addendum BoqYash SharmaNo ratings yet

- Hyrib User Guide PDFDocument35 pagesHyrib User Guide PDFYoong Lai YeeNo ratings yet

- Reinforced Concrete Foundation SpecificationDocument20 pagesReinforced Concrete Foundation SpecificationRianto FelissimoNo ratings yet

- Subject: Method Statement For The Constructio NOF Chimney RaftDocument10 pagesSubject: Method Statement For The Constructio NOF Chimney RaftSandip PaulNo ratings yet

- Mammut350 Heavy Duty Formwork PL PDFDocument34 pagesMammut350 Heavy Duty Formwork PL PDFMae FalcunitinNo ratings yet

- Engineering 2022 02 22Document11 pagesEngineering 2022 02 22shabirnawidNo ratings yet

- Slip Form ConstructionDocument10 pagesSlip Form ConstructionAkshay JangidNo ratings yet

- Concrete Slab Formwork - Safety GuideDocument53 pagesConcrete Slab Formwork - Safety GuideThành KC100% (4)

- L T Formwork Component List PDFDocument54 pagesL T Formwork Component List PDFRani Yamin100% (1)

- Taking Off Quantities for Concrete & Reinforcement WorksDocument17 pagesTaking Off Quantities for Concrete & Reinforcement WorksSaidatul SazwaNo ratings yet

- Final Detail Estimates Erarpar Ambassa Road TripuraDocument242 pagesFinal Detail Estimates Erarpar Ambassa Road TripuraHimanshuNo ratings yet

- Developments in Formwork: Larsen & Toubro LimitedDocument83 pagesDevelopments in Formwork: Larsen & Toubro LimitedRavi RajanNo ratings yet

- Renovation Bill of Quantities for Police Training SchoolDocument112 pagesRenovation Bill of Quantities for Police Training SchoolNALEEMNo ratings yet

- TECHNICAL INSTRUCTION 1D-2013-MAy PDFDocument65 pagesTECHNICAL INSTRUCTION 1D-2013-MAy PDFStelian ConstantinescuNo ratings yet

- 4.building WorksDocument27 pages4.building WorksjanithNo ratings yet

- Method Statement Striking FormworkDocument3 pagesMethod Statement Striking FormworkSurya HeriwijayaNo ratings yet

- Bill of Engineering Measurement and Evaluation (Beme) For One Storey Mini-Shopping ComplexDocument10 pagesBill of Engineering Measurement and Evaluation (Beme) For One Storey Mini-Shopping ComplexANAYO EZE100% (1)

- Mexican BovedasDocument9 pagesMexican Bovedas4gen_7No ratings yet

- 0C-F027-QA-PPIC - Pre-Pour Inspection Checklist (Walls, Columns, Slabs, Beams, Pile Caps, Cores, Capping BeamsDocument2 pages0C-F027-QA-PPIC - Pre-Pour Inspection Checklist (Walls, Columns, Slabs, Beams, Pile Caps, Cores, Capping BeamsRomeo FagurelNo ratings yet

- Annex 1 - Bill of Qunatities 1 - To 3-8 - ENGDocument387 pagesAnnex 1 - Bill of Qunatities 1 - To 3-8 - ENGErman GogenNo ratings yet

- Calculations - Rate Analysis 07-07-21Document17 pagesCalculations - Rate Analysis 07-07-21Rajesh Jujare100% (1)

- Method Statement Formwork and Concrete Execution Work Foundation and PillarDocument9 pagesMethod Statement Formwork and Concrete Execution Work Foundation and PillarAneelKhatriNo ratings yet

- Elevis 4 No. 2 Bed ApartmentDocument90 pagesElevis 4 No. 2 Bed ApartmentNana BarimaNo ratings yet

- Application Procedure - Castocrete SuperDocument3 pagesApplication Procedure - Castocrete SuperRAJKUMARNo ratings yet

- DG7 Gass Design Guide Rev G PDFDocument54 pagesDG7 Gass Design Guide Rev G PDFAnonymous BAYE9xVnLNo ratings yet

- Step of Concrete SlabDocument5 pagesStep of Concrete SlabMine MienNo ratings yet