Professional Documents

Culture Documents

METHOD STATEMENT FOR Grout WORKS

Uploaded by

wajid ZiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

METHOD STATEMENT FOR Grout WORKS

Uploaded by

wajid ZiaCopyright:

Available Formats

JEDDAH JAZAN

EXPRESSWAY JUNCTION

PROJECT

Procedure for Cementitious Grout

DOCUMENT NO. : CCCC-CIPDEJ-72-QC-PRO-0005

Contract No. : 6600042902

JEDDAH JAZAN EXPRESSWAY JUNCTION

CONTENTS

1.0 SCOPE

2.0 GENERRAL

3.0 REFERENCES

4.0 DEFINITIONS

5.0 PROCEDURES

6.0 HEALTH SAFETY AND EQUIPMENT REQUIREMENTS

7.0 INTERNAL INSPECTION

8.0 INSPECTION NOTIFICATION

Doc. No. CCCC-CIPDEJ-72-QC-PRO-0005

PROCEDURE for Cementitious Grout

Page Page 2 of 6

Revision 00

REVISION HISTORY

Rev. No Section Descriptions Remarks

00 -

1.0. SCOPE

This procedure covered for Concrete Base grout sampling testing and

placement

If a Conflict is observed between this Procedure and other reference

adopted, Manufacture recommendation shall be followed,

3.0. REFERENCES

SAES-Q-010

PIP STS03600

Manufacturer Recommendations.

Project Quality Policy.

Project Schedule “Q”

Applicable Saudi Aramco (Health & Safety) Standard Specification

4.0. DEFINATIONS

Client : Saudi Aramco

Project : Jeddah Jazan Expressway Junction Project

Contractor : CCCC China communication Construction Company.

Procedure for Cementitious Grout

Doc. No. CCCC-CIPDEJ-72-QC-PRO-0005

PROCEDURE for Cementitious Grout

Page Page 3 of 6

Revision 00

QA/QC : Quality Assurance Quality Control

5.0. PROCEDURE

5.1. Responsibilities:

5.1.1. Construction Manager

The Construction Manager solely responsible the construction

Cementitious Grout works being implemented are in conformance

with specifications and approved drawings.

5.1.2. QA/QC Manager

The QA/QC Manager is overall responsible for the implementation

of this procedure. He will monitor that the project activities are

performed and accomplished effectively in accordance with the

quality systems, through regular review. QA/QC Manager will guide

the QC supervisor and inspectors assigned to this project.

5.1.3. QC Supervisor

The QC Supervisor will do inspection coordination between PID,

PMT and QC inspector. Ensure compliance by all site personnel to

this procedure in line with project specification and IFC drawings.

Make regular site surveillance. Facilitate, review and is in charge of

disposition of any generated non conformances at his level. Compile

all QC documents.

5.1.3. QC Inspector

The QC Civil Inspector shall ensure that approved quality control

procedure is implemented throughout the Cementitious Grout

activity. He will perform the inspection as per approved ITP and

witness for all the inspection activities. He shall coordinate with

Procedure for Cementitious Grout

Doc. No. CCCC-CIPDEJ-72-QC-PRO-0005

PROCEDURE for Cementitious Grout

Page Page 4 of 6

Revision 00

Client Representative regarding inspection and testing activities.

Documentation of all inspection and tests made shall also be his

responsibility.

5.2. Placement of Cementitious Grout.

5.2.1 Material.

Polycrete MC, by Polybit

Or any other approved by Company

5.2.2 Surface Preparation.

Concrete foundations or any other structure which will receive cement

base Grout, shall be cured for a minimum of 7 days before surface

preparations for grouting.

Concrete substrate to be receive grout, should be clean &

uncontaminated.

Laitance, oil-soaked or damaged concrete shall be removed down to

sound concrete by chipping to the level of sound fractured aggregate.

Provide proper formwork as per required shape.

The formwork should be rigged and tight to prevent loss and have

properly sealed faces to insure that no water in absorbed from the

grout material.

Concrete surfaces in contact with the grout shall be saturated with

clean water before grout placement.

5.2.3 Mixing Placement & testing.

Grout shall be mixed per the Grout Manufacturer's instructions.

The quantity of mixing water added shall be that recommended by the

Grout Manufacturer's instructions.

The total dissolved solids in the mixing water to be used for mixing

prepackaged grouts shall not exceed 500ppm.

The minimum thickness of the grout shall be the space between the

bottom of the base plate and the top of the concrete foundation.

Procedure for Cementitious Grout

Doc. No. CCCC-CIPDEJ-72-QC-PRO-0005

PROCEDURE for Cementitious Grout

Page Page 5 of 6

Revision 00

Grout shall be dry packed, flowed or pumped into place per the

manufacturer's written instructions for the type of grout being

installed

The grout manufacturer's written instructions shall be strictly followed.

Retendering of grout by adding water after stiffening is not permitted.

Grout shall be mixed, placed and cured in accordance with

manufacturer’s written requirements.

The grout shall be cut back to the lower edge of the base plate by 45⁰

angle unless otherwise indicated.

Sampling and testing shall be performed by a Saudi Aramco approved

independent testing laboratory.

Two sets of three test cubes shall be casted in the field for each day

that grout is mixed and placed

One cube shall be tested set at 7 days and one cube set at 28 days.

The compressive strength of the grout shall be a minimum of 24MPa

(3500psi) at 7 days of age

The compressive strength of the grout shall be a minimum of 35MPa

(5000psi) at 28 days of age.

For standard temperature testing, maintain the grout mixture and the

testing equipment at a temperature of 73.4 +/- 5°F (23 +/- 3°C).

5.2.4 Curing.

Curing shall be done by curing compound or wet hessian clothes.

When cured with wet hessian clothes, cover with plastic sheet as well.

Ponding method of curing is not suitable for grouting.

6.0. HEALTH, SAFETY AND EQUIPMENT REQUIREMENTS

Procedure for Cementitious Grout

Doc. No. CCCC-CIPDEJ-72-QC-PRO-0005

PROCEDURE for Cementitious Grout

Page Page 6 of 6

Revision 00

In overall the project safety policy requirement shall be implemented.

Barricade and install the safety sign board to keep unauthorized personnel

clear of areas in which construction works area.

Equipment for use shall be in good working condition and appropriate

desirable accuracy. Personnel Protection Equipment (PPE) shall be

implemented. FRC shall be provided to all personnel in the specific location

and operating areas where flash fire hazard and determined that FRC is

required. Proper dust control system shall be installed.

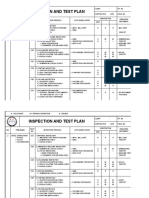

7.0 INSPECTION

CCCC QC Inspector and shall carry out the necessary inspections in various

stages of the Finishing after Cementitious Grout works. Inspections shall be

based on SATIP-Q-010 and discrepancies shall be within the accepted

allowable tolerances.

8.0 INSPECTION NOTIFICATION

Upon Completion and acceptance of CCCC QC will notify to SAPID through

QMIS or approved inspection request format for client inspection.

Procedure for Cementitious Grout

You might also like

- Concrete Works Inspection & TestingDocument9 pagesConcrete Works Inspection & Testingkbldam100% (2)

- Pier capDocument15 pagesPier capGANGARAJU N BNo ratings yet

- Underck Insulation MSTDocument8 pagesUnderck Insulation MSTmahesh naikNo ratings yet

- UIPS QCP 003 Concrete Finishing Procedure After Pouring Concrete Rev 00 Sales Gas ProjectDocument8 pagesUIPS QCP 003 Concrete Finishing Procedure After Pouring Concrete Rev 00 Sales Gas ProjectNeil JavierNo ratings yet

- Concrete Works Method StatementDocument12 pagesConcrete Works Method StatementRajarajan RajaNo ratings yet

- Pier (1)Document15 pagesPier (1)GANGARAJU N BNo ratings yet

- Method Statement 03g-Placing of CC BlockDocument5 pagesMethod Statement 03g-Placing of CC BlockAbdullah Al MarufNo ratings yet

- Quality Systems Manual Method Statement: Sub-Structure Waterproofing - Bituminous Waterproofing PaintDocument8 pagesQuality Systems Manual Method Statement: Sub-Structure Waterproofing - Bituminous Waterproofing PaintLloyd MariNo ratings yet

- Procedure For Flushing and Hydrotesting (On-Plot)Document11 pagesProcedure For Flushing and Hydrotesting (On-Plot)Vijay Allimuthu Avathipalayam100% (3)

- Quality Control for Concrete Block WallsDocument11 pagesQuality Control for Concrete Block WallsYash Sharma100% (2)

- QC Procedure for Placement of Earth Works, Sub-Base & Base MaterialsDocument8 pagesQC Procedure for Placement of Earth Works, Sub-Base & Base MaterialsKB100% (1)

- UGFC-PQCP-49, Rev01 March 01Document7 pagesUGFC-PQCP-49, Rev01 March 01Mahaboob PashaNo ratings yet

- P140I Fencing WorksDocument5 pagesP140I Fencing WorkskbldamNo ratings yet

- Method Statement InstallationDocument22 pagesMethod Statement InstallationrayNo ratings yet

- Turnkey Site Builders, Civil & Maintenance: Quality Assurance, Quality Plan & Quality Control ManualDocument21 pagesTurnkey Site Builders, Civil & Maintenance: Quality Assurance, Quality Plan & Quality Control ManualKeith ChooNo ratings yet

- Method Statement For Concrete WorkDocument11 pagesMethod Statement For Concrete WorkSyed AliNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Scope of Work for Pipeline InstallationDocument10 pagesScope of Work for Pipeline InstallationAsongwe HansNo ratings yet

- HDD Procedure For Road ClosureDocument15 pagesHDD Procedure For Road ClosureooichinhuiNo ratings yet

- 08 - CP 11-16-4 - Hydraulic CementDocument4 pages08 - CP 11-16-4 - Hydraulic CementMed Hédi BANNANINo ratings yet

- China Harbour Roof Waterproofing MethodDocument18 pagesChina Harbour Roof Waterproofing MethodYash Sharma100% (6)

- Method Statement For Pipe Flushing and Internal Cleaning (SAMPLE)Document7 pagesMethod Statement For Pipe Flushing and Internal Cleaning (SAMPLE)Hasann MaawiaNo ratings yet

- Method Statement of Export LinesDocument15 pagesMethod Statement of Export Linesyoussef gaafarNo ratings yet

- CEMENTING TITLEDocument31 pagesCEMENTING TITLEamitNo ratings yet

- Plant & Guide Wall ConstructionDocument10 pagesPlant & Guide Wall ConstructionAnonymous S7Cq7ZDgPNo ratings yet

- Method of Statement For Under-Ground and Above-Ground Piping InstallationDocument10 pagesMethod of Statement For Under-Ground and Above-Ground Piping Installationamr100% (1)

- METHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Document7 pagesMETHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Osama MZ100% (1)

- Blinding & Concrete Method StatementDocument5 pagesBlinding & Concrete Method Statementشاز إياسNo ratings yet

- Quality Requirements For Subcontractor: Project ProcedureDocument15 pagesQuality Requirements For Subcontractor: Project ProcedureDindo QuintanNo ratings yet

- Structural Procedure UGFC-PQCP-52, Rev00Document6 pagesStructural Procedure UGFC-PQCP-52, Rev00Mahaboob PashaNo ratings yet

- Vendor Approval Compliance Sheet for GFRC WorksDocument16 pagesVendor Approval Compliance Sheet for GFRC WorksRavi Shankar KolluruNo ratings yet

- MST For Below Ground UPVC Drainage PipesDocument13 pagesMST For Below Ground UPVC Drainage Pipesمقاول تكييف كهرباء وصحيNo ratings yet

- Replacement of The Pontoon Outer Rim Method StatementDocument2 pagesReplacement of The Pontoon Outer Rim Method StatementGvdB75No ratings yet

- Dimensional Control ProcedureDocument22 pagesDimensional Control Proceduresilitonga3388100% (2)

- Method Statement For WTG FoundationDocument7 pagesMethod Statement For WTG FoundationTariq Ali Sial100% (1)

- 502.00 Asphalt Pavement 502.10 Asphalt Pavement DescriptionDocument30 pages502.00 Asphalt Pavement 502.10 Asphalt Pavement DescriptionAdjei BaldanNo ratings yet

- Job Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006Document11 pagesJob Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006mahesh naikNo ratings yet

- MS-PI-005 Underground Pipe Installation (Blank Project)Document12 pagesMS-PI-005 Underground Pipe Installation (Blank Project)Naning KusumaNo ratings yet

- 1.0 Method Statement - Installation of GI ConduitsDocument9 pages1.0 Method Statement - Installation of GI Conduitsمقاول تكييف كهرباء وصحيNo ratings yet

- NSH-SAOMPP-CMS-PI-004-tie in WorksDocument11 pagesNSH-SAOMPP-CMS-PI-004-tie in WorksNeil JavierNo ratings yet

- Peneterant Testing For NDT - Procedure Details - Latest FinalDocument8 pagesPeneterant Testing For NDT - Procedure Details - Latest FinalAlam MD Sazid100% (1)

- MS - Raft PouringDocument14 pagesMS - Raft PouringAby ThykkodathuNo ratings yet

- S96029 P3T F07C PQP 001Document10 pagesS96029 P3T F07C PQP 001tinzarmoeNo ratings yet

- Excavation and Fill Method Statement SummaryDocument12 pagesExcavation and Fill Method Statement Summary한상호No ratings yet

- PT ProcedureDocument18 pagesPT Procedureاباذر الدراجيNo ratings yet

- Galvanic Anode Installation Method of StatementDocument13 pagesGalvanic Anode Installation Method of StatementNeil JavierNo ratings yet

- WMS - ARCHI - 004 - WMS For Brickwork Rectification WorksDocument5 pagesWMS - ARCHI - 004 - WMS For Brickwork Rectification WorksEchoNo ratings yet

- Work Procedure For Drain PipingDocument10 pagesWork Procedure For Drain PipingResearcherNo ratings yet

- MS FOR CAST IN PLACE CONCRETE - Rev. 01Document23 pagesMS FOR CAST IN PLACE CONCRETE - Rev. 01Goku Saito100% (1)

- PDOC-476-CTRU-06 Rotating Equipment Installation ProcedureDocument7 pagesPDOC-476-CTRU-06 Rotating Equipment Installation Procedure1339979No ratings yet

- Mos - PaintingDocument11 pagesMos - PaintingMuthuram NNo ratings yet

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanNo ratings yet

- Fabrication and Installation of PipingDocument28 pagesFabrication and Installation of PipingRuel BuntogNo ratings yet

- Method Statement For BACKFILLING WORKSDocument12 pagesMethod Statement For BACKFILLING WORKSYash Sharma50% (2)

- Method Statement for Excavation & Backfilling for Open Foundations & FootingsDocument10 pagesMethod Statement for Excavation & Backfilling for Open Foundations & FootingsmoonisqNo ratings yet

- DRP001 Ouf Pro Q 000 515 O1Document15 pagesDRP001 Ouf Pro Q 000 515 O1Daniel MartinezNo ratings yet

- Work Procedure For Drain PipingDocument10 pagesWork Procedure For Drain PipingResearcherNo ratings yet

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Termite Control Method StatementDocument7 pagesTermite Control Method Statementwajid ZiaNo ratings yet

- Termite Control Method StatementDocument7 pagesTermite Control Method Statementwajid ZiaNo ratings yet

- Method Statement For Rebar, Formworks and Concrete WorksDocument13 pagesMethod Statement For Rebar, Formworks and Concrete Workswajid Zia100% (7)

- Method Statement For Underground Utilities Excavation and BackfillingDocument12 pagesMethod Statement For Underground Utilities Excavation and Backfillingwajid ZiaNo ratings yet

- Method Statement For Structural Excavation and BackfillDocument14 pagesMethod Statement For Structural Excavation and Backfillwajid ZiaNo ratings yet

- RTA Waterproofing Works ApprovalDocument1 pageRTA Waterproofing Works Approvalwajid ZiaNo ratings yet

- Method Statement For Structural Excavation and BackfillDocument14 pagesMethod Statement For Structural Excavation and Backfillwajid ZiaNo ratings yet

- Maintain Training Facilities Comcok NC IiiDocument21 pagesMaintain Training Facilities Comcok NC IiiMylina FabiNo ratings yet

- Special Inspection ManualDocument38 pagesSpecial Inspection ManualJuan Carlos PlasenciaNo ratings yet

- Improve Inspection Accuracy with Six Step MethodDocument11 pagesImprove Inspection Accuracy with Six Step Methodponnivalavans_994423100% (1)

- Saudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilDocument11 pagesSaudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilKhurram ShehzadNo ratings yet

- James DjurakovDocument2 pagesJames Djurakovjimmydj382No ratings yet

- WELDING GUIDELINES: COST-EFFECTIVE DESIGN TIPSDocument6 pagesWELDING GUIDELINES: COST-EFFECTIVE DESIGN TIPSsarath6725No ratings yet

- SOP C&A Final Inspection/ V4.0 Effective Date 01 May 2019 Global Quality Assurance & DevelopmentDocument12 pagesSOP C&A Final Inspection/ V4.0 Effective Date 01 May 2019 Global Quality Assurance & DevelopmentDebashishDolonNo ratings yet

- J910-DH02-P10ZEN-040001 Field ITP For Earth Work For Ash Handling Facilities - Rev.1 (AFC)Document15 pagesJ910-DH02-P10ZEN-040001 Field ITP For Earth Work For Ash Handling Facilities - Rev.1 (AFC)rudi sarifudinNo ratings yet

- Sample Template Itp For Piping Fabrication and InstallationDocument10 pagesSample Template Itp For Piping Fabrication and Installationmohd as shahiddin jafri100% (1)

- IATF 16949 FAQs - Oct 2018 - 12nov2018Document20 pagesIATF 16949 FAQs - Oct 2018 - 12nov2018danielsasikumarNo ratings yet

- Lithuania Power PolicyDocument32 pagesLithuania Power PolicyVaibhav RaiNo ratings yet

- WTG ITP Steel Fabrication InspectionDocument6 pagesWTG ITP Steel Fabrication Inspectionrahid iqubalNo ratings yet

- Mobile Equipment Inspection Procedure-GuideDocument2 pagesMobile Equipment Inspection Procedure-GuideElavarasan JayachandranNo ratings yet

- Asq Presentation Iso 13485Document48 pagesAsq Presentation Iso 13485dhir.ankur100% (1)

- ISO 3183-3 SupersededDocument60 pagesISO 3183-3 SupersededDBasak_1974No ratings yet

- ITP For Wall Panels InstallationDocument3 pagesITP For Wall Panels InstallationChristos LoutrakisNo ratings yet

- Dorafshan - 2018 - Bridge Inspection, Human Performance, UASs and AutomationDocument34 pagesDorafshan - 2018 - Bridge Inspection, Human Performance, UASs and AutomationBarabingaNo ratings yet

- Quality Control - Works Inspection: Base Coat For WallDocument1 pageQuality Control - Works Inspection: Base Coat For WallParasNo ratings yet

- Iso 45001 2018 Manual Documents PDFDocument10 pagesIso 45001 2018 Manual Documents PDFabdelnasser hasan60% (5)

- Chapter 2 SQADocument13 pagesChapter 2 SQAInam Ullah KhanNo ratings yet

- ZJP Roots Vacuum Pump - Manual - 1ED.20200422.ENDocument17 pagesZJP Roots Vacuum Pump - Manual - 1ED.20200422.ENLuisAngelChavezNo ratings yet

- JK-Aging Infrastructure V04Document96 pagesJK-Aging Infrastructure V04Julio LopesNo ratings yet

- BS en 14587 1 PDFDocument42 pagesBS en 14587 1 PDFlamhuu quangNo ratings yet

- Curriculum Vitae: Mohammad Shahid IqbalDocument4 pagesCurriculum Vitae: Mohammad Shahid Iqbalshahid imamNo ratings yet

- Method Statement FOR Sanitary SewerageDocument42 pagesMethod Statement FOR Sanitary Seweragemd_rehan_2100% (3)

- Crawler Crane PDFDocument191 pagesCrawler Crane PDFmajdi jerbiNo ratings yet

- Swivel Lifting Key Leaflet - 11-2016 PDFDocument12 pagesSwivel Lifting Key Leaflet - 11-2016 PDFsherwin veroNo ratings yet

- Saep 122Document18 pagesSaep 122Handa Bin AdiNo ratings yet

- Astm 403Document7 pagesAstm 403JOSEPH REFUERZONo ratings yet

- Addendum - 2 Implementation GuideDocument12 pagesAddendum - 2 Implementation GuideMuhammad Irfan ArshadNo ratings yet