Professional Documents

Culture Documents

Reference Unloading JHA

Uploaded by

NarayanKavitakeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reference Unloading JHA

Uploaded by

NarayanKavitakeCopyright:

Available Formats

For.

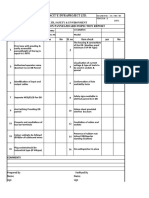

NO:-HMPPL/EHS/04

JOB HAZARD ANALYSIS Rev:-01

Date:-27/03/2017

Last Updated -26.12.2018

Department:- PPIC

Location Of Job:- Unloading Coil Point

Job Description:- Unloading Coil from truck

Team:- Mr.Bablu,Baba,Vishal

Sr. Sequence Of Basic Job Steps Potential Hazards Safeguard/Controls To Be Put In place Responsibility

No.

1)Moving of truck while unloading. 1)Insure that driver applied hand break Mr.Bablu

Chances of hand wrist injury during unpacking coils 2)be away from truck during moments

from truck 3)Provide stoppers to back side and front side wheels

Park coil loaded truck outside of coil 4)Inform all near by persons that unloading is in process

1

unloading platform Use wrist guard

2 Unload a coil from loaded truck and 1) Stock movement and falling items. 1) Steel toe-cap footwear suitable head protection. Mr.Bablu

place on weighing scale platform with 2) Slips 2) Safety footwear with slip resistant soles.

the help of crane 3) Sharp edges 3) Read instructions which are shown in sop of coil loading -

4) Burris to hand unloading.

4) Restrict entry to any unauthorized person who is not in

recommend PPEs .

5) Use cut resistance hand-gloves.

3 Remove a coil from wheighing scale 1)Slips from coil edge. 1)Use safety helmet Mr.Bablu

after completion of weight 2)Undesirable moment of crane lifting slings due to 2)Use steel toe safety foot ware

measurment. heavy load. 3)Do not lift extreme load crane capacity.

3)Falling of coil due to improper lifting. 4)Work in under trained supervisor

4)Loose packing strip sudden removal 5)Take all precautions of work related hazards

6)While handling of coil keep safe distance from moments of coil.

Use safety grills for face protection

4 Stack a coil on coil yard . 1) Collision of coils 1)Use safety helmet Mr.Bablu

2) Trashed of coil stopper if that wooden 2)Use steel toe safety foot ware

3) Heavy load impact to other things 3)Do not lift extreme load crane capacity.

4)Work in under trained supervisor

5)Use a couple of a metal stopper for complete load division .

6)Give a training of safe material stacking to the workmen

5 Maintaining stack height of coils 1) Coils falling from height 1) While handling of coil keep safe distance from moments of coil. Mr.Bablu

2) Hazard of trauma ,up to fatality 2) Pay attention on your job

3) Fracture of workmen 3) Maintain stack height up to two layers .

4) Stopper failure if broken already 4) Be alert In emergency

5) Use all PPEs .

6) Provide Proper Stopper.

Special Skilled

Required PPE Required Tools & Equipments Required Training Employees

As per PPE Matrix Crane & Lifting tools Tackles Safety, Material Handling Mr.Bablu,Baba,Vishal

You might also like

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- User'S Manual: MODEL: MMA160/200Document9 pagesUser'S Manual: MODEL: MMA160/200Vlaovic GoranNo ratings yet

- EDPF-NT Plus Training Manual EnglishDocument214 pagesEDPF-NT Plus Training Manual Englishtayyab zafarNo ratings yet

- POH Procedure of Wagon in WorkshopDocument8 pagesPOH Procedure of Wagon in WorkshopMrityunjay KrNo ratings yet

- Isgec TrainingDocument13 pagesIsgec TrainingAmul KumarNo ratings yet

- JSP 42 Use of Power ToolsDocument6 pagesJSP 42 Use of Power ToolsMuhammad AtifNo ratings yet

- Technical Specification For Earth WireDocument2 pagesTechnical Specification For Earth WirePritam Singh100% (1)

- 12NDT150SDocument2 pages12NDT150SHarold JansenNo ratings yet

- JSEA FOR DISMNTLING OF MACHINES (Central Work Shop)Document16 pagesJSEA FOR DISMNTLING OF MACHINES (Central Work Shop)B&R HSE BALCO SEP SiteNo ratings yet

- Lockout - Tagout (LOTO) Annual Inspection and Training Assessment Checklist Department: Shop: Location: EquipmentDocument2 pagesLockout - Tagout (LOTO) Annual Inspection and Training Assessment Checklist Department: Shop: Location: EquipmentSayed Saad ShehataNo ratings yet

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- Risk Assessment and Safety in FormworkDocument9 pagesRisk Assessment and Safety in Formworkvasanth pugazhendhi0% (1)

- Garbage Chute Tender 2Document60 pagesGarbage Chute Tender 2Faizan100% (1)

- Cable Pulling Lubricant - Data Sheet (En Ingles)Document2 pagesCable Pulling Lubricant - Data Sheet (En Ingles)angel de mi guardaNo ratings yet

- EOHSMS-02-C28 LOA Site Engineer or Site SupervisorDocument1 pageEOHSMS-02-C28 LOA Site Engineer or Site SupervisorHassan AbdullahNo ratings yet

- CWB Procedure and RulesDocument4 pagesCWB Procedure and Rulesippon_osoto100% (1)

- Hydraulic Sheet Bending MachineDocument15 pagesHydraulic Sheet Bending MachineNitinNo ratings yet

- Splitup Syllabus - Semester - IDocument3 pagesSplitup Syllabus - Semester - IDijesh Punathil100% (3)

- Electrical Safety Manual - 2Document1 pageElectrical Safety Manual - 2MarianoNo ratings yet

- Material Handling (Rigging)Document61 pagesMaterial Handling (Rigging)md yasinNo ratings yet

- Kursus Sijil Kompeten Penyelia Keselamatan Tapak Bina: Site Safety Supervisor Competency Course CertificateDocument163 pagesKursus Sijil Kompeten Penyelia Keselamatan Tapak Bina: Site Safety Supervisor Competency Course CertificateDurga SreetharanNo ratings yet

- SWP-14 For Chemical in Use DaimanDocument2 pagesSWP-14 For Chemical in Use DaimanHassan AbdullahNo ratings yet

- Standard Operating Procedure (Sop) : CK College of Engineering and TechnologyDocument7 pagesStandard Operating Procedure (Sop) : CK College of Engineering and TechnologyBalaChandarNo ratings yet

- Wardrobe Detail DrawingDocument1 pageWardrobe Detail DrawingSandip SharmaNo ratings yet

- EHS-2035.Safety Management Procedure - 582020Document11 pagesEHS-2035.Safety Management Procedure - 582020hoangmtbNo ratings yet

- 13-3 Worksheet KEYDocument2 pages13-3 Worksheet KEYGabriella OwensNo ratings yet

- Method Statement For Light Beacons and Buoys C04Document93 pagesMethod Statement For Light Beacons and Buoys C04Olugbemiga James OlalekanNo ratings yet

- Scaffolding: Your Key To Stability: By: Georgia Tech Occupational Safety and Health ProgramDocument33 pagesScaffolding: Your Key To Stability: By: Georgia Tech Occupational Safety and Health ProgramShalimar Ladenne Figuracion BuaquiñaNo ratings yet

- Safety Observation & Non-Compliances Report For R-8A (07092021) PDFDocument8 pagesSafety Observation & Non-Compliances Report For R-8A (07092021) PDFmyo lwin100% (1)

- Quiz For TT DriverDocument8 pagesQuiz For TT DriverGulbarga DepotNo ratings yet

- Locating and Clamping Principles: The Mechanics of LocatingDocument4 pagesLocating and Clamping Principles: The Mechanics of Locatingniloy_67No ratings yet

- JSA Mechanical Plant and Machinery SafetyDocument8 pagesJSA Mechanical Plant and Machinery SafetyMazlan Ashaari100% (1)

- Hira - CivilDocument20 pagesHira - Civilmurthy100% (1)

- Design and Fabrication of Tilting ViceDocument33 pagesDesign and Fabrication of Tilting ViceYOGAKRISHNANNo ratings yet

- HDSD Mig OTC DM350 PDFDocument72 pagesHDSD Mig OTC DM350 PDFHOryshorNo ratings yet

- Apr 2023Document6 pagesApr 2023Ana Paula EberleNo ratings yet

- Job Safety Analysis (Jsa) Job Safety Analysis (Jsa) (Erection Tower)Document1 pageJob Safety Analysis (Jsa) Job Safety Analysis (Jsa) (Erection Tower)Christo Stiocal DjNo ratings yet

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

- JHA For Welding ShopDocument36 pagesJHA For Welding ShopSaboor KhanNo ratings yet

- 07 - TDS - Masterflow 520Document3 pages07 - TDS - Masterflow 520Alexi ALfred H. TagoNo ratings yet

- WMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1Document8 pagesWMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1tanaNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- 01 - Process Control IntroDocument16 pages01 - Process Control IntroqaNo ratings yet

- BW Gas Detector ManualDocument3 pagesBW Gas Detector ManualYume HendraNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- JSA For Blinding and De-Blinding (Opening Process Equipment)Document11 pagesJSA For Blinding and De-Blinding (Opening Process Equipment)Thái Đạo Phạm Lê100% (1)

- Advance Welding - Syllabus (KME-055)Document3 pagesAdvance Welding - Syllabus (KME-055)Shashank DwivediNo ratings yet

- WMS Infineon Project Tower (HT HV Cabling Work) - Rev-1Document6 pagesWMS Infineon Project Tower (HT HV Cabling Work) - Rev-1tanaNo ratings yet

- Mechanical Job Hazard Analysis Name of The Job: WELDING JOBDocument1 pageMechanical Job Hazard Analysis Name of The Job: WELDING JOBbrandybuckNo ratings yet

- Form 13Document4 pagesForm 13Jayendra NaiduNo ratings yet

- Carrier Light Commercial Air Conditioner Split UnitDocument14 pagesCarrier Light Commercial Air Conditioner Split UnitABie ShallabyNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- Chiang Ying Engineering PDFDocument23 pagesChiang Ying Engineering PDFSim Khoon AunNo ratings yet

- Diwakarmr InternshipDocument65 pagesDiwakarmr InternshipDIWAKAR MRNo ratings yet

- Luxathane 5160Document2 pagesLuxathane 5160shameelNo ratings yet

- Dos DontsDocument1 pageDos DontsJoel BrasilBorgesNo ratings yet

- HVT Group AssignmentDocument17 pagesHVT Group AssignmentSiti Farhana100% (2)

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (3)

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- Top Error Areas E-MailDocument2 pagesTop Error Areas E-MailNarayanKavitakeNo ratings yet

- JHA List of Activity - Storev RevisedDocument13 pagesJHA List of Activity - Storev RevisedNarayanKavitakeNo ratings yet

- L6 - The Swing (Notes)Document2 pagesL6 - The Swing (Notes)NarayanKavitakeNo ratings yet

- Electrical Maintenance: SR - No. Point of DiscussionDocument33 pagesElectrical Maintenance: SR - No. Point of DiscussionNarayanKavitakeNo ratings yet

- Office JHA - ReferenceDocument1 pageOffice JHA - ReferenceNarayanKavitakeNo ratings yet

- JHA - Gas Cutting For ReferenceDocument2 pagesJHA - Gas Cutting For ReferenceNarayanKavitakeNo ratings yet

- Reference JHADocument2 pagesReference JHANarayanKavitakeNo ratings yet

- UBE Automotive MSA System Bias and Linearity StudiesDocument6 pagesUBE Automotive MSA System Bias and Linearity StudiesNarayanKavitakeNo ratings yet

- MSA StudyDocument22 pagesMSA StudyNarayanKavitakeNo ratings yet

- Application For Associate Membership (AMIE) : DdmmyyyyDocument8 pagesApplication For Associate Membership (AMIE) : DdmmyyyyNarayanKavitakeNo ratings yet

- Allergist OIT Packet 180913 NutsDocument74 pagesAllergist OIT Packet 180913 Nutsmuaz.rizviNo ratings yet

- Cold Agglutinin DiseaseDocument8 pagesCold Agglutinin Diseasehtunnm@gmail.comNo ratings yet

- 978 3 642 25446 8Document166 pages978 3 642 25446 8Gv IIITNo ratings yet

- Irrigation SchedulingDocument3 pagesIrrigation SchedulingLuojisi CilNo ratings yet

- Congestive Heart Failure Pathophysiology Schematic DiagramDocument3 pagesCongestive Heart Failure Pathophysiology Schematic DiagramJasleen KaurNo ratings yet

- Msds Uq160 enDocument5 pagesMsds Uq160 enAnnalisa GiammòNo ratings yet

- Qand ADocument5 pagesQand AJoshua PascasioNo ratings yet

- Altius Annual Leave Policy Wef 1st January 2012 Ver 1.1Document11 pagesAltius Annual Leave Policy Wef 1st January 2012 Ver 1.1Mudassar HakimNo ratings yet

- Story of ChangeDocument3 pagesStory of ChangeSend Sierra LeoneNo ratings yet

- Adoption LawsDocument10 pagesAdoption LawsAneesh PandeyNo ratings yet

- Sps8 Q1mod1 Skill Related Parameters Noel Rullan Bgo v2Document20 pagesSps8 Q1mod1 Skill Related Parameters Noel Rullan Bgo v2RandyNo ratings yet

- Effect of A Physiotherapy Program in Women With Primary DysmenorrheaDocument6 pagesEffect of A Physiotherapy Program in Women With Primary DysmenorrheaPaula RangelNo ratings yet

- IOT Based Health Monitoring SystemDocument3 pagesIOT Based Health Monitoring SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- RP 11 - Measuring Concentration of Glucose Using A Calibration CurveDocument4 pagesRP 11 - Measuring Concentration of Glucose Using A Calibration CurveAlfred SangNo ratings yet

- FR 2011 02 23Document275 pagesFR 2011 02 23Ngô Mạnh TiếnNo ratings yet

- Dental Juris and Practice MGT Board 2008Document14 pagesDental Juris and Practice MGT Board 2008Anonymous FwwfR650% (2)

- Intro To EugenicsDocument16 pagesIntro To EugenicsJesus LivesNo ratings yet

- Hazops Should Be Fun - The Stream-Based HazopDocument77 pagesHazops Should Be Fun - The Stream-Based HazopHector Tejeda100% (1)

- Cbse Term 1 Final Exam Instructions 2021-21Document9 pagesCbse Term 1 Final Exam Instructions 2021-21Eshaan123thebestNo ratings yet

- School Form 2 (SF2) Daily Attendance Report of LearnersDocument4 pagesSchool Form 2 (SF2) Daily Attendance Report of LearnersRyan A. CabalidaNo ratings yet

- Prevalence of Burkholderia Mallei in Equids of Remount Depot, Sargodha, PakistanDocument6 pagesPrevalence of Burkholderia Mallei in Equids of Remount Depot, Sargodha, PakistanMuhammad Naeem IqbalNo ratings yet

- REFERENCES in APA Style 7th EditionDocument2 pagesREFERENCES in APA Style 7th EditionReabels FranciscoNo ratings yet

- A Guide For The Assessment and Management of Post-Obstructive DiuresisDocument3 pagesA Guide For The Assessment and Management of Post-Obstructive DiuresisRara Aulia IINo ratings yet

- ARTIGO 2002 - Clarke, D. M., & Kissane, D. W. (2002) - Demoralization: Its Phenomenology and Importance.Document11 pagesARTIGO 2002 - Clarke, D. M., & Kissane, D. W. (2002) - Demoralization: Its Phenomenology and Importance.GTGTNo ratings yet

- Psych 7A FinalDocument16 pagesPsych 7A FinalMatthew Kim100% (1)

- Gavi - 2015 Country TA RFIDocument20 pagesGavi - 2015 Country TA RFIDeepakSinghNo ratings yet

- 3.3.2.4 Love AnimalDocument8 pages3.3.2.4 Love AnimalRina ErnawatiNo ratings yet

- Abs & Core Workout Calendar - Mar 2020Document1 pageAbs & Core Workout Calendar - Mar 2020Claudia anahiNo ratings yet

- 1st Announcement 66th COE - IOA, Banjarmasin, 9-12 May 2018Document15 pages1st Announcement 66th COE - IOA, Banjarmasin, 9-12 May 2018Masda Kamarullah Ribas100% (1)